Coating method for preventing high-speed impact

A high-speed impact and coating technology, applied in the direction of coating, metal material coating process, protective equipment, etc., can solve the problems of poor protection effect, inconvenience to carry, large quality, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

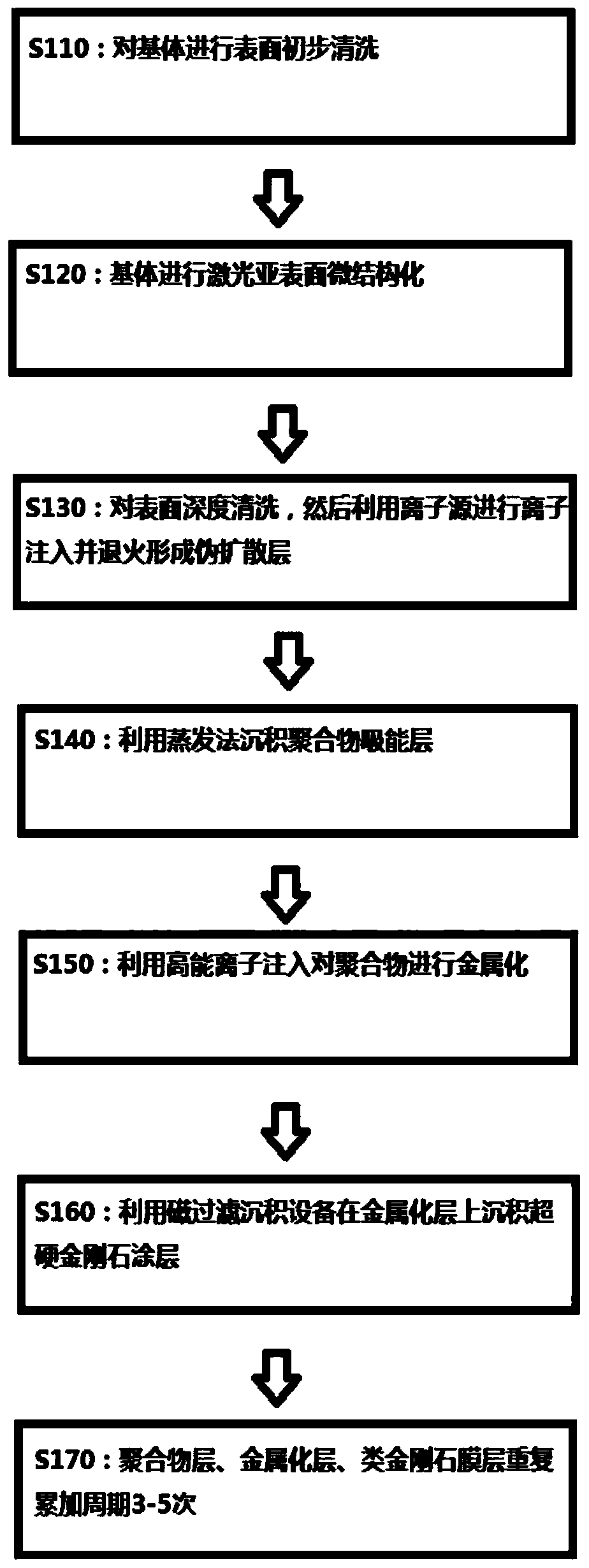

[0072] S110 performing preliminary surface cleaning on the substrate;

[0073] Using high-power pulsed magnetron deposition technology to clean the substrate with ions, the total beam current during cleaning is 2A, the negative pressure is 600V, the high-power pulse power is 0.5MW, the temperature is 450°C, and the air pressure is 1×10 -2 -10Pa, the gas is Ar, and the bombardment time is 60min.

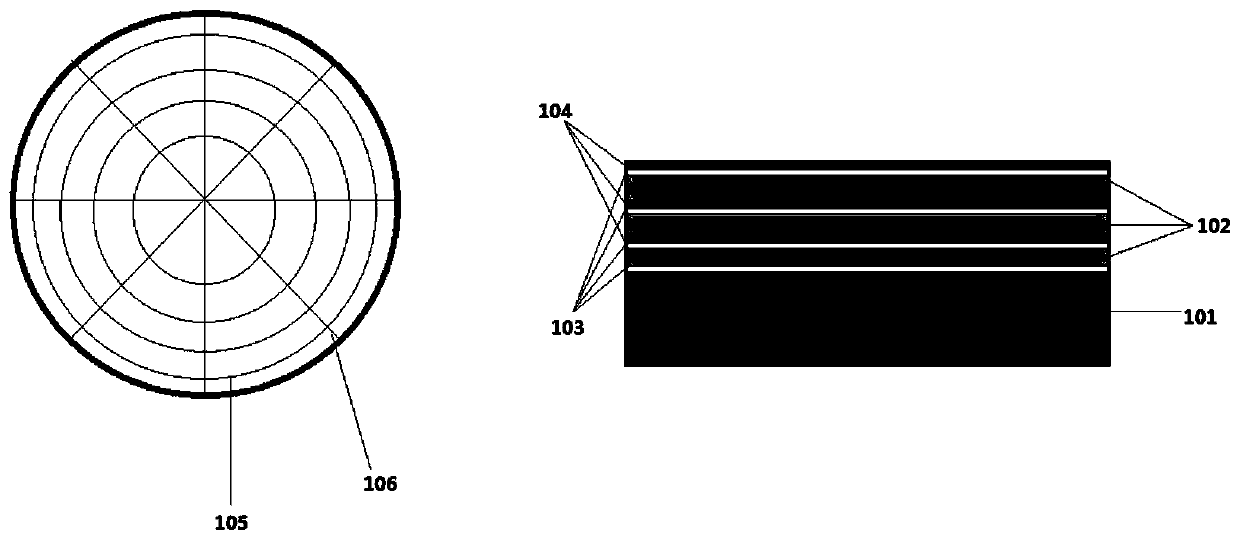

[0074] S120 substrate for laser subsurface microstructuring;

[0075] The subsurface microstructure of the substrate was carried out by ultraviolet laser, the midline width of the microstructure was 4 μm, and the total number of dispersed structures was 60.

[0076] S130 deeply cleans the surface, then uses ion source to perform ion implantation and annealing to form a pseudo-diffusion layer;

[0077] The ion source is a metal vacuum steam ion source, and the implanted elements for ion implantation are metal elements Ti and Hf. During the surface ion implantation process, heat treat...

Embodiment 2

[0086] S110 performing preliminary surface cleaning on the substrate;

[0087] Using high-power pulsed magnetron deposition technology to clean the substrate with ions, the total beam current during cleaning is 2A, the negative pressure is 600V, the high-power pulse power is 0.5MW, the temperature is 450°C, and the air pressure is 1×10 -2 -10Pa, the gas is Ar, and the bombardment time is 60min.

[0088] S120 substrate for laser subsurface microstructuring;

[0089] The subsurface microstructure of the matrix was carried out by ultraviolet laser, the midline width of the microstructure was 4 μm, and the total number of dispersed structures was 90.

[0090] S130 deeply cleans the surface, then uses ion source to perform ion implantation and annealing to form a pseudo-diffusion layer;

[0091] The ion source is a metal vacuum steam ion source, and the implanted elements for ion implantation are metal elements Ti and Hf. During the surface ion implantation process, heat treatmen...

Embodiment 3

[0100] S110 performing preliminary surface cleaning on the substrate;

[0101] Using high-power pulsed magnetron deposition technology to clean the substrate with ions, the total beam current during cleaning is 2A, the negative pressure is 600V, the high-power pulse power is 0.5MW, the temperature is 450°C, and the air pressure is 1×10 -2 -10Pa, the gas is Ar, and the bombardment time is 60min.

[0102] S120 substrate for laser subsurface microstructuring;

[0103] The subsurface microstructure of the matrix was carried out by ultraviolet laser, the midline width of the microstructure was 4 μm, and the total number of dispersed structures was 90.

[0104] S130 deeply cleans the surface, then uses ion source to perform ion implantation and annealing to form a pseudo-diffusion layer;

[0105] The ion source is a metal vacuum steam ion source, and the implanted elements for ion implantation are metal elements Ti and Hf. During the surface ion implantation process, heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com