Doped graphite-like composite film, preparation method thereof and component comprising doped graphite-like composite film

A composite film and graphite technology, applied in the field of surface engineering, can solve the problems of complex preparation methods, high friction coefficient, high wear rate, etc., and achieve the effects of enhanced mechanical properties, high crystallization strength, hardness and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The doped graphite-like composite film of this embodiment is composed of doping elements and graphite-like, the doping elements are cerium and aluminum, the mass percentage of the doping element cerium is 12.98%, and the mass percentage of the doping element aluminum is 2.12% , and the balance is graphite-like.

Embodiment 2-14

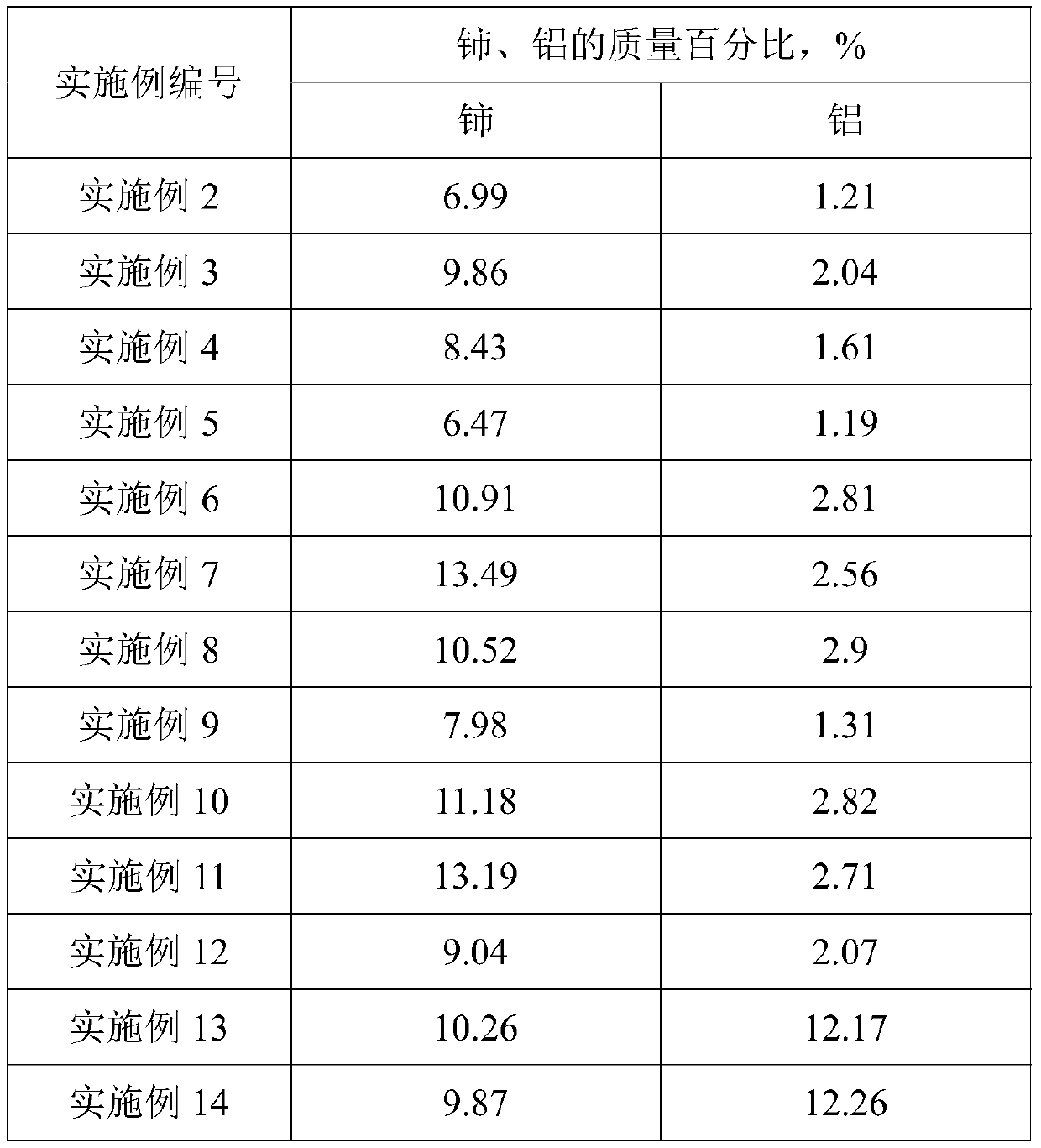

[0031] The doped graphite-like composite films of Examples 2-14 are composed of doping elements and graphite-like composite films, and the doping elements are cerium and aluminum; the content of each component is listed in Table 1.

[0032] The doped sulfide (WS) of table 1 embodiment 2-13 2 ) composition of the composite film

[0033]

[0034] 2. The following specific examples of the preparation method of the doped graphite-like composite film will describe the preparation of the doped graphite-like composite film in Examples 1-14 respectively.

Embodiment 15

[0036] The preparation method of the doped graphite-like composite film of the present embodiment describes the preparation of the doped graphite-like composite film of Example 1, specifically comprising the following steps:

[0037] 1) Use absolute ethanol to clean the surface of the substrate silicon wafer in an ultrasonic cleaner for 15 minutes, then use acetone to clean the surface of the substrate silicon wafer in an ultrasonic cleaner for 10 minutes; put the substrate silicon wafer into a vacuum chamber for vacuum treatment, and the vacuum degree is 5e-4Pa; Introduce argon gas, the flow rate of argon gas is 40sccm, control the pressure of argon gas in the vacuum chamber to 1.2Pa, preheat the substrate for 60 minutes, and the temperature of the preheat treatment is 300°C;

[0038] 2) Maintain the argon gas flow rate in the vacuum chamber at 40 sccm, and the argon gas pressure at 1.2 Pa; use the magnetron sputtering method to deposit a doped graphite-like composite film on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com