Self-lubricating composite coating, coating preparation method and product with coating

A composite coating and self-lubricating technology, which is applied in coatings, metal material coating processes, mechanical equipment, etc., can solve problems such as difficult process adjustment and optimization, reduced service life of bearing bushes, poor coating compactness, etc., and achieve improvement Excellent tribological performance, stress reduction and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

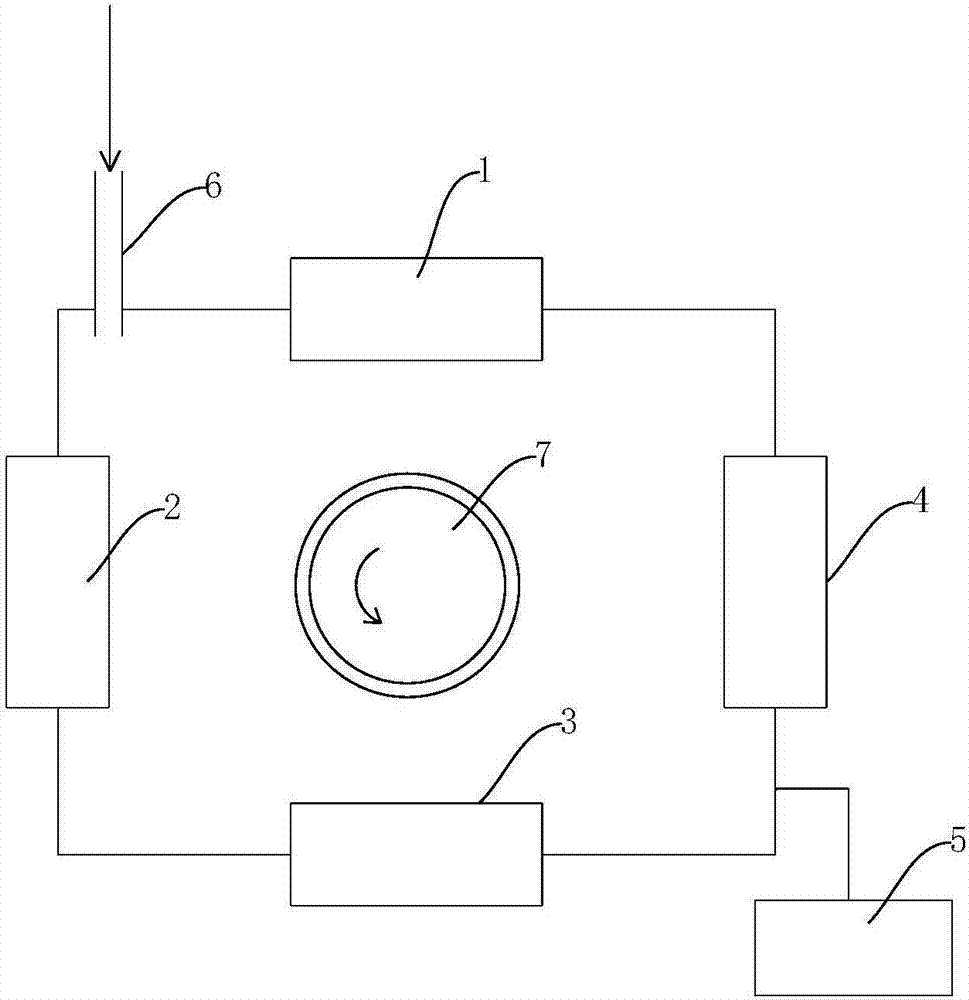

[0038] The preparation method of above-mentioned self-lubricating composite coating comprises the following steps:

[0039]Target material selection steps: AlSn20Cu alloy target is selected as the intermediate frequency AC sputtering target, wherein the weight percentages of Al, Sn and Cu are 79%, 20% and 1% respectively, and MoS with a purity of not less than 99.99% is selected respectively 2 Target and Ni target are used as pulsed DC sputtering targets;

[0040] Sample pretreatment step: put the sample to be coated into the cavity of the coating equipment, and vacuum the cavity to 0.5×10 -3 ~2×10 -3 Pa, introduce Ar gas into the coating cavity to keep the vacuum in the cavity at 1-1.6Pa, and at the same time apply a bias voltage of -600V--800V with a duty ratio of 40%-60% to remove the Dust and adsorbents, the cleaning time is 30 minutes;

[0041] Step of depositing Ni gate layer: adjust the Ar gas to keep the pressure in the cavity at 3×10 -3 Pa~5×10 -3 Pa, the substra...

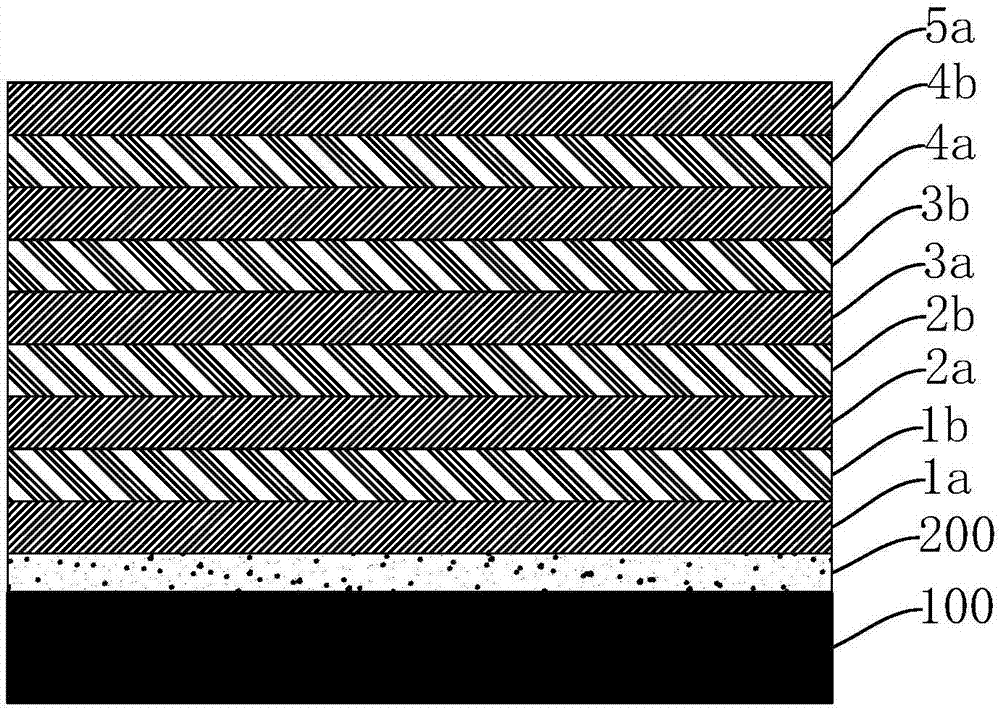

Embodiment 1

[0046] A preparation method for a self-lubricating composite coating on a bearing bush is provided, comprising the following steps:

[0047] Target material selection steps: AlSn20Cu alloy target is selected as the intermediate frequency AC sputtering target, wherein the weight percentages of Al, Sn and Cu are 79%, 20% and 1% respectively, and MoS with a purity of not less than 99.99% is selected respectively 2 Target and Ni target are used as pulsed DC sputtering targets;

[0048] Sample pretreatment steps: select steel / CuPb22Sn4 bearing blanks, and ultrasonically clean the bearing blanks in ultrapure water, ethanol, and acetone for 15 minutes, and then wash them with N 2 Dry it and put it into the coating chamber; place the polished and cleaned bearing bush sample in the cavity of the coating equipment and then vacuumize it to 0.5×10 -3 ~2×10 -3 Pa, argon gas is introduced into the coating chamber to keep the vacuum in the chamber at a vacuum pressure of 1 to 1.6 Pa, and a...

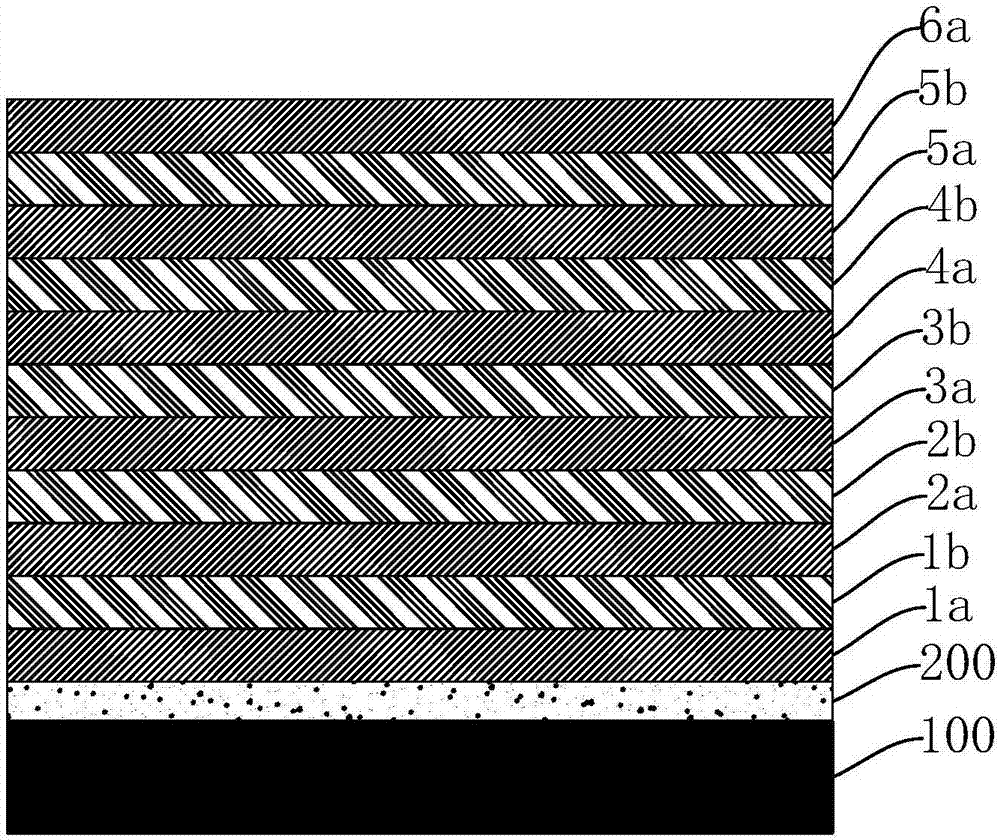

Embodiment 2

[0055] A preparation method for a self-lubricating composite coating on a bearing bush is provided, comprising the following steps:

[0056] Target material selection steps: AlSn20Cu alloy target is selected as the intermediate frequency AC sputtering target, wherein the weight percentages of Al, Sn and Cu are 79%, 20% and 1% respectively, and MoS with a purity of not less than 99.99% is selected respectively 2 Target and Ni target are used as pulsed DC sputtering targets;

[0057] Sample pretreatment steps: select steel / CuPb22Sn4 bearing blanks, and ultrasonically clean the bearing blanks in ultrapure water, ethanol, and acetone for 15 minutes, and then wash them with N 2 Dry it and put it into the coating chamber; place the polished and cleaned bearing bush sample in the cavity of the coating equipment and then vacuumize it to 0.5×10 -3 ~2×10 -3 Pa, argon gas is introduced into the coating chamber to keep the vacuum in the chamber at a vacuum pressure of 1 to 1.6 Pa, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com