Patents

Literature

47results about How to "High oxygen ion conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perovskite Materials for Solid Oxide Fuel Cell Cathodes

ActiveUS20110143255A1Reduced electrical conductivityIncrease conductivityIron compoundsCobalt compoundsIonAdverse effect

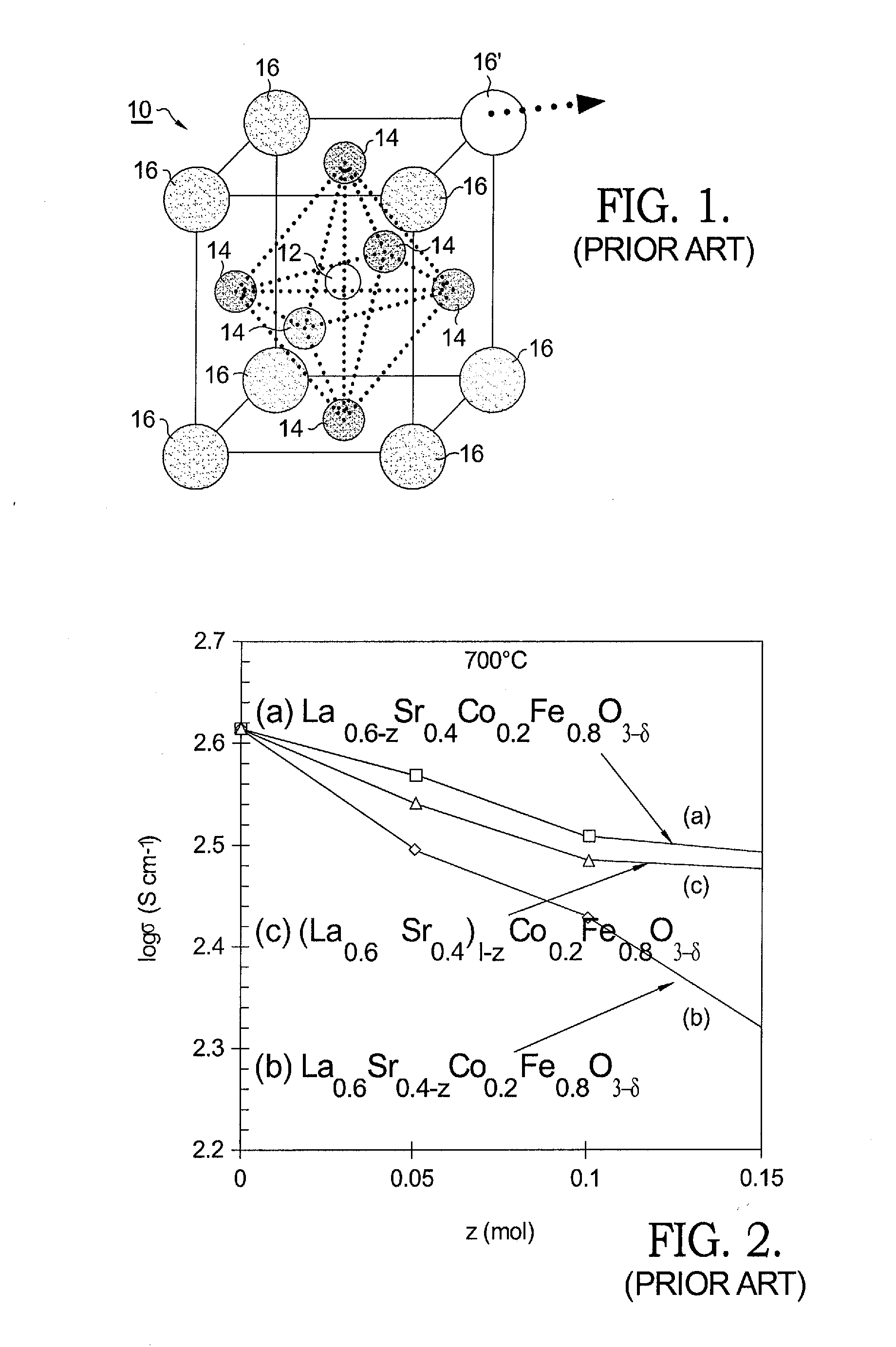

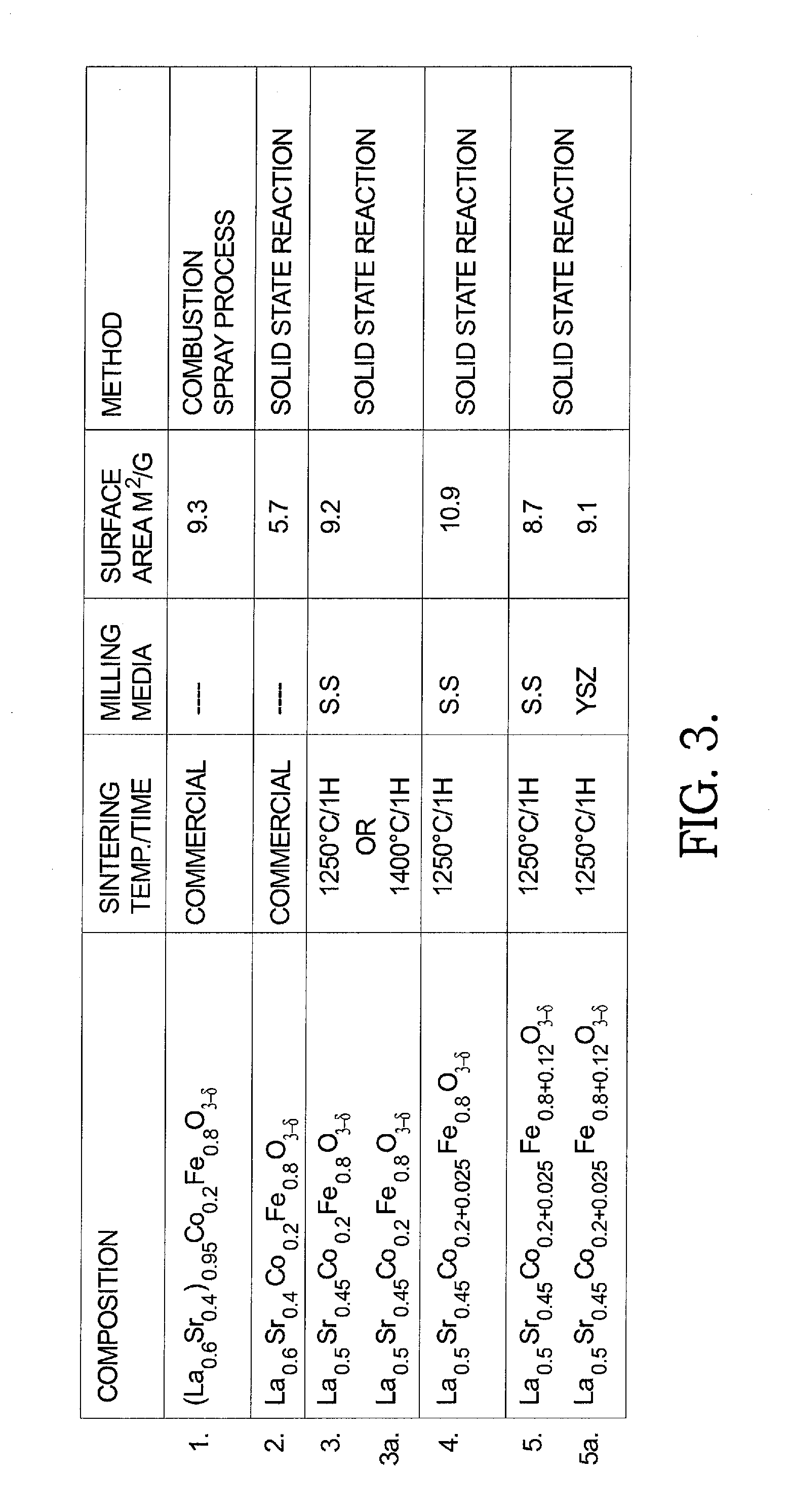

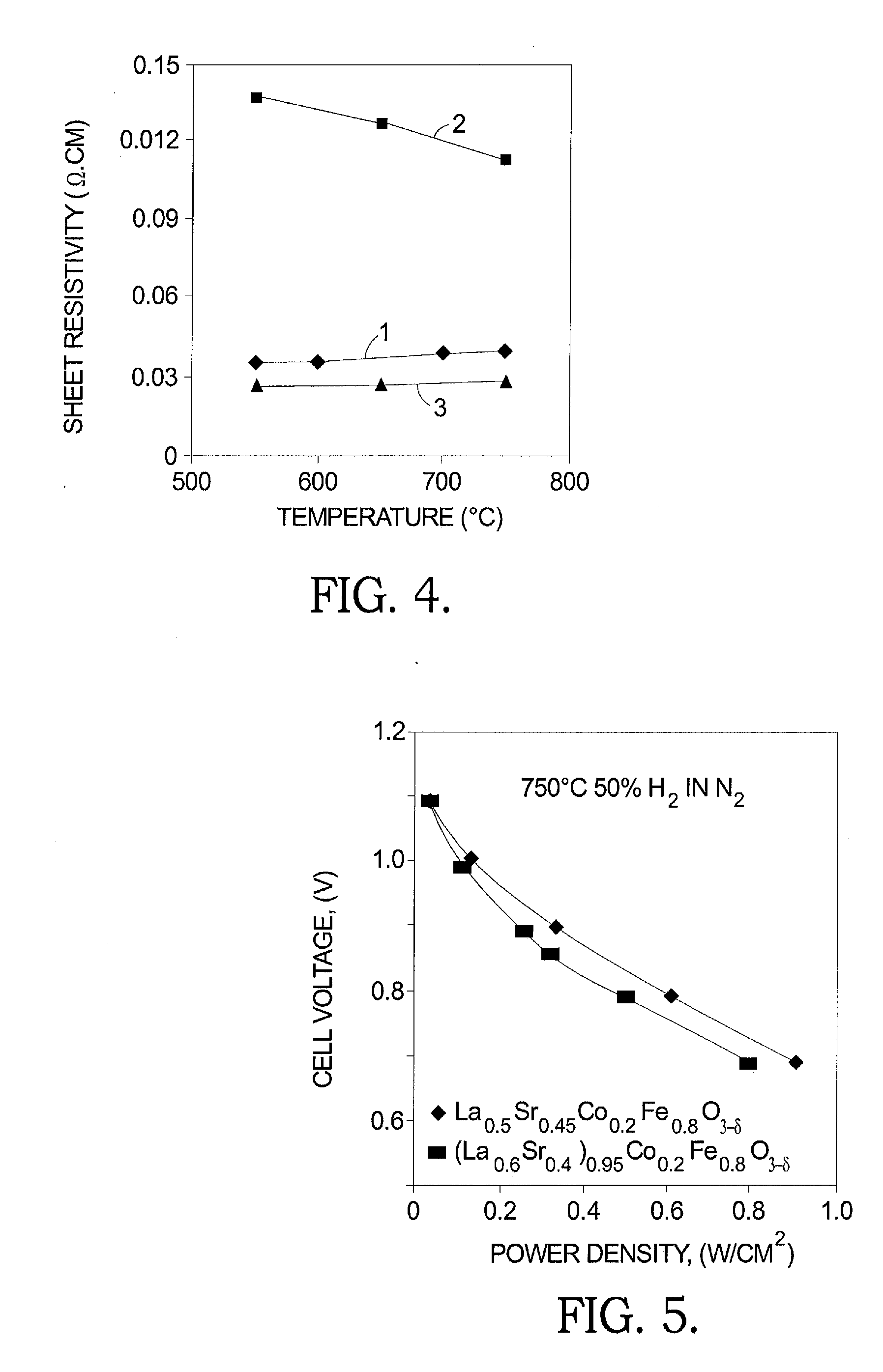

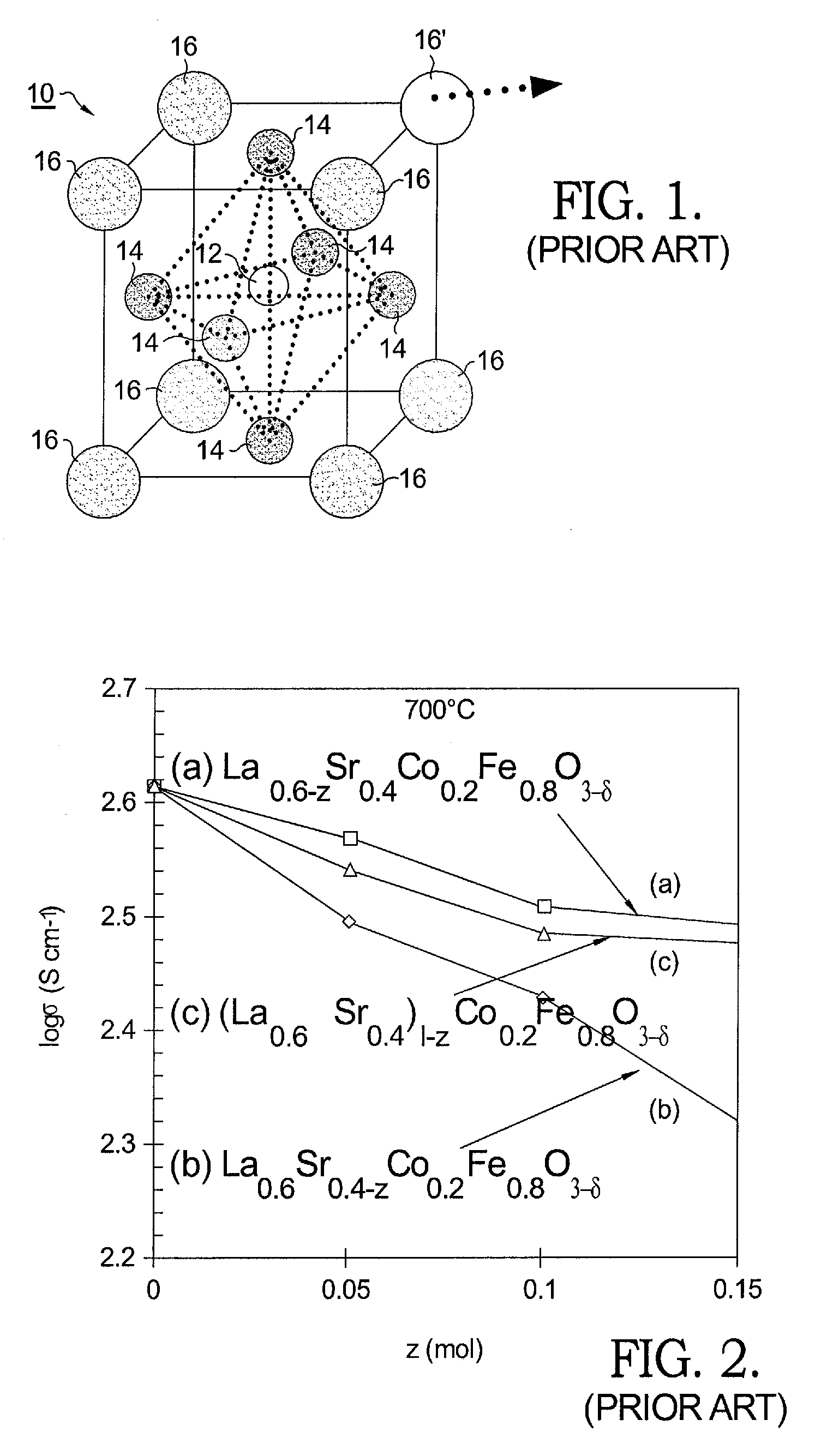

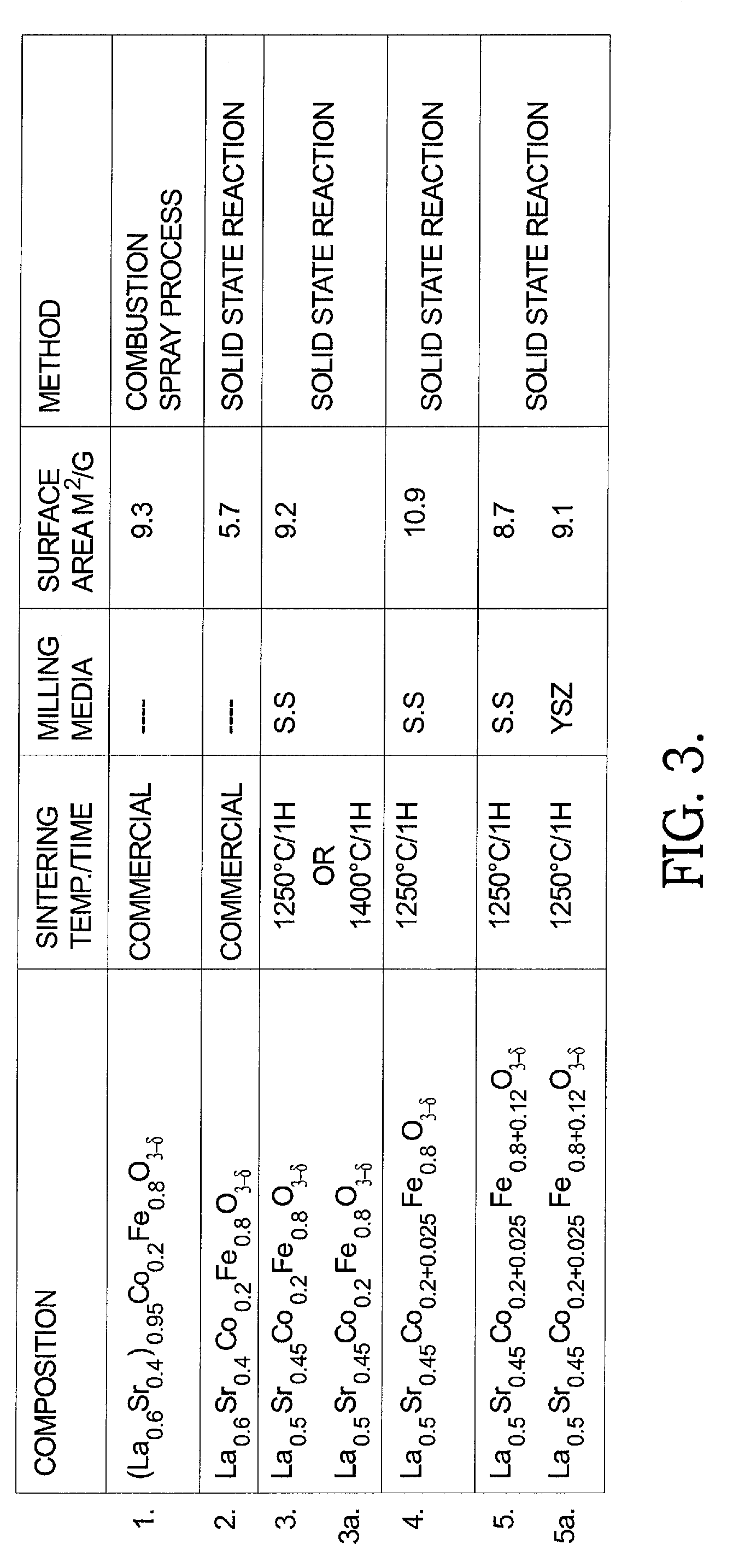

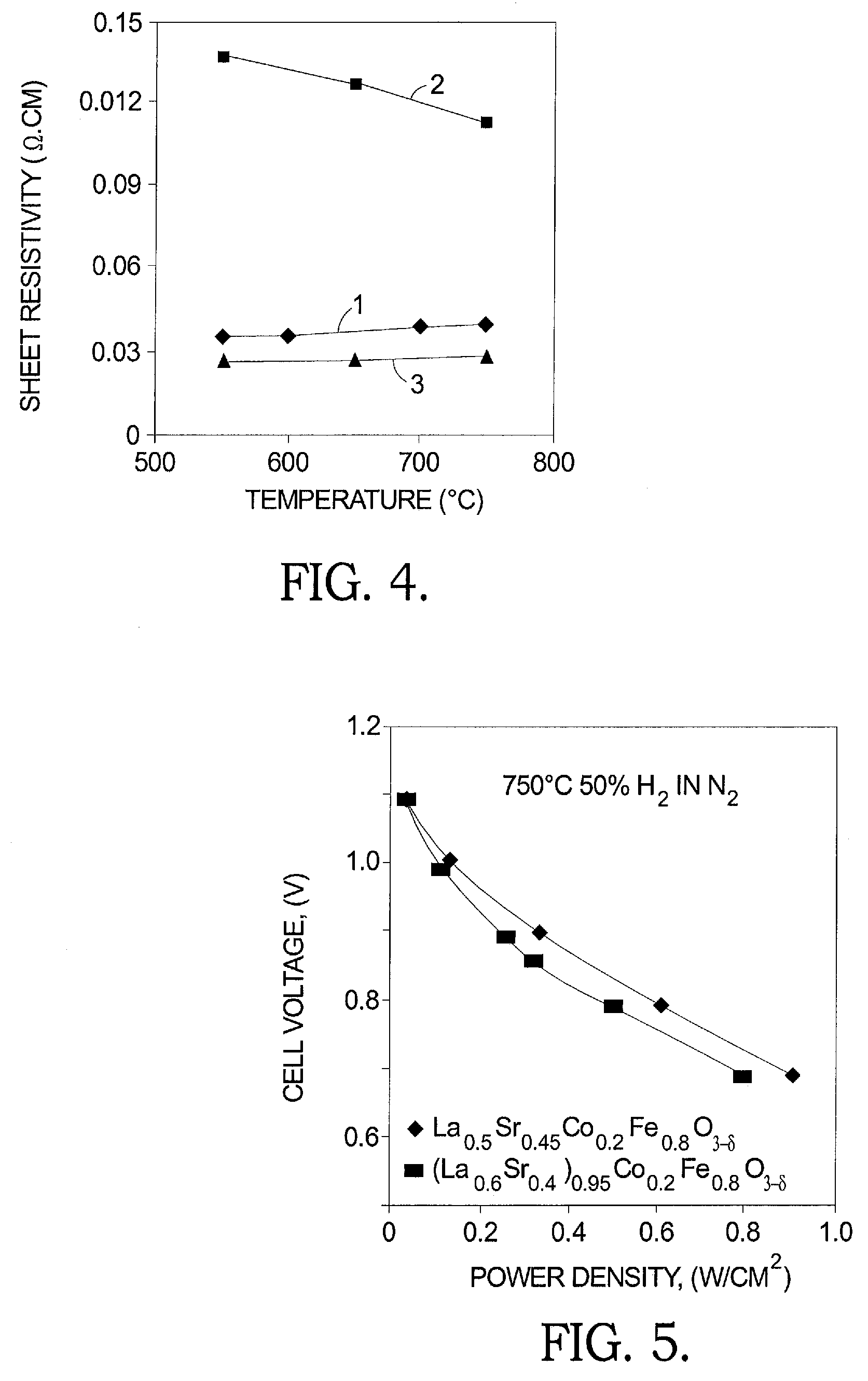

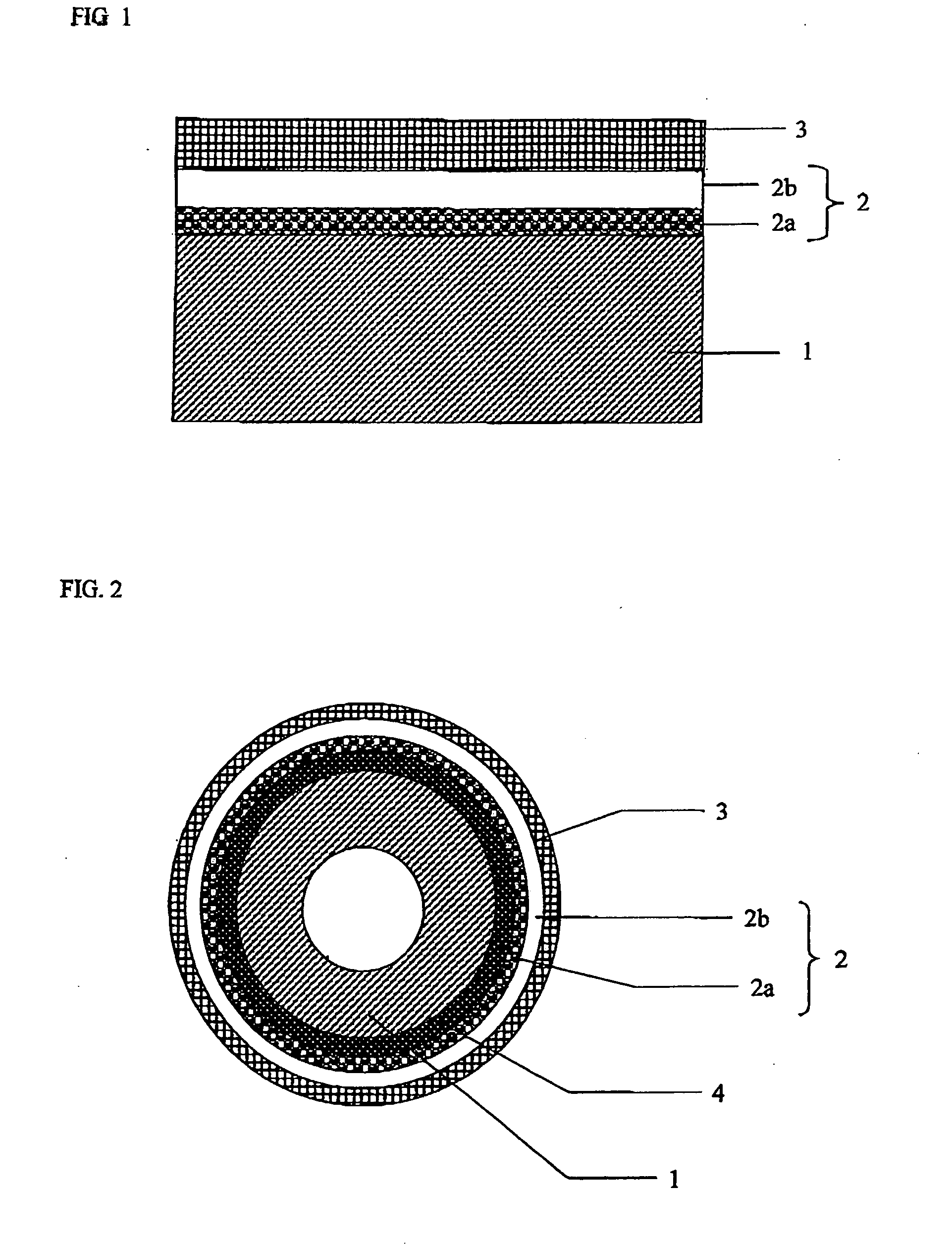

An improved LSCF 6428 perovskite material of the type La12zSrx+zCo0.2+aFe0.8+bO3−δ wherein x=0.4, z=(0.01−0.1), a=(0.01−0.04), and b=(0.05−0.15) for use as an SOFC cathode having increased electronic and ionic conductivity. The general formula is similar to the prior art formulae (La0.6Sr0.4)1−z Co0.2 Fe0.8O3−δ and La0.6Sr0.4 Co0.2 Fe0.8O3−δ but applies the z term to La and Sr independently as well as reducing the overall content of La. Further, by adding a small amount (a) of extra Co ions, catalytic activity, conductivity, and sinterability are further enhanced. Adding small amounts (b) of Fe and / or Fe and Co moderates the thermal expansion coefficient with no adverse effect on crystal structure or fuel cell performance. Improved sinterability, microstructure, and reduced film cracking result in high power density of fuel cells. An inherently low-cost solid state reaction method is described.

Owner:APTIV TECH LTD

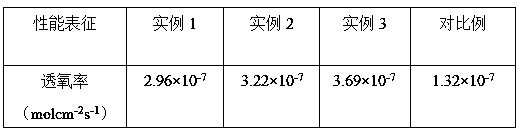

High-stability high-permeability compact ceramic oxygen-permeation membrane and preparation method thereof

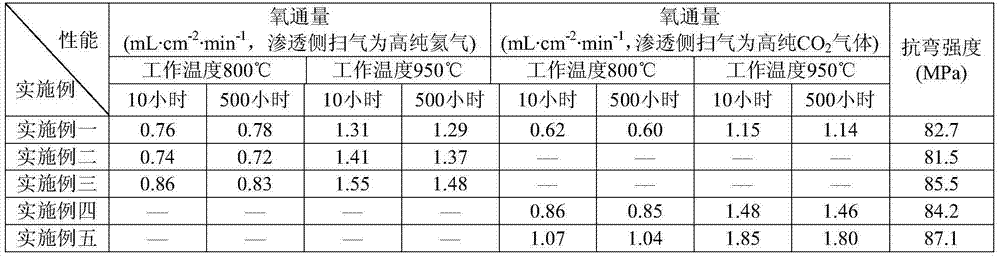

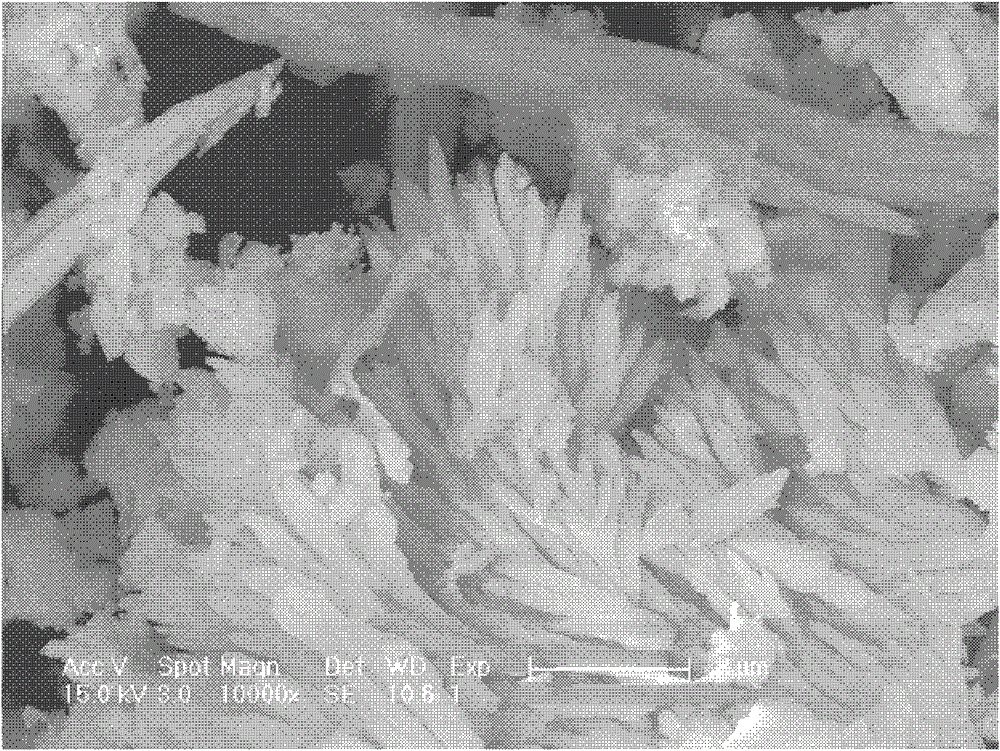

InactiveCN104492278AImprove stabilityHigh mechanical strengthSemi-permeable membranesDispersed particle separationElectrical conductorOxygen ions

A disclosed high-stability high-permeability compact ceramic oxygen-permeation membrane is composed of, in percentage by volume, 75-92% of an oxygen ion conductor phase and 8-25% of an ion-electron conductor phase; the oxygen ion conductor phase is a doped CeO2 porous matrix, and the ion-electron mixed conductor phase is a perovskite structure oxygen ion-electron mixed conductor and is disposed in a connected pore channel of the matrix. Additionally, the invention also discloses a preparation method for the above high-stability high-permeability compact ceramic oxygen-permeation membrane. The technical scheme effectively solves the problem that a ceramic oxygen-permeation membrane cannot simultaneously possess the long-term stability and the high oxygen permeation flux in the prior art. The oxygen permeation flux is improved, and also the high-stability high-permeability compact ceramic oxygen-permeation membrane has good long-term working stability.

Owner:JINGDEZHEN CERAMIC INSTITUTE

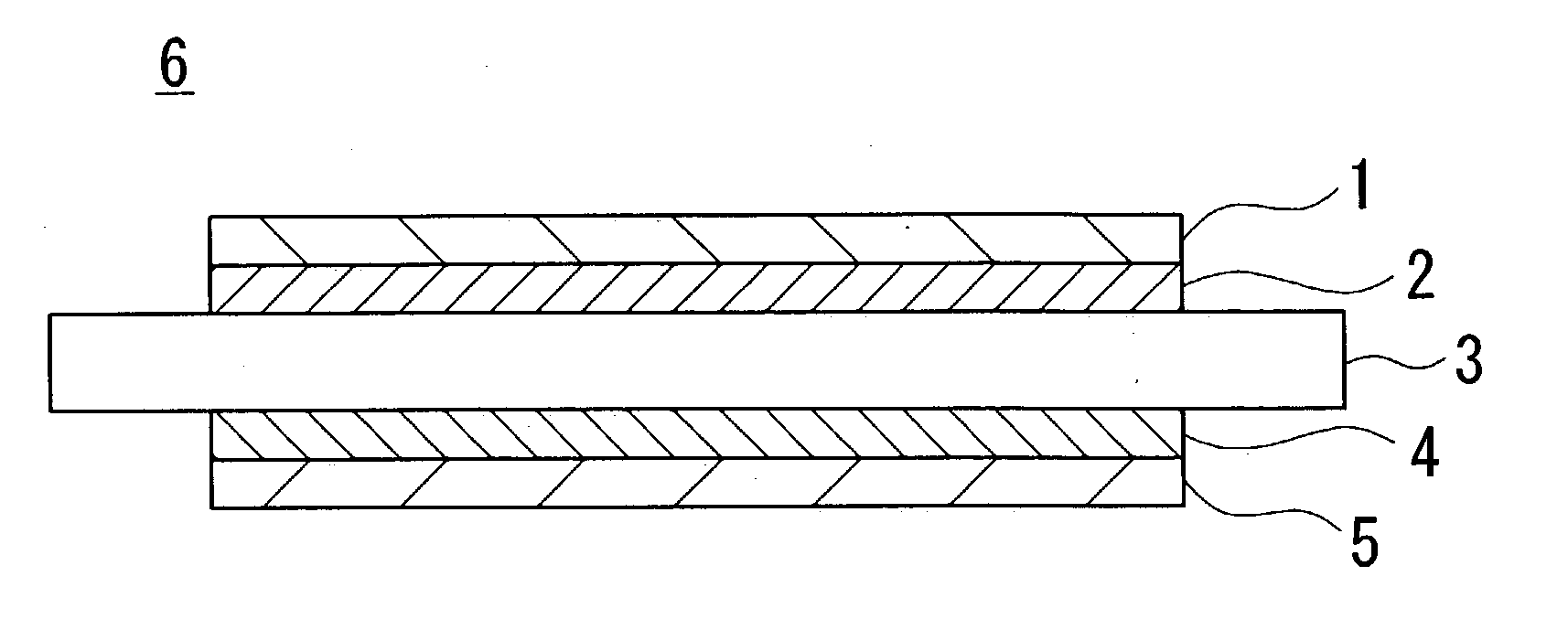

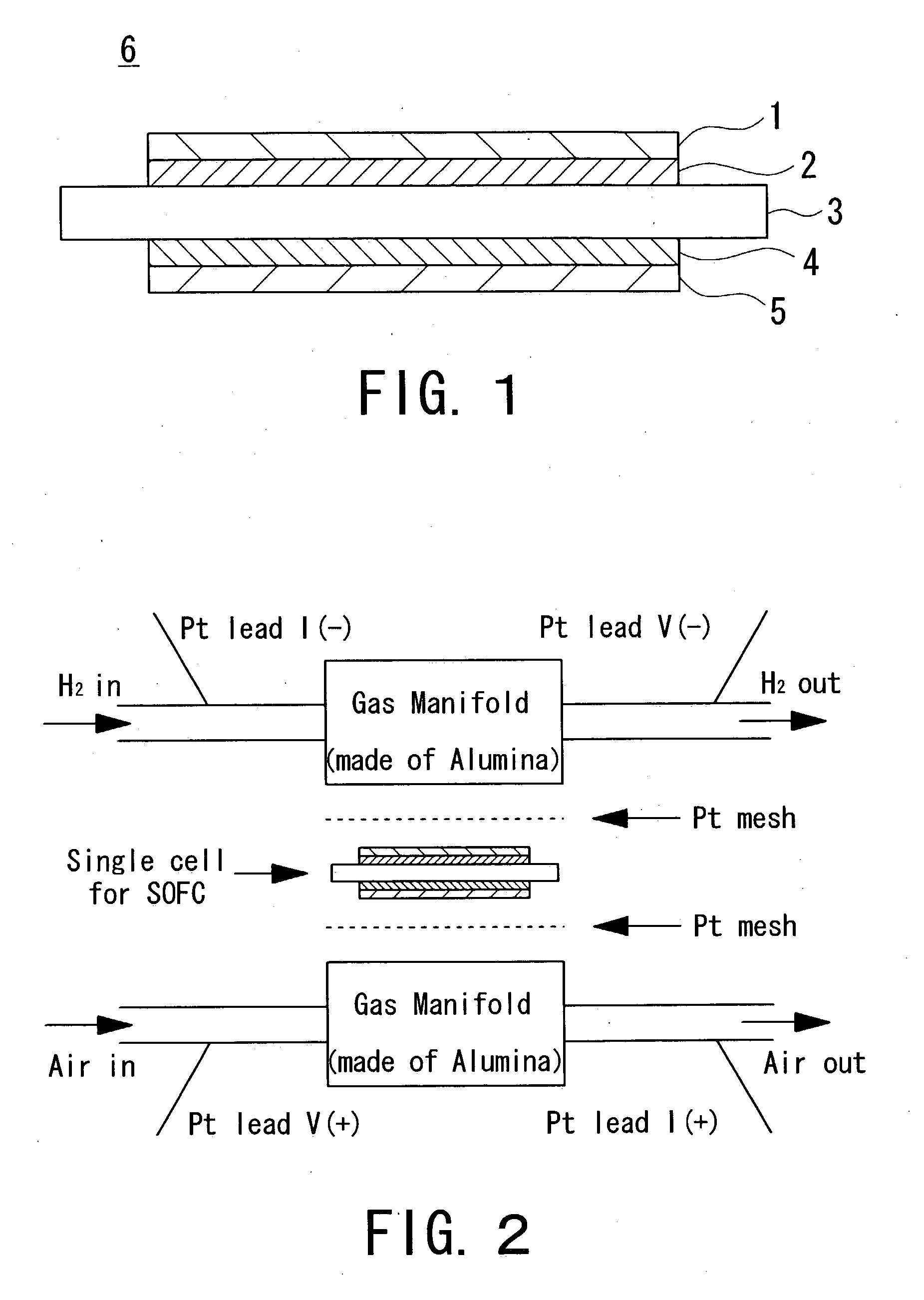

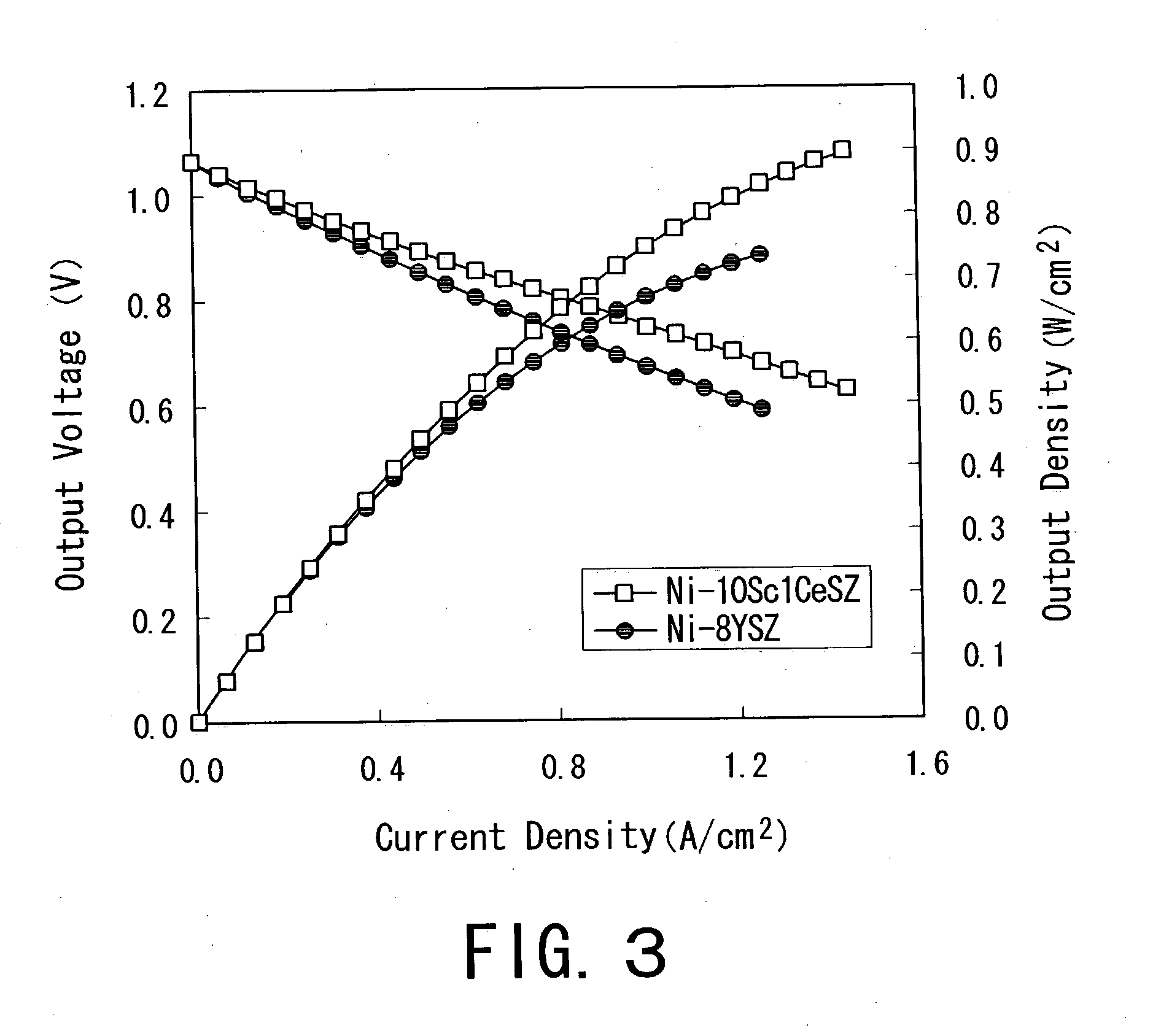

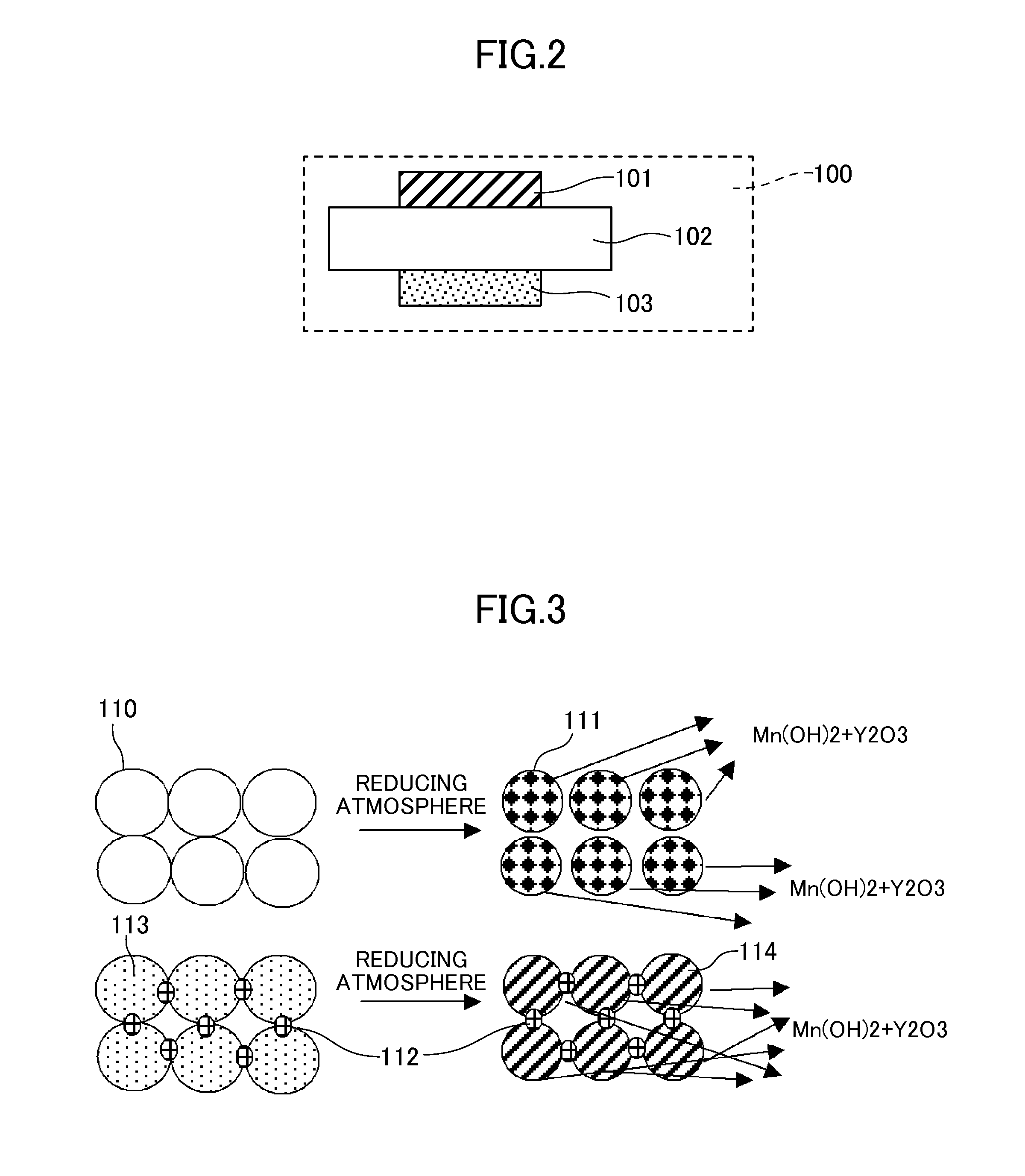

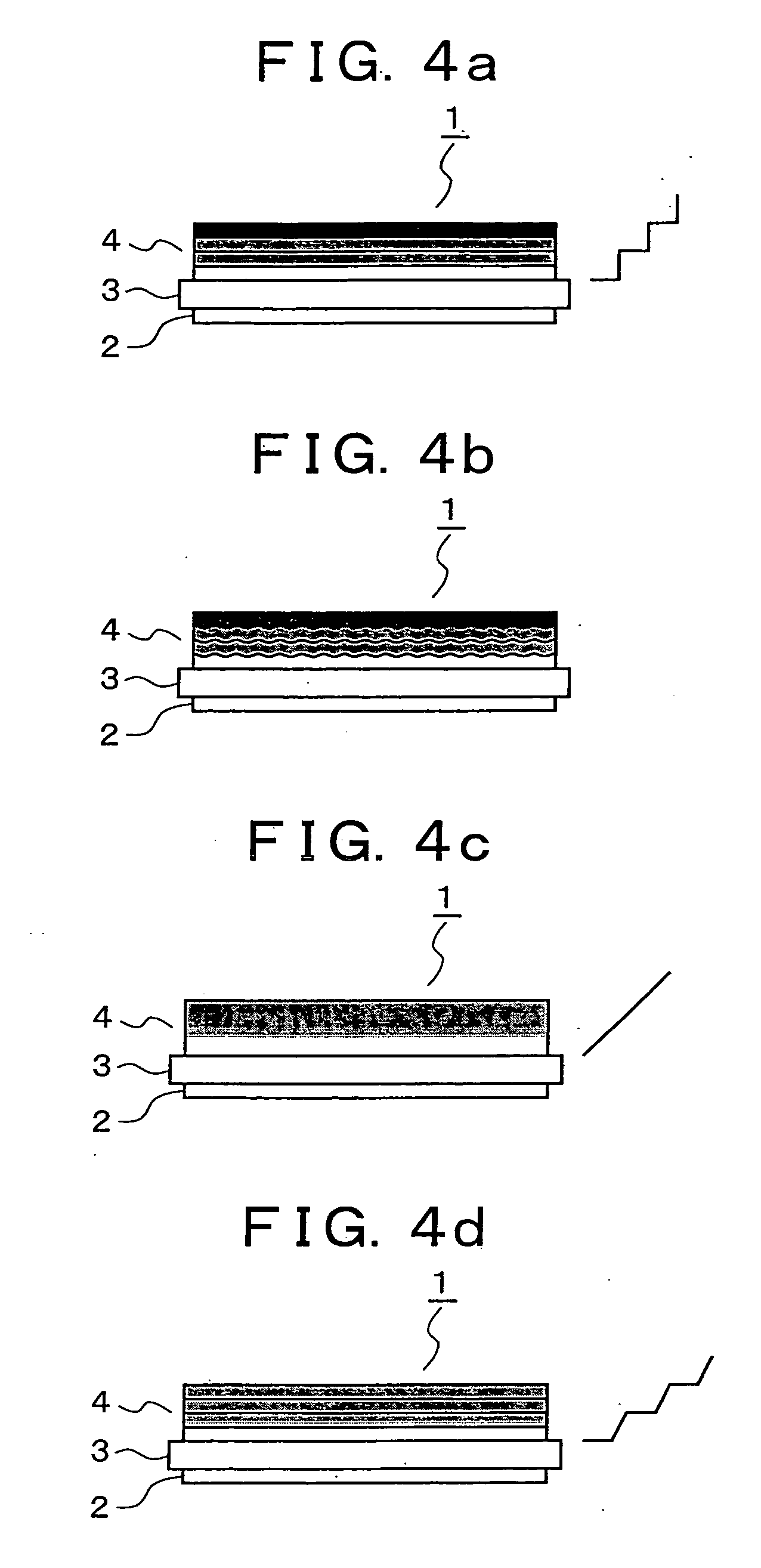

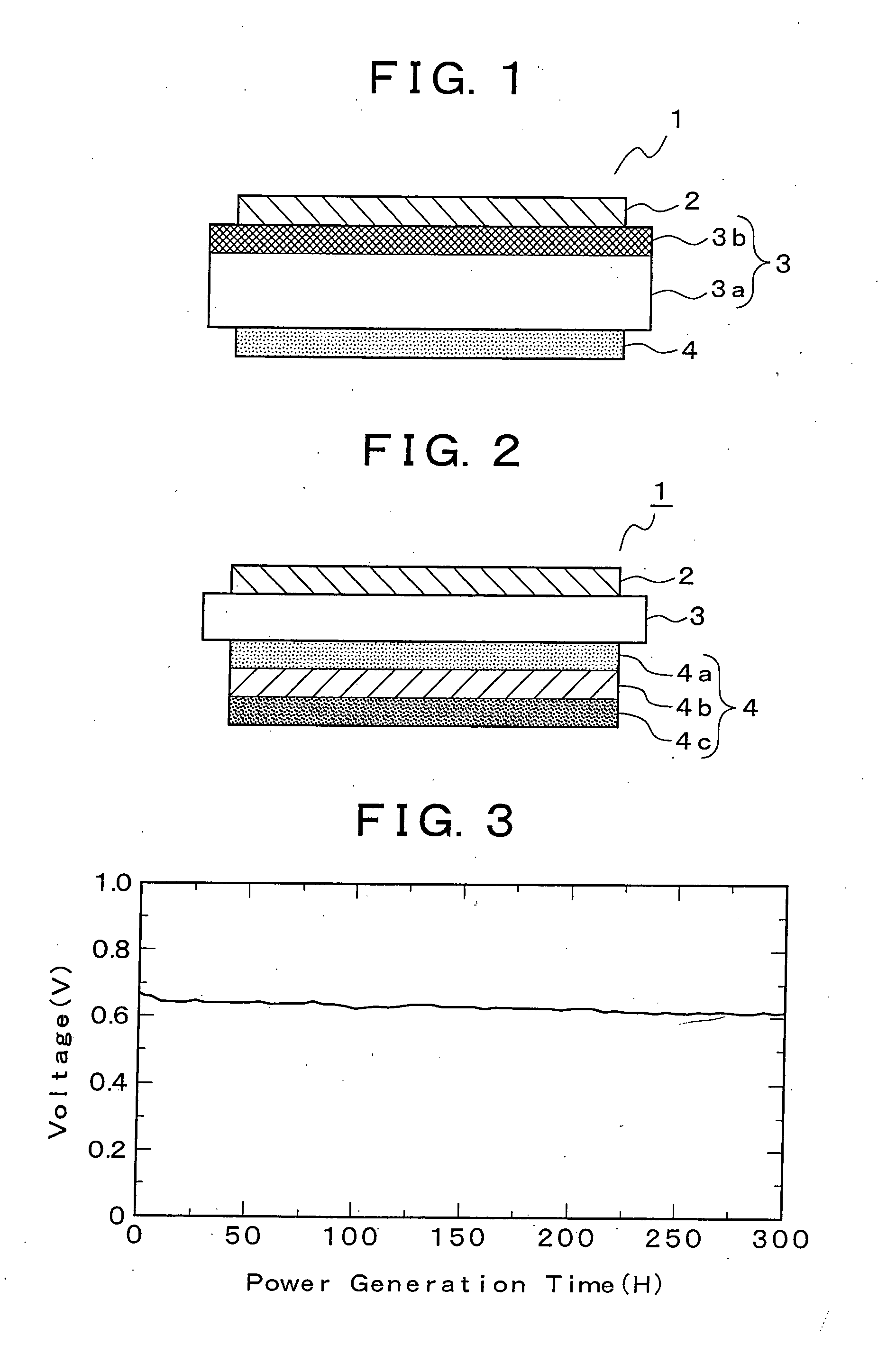

Single cell for a solid oxide fuel cell

InactiveUS20040072060A1Improve electrode activityReduce degradationSolid electrolytesFuel cells groupingFuel cellsFlexural strength

A single cell for a solid oxide fuel cell and a solid oxide fuel cell using the same practicable and excellent in generation performance and durability, wherein a fuel electrode including a cermet of a catalyst and a second solid electrolyte with oxide ion conductivity at 1000° C. of 0.20 S / cm or more is bonded to one side of a solid electrolyte plate with the conductivity of 0.07 S / cm or more and bending strength of 700 MPa or more, and an air electrode including a compound of perovskite type transition metal oxide with a third solid electrolyte is bonded to the other side. A surface of the fuel electrode is coated with a layer, and an air electrode surface is coated with a layer, and an aqueous solution where a noble metal compound is dissolved in water is impregnated into the air electrode.

Owner:TOHO GAS

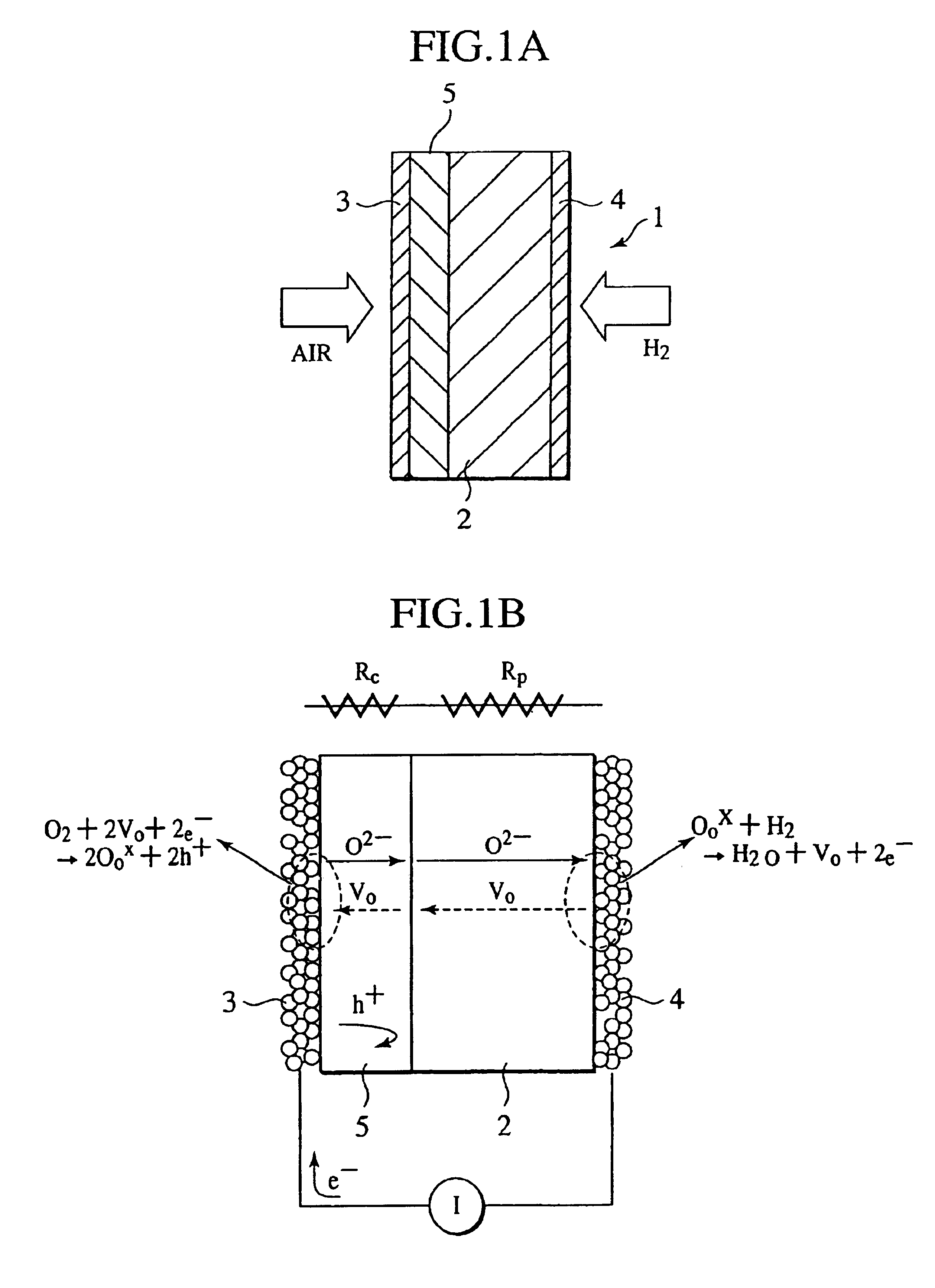

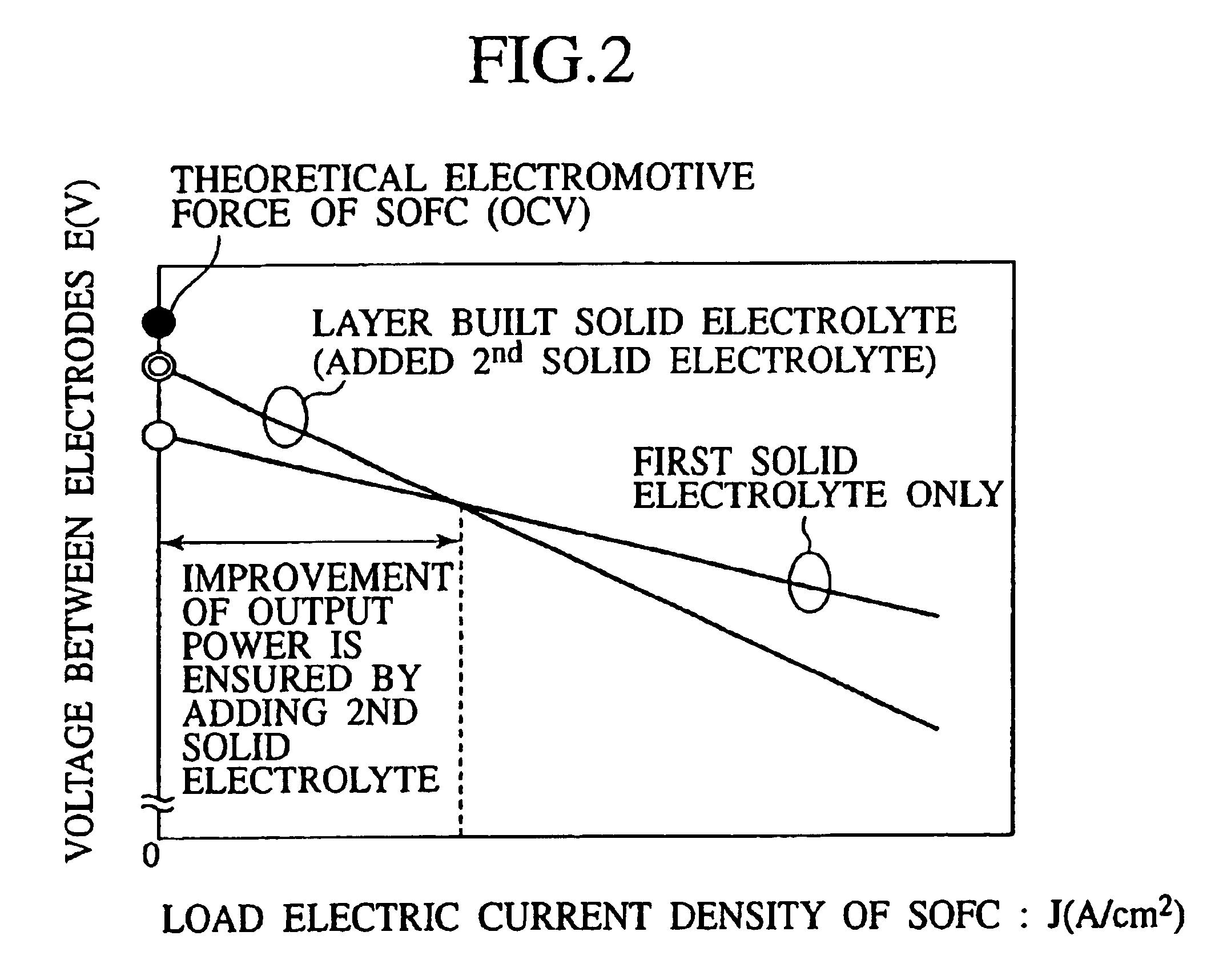

Solid oxide fuel cell having perovskite solid electrolytes

InactiveUS6849354B2Suppresses mixed conductivityIncrease substantial transport numberFinal product manufactureElectrolytesFuel cellsProton

A solid oxide fuel cell (SOFC) contains a first solid electrolyte layer of LaGa-based perovskite, an air electrode, a fuel electrode and a second solid electrolyte layer (having a hole transport number smaller than that of the first solid electrolyte layer), which is provided between the first solid electrolyte layer and an air electrode. Also, another SOFC contains a first solid electrolyte layer of LaGa-based perovskite, an air electrode, a fuel electrode and a third solid electrolyte layer (having electron and proton conductivity lower than that of the first solid electrolyte layer), which is provided between the first solid electrolyte layer and the fuel electrode. Still another SOFC contains the second solid electrolyte layer provided between a first solid electrolyte layer and an air electrode and the third solid electrolyte layer provided between the first solid electrolyte layer and a fuel electrode.

Owner:NISSAN MOTOR CO LTD

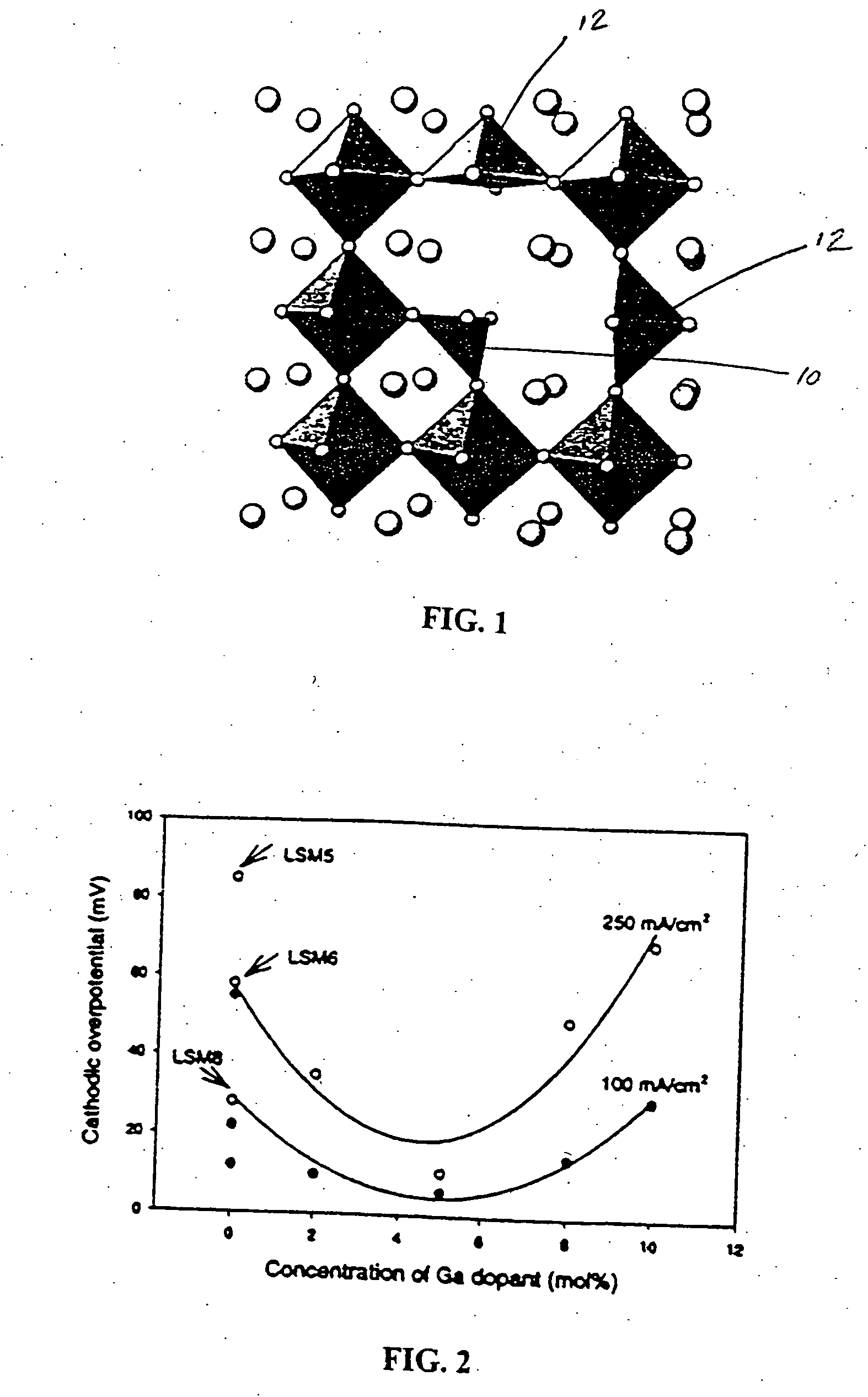

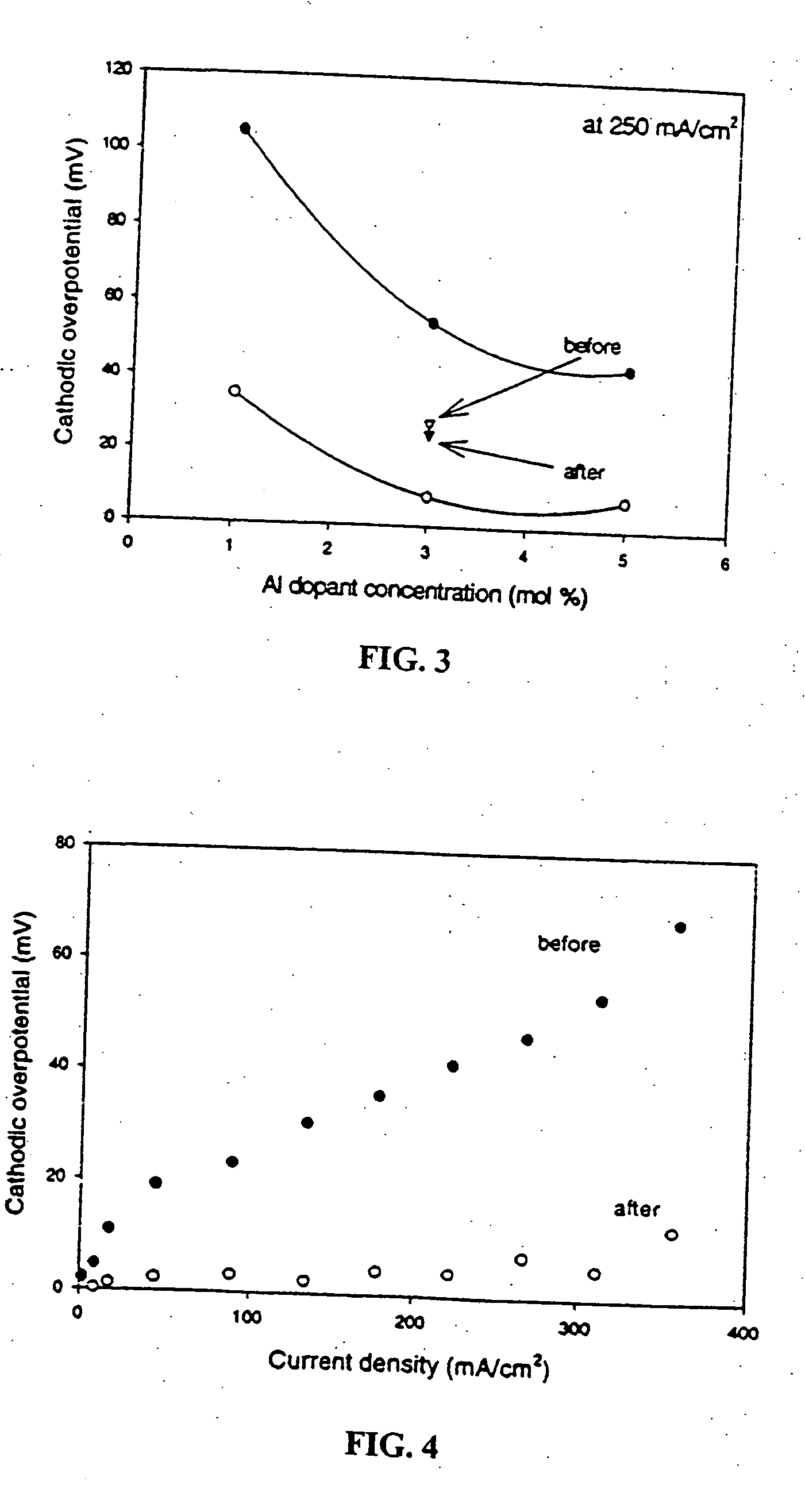

Oxygen ion conducting materials

InactiveUS20050031519A1Improve conductivityHigh catalytic activityHeterogenous catalyst chemical elementsNon-aqueous electrolyte accumulator electrodesDopantFuel cells

Owner:UCHICAGO ARGONNE LLC

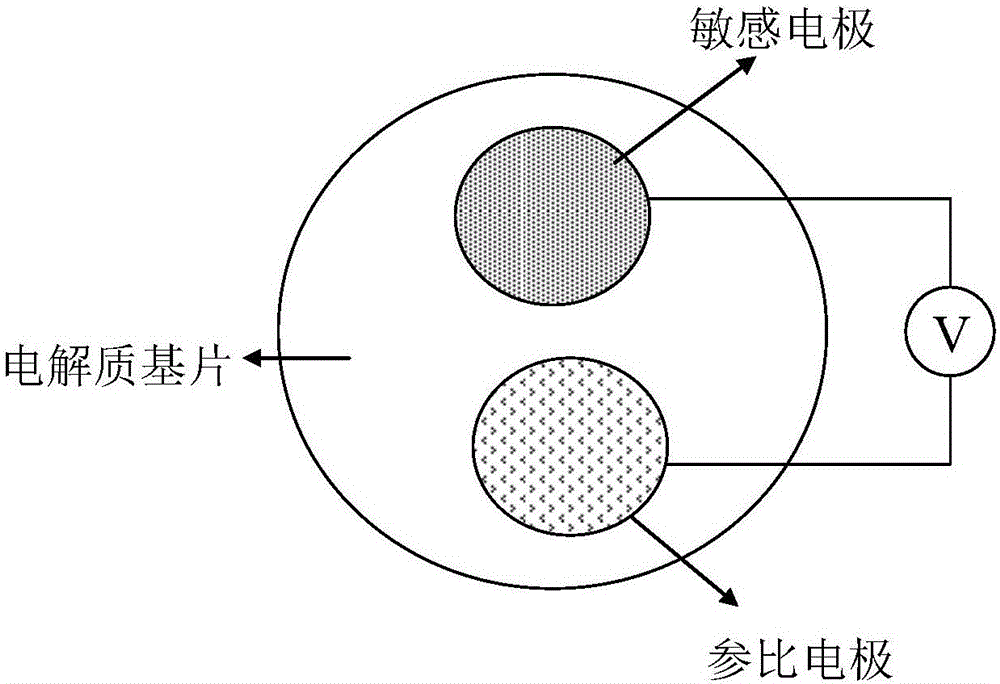

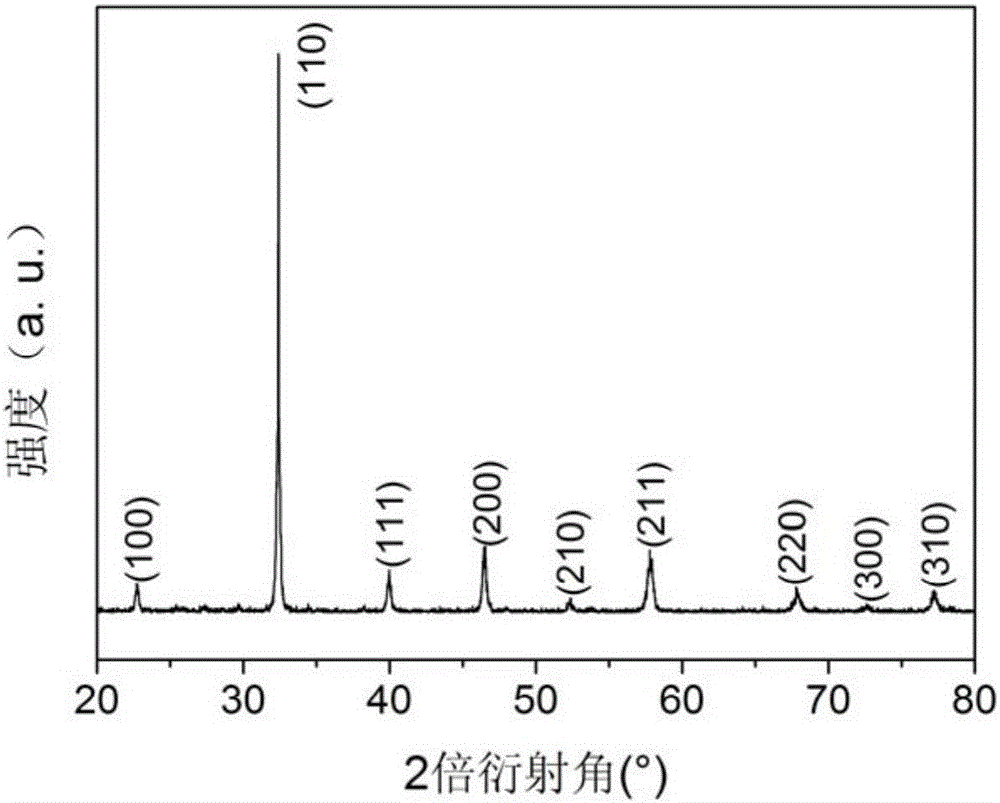

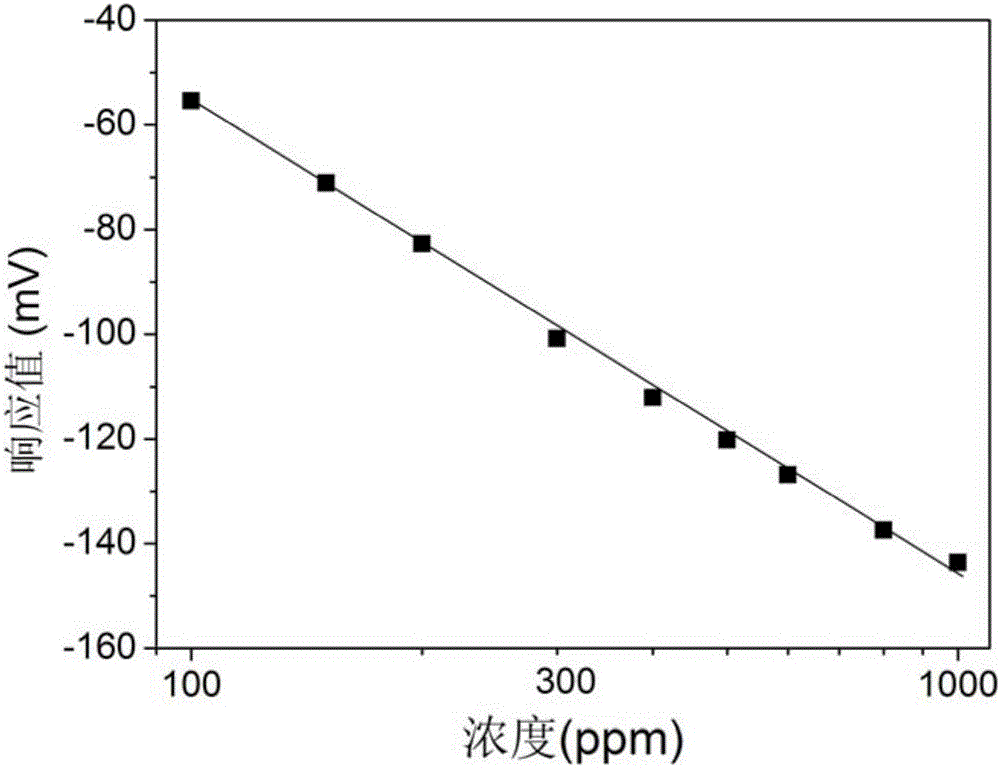

Potentiometric hydrogen sensor using strontium and iron-doped lanthanum chromate as sensitive electrode and manufacturing method of potentiometric hydrogen sensor

ActiveCN106770560AHigh electrochemical catalytic activityHigh responseMaterial electrochemical variablesPhysical chemistryStrontium

The invention discloses a potentiometric hydrogen sensor using strontium and iron-doped lanthanum chromate as a sensitive electrode and a manufacturing method of the potentiometric hydrogen sensor. The potentiometric hydrogen sensor uses La<1-x>Sr<x>Cr<1-y>FeyO<3-delta> as a sensitive electrode, Pt as a reference electrode, and YSZ or GDC as a solid electrolyte, wherein x is more than or equal to 0.1 and less than or equal to 0.6, and y is more than or equal to 0.3 and less than or equal to 0.7. The potentiometric hydrogen sensor disclosed by the invention uses a perovskite structure oxide La<1-x>Sr<x>Cr<1-y>FeyO<3-delta>, which has relatively good electrochemical catalytic activity to hydrogen, as a sensitive electrode, so that the sensor can have a relatively high response value to hydrogen; and YSZ or GDC is used as an electrolyte, so that the gas sensitivity and long-term stability of the sensor can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

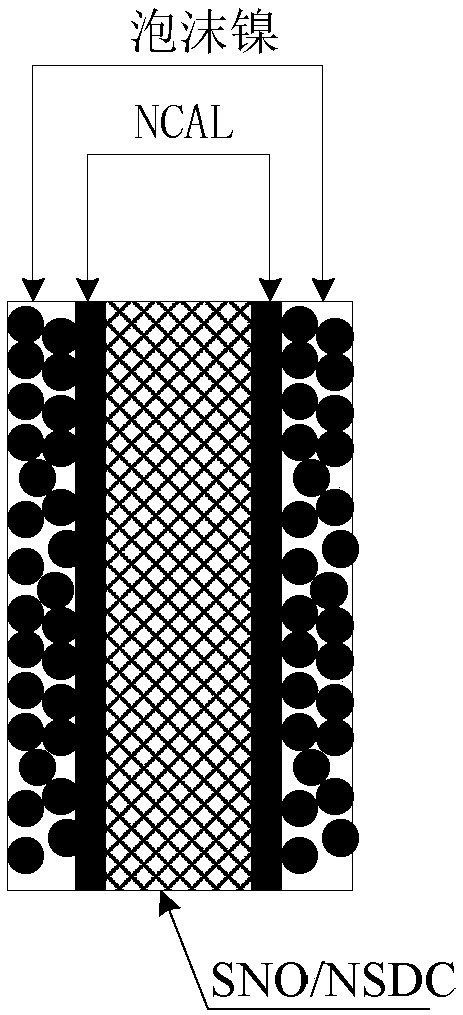

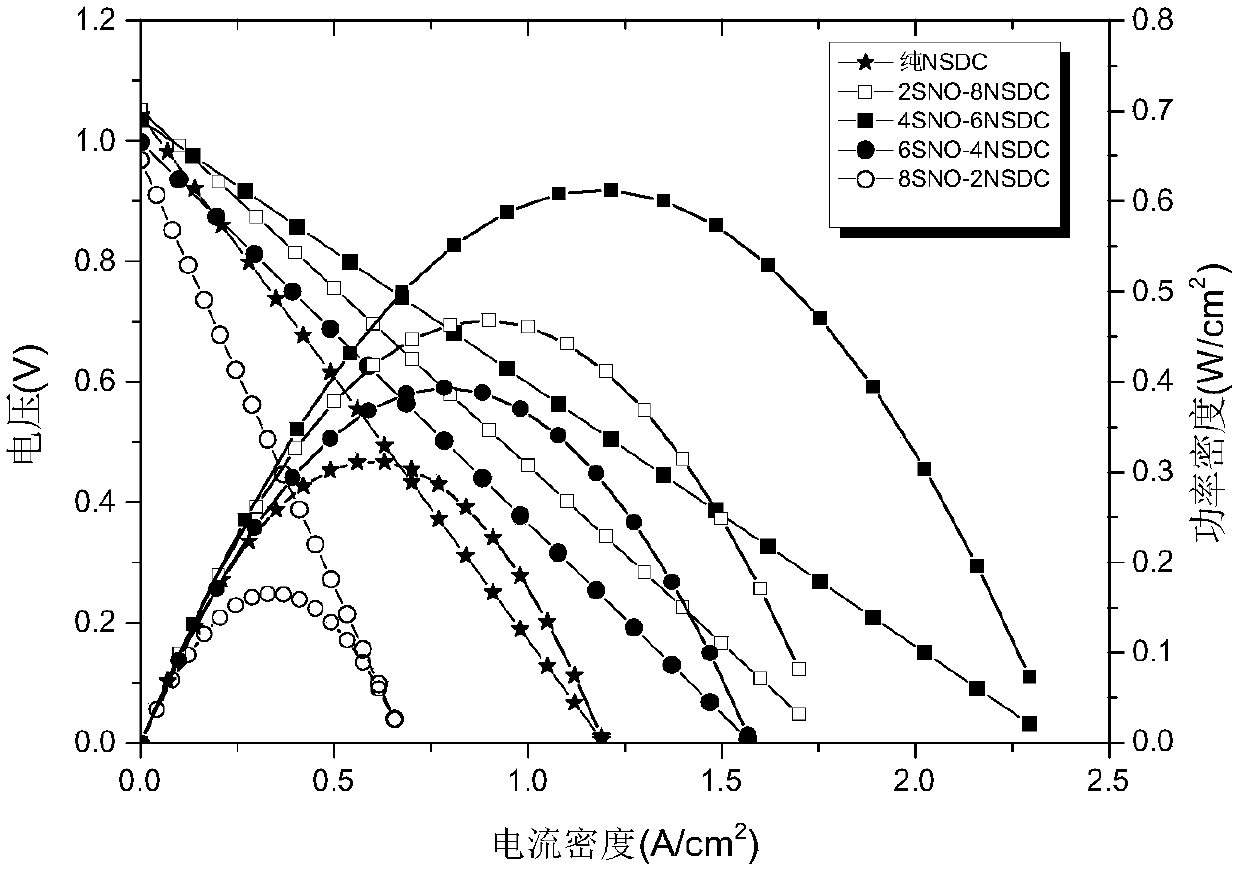

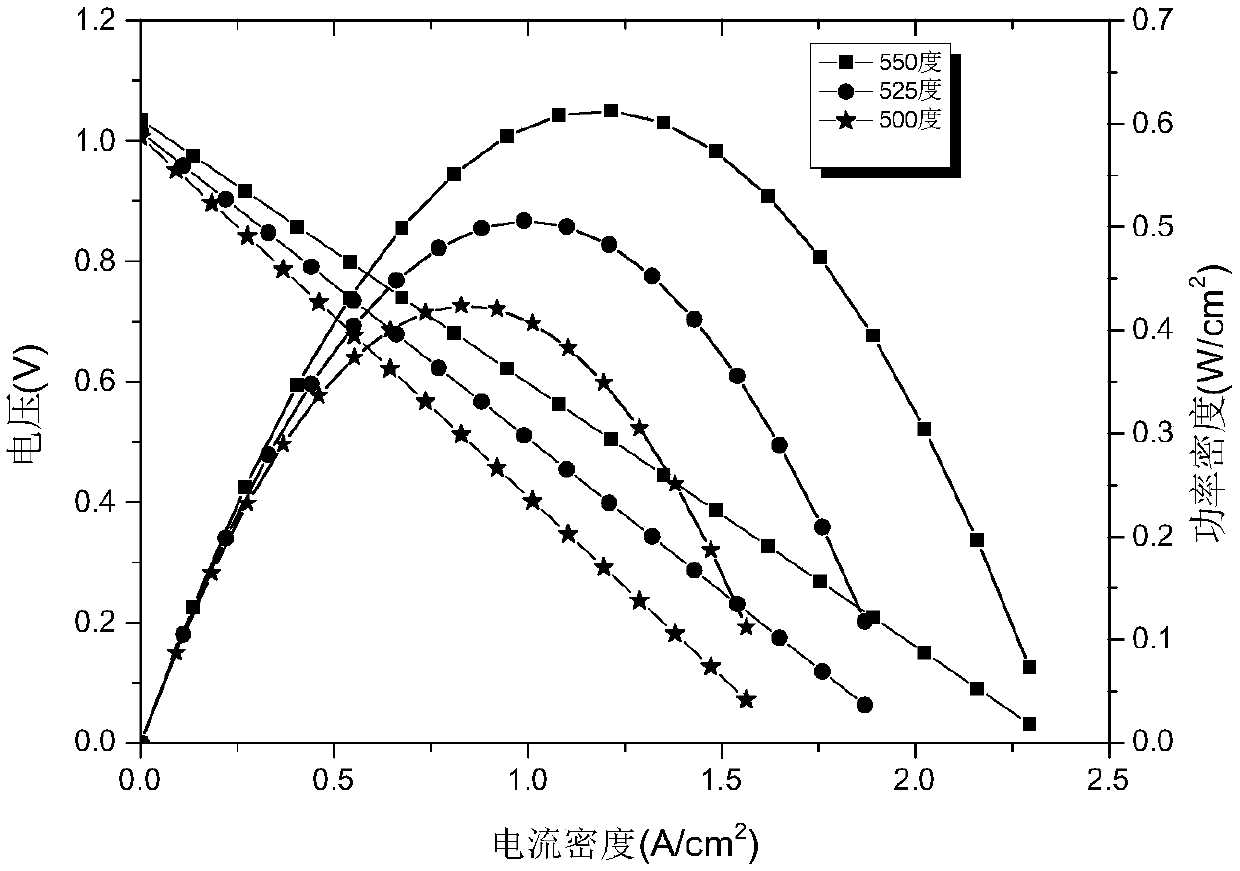

Oxide fuel cell based on lanthanum nickelate and lanthanum-doped yttrium oxide composite material

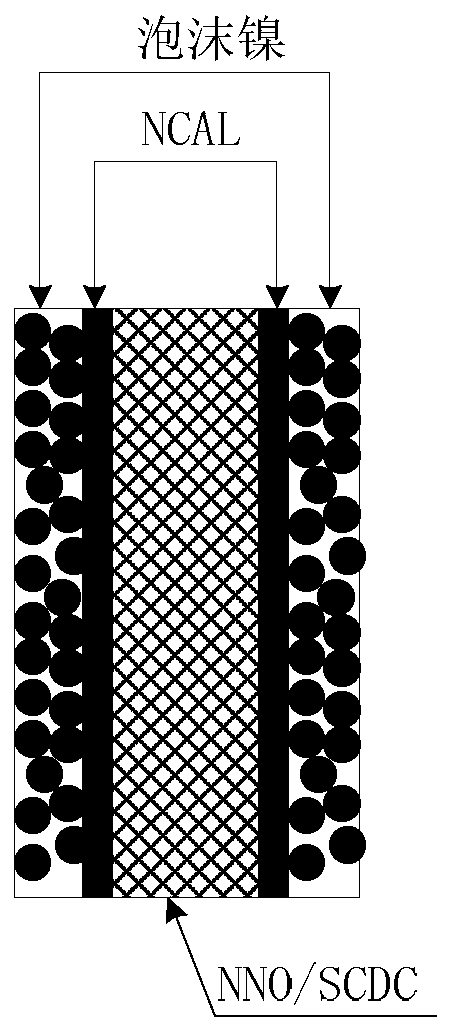

InactiveCN109687005AImprove transmission performanceIncrease output powerElectrolytesFuel cellsElectrical conductorOxide composite

The invention discloses an oxide fuel cell based on a lanthanum nickelate and lanthanum-doped yttrium oxide composite material. A cathode and an anode of the fuel cell are made from foam nickel coatedwith NCAL on the surface, and an electrolyte layer of the fuel cell is a SNO / NSDC composite material, that is, the structure of the fuel cell is made from foam nickel / / NCAL / / SNO / NSDC / / NCAL / / foam nickel. The low-temperature solid oxide fuel cell uses the lanthanum-doped yttrium oxide (NSDC) composite material, prepared by utilizing a sodium carbonate precipitation process, of an ionic conductor asan electrolyte layer, and greatly reduces the electrode polarization loss during the electrochemical reaction of the fuel cell; in addition, the electrolyte material has good output power in the lowtemperature section, so that the solid oxide fuel cell using the electrolyte material can be efficiently and stably operate in a low temperature range (300-600 DEG C) for a long period of time. Stableoperation.

Owner:NANJING XIAOZHUANG UNIV

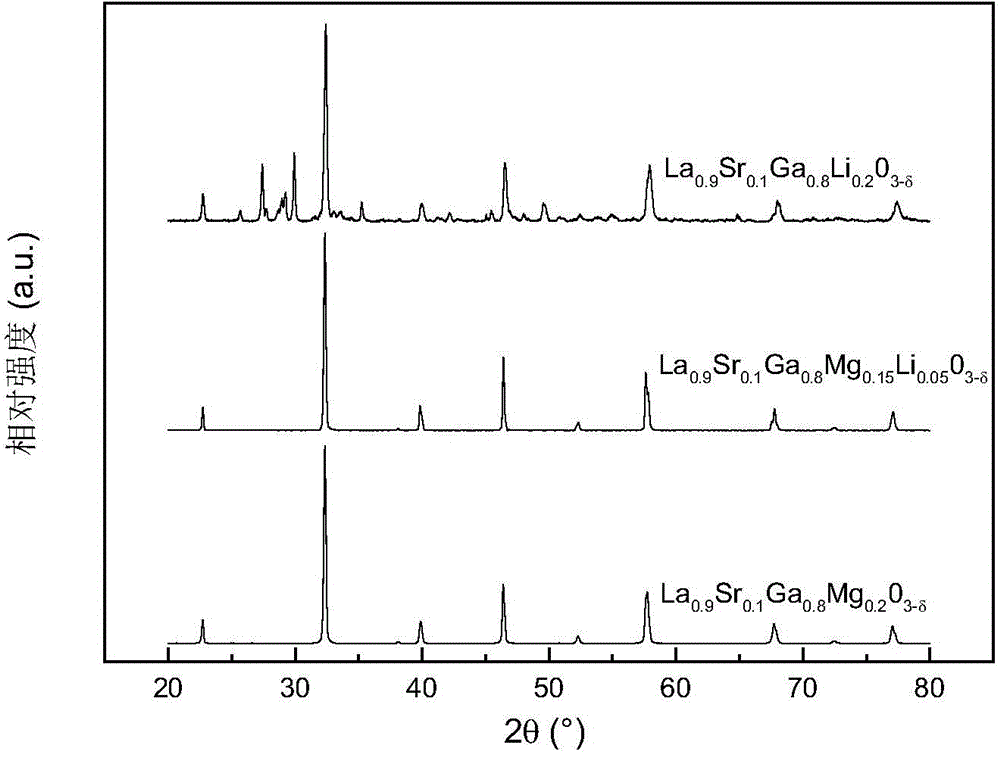

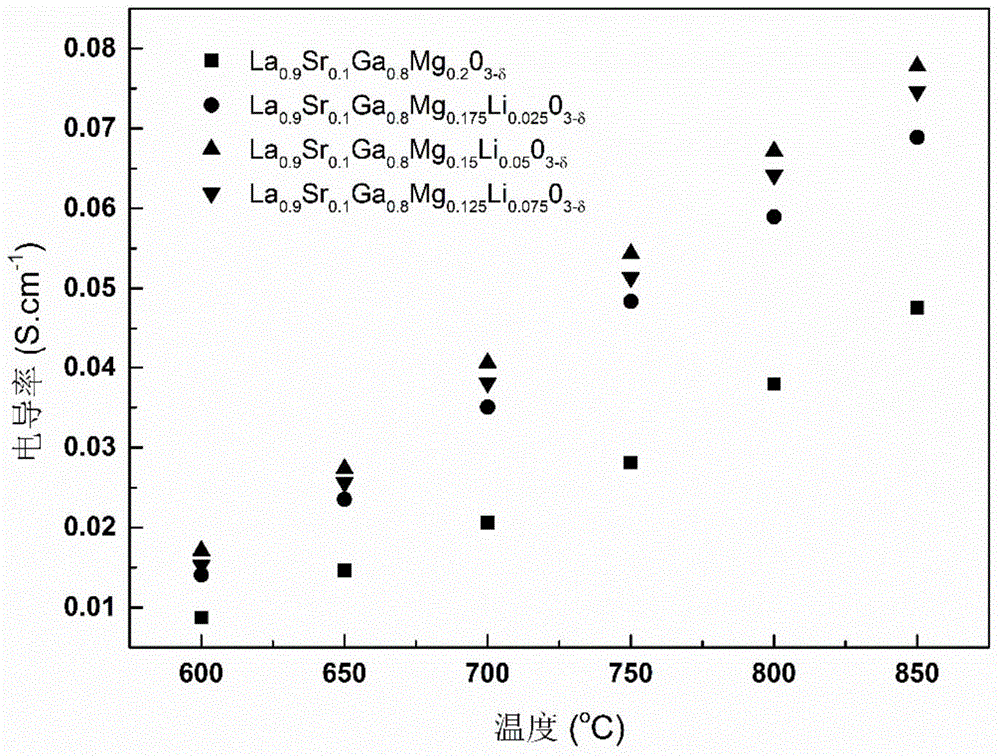

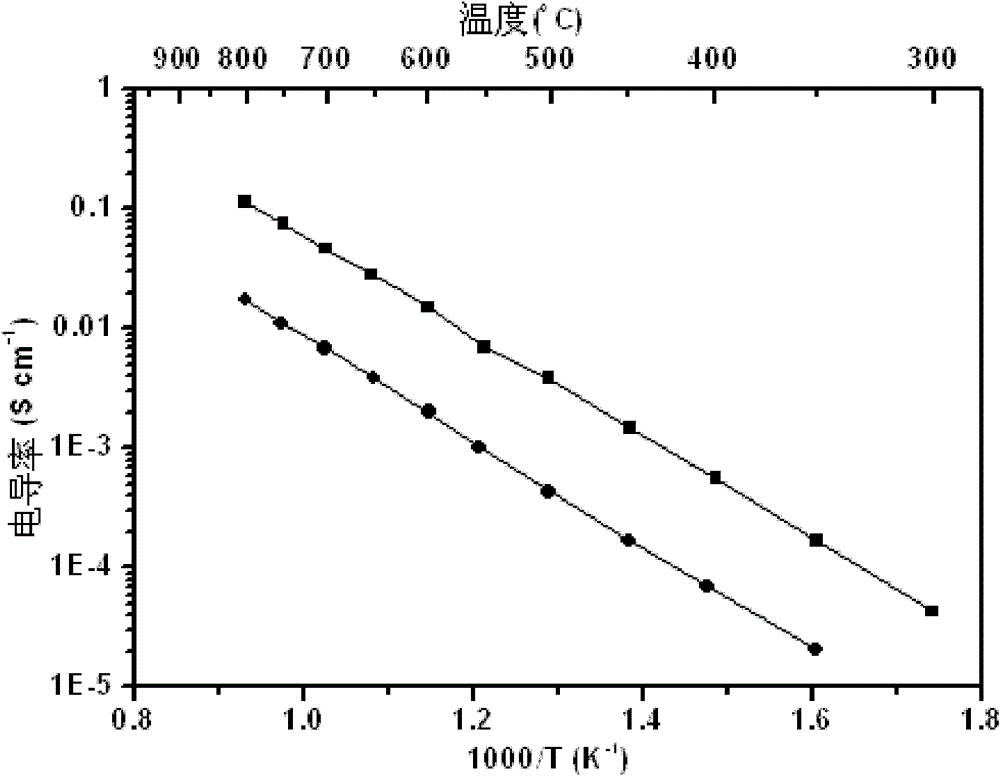

Electrolyte material with perovskite structure

The invention relates to an electrolyte material with a perovskite structure, and belongs to the technical field of fuel cells. The electrolyte material is a novel electrolyte material LSGML (La1-aSraGa1-b-cMgbLicO3-delta, wherein a ranges from 0.01 to 0.2, b ranges from 0.01 to 0.25, and c ranges from 0.01 to 0.2) formed by partly replacing a conventional LSGM (La1-aSraGa1-bMgbO3-delta) electrolyte material by lithium elements. The electrolyte material has higher oxygen vacancy concentration and lower oxygen ion migration energy compared with the current LSGM, then has an electrical conductivity better than that of the LSGM at the same temperature, and is relatively suitable for being used as electrolyte of solid oxide fuel cells and solid oxide electrolytic cells.

Owner:TSINGHUA UNIV

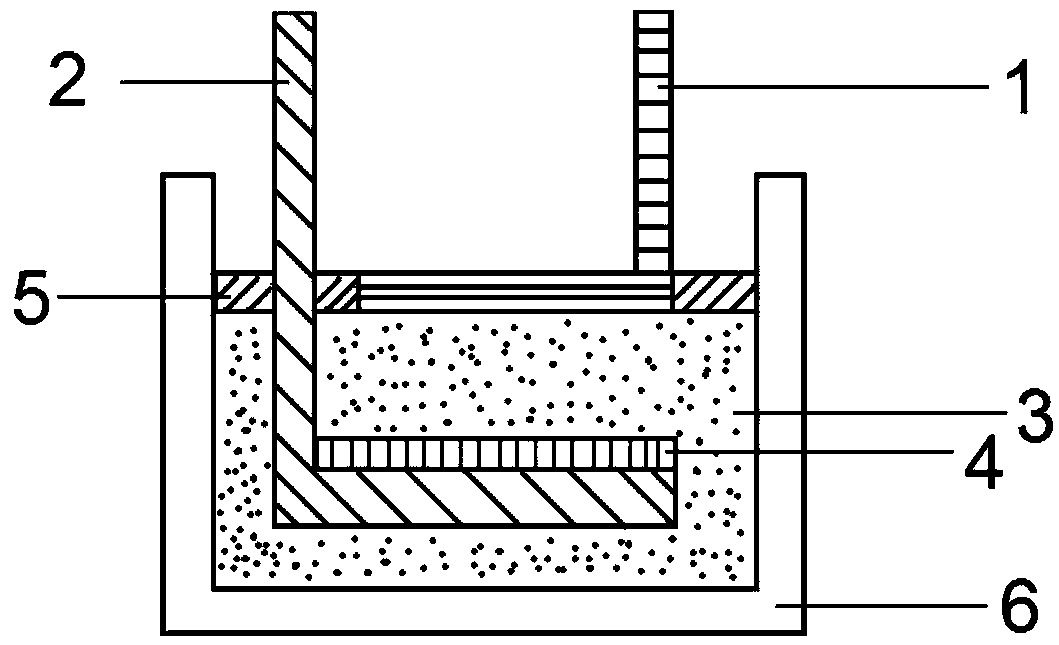

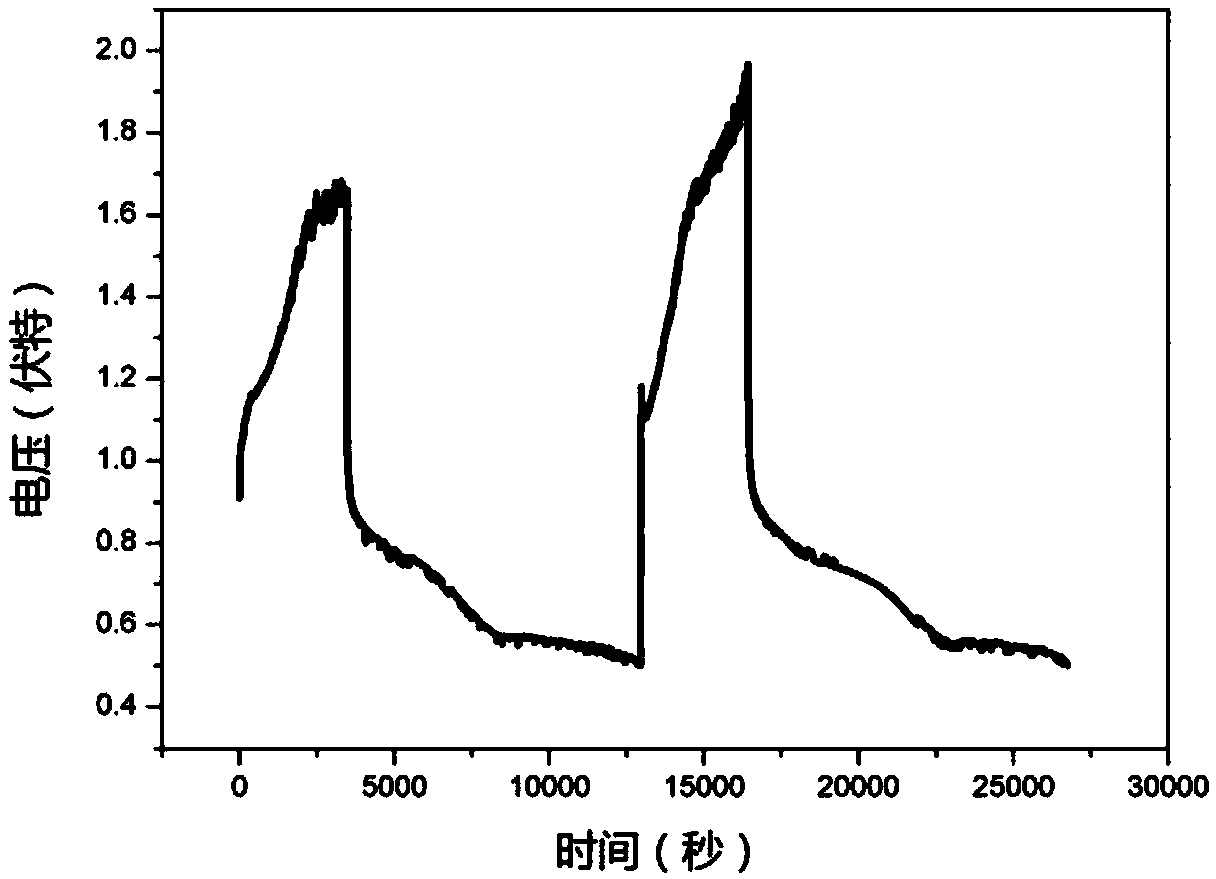

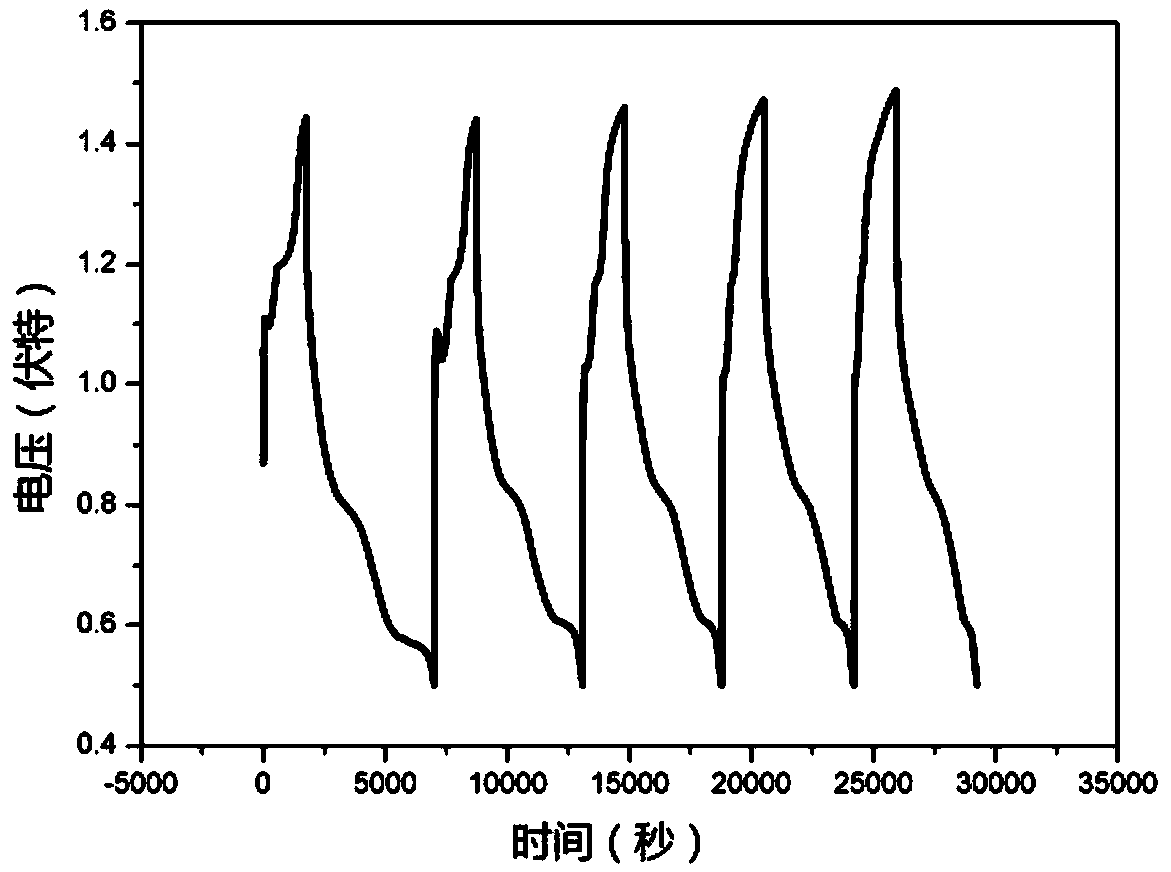

High-temperature fused salt battery

The invention relates to a high-temperature fused salt battery which comprises a positive pole, pasty dual electrolyte and a negative pole, wherein the positive pole is exposed in air, the pasty dualelectrolyte is prepared from fused salt and solid electrolyte powder by mixing, the fused salt is potassium carbonate and / or sodium carbonate, the solid electrolyte powder is zirconium oxide micron powder containing yttrium oxide, and the negative pole is separated from the positive pole by the pasty dual electrolyte. The high-temperature fused salt battery disclosed by the invention is a high-temperature fused salt battery which can be applied to large-scale power grid energy storage and is based on the fused salt and the solid electrolyte powder material. The pasty dual electrolyte disclosedby the invention can be easily prepared from the fused salt and the solid electrolyte powder through direct mixing, so that the pasty dual electrolyte has the advantages of higher oxygen ion conductivity, lower fluidity and good filling ability; furthermore, the short circuit and open circuit phenomena between the positive pole and the negative pole of the battery are effectively avoided, circular charge-discharge property of the battery is remarkably improved, and the processing manufacturing cost of the high-temperature fused salt battery is obviously reduced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Perovskite materials for solid oxide fuel cell cathodes

ActiveUS8124037B2Reduce conductivityHigh oxygen ion conductivityIron compoundsCobalt compoundsThermal expansionSolid state reaction method

An improved LSCF 6428 perovskite material of the type La12zSrx+zCo0.2+aFe0.8+bO3−δ wherein x=0.4, z=(0-0.1), a=(0.01-0.04), and b=(0.05-0.15) for use as an SOFC cathode having increased electronic and ionic conductivity. The general formula is similar to the prior art formulae (La0.6Sr0.4)1−zCo0.2Fe0.8O3−δ and La0.6Sr0.4Co0.2Fe0.8O3−δ but applies the z term to La and Sr independently as well as reducing the overall content of La. Further, by adding a small amount (a) of extra Co ions, catalytic activity, conductivity, and sinterability are further enhanced. Adding small amounts (b) of Fe and / or Fe and Co moderates the thermal expansion coefficient with no adverse effect on crystal structure or fuel cell performance. Improved sinterability, microstructure, and reduced film cracking result in high power density of fuel cells. An inherently low-cost solid state reaction method is described.

Owner:APTIV TECH LTD

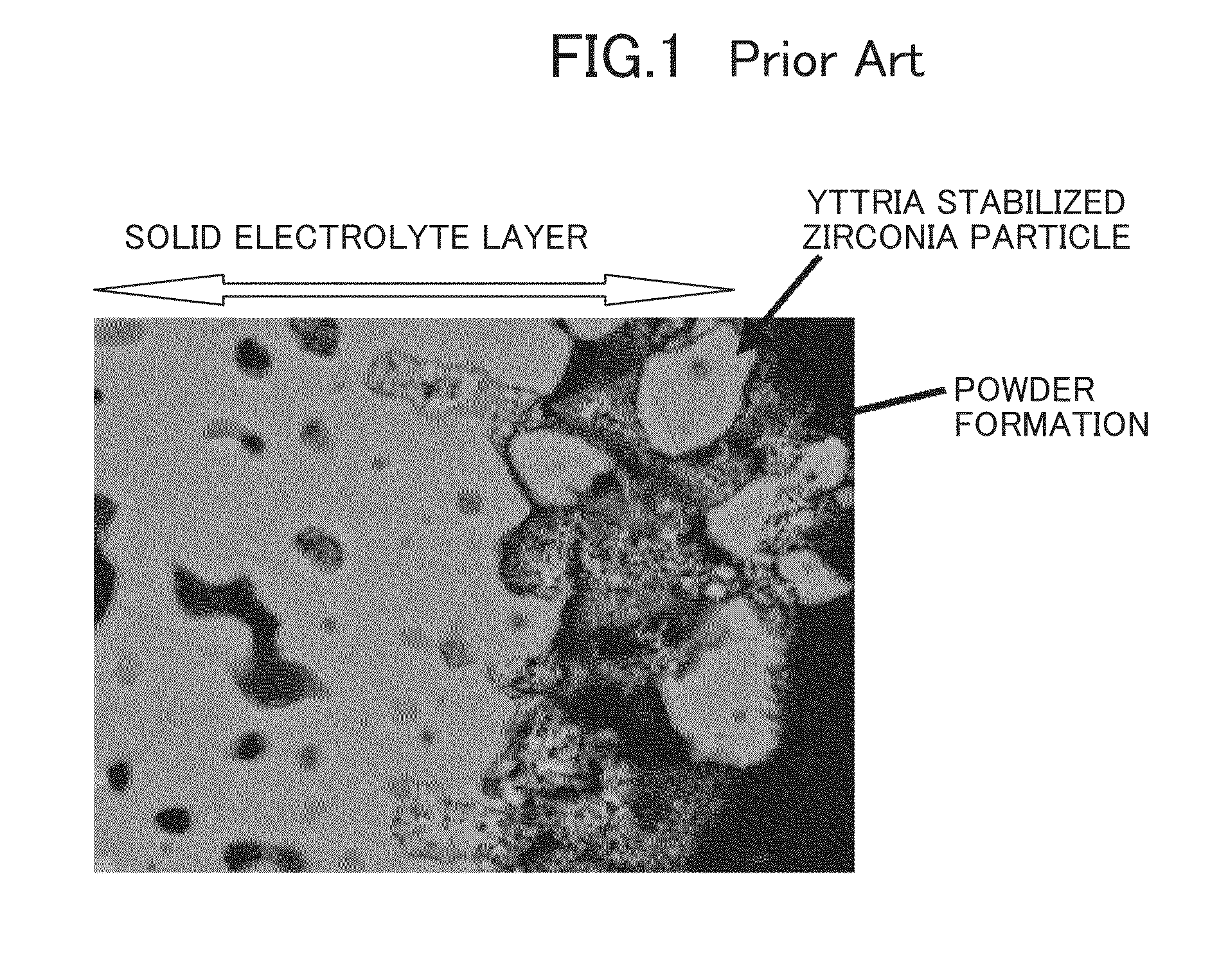

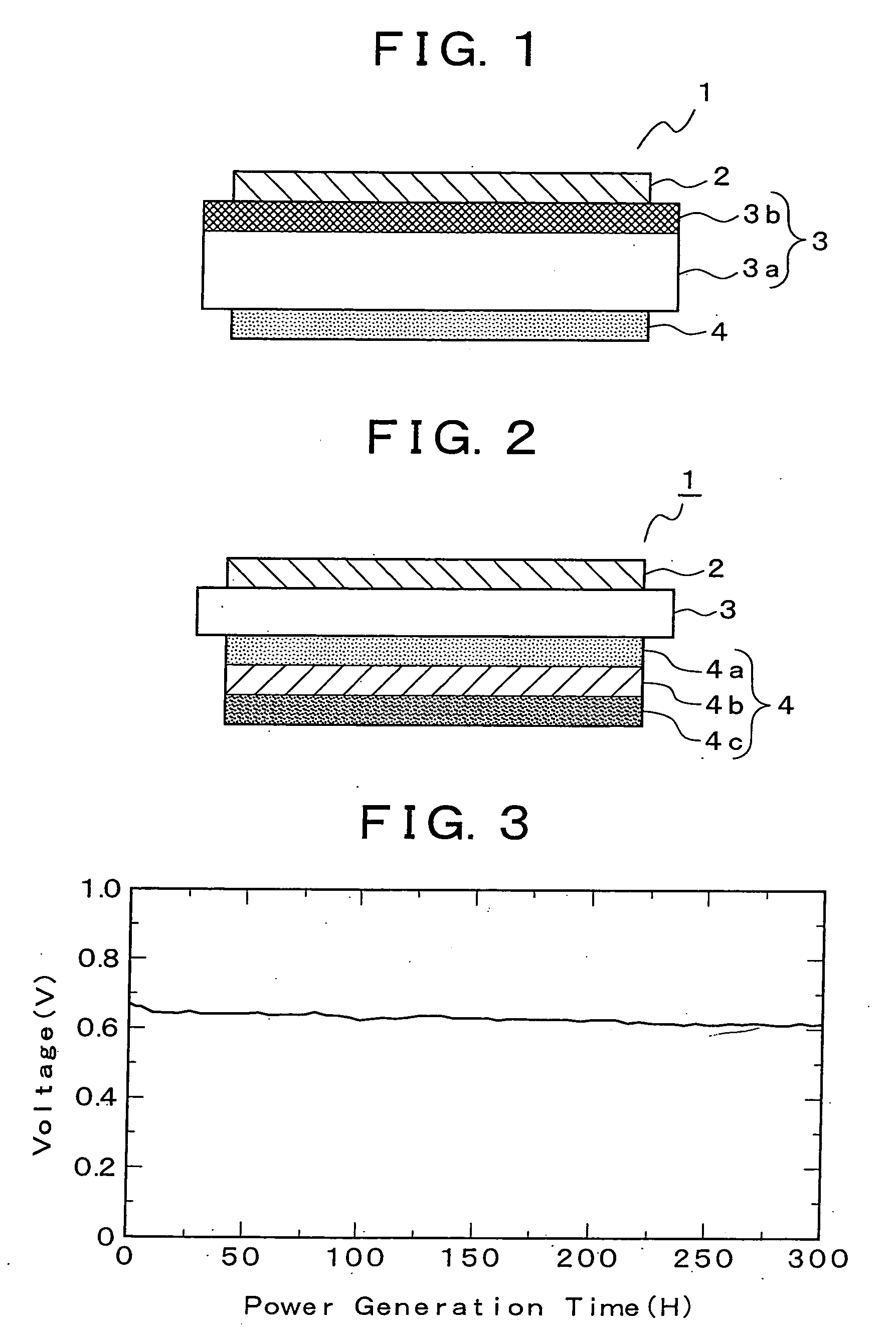

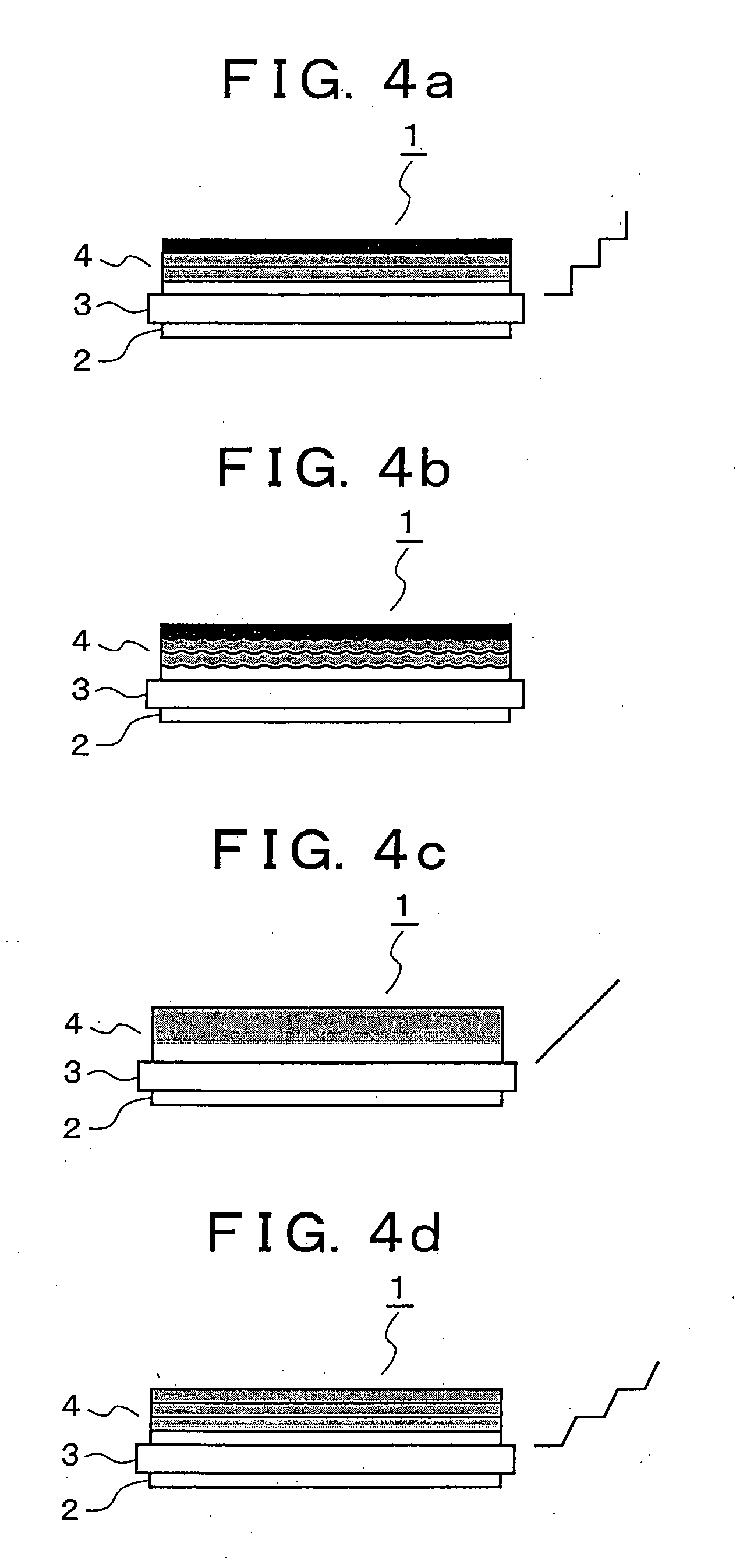

Solid oxide fuel cell

ActiveUS20080102340A1High strengthImprove stabilityFinal product manufactureActive material electrodesFuel cellsCerium

A solid oxide fuel cell which has high output capacity especially at an operating temperature of 600° C.-800° C. and effectively prevents influence of reaction between respective layers. The solid oxide fuel cell includes a solid electrolyte layer between a fuel electrode and an air electrode, a support comprised of either the fuel electrode or the air electrode, and at least first and second layers provided in turn from the side of the support. The first layer is comprised of a cerium-containing oxide and the second layer is comprised of a lanthanum-gallate oxide containing at least lanthanum and gallate. A sintering assistant for improving sintering property of the cerium-containing oxide is contained in the first layer. When the thickness of the second layer is T μm, the value of T is 2<T<70.

Owner:MORIMURA SOFC TECH CO LTD

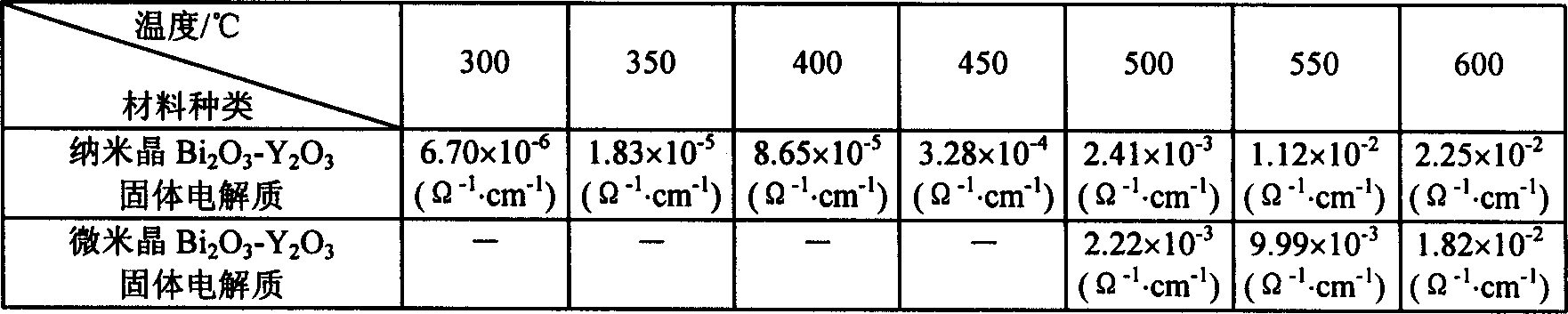

Preparation of nano crystallized bismuth oxide based oxygen ion conductive solid electrolyte

InactiveCN1583664ASpeed up the reaction sintering processLower sintering temperatureElectrical conductorOxygen ions

A process for nano crystal oxidize bismuth base oxygen ion solid electrolyte working in middle or low temperature by chemical liquid phase law and basic technics of ceramic material include reverse chemical coprecipitation method of titration and frit technics, use nano Bi2O3+Y2O3mixed power as material. The conductance rate of solid electrolyte is more than 10 to the power -6 omega to the power -1 . cm-1 in the condition of beyond 300deg.C, so it is used for gas sensor, also for fuel cell and penetrating oxygen material working in the 500deg.C or below.

Owner:SHANGHAI UNIV

Preparation method of electrolyte material for medium-temperature solid fuel cell

ActiveCN108232259AGood chemical compatibility and mechanical compatibilityIncreased concentration of oxygen vacanciesFuel cellsRare-earth elementOxygen vacancy

The invention relates to a preparation method of an electrolyte material for a medium-temperature solid fuel cell, and belongs to the technical field of new energy sources. Based on the characteristics of higher oxygen ion conductivity of the cerium-oxide-doped electrolyte at a relatively low temperature as well as better chemical compatibility and mechanical matching property with a high-performance cathode material at sintering and working temperatures, the electrolyte material of the cell is formed by doping rare earth elements such as cerium, gadolinium and the like, the oxygen vacancy concentration of the cell is greatly increased, and accordingly, the ion conductivity of the cell is improved; the crystal size of the material is reduced at a lower synthesis temperature, and the sintering performance and the sintering density of the material are improved, so that the oxygen ion conduction of the electrolyte is ensured; the average crystal size of the electrolyte is reduced by compounding titanium dioxide and strontium oxide, particles of the electrolyte are homogenized, the whole electrolyte can be more densified, the ionic conductivity is improved, and the output power of thesingle cell supported by the electrolyte is further improved.

Owner:湖州达立智能设备制造有限公司

Solid electrolyte material and solid oxide fuel cell provided with same

InactiveUS20130316266A1High oxygen ion conductivitySuppresses extractionFinal product manufactureConductive materialFuel cellsUltimate tensile strength

Provided is a solid electrolyte material provided which, while maintaining a high oxygen ion conductivity, minimizes the extraction of scandia caused by impurities such as silicon in the fuel gas, and has improved intergranular strength in order to eliminate intergranular fracture caused by crystalline modification. The solid electrolyte material is a zirconia solid electrolyte material having yttria dissolved therein, has cubic crystals as the main ingredient, and is further characterized by having a lanthanoid oxide dissolved therein.

Owner:TOTO LTD

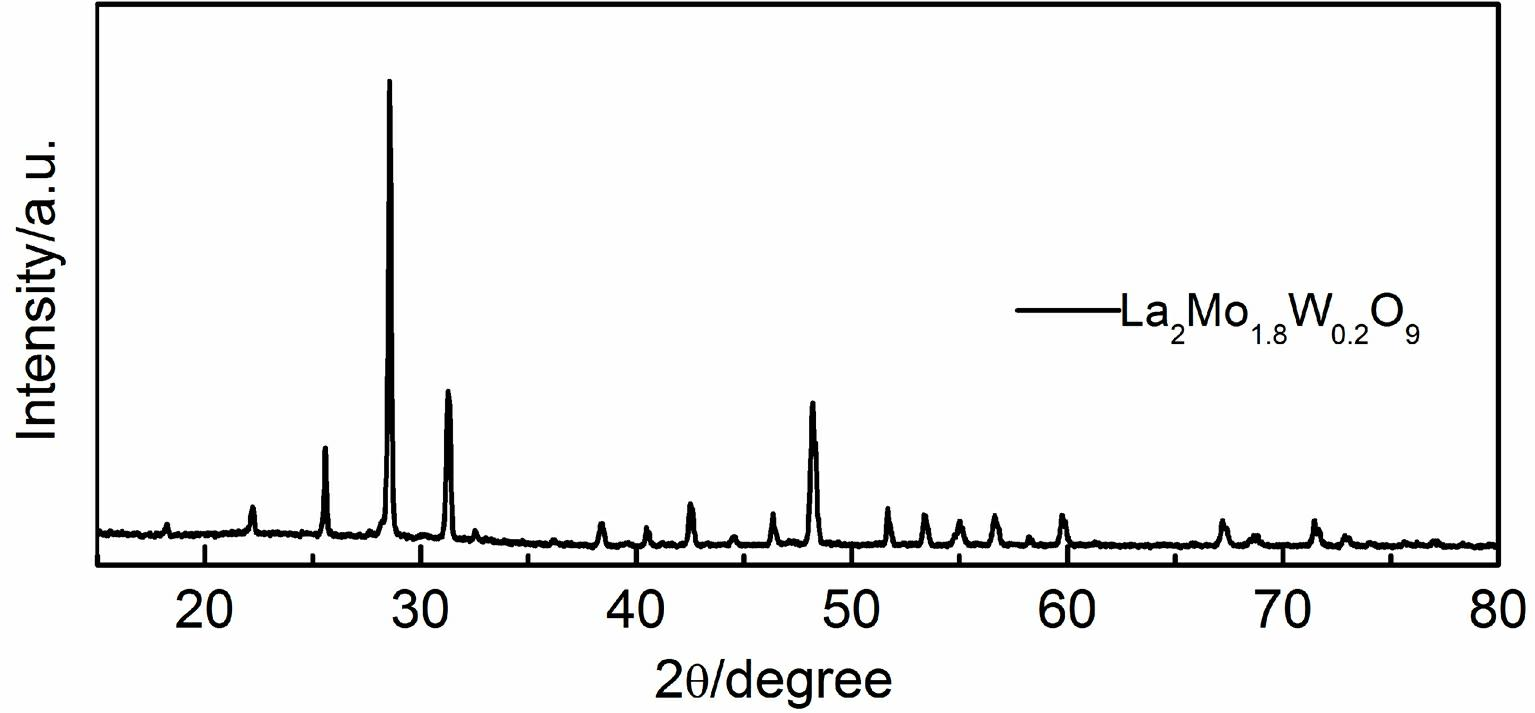

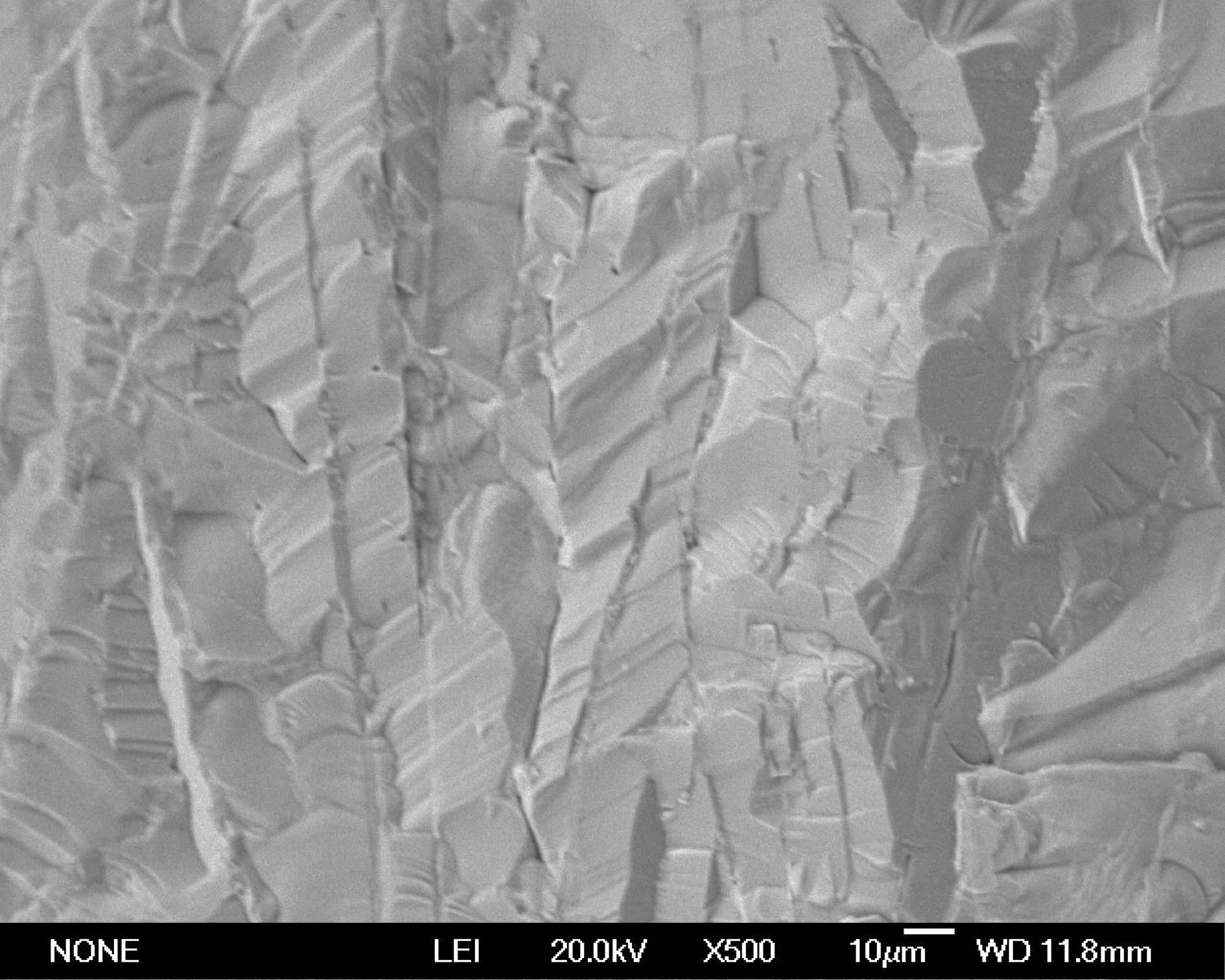

Laser preparation method of lanthanum molybdate based oxygen ion conductor

The invention belongs to the technical field of preparing a solid oxide oxygen ion conductor and in particular relates to a laser preparation method of a lanthanum molybdate based oxygen ion conductor. The preparation method comprises the following steps of: adopting La2O3, MoO3 and WO3 powder as the raw materials; proportioning according to the mole ratio of La2Mo(2-x)WxO9 with the value of x between 0.2 and 1.2; and mixing evenly and compacting the raw materials to obtain blanks, presintering and subjecting the blanks to irradiation of CO2 laser beams for full reaction. The preparation method provided by the invention is simple in process, low in cost, short in time consumption, low in energy consumption and good in process repeatability and the obtained sample of the lanthanum molybdate based oxygen ion conductor has high density and high oxygen ion conductivity.

Owner:ZHENGZHOU UNIV

Construction of oxygen ion conductor electrolyte film and its pulse magnetic controlled sputtering prepn. method

InactiveCN1564266AHigh oxygen ion conductivityReduce the use temperatureConductive materialSolid electrolyte fuel cellsElectrical conductorOxygen ions

The invention includes following structures and steps: using YSZ and RCO ceramics target as well as using monocrystalline silicon MgO and Ni-YSZ or Ni-RCO anode plate as substrate, distance between target and substrate as 30-80mm; vacuum degree 1X10-4-1X10-5 Pa, substrate temperature 300 deg.C-800 deg.C; ratio of gas pressure between oxygen and argon as 5%-40%; Thickness of each film is 10-200 nano, and number of layer is larger than or equal to three, the invention also contains other technical parameters. Multiple layers of nano film provides advantages of raising conductivity of oxyanion 10%-50%, optimizing fuel cell performance. The disclosed sputtering technique has features of fast, and high quality.

Owner:DALIAN UNIV OF TECH

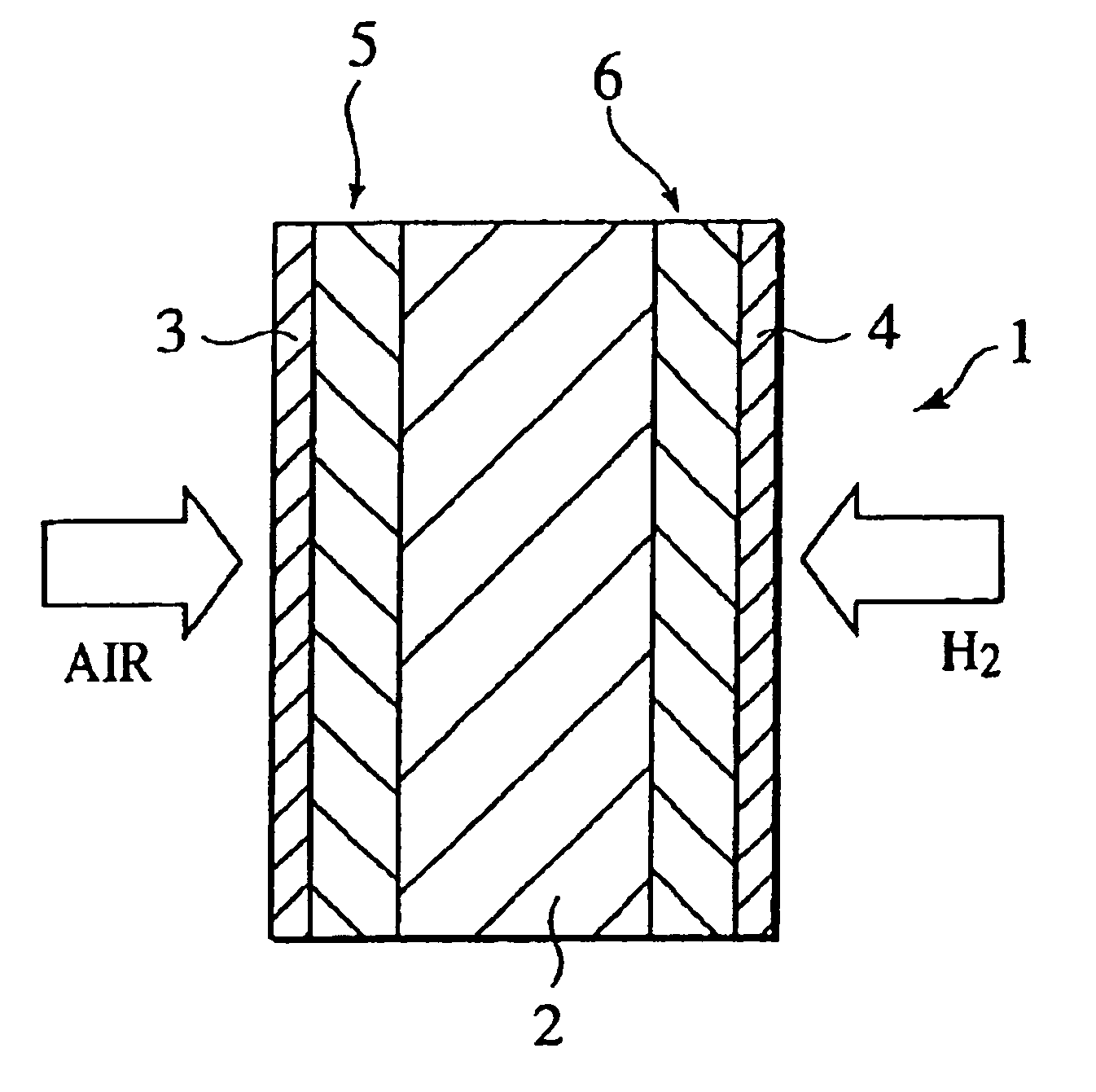

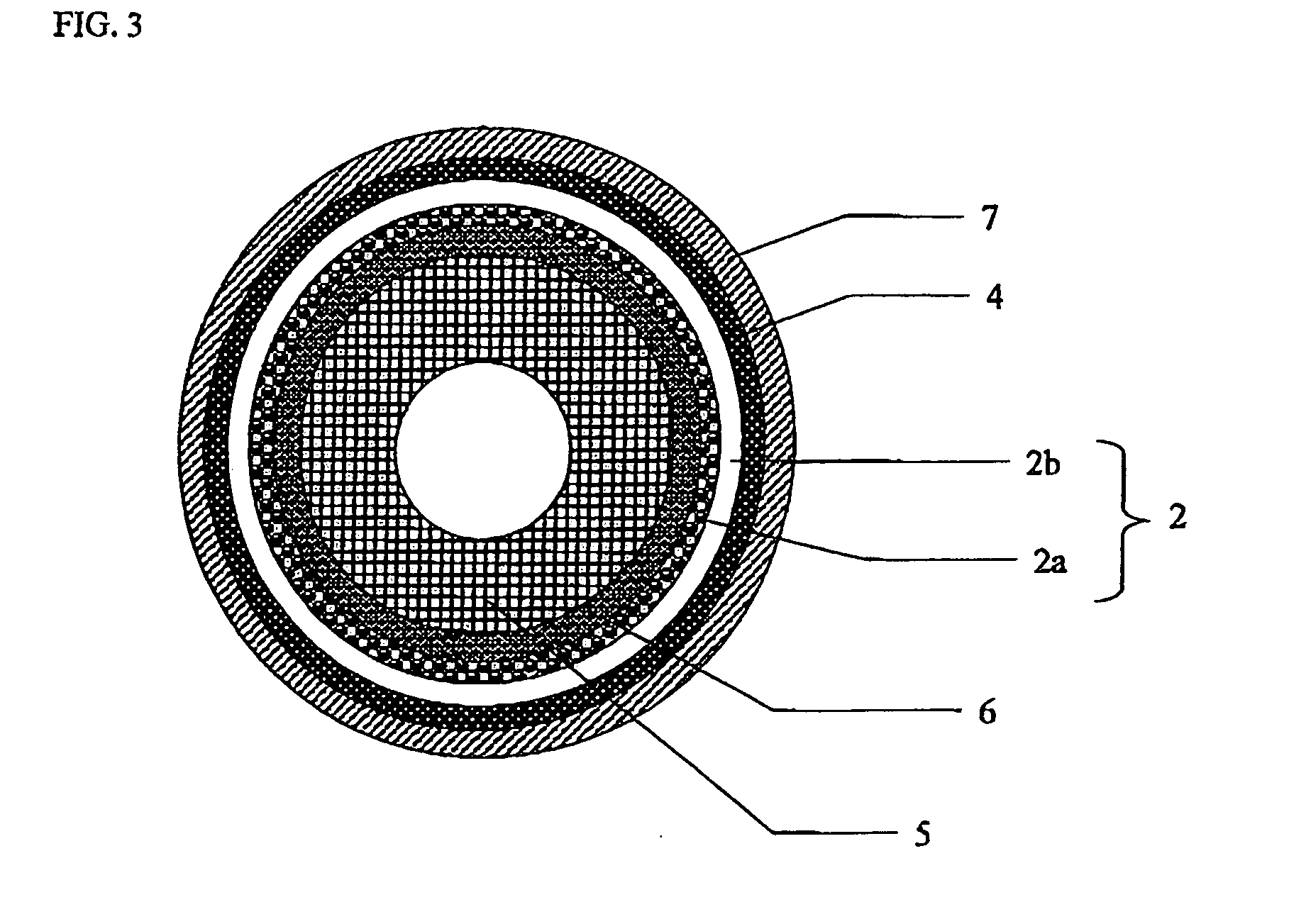

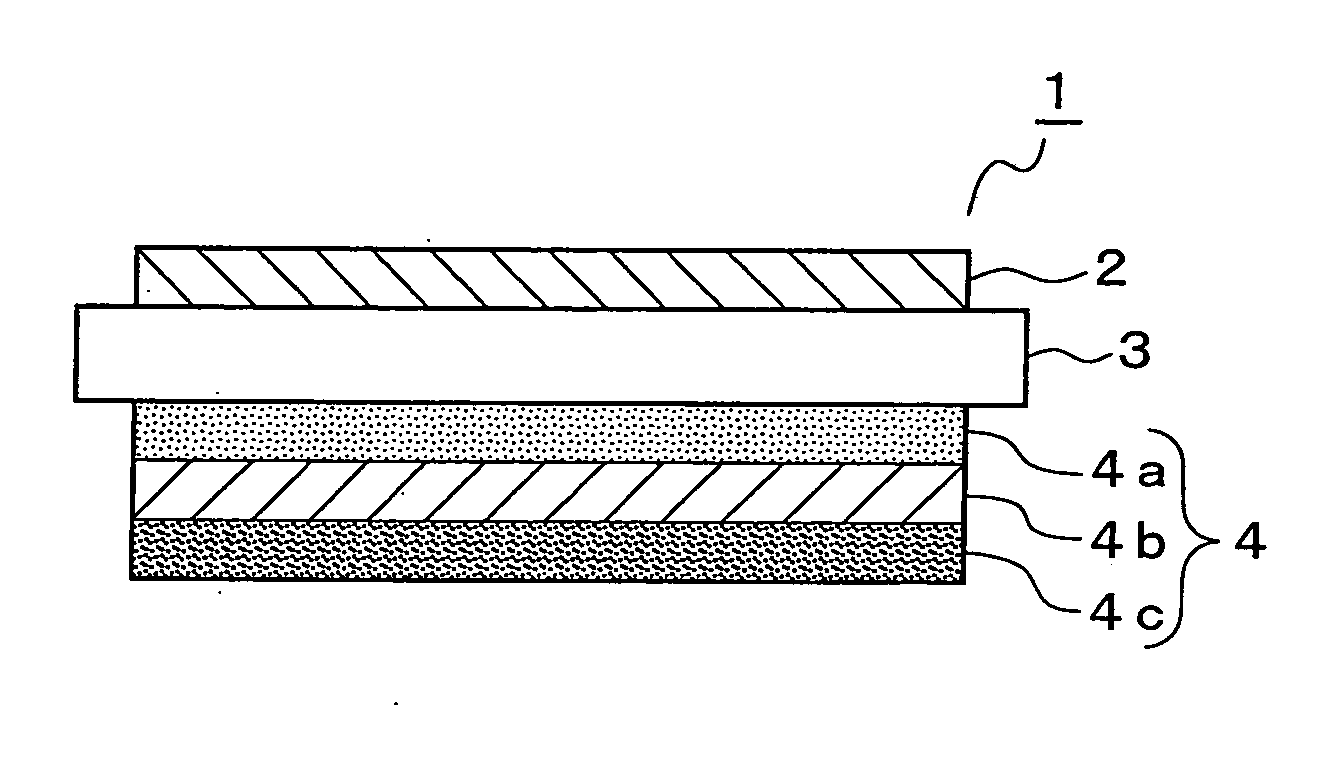

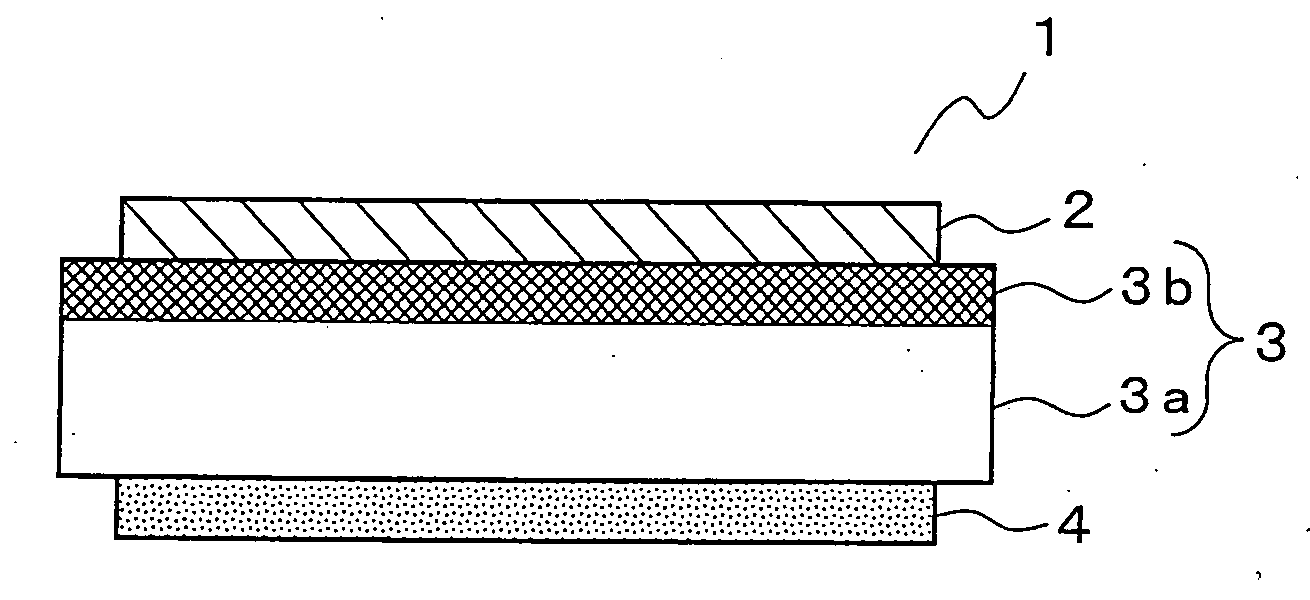

Solid oxide fuel cell

InactiveUS20050221140A1Resistance to exfoliationIncreased durabilityActive material electrodesSolid electrolyte fuel cellsElectrical resistance and conductanceFuel cells

A solid oxide fuel cell provided with a power cell (1) in which a fuel electrode layer (4) is arranged on one surface of a solid electrolyte layer (3) and an air electrode layer (2) is arranged on the other surface thereof, wherein the solid electrolyte layer (3) has a two layer structure including a first electrolyte layer (3a) made of a ceria based oxide material and a second electrolyte layer (3b) made of a lanthanum gallate based oxide material, and the second electrolyte layer is formed on the side of the air electrode layer. It is preferable that the first electrolyte layer is formed thinner than the second electrolyte layer. According to such a configuration, there can be provided a solid oxide fuel cell comprising an inexpensive solid electrolyte layer which reduces the contact resistances in the interfaces between the solid electrolyte layer and the respective electrode layers, and thereby improves the generation efficiency. Additionally, by adopting a configuration in which the composition ratio of component materials in the fuel electrode layer (4) is graded along the thickness thereof, there can be provided a solid oxide fuel cell in which the generation characteristics of the power cell are improved and the durability of the solid oxide fuel cell is improved. Preferably, the material composition for the fuel electrode layer (4) is a mixture of Ni and CeSmO2, wherein the composition ratio of component materials is graded along the thickness thereof in such a way that the quantity of Ni is made less than the quantity of CeSmO2 near the boundary interface with said solid electrolyte layer, and the mixing ratio of Ni is gradually increased with an increasing distance away from the interface.

Owner:MITSUBISHI MATERIALS CORP +1

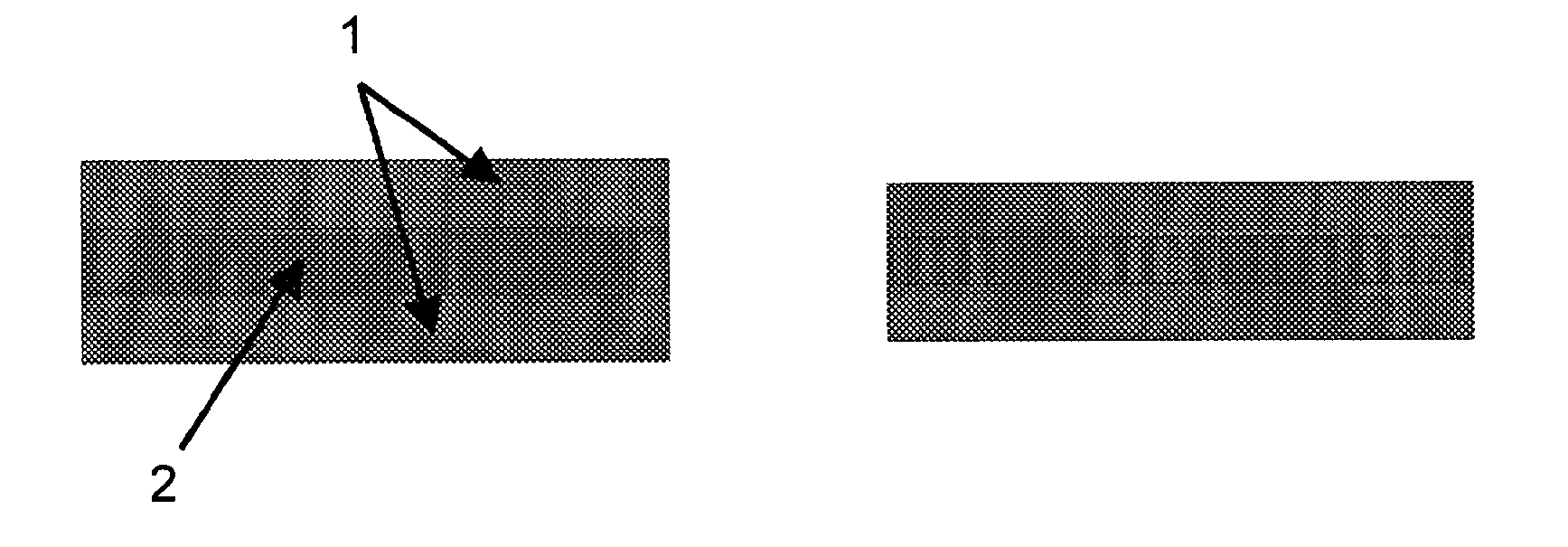

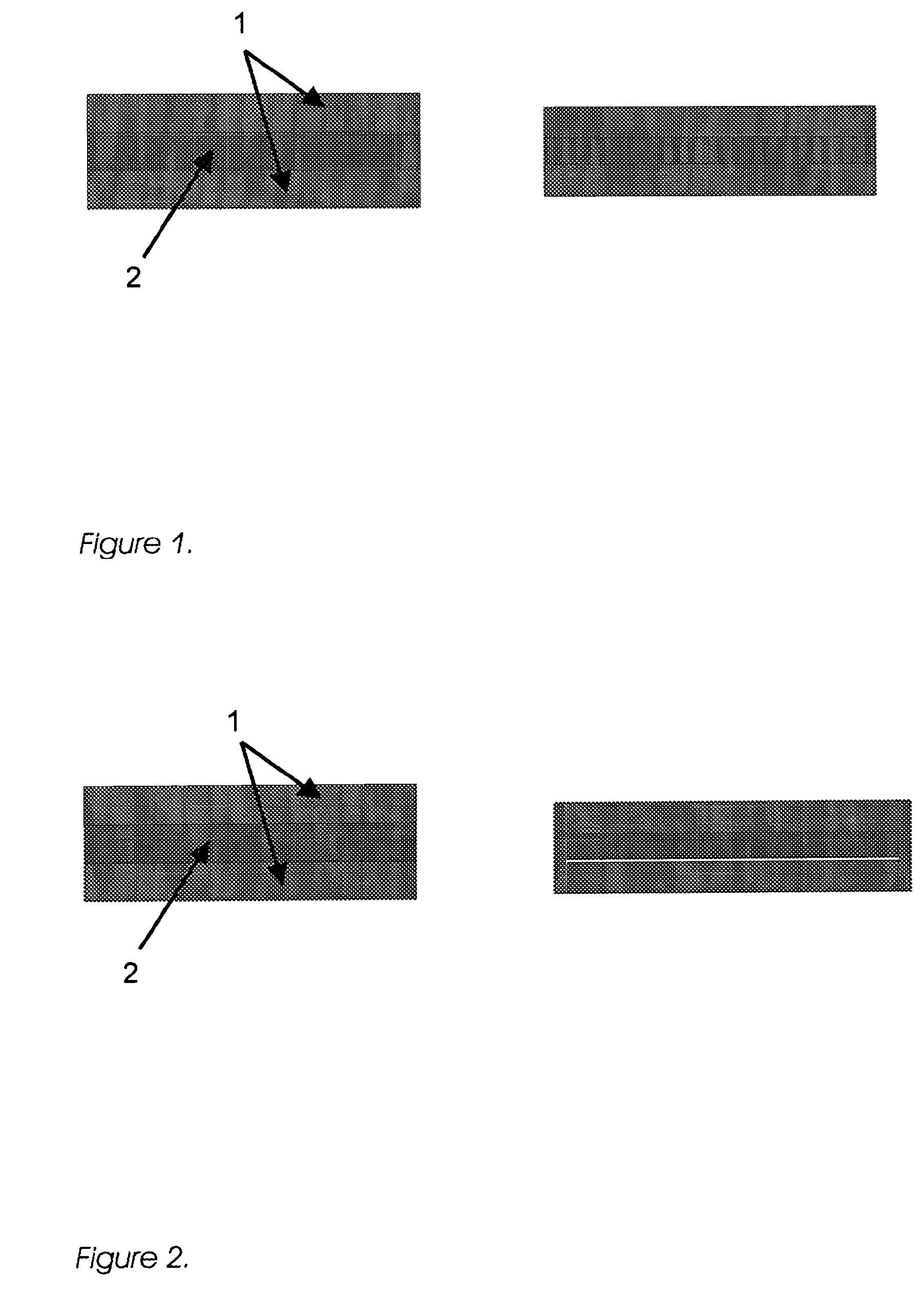

Preparation method of oxygen permeable membrane

PendingCN110156487AImprove compactnessGood chemical stabilitySemi-permeable membranesConjugated synthetic polymer artificial filamentsOxygen ionsYttrium

The invention relates to a preparation method of an oxygen permeable membrane, belonging to the technical field of new materials. The invention utilizes better oxygen ion conductivity and chemical stability at high temperature of zirconia solid electrolyte with stable yttrium oxide. As that cubic perovskite structure has relatively open space inside, a larger channel is provided for oxygen ion conduction in the cubic perovskite structure, and therefore, the prepared oxygen permeable membrane has high oxygen ion conductivity; the present invention adopts phase inversion-sintering technology, aspinning solution is extruded into a wet film by a spinneret, as that wet membrane is immersed in a non-solvent, the thermodynamic state of the wet film is changed, so as to generate phase splitting to form a solid film, so as to prepare the oxygen permeable membrane with high oxygen permeability, and during the phase inversion process, because of rapid diffusion between solvent and non-solvent, afinger pore structure is formed on the inner and outer surfaces of the hollow fiber membranes and a sponge pore structure is formed on the middle layer, the sandwich structure reduces the actual working thickness of the membranes and greatly improves the oxygen permeation performance.

Owner:陈松

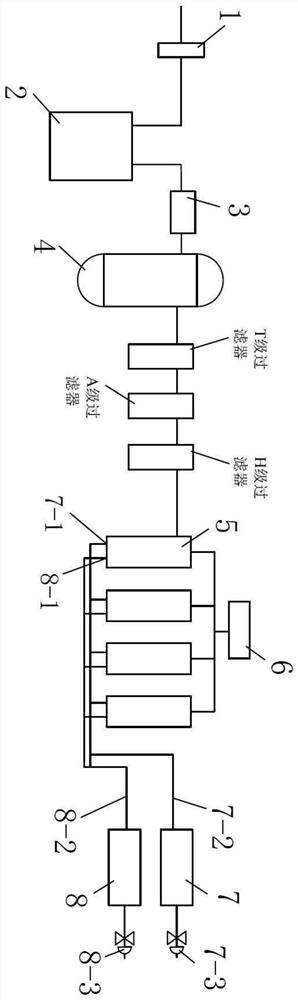

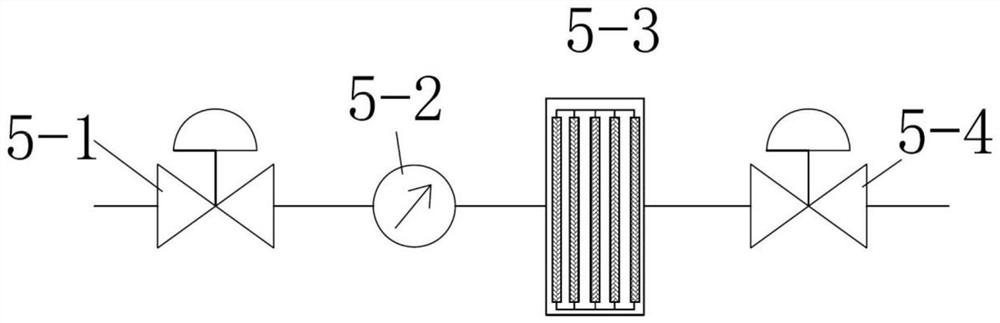

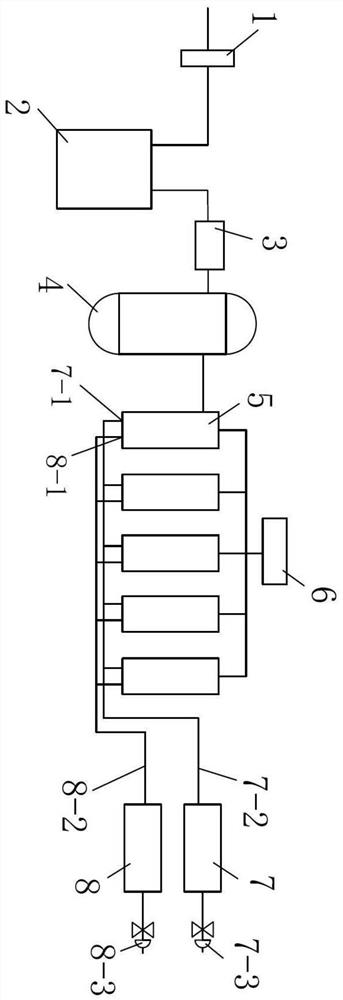

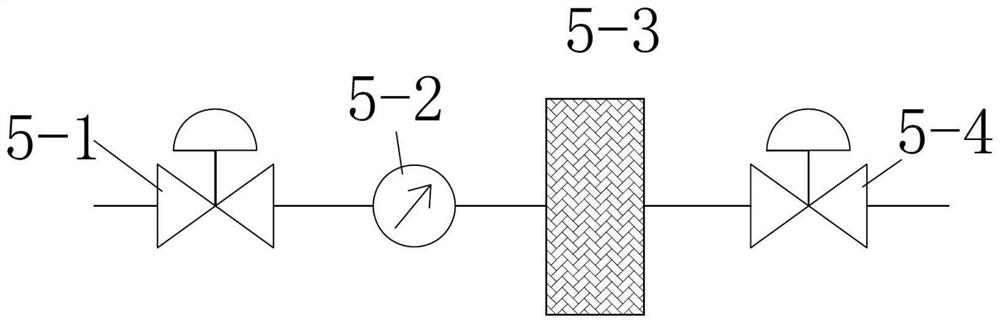

Oxygen production device of medical-grade high-temperature molecular sieve membrane adsorption tower and use method of oxygen production device

ActiveCN113023679AImprove the sterility rateHigh oxygen ion conductivityOxygen preparationMolecular sieveCeramic

The invention provides an oxygen production device of a medical-grade high-temperature molecular sieve membrane adsorption tower and a use method of the oxygen production device. The oxygen production device comprises a gas source access port, an air compressor, a C-grade filter, an air storage tank, a T-grade filter, an A-grade filter, an H-grade filter, 2-4 high-temperature carbonized ceramic-based molecular sieve adsorption units, a vacuum pump, an oxygen storage tank and a nitrogen storage tank which are communicated in sequence, the vacuum pump is arranged in the high-temperature carbonized ceramic-based molecular sieve adsorption unit, the high-temperature carbonized ceramic-based molecular sieve adsorption unit is communicated with the oxygen storage tank through an oxygen diversion pipeline, and the high-temperature carbonized ceramic-based molecular sieve adsorption unit is communicated with the nitrogen storage tank through a nitrogen diversion pipeline. The oxygen production device provided by the invention is provided with the molecular sieve of the adsorption tower of the oxygen ion conductive carbonized ceramic-based molecular sieve membrane with good cyclic utilization rate, and oxygen ions are adsorbed and desorbed under high-temperature vacuum, so that oxygen and nitrogen are efficiently separated, and the oxygen production purity is improved.

Owner:HUNAN VENTMED MEDICAL TECH CO LTD

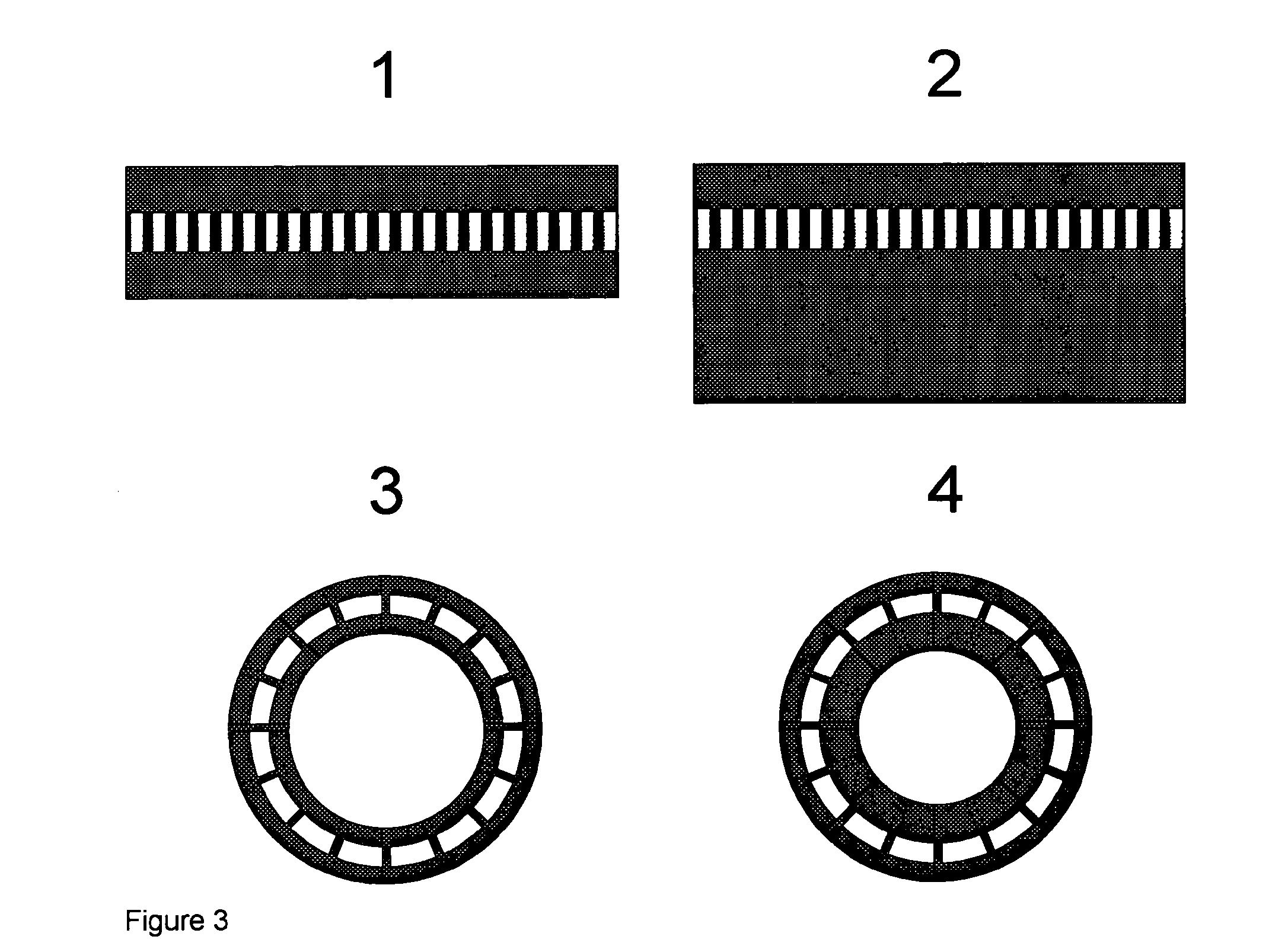

Robust mixed conducting membrane structure

InactiveUS20110189066A1Improve heat resistanceImprove electronic conductivityMembranesSemi-permeable membranesElectronChemistry

The present invention provides a membrane, comprising in said order a first electronically conducting layer, an ionically conducting layer, and a second electronically conducting layer,characterized in that the first and second electronically conducting layers are internally short circuited.The present invention further provides a method of producing the above membrane, comprising the steps of:providing a ionically conducting layer;applying at least one layer of electronically conducting material on each side of said ionically conducting layer;sintering the multilayer structure; andimpregnating the electronically conducting layers with a catalyst material or catalyst precursor material.

Owner:DANMARKS TEKNISKE UNIV

Solid oxide fuel cell

InactiveUS20070166593A1Reduce contact resistanceImprove power generation efficiencyCell electrodesFinal product manufactureElectrical resistance and conductanceFuel cells

A solid oxide fuel cell provided with a power cell (1) in which a fuel electrode layer (4) is arranged on one surface of a solid electrolyte layer (3) and an air electrode layer (2) is arranged on the other surface thereof, wherein the solid electrolyte layer (3) has a two layer structure including a first electrolyte layer (3a) made of a ceria based oxide material and a second electrolyte layer (3b) made of a lanthanum gallate based oxide material, and the second electrolyte layer is formed on the side of the air electrode layer. It is preferable that the first electrolyte layer is formed thinner than the second electrolyte layer. According to such a configuration, there can be provided a solid oxide fuel cell comprising an inexpensive solid electrolyte layer which reduces the contact resistances in the interfaces between the solid electrolyte layer and the respective electrode layers, and thereby improves the generation efficiency. Additionally, by adopting a configuration in which the composition ratio of component materials in the fuel electrode layer (4) is graded along the thickness thereof, there can be provided a solid oxide fuel cell in which the generation characteristics of the power cell are improved and the durability of the solid oxide fuel cell is improved. Preferably, the material composition for the fuel electrode layer (4) is a mixture of Ni and CeSmO2, wherein the composition ratio of component materials is graded along the thickness thereof in such a way that the quantity of Ni is made less than the quantity of CeSmO2 near the boundary interface with said solid electrolyte layer, and the mixing ratio of Ni is gradually increased with an increasing distance away from the interface.

Owner:MITSUBISHI MATERIALS CORP +1

Oxide fuel cell based on neodymium nickelate and samarium-calcium co-doped cerium oxide composite material

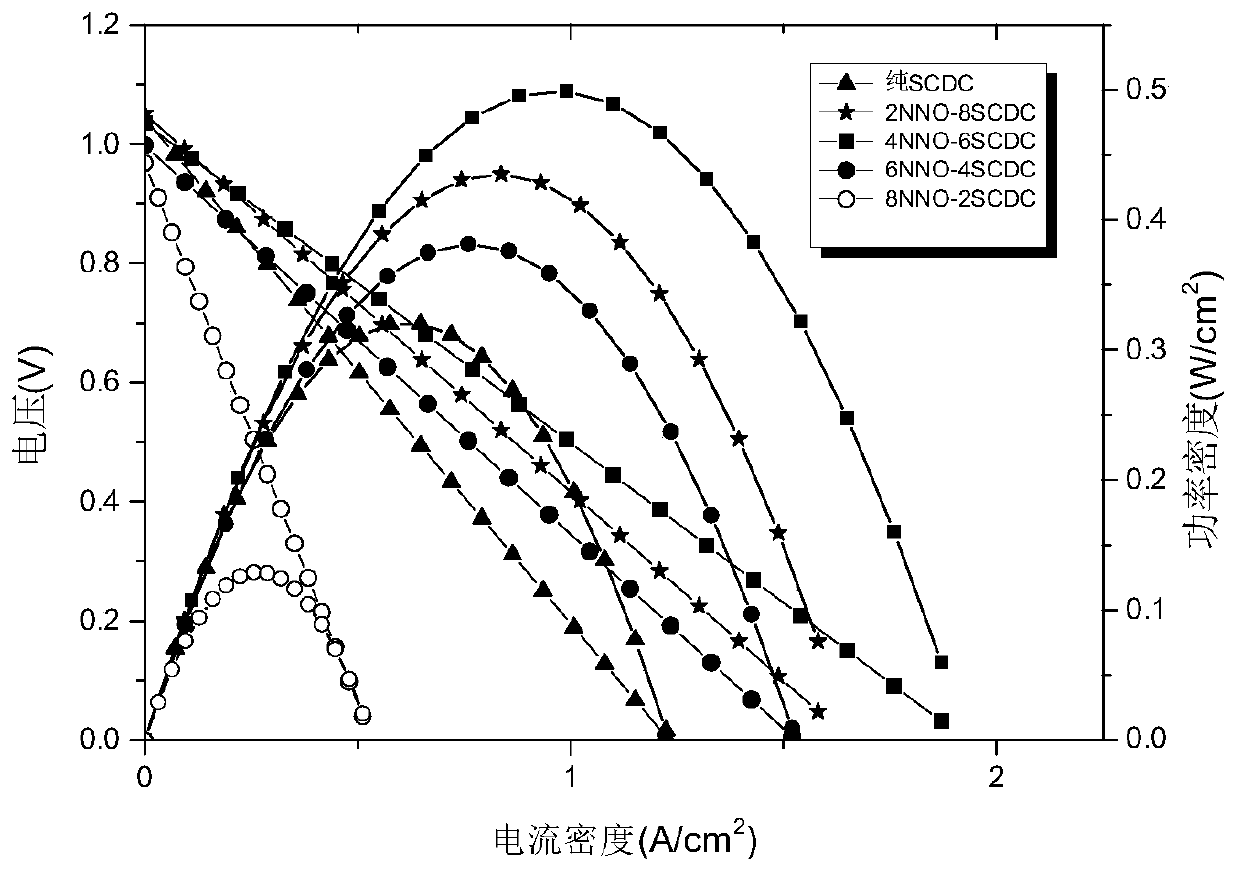

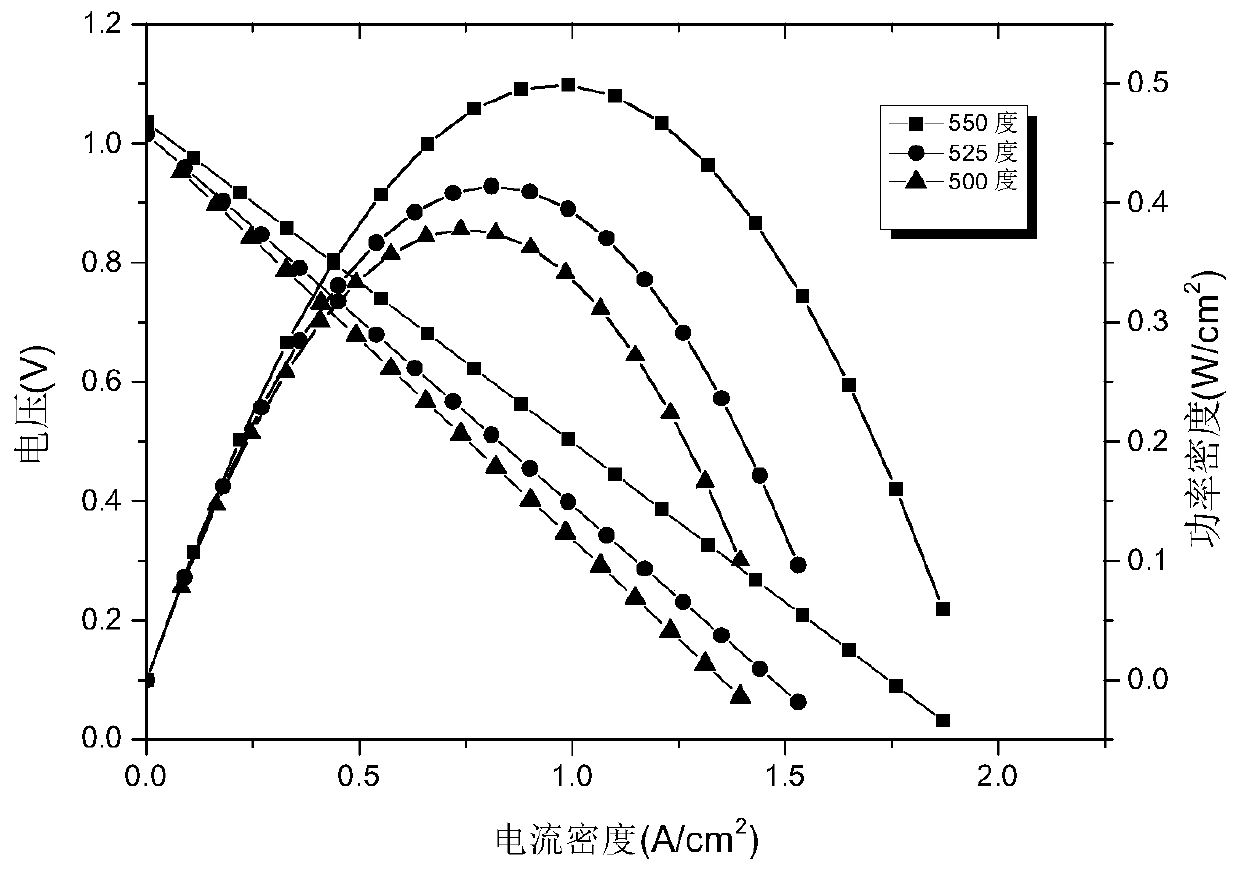

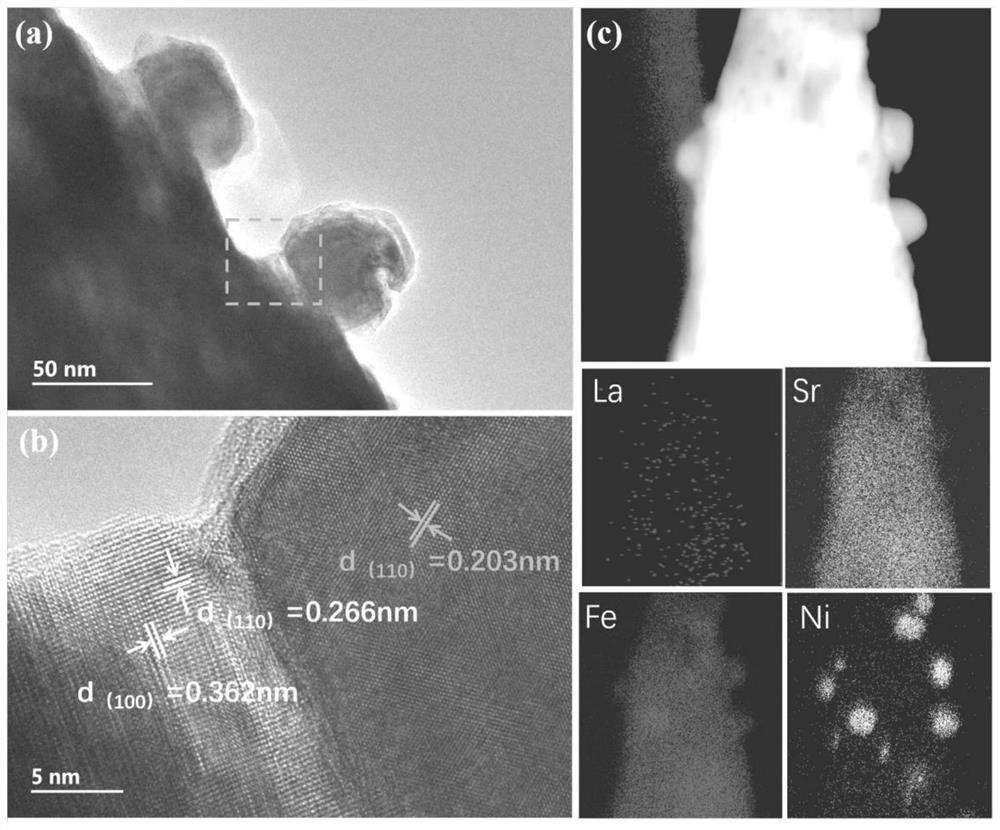

InactiveCN109818027AImprove transmission performanceIncrease output powerFuel cellsElectrical conductorElectrochemistry

The invention discloses an oxide fuel cell based on a neodymium nickelate and samarium-calcium co-doped cerium oxide composite material. A cathode and an anode of the fuel cell are foamed nickel withNCAL coated on the surfaces, and an electrolyte layer of the fuel cell is an NNO / SCDC composite material. The structure of the fuel cell is foamed nickel / / NCAL / NNO / SCDC / / NCAL / foamed nickel. Neodymiumnickelate which is of a perovskite structure and a samarium-calcium co-doped cerium oxide composite material are used as the electrolyte layer, so that the electrode polarization loss in the electrochemical reaction process of the fuel cell is greatly reduced; In addition, the electrolyte material has good output power in a low-temperature section, so that the solid oxide fuel cell adopting the electrolyte material can efficiently and stably operate for a long time in the low-temperature section (400-600 DEG C).

Owner:NANJING XIAOZHUANG UNIV

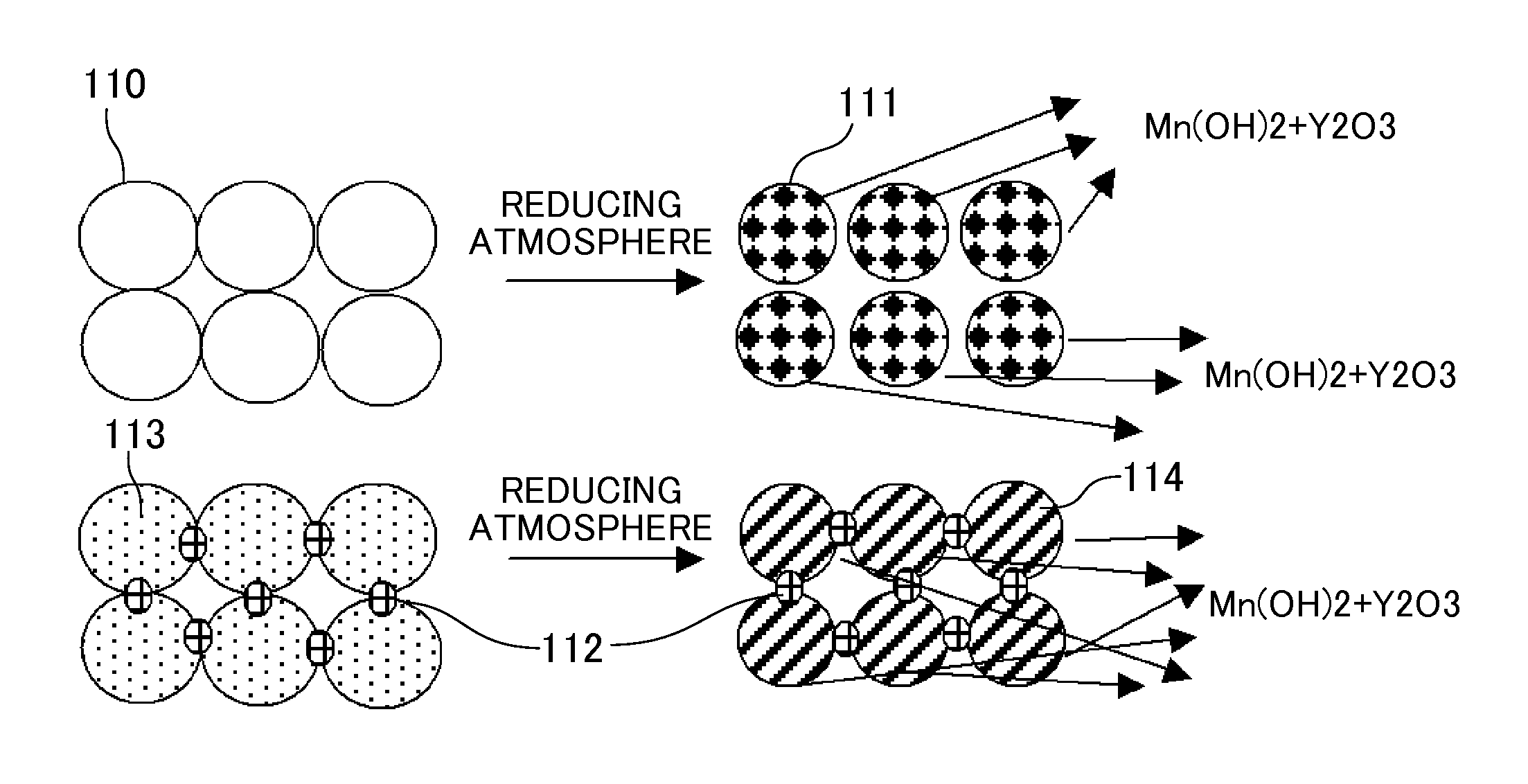

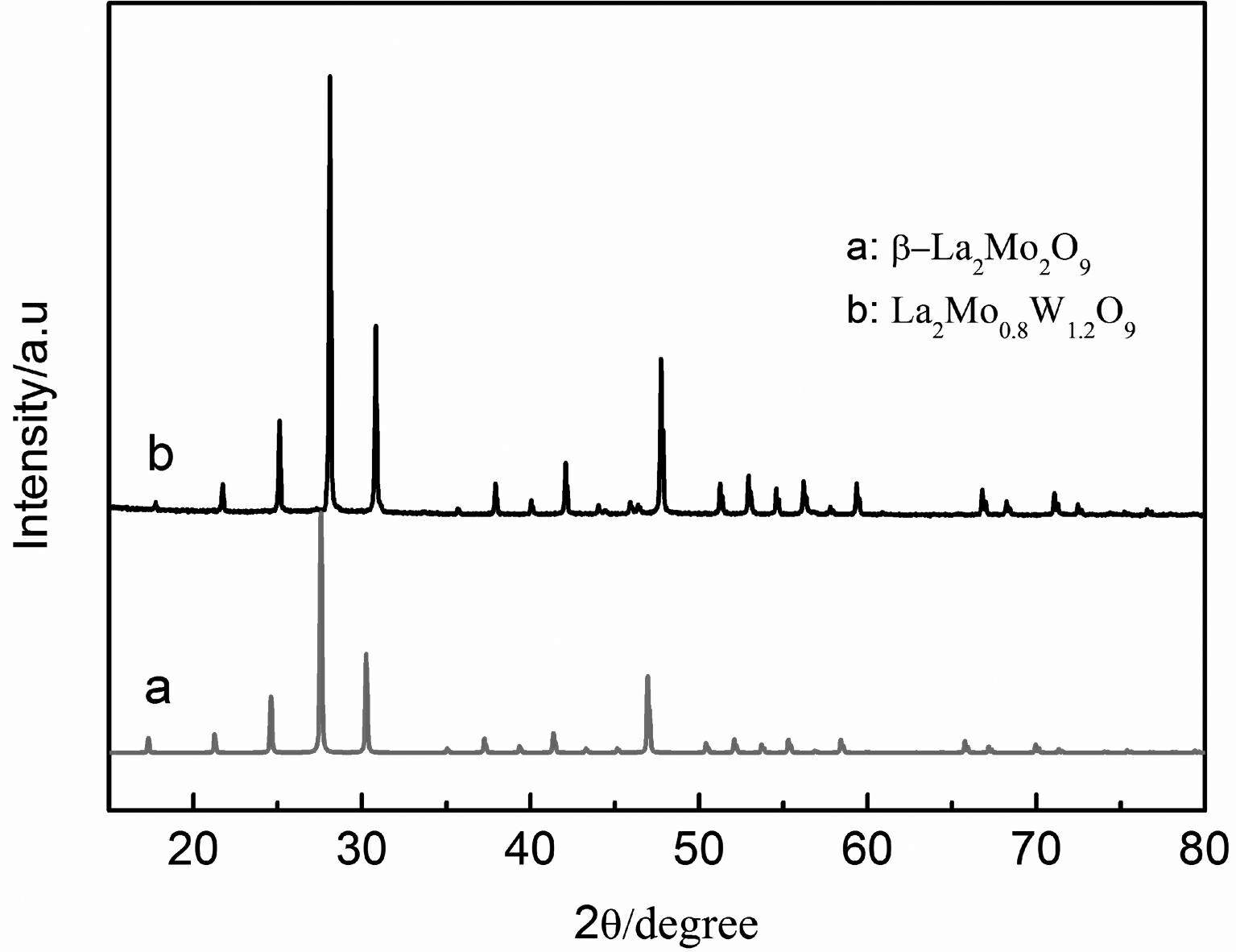

Solid oxide electrolytic cell working electrode modified by binary alloy nano-particles as well as preparation method and application of solid oxide electrolytic cell working electrode

PendingCN114657579AIncrease the rate of ammonia synthesisLower polarization resistanceElectrodesElectrochemical responseOxygen ions

The invention discloses a binary alloy nanoparticle modified solid oxide electrolytic cell working electrode as well as a preparation method and application thereof. The preparation method comprises the following steps: S1, taking oxides and carbonates of metal elements as raw materials, or directly taking perovskite oxides and pre-doped compounds as raw materials; after ball-milling and mixing, calcining at 1000-1200 DEG C, and performing high-temperature solid-phase synthesis to obtain a binary metal doped perovskite oxide; s2, preparing working electrode slurry from the binary metal doped perovskite oxide; and S3, coating an electrolyte sheet with the working electrode slurry, drying and sintering to prepare the working electrode of the solid oxide electrolytic cell, and S4, introducing a reducing atmosphere, and carrying out high-temperature treatment. The binary metal nanoparticles on the surface of the obtained electrode increase the active sites of electrochemical reaction, which is beneficial to the proceeding of the electrode reaction; the dissolution of the B-site element is beneficial to the oxygen reduction reaction on the surface of the electrode, and the oxygen ion conductivity of the electrode is improved.

Owner:SHANGHAI UNIV

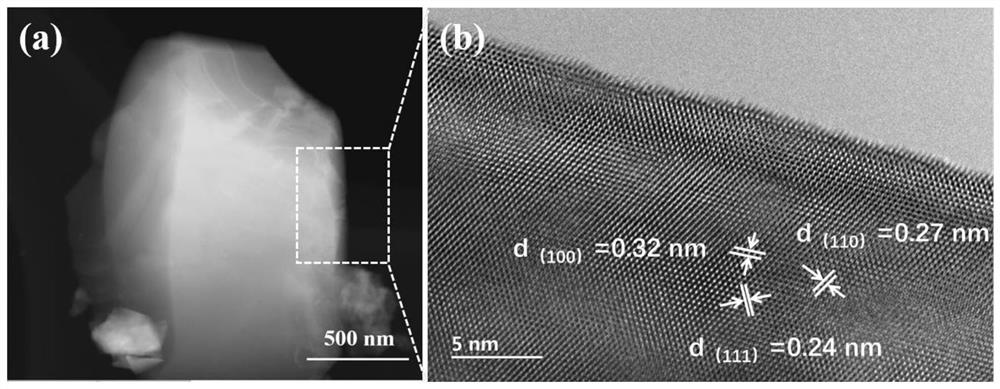

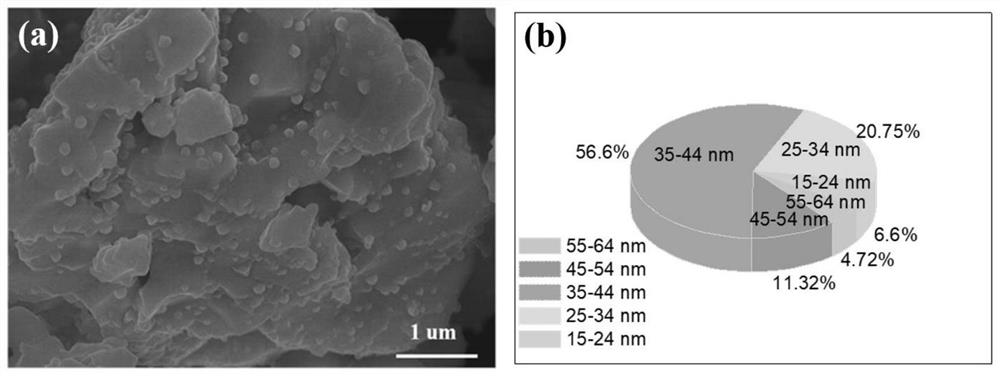

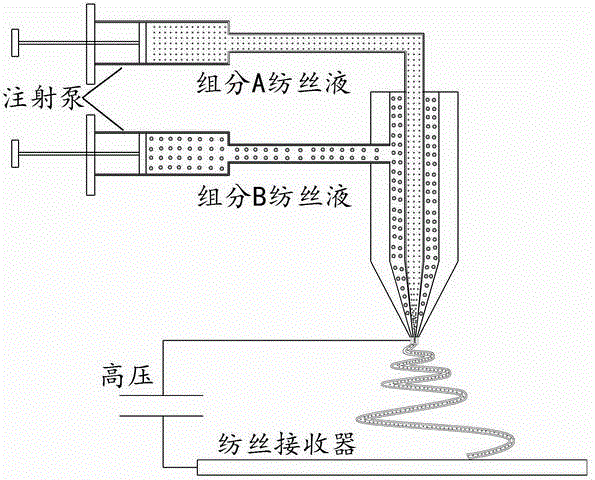

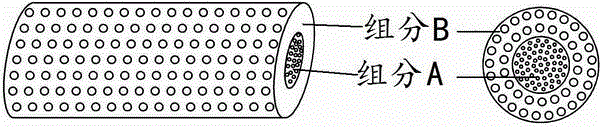

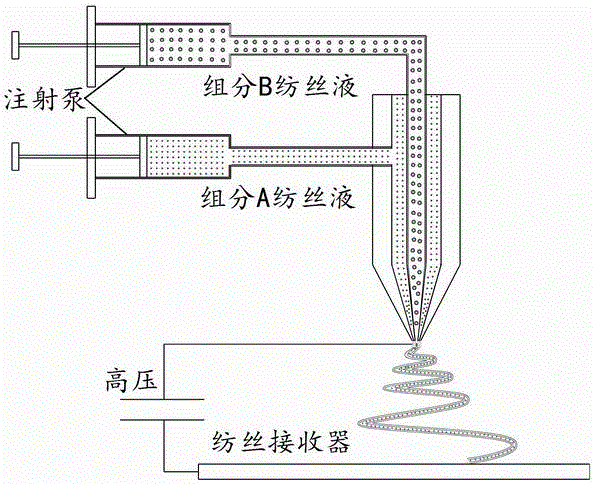

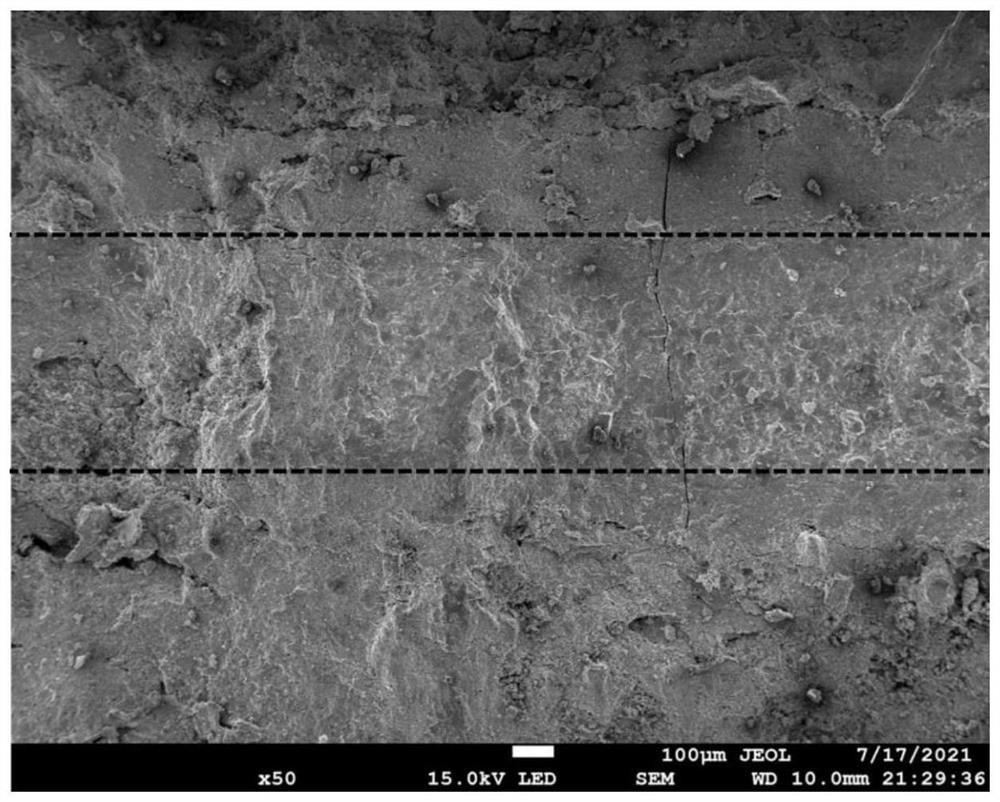

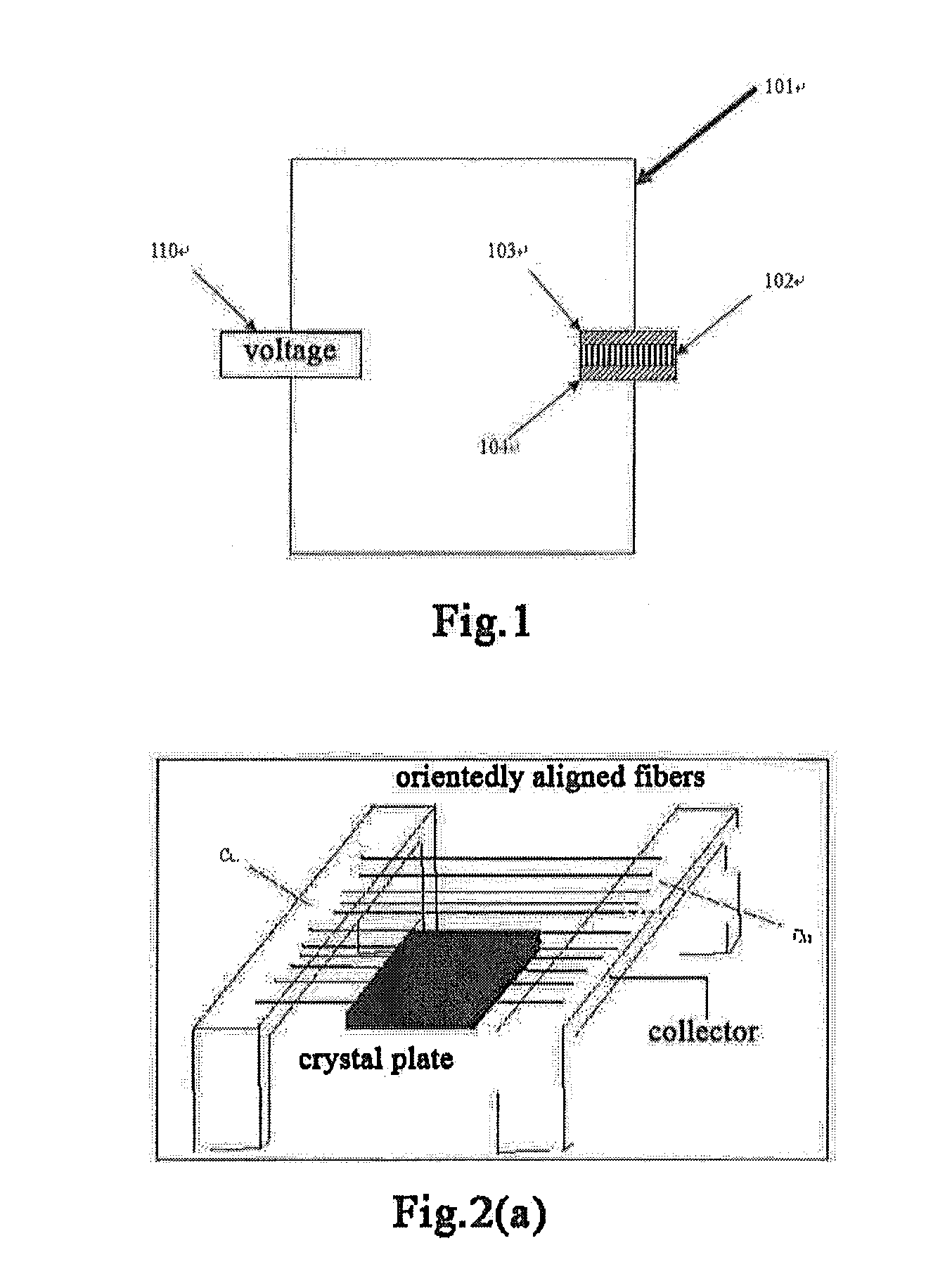

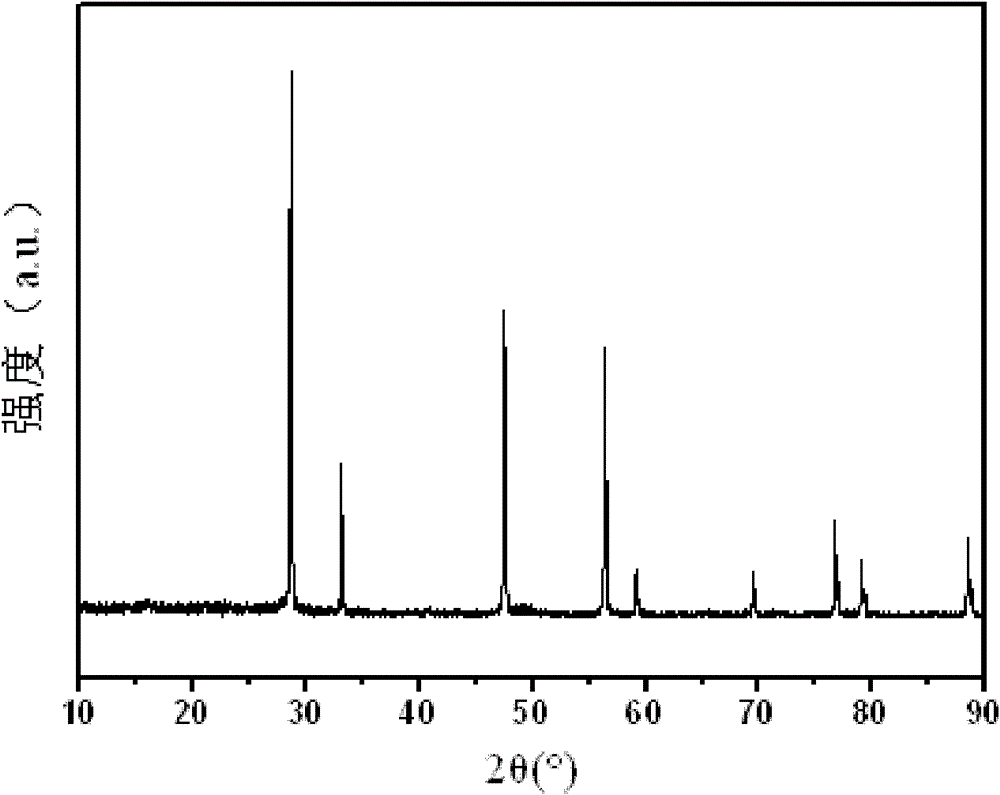

Low-temperature solid oxide fuel cell cathode in a core-shell nanofiber structure and preparation method thereof by electrospinning

InactiveCN104752734BHigh catalytic activity for oxygen reductionSmall coefficient of thermal expansionMaterial nanotechnologyCell electrodesElectrical conductorOxygen ions

The invention relates to a low-temperature solid oxide fuel cell cathode in a core-shell nano fiber structure and an electrostatic spinning preparation method and belongs to the field of functional materials. The core-shell nano fiber structure cathode consists of a nano fiber core and a nano shell layer, wherein the fiber core and the shell layer respectively consist of a perovskite structure ion-electron mixed conductor component A and an oxygen ion conductor electrolyte component B or consist of opposite components; the core-shell nano fiber cathode is prepared in an electrostatic spinning manner, a component A before-spinning precursor solution and a component B before-spinning precursor solution are respectively prepared and then are respectively injected into an inner-layer spinning passage or an outer-layer spinning passage so as to carry out the spinning, and composite fibers are dried and sintered at a high temperature to obtain the core-shell nano fiber structure cathode material. By adopting the core-shell nano fiber structure, the oxygen reduction catalytic activity, anti-CO2 surface adsorption toxicity capacity and structural and performance stability of the low-temperature SOFC cathode are improved; moreover, the process is simple, and the cost is low.

Owner:DALIAN UNIV OF TECH

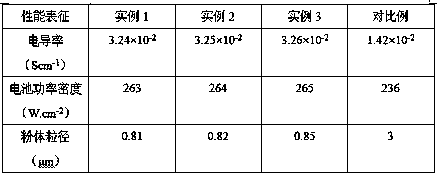

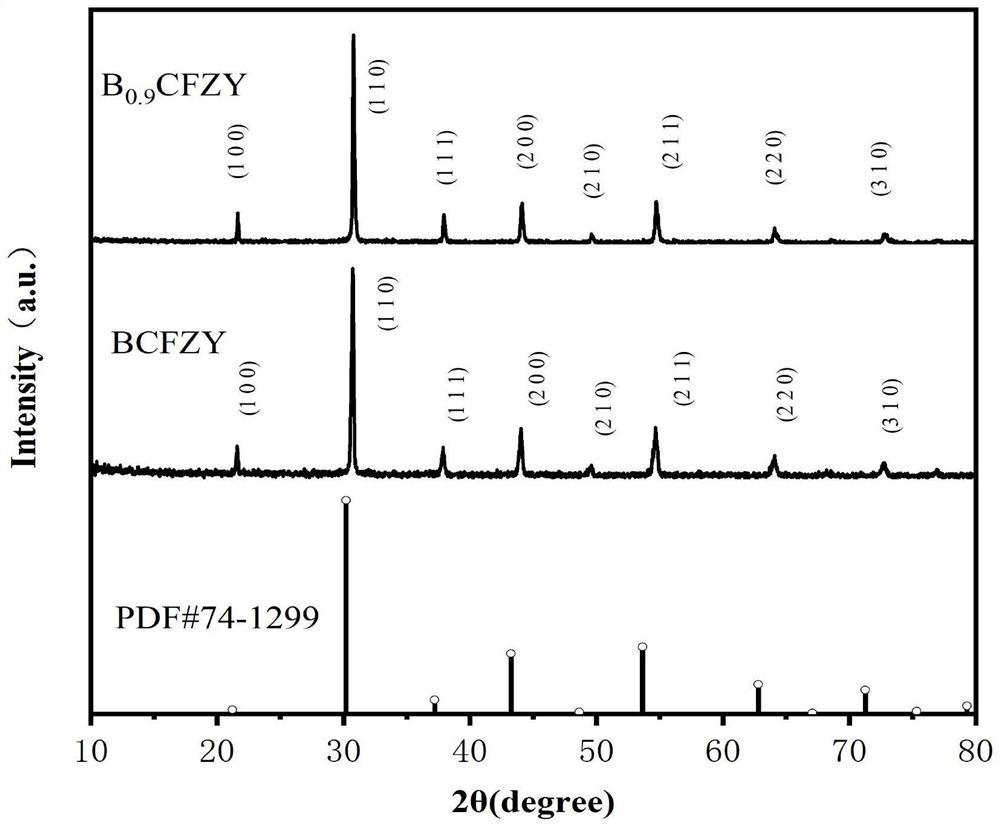

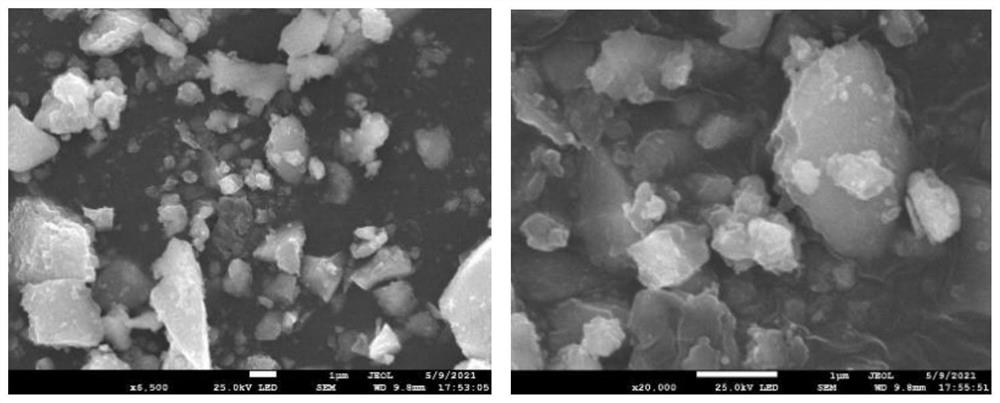

A-site defect type perovskite structure fuel cell electrolyte, preparation method thereof and fuel cell

PendingCN114447384ASmall grain sizeHigh oxygen ion conductivityFuel cellsFuel cellsPerovskite (structure)

The invention relates to an A-site defect type perovskite structure fuel cell electrolyte, a preparation method thereof and a fuel cell, the chemical formula of the electrolyte is Ba < 0.9 > Co < 0.4 > Fe < 0.4 > Zr < 0.1 > Y < 0.1 > O < 3-delta > (BCFZY < 0.9 >), and the electrolyte is an ABO < 3-delta > type perovskite structure material. According to the invention, the ionic conductivity and the electrolyte function are obviously improved through an A-site defect method, and good low-temperature output performance is shown in a fuel cell taking Ni0. 8Co0. 15Al0. 05LiO2-delta (NCAL) permeated foamed nickel as a symmetrical electrode. Compared with the traditional pure ion conduction type electrolyte, the electrolyte provided by the invention is an oxygen ion / proton / electron mixed conduction type semiconductor and shows good ionic conductivity in a low-temperature interval, so that the electrolyte has an important application prospect in a low-temperature solid oxide fuel cell system.

Owner:HUBEI UNIV

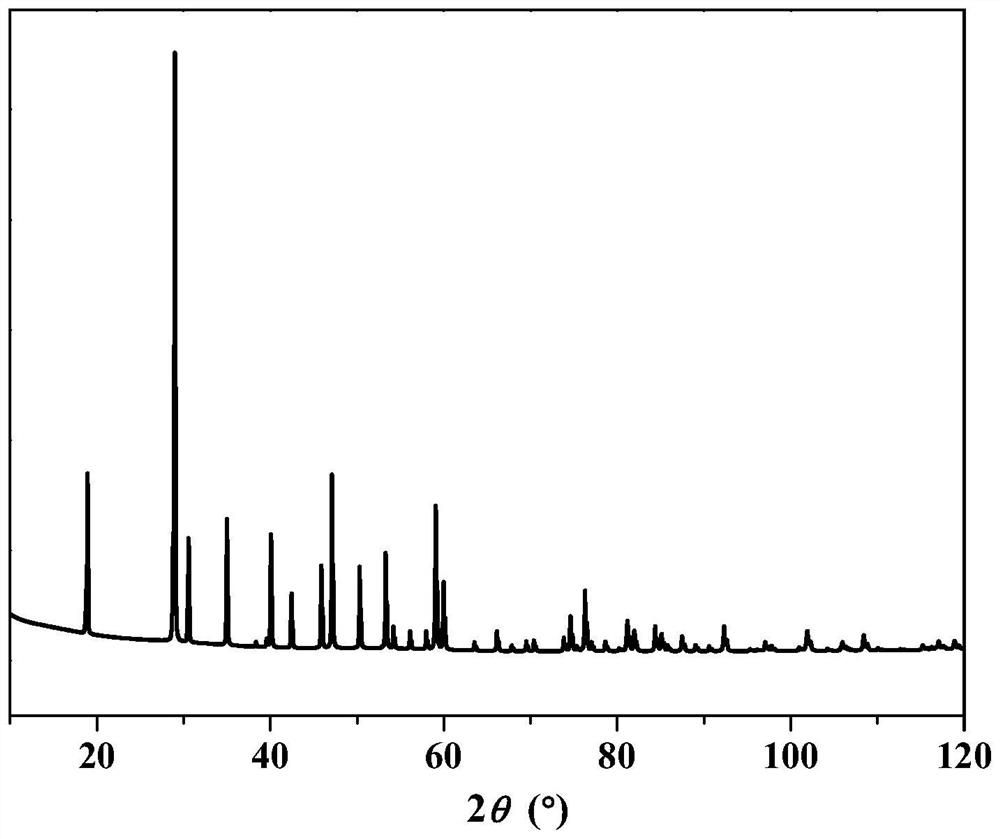

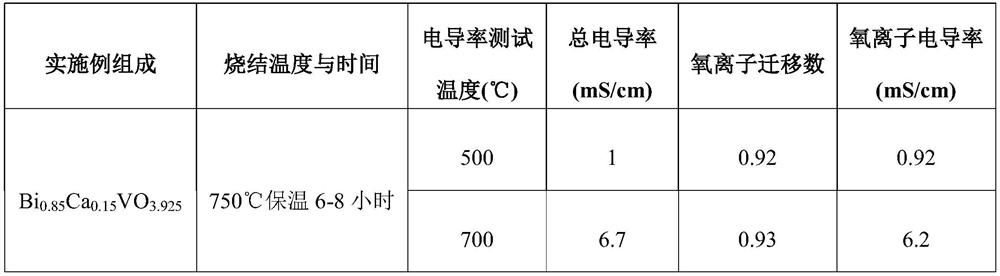

Bismuth vanadate-based ceramic with tetragonal scheelite structure and high oxygen ion conductivity in medium-temperature zone and preparation method of bismuth vanadate-based ceramic

InactiveCN114804852AMeet application requirementsStable structureOxide conductorsCable/conductor manufactureElectrical conductorBismuth vanadate

The invention discloses a tetragonal scheelite structure bismuth vanadate-based ceramic with high oxygen ion conductivity in a medium temperature zone and a preparation method thereof, and belongs to the technical field of preparation of novel solid-state ion conductors, the oxygen ion conductivity of the tetragonal scheelite structure bismuth vanadate-based ceramic reaches 0.92-6.2 mS / cm at 500-700 DEG C, and the chemical composition of the tetragonal scheelite structure bismuth vanadate-based ceramic is Bi < 0.85 > Ca < 0.15 > VO3. 925. The bismuth vanadate-based oxygen ion conductor with the tetragonal scheelite structure, disclosed by the invention, is simple in chemical composition and preparation process and low in cost, and can be applied to manufacturing of devices such as a solid oxide fuel cell, an oxygen sensor and an oxygen permeable membrane in a medium-temperature region.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

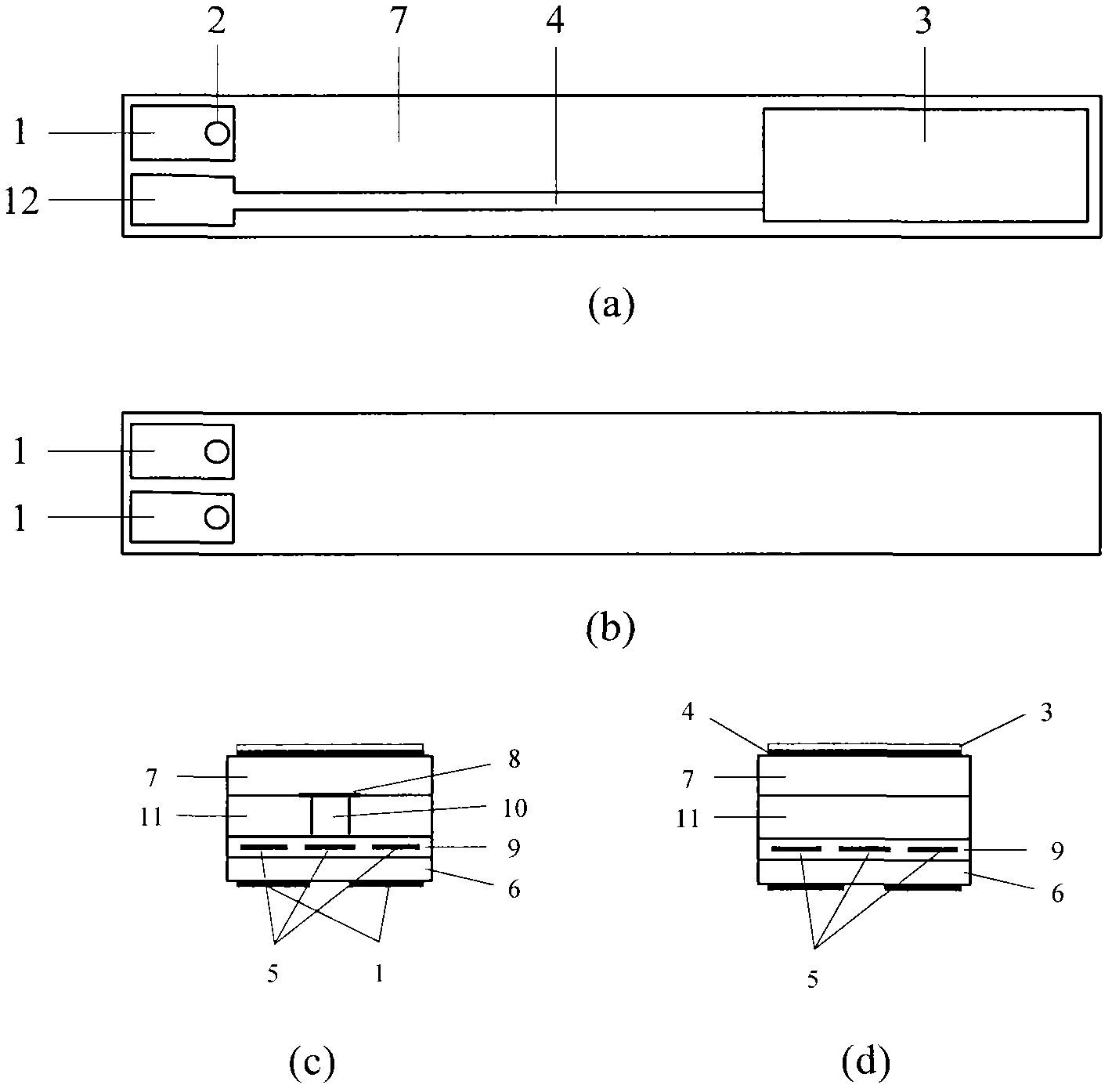

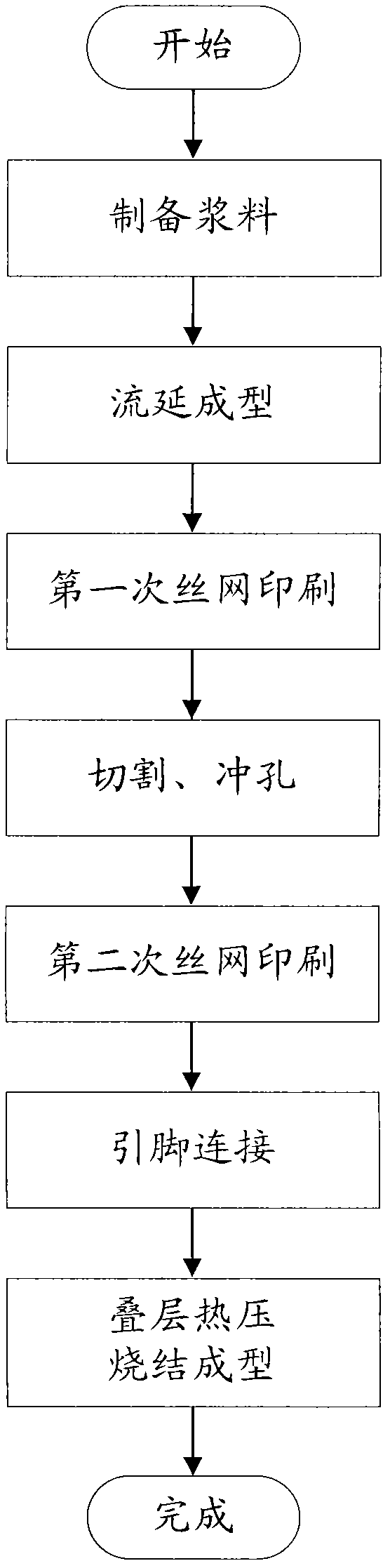

Method for manufacturing chip oxygen sensor and chip oxygen sensor

ActiveCN102288664BSimple processImprove yieldMaterial analysis by electric/magnetic meansPunchingOxygen sensor

The invention provides a method for manufacturing a chip oxygen sensor. The method comprises the following steps of: adding a solvent, a plasticizing agent and a bonding agent into a substrate to obtain slurry; performing tape casting on the slurry; printing an inner electrode, an outer electrode, a protection layer, a heater and an insulating layer on the molded substrate respectively; cutting the printed substrate into single blank pieces respectively, and punching; printing conducting pins at the punched positions, and printing electrode pins on the blank pieces on one face printed with the outer electrode; connecting the conducting pins; and overlapping each single blank piece, performing heat pressing, and sintering at high temperature to form the chip oxygen sensor. Correspondingly, the invention provides a chip oxygen sensor manufactured by adopting the method. The chip oxygen sensor and the manufacturing method thereof have the advantages of simple process flow, high yield, fast response time, short activating time, high airtightness and the like.

Owner:CHERY AUTOMOBILE CO LTD

Method for producing fuel cell including nanofibers of metal oxide

ActiveUS20150244015A1Improve ionic conductivityIncrease output powerMaterial nanotechnologyFinal product manufactureFuel cellsNanofiber

Owner:TOYOTA JIDOSHA KK +1

Preparation method of nano electrolyte material for mesothermal solid oxide fuel cell

InactiveCN102201589BHigh crystallinityImprove electrochemical performanceMaterial nanotechnologySolid electrolyte fuel cellsRare-earth elementElectrical conductor

The invention provides a preparation method of a nano electrolyte material for a mesothermal solid oxide fuel cell, and relates to a preparation method of a nano electrolyte material for a solid oxide fuel cell. By the invention, the problems that the ionic conductivity of a mesothermal region of the conventional electrolyte material for the mesothermal solid oxide fuel cell is low and the preparation temperature of the conventional oxyen ion conductor electrolyte material is higher can be solved. The method comprises steps, including: weighing CeO2, rare-earth element nitrate and cobalt nitrate, grinding and mixing uniformly, adding mixed inorganic alkali, heating, washing and drying. Within the temperature of 500 to 700 DEG C, the ionic conductivity is high and reaches 0.047Scm<-1> at most; due to doping of Co3<+>, the conduction performance of the electrolyte material is enhanced and the ionic conductivity is increased, and the electrochemical performance of the CeO2 electrolyte doped with the single rare-earth Nd3<+> ion is improved.

Owner:HEILONGJIANG UNIV

A high-temperature carbonized ceramic-based molecular sieve membrane oxygen generator and its application method

ActiveCN113023678BHigh oxygen ion conductivityAchieve chemical adsorptionOxygen preparationOxygen ionsCarbonization

The invention provides a high-temperature carbonized ceramic-based molecular sieve membrane oxygen generator and a method for using the same, which include sequentially connected air source inlets, an air compressor, a C-level filter, an air storage tank, and 3-5 high-temperature carbonized ceramic-based molecular sieve membranes. Molecular sieve adsorption unit, vacuum pump, oxygen gas storage tank, nitrogen gas storage tank, the end of the oxygen gas storage tank is provided with a first check valve, and the end of the nitrogen gas storage tank is provided with a second check valve; the vacuum pump is set on a high-temperature carbonized ceramic-based molecular sieve In the adsorption unit, the high-temperature carbonized ceramic-based molecular sieve adsorption unit communicates with the oxygen storage tank through an oxygen distribution pipeline, and the high-temperature carbonized ceramic-based molecular sieve adsorption unit communicates with the nitrogen gas storage tank through a nitrogen distribution pipeline. The oxygen generating device provided by the present invention has the molecular sieve of the adsorption tower of oxygen ion conductive carbonized ceramic-based molecular sieve membrane with good recycling rate, and absorbs and desorbs oxygen ions under high temperature and vacuum to efficiently separate oxygen and nitrogen to improve the purity of oxygen production.

Owner:HUNAN VENTMED MEDICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com