Preparation of nano crystallized bismuth oxide based oxygen ion conductive solid electrolyte

The technology of solid electrolyte and ion conductor is applied in the field of preparation of nanocrystalline bismuth oxide-based oxygen ion conductor solid electrolyte, which can solve the problems of poor chemical stability of oxygen ion conductor and the like, so as to speed up the reaction sintering process, reduce the sintering time, and reduce the sintering temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

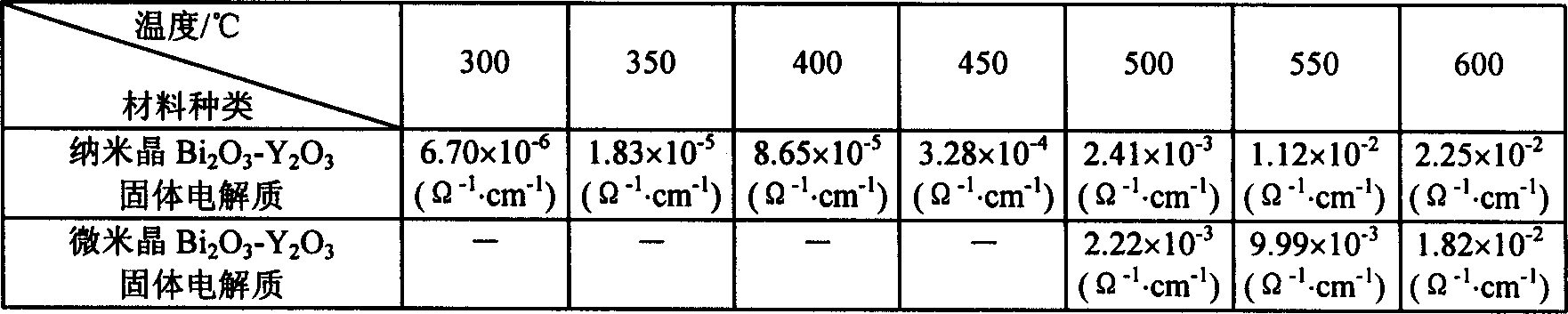

[0024] Embodiment one: the present embodiment is to prepare nanocrystalline Bi 2 o 3 -Y 2 o 3 A process for a solid electrolyte, specifically comprising the steps of:

[0025] a. Preparation of nano-Bi 2 o 3 +Y 2 o 3 Mixed powder raw materials: first use analytically pure 75mol% Bi(NO 3 )3 ·5H 2 O and 25mol% Y (NO 3 ) 3 ·6H 2 O is mixed and dissolved in the least amount of dilute nitric acid solution to prepare (Bi 3+ +Y 3+ ) 100ml of a mixed solution with a total concentration of 0.1mol / l. Then use analytically pure ammonia and distilled water to make 1.26mol / l ammonia solution 600ml according to the ratio of 1: 10, and add the polyethylene glycol PEG6000 dispersant that accounts for mixed solution total amount 2% (mass percentage), the pH of ammonia solution ≈12. Then, at room temperature, the mixed solution was gradually titrated into excess ammonia solution containing polyethylene glycol PEG6000 dispersant to carry out hydrolysis reaction. During the titrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com