Preparation method of nano electrolyte material for mesothermal solid oxide fuel cell

A technology of solid oxide and electrolyte materials, which is applied in the field of preparation of nano-electrolyte materials, can solve the problems of low ionic conductivity and high preparation temperature in the middle temperature region, and achieve improved oxygen vacancy density, simple operation, and increased particle surface activity and reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific Embodiment 1: This embodiment is a nano-electrolyte material for medium-temperature solid oxide fuel cells, which is a cerium oxide-based oxygen-ion conductive electrolyte nano-powder co-doped with rare earth element ions and cobalt ions, and its chemical formula is Ce (1-x-y) Re x co y o 2-δ , where x:y=4~20:1, x+y=0.21~0.25, δ=0.10~0.12, Re is a rare earth element.

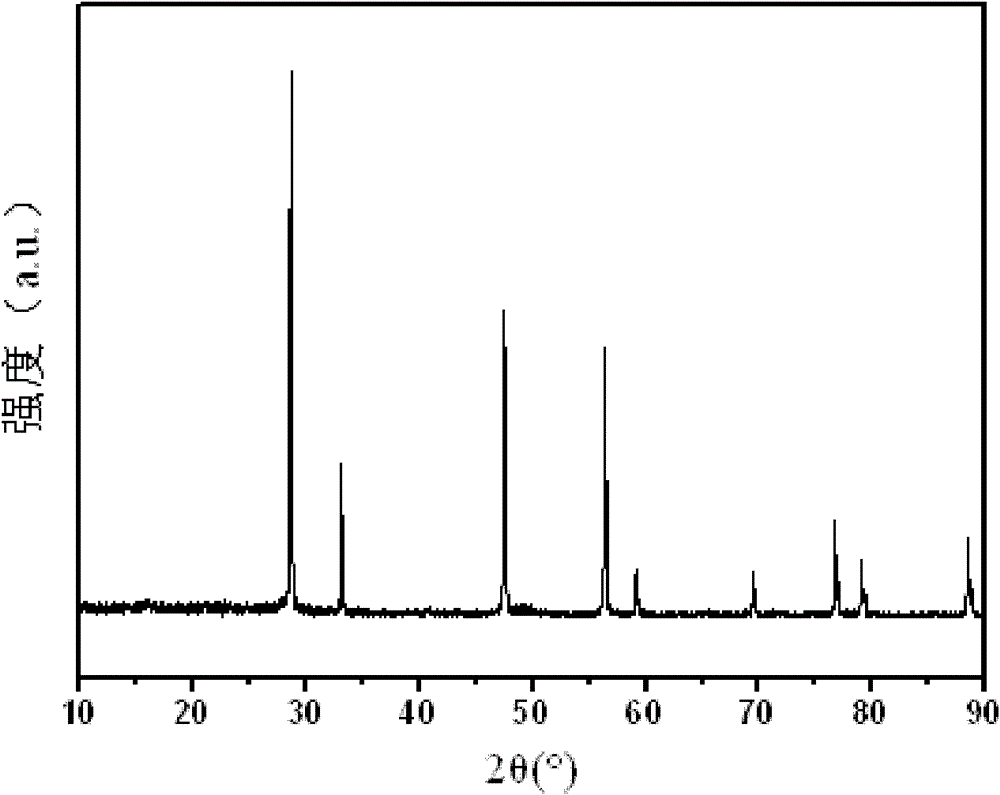

[0018] The nano-electrolyte material used in the medium-temperature solid oxide fuel cell in this embodiment is a single fluorite structure compound with relatively high crystallinity.

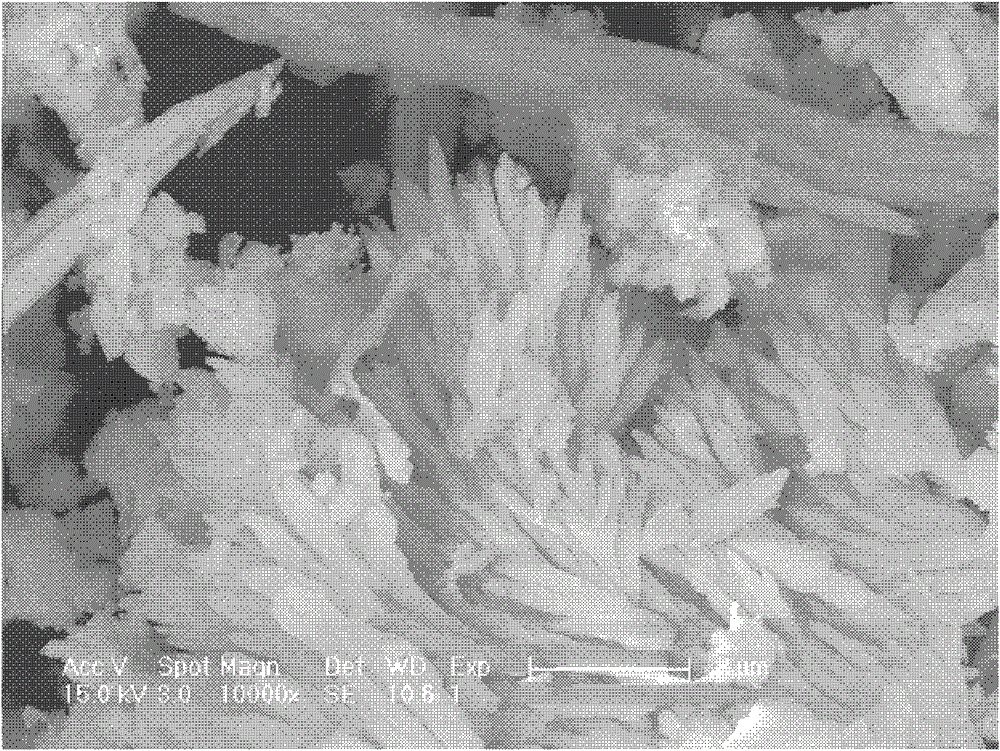

[0019]The nano-electrolyte material in this embodiment is a coral-like particle assembled and assembled from wheat ear-shaped nanoparticles.

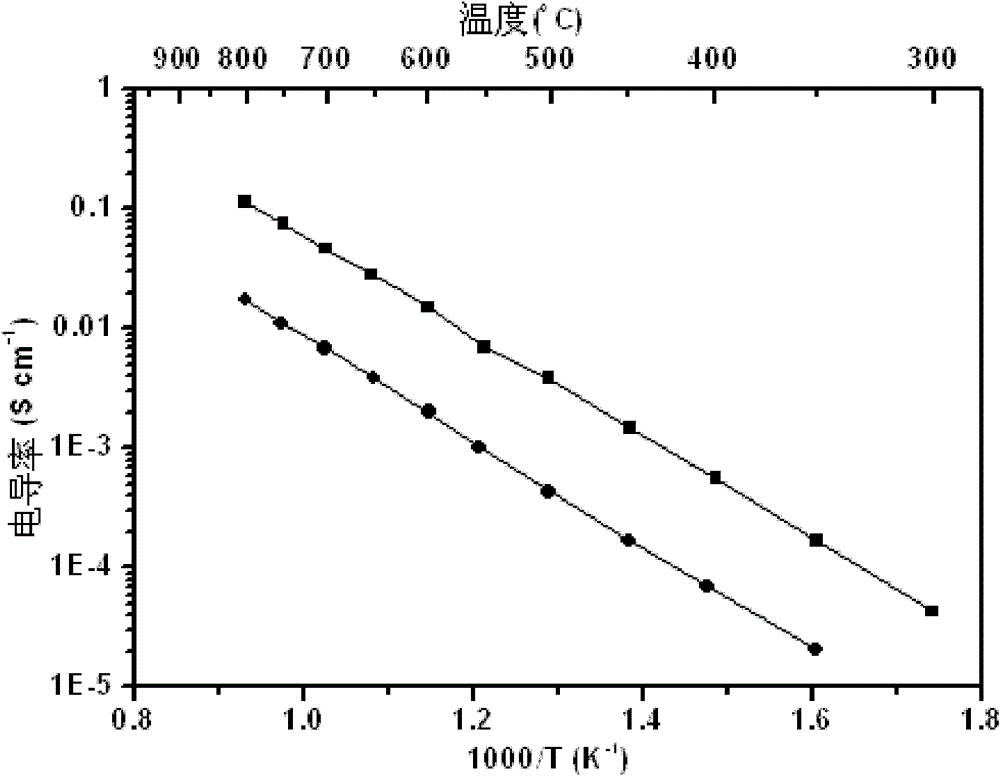

[0020] In the temperature range of 500-700°C, the nano-electrolyte material of this embodiment has a high ion conductivity, up to 0.11S cm -1 , so as to obtain a general-purpose high-activity and high-long-term stability nano-electrolyte material for solid oxide fuel c...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the rare earth element ion is Nd 3+ 、Sm 3+ 、Gd 3+ 、Eu 3+ or Pr 3+ . Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is the nano-electrolyte material used in medium temperature solid oxide fuel cells, which is a cerium oxide-based oxygen ion conductive material co-doped with neodymium rare earth element ions and cobalt ions. Electrolyte nanopowder, chemical formula is Ce (1-x-y) Nd x co y o 2-δ , where x:y=4~10:1, x+y=0.22~0.25, δ=0.10~0.12. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com