Potentiometric hydrogen sensor using strontium and iron-doped lanthanum chromate as sensitive electrode and manufacturing method of potentiometric hydrogen sensor

A sensitive electrode and potential-type technology, applied in the direction of material electrochemical variables, can solve the problems of small ignition energy, easy to cause explosion accidents, wide explosion limit, etc., achieve fast response speed, improve gas sensitivity performance, and high response value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

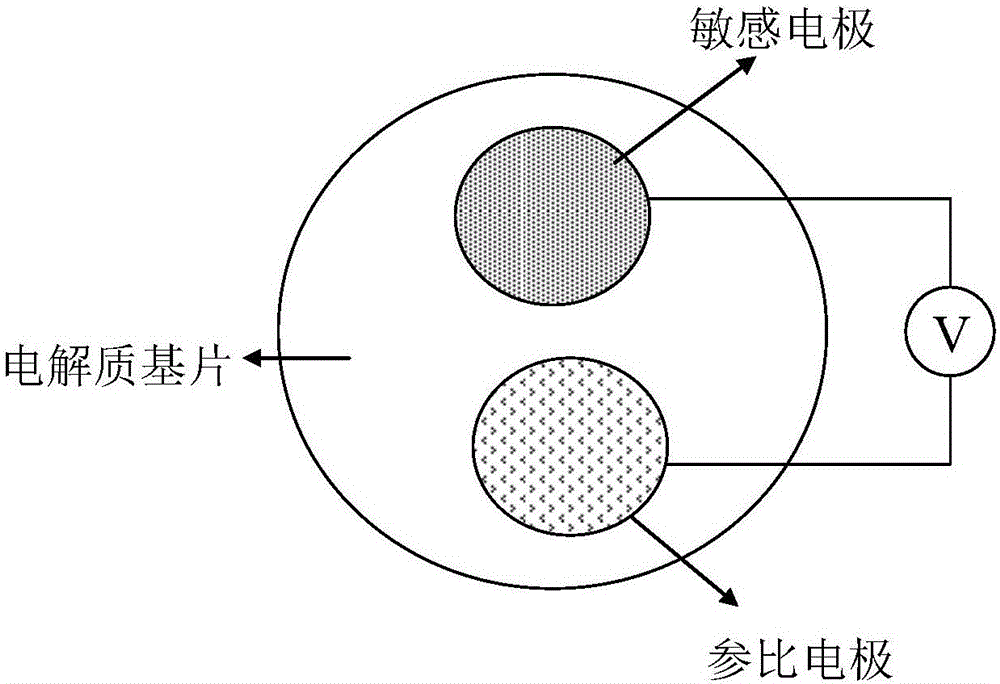

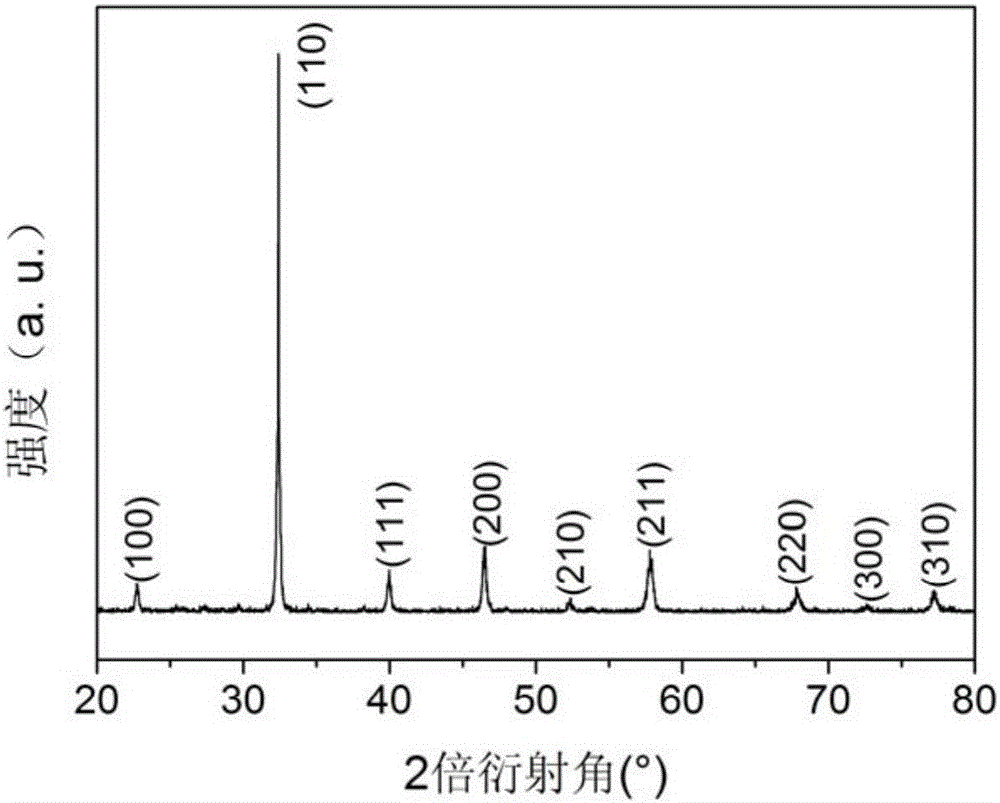

[0026] The potentiometric hydrogen sensor of the present embodiment is based on La 0.8 Sr 0.2 Cr 0.5 Fe 0.5 o 3-δ As a sensitive electrode, with Pt as a reference electrode, and YSZ as a solid electrolyte, the preparation method is as follows:

[0027] (1) Mix terpineol and ethyl cellulose in a mass ratio of 9:1 to obtain modified terpineol; weigh a certain amount of commercial La 0.8 Sr 0.2 Cr 0.5 Fe 0.5 o 3-δ powder, drop the same mass of modified terpineol into the powder, and then fully grind for 2 hours to obtain a sensitive electrode slurry;

[0028] (2) Take a YSZ electrolyte substrate with a diameter of 13mm; brush the sensitive electrode slurry on the electrolyte substrate by screen printing, and then place the electrolyte substrate in an oven at 150°C for 30 minutes to dry the electrolyte substrate in the sensitive electrode slurry The organic solvent is completely volatilized, and then the electrolyte substrate is calcined at 1000°C for 3 hours to increase ...

Embodiment 2

[0035] The structure and preparation method of the potentiometric hydrogen sensor in this embodiment are the same as those in Embodiment 1, except that the solid electrolyte substrate used is GDC, and the obtained sensor is denoted as LSCF / GDC / Pt sensor.

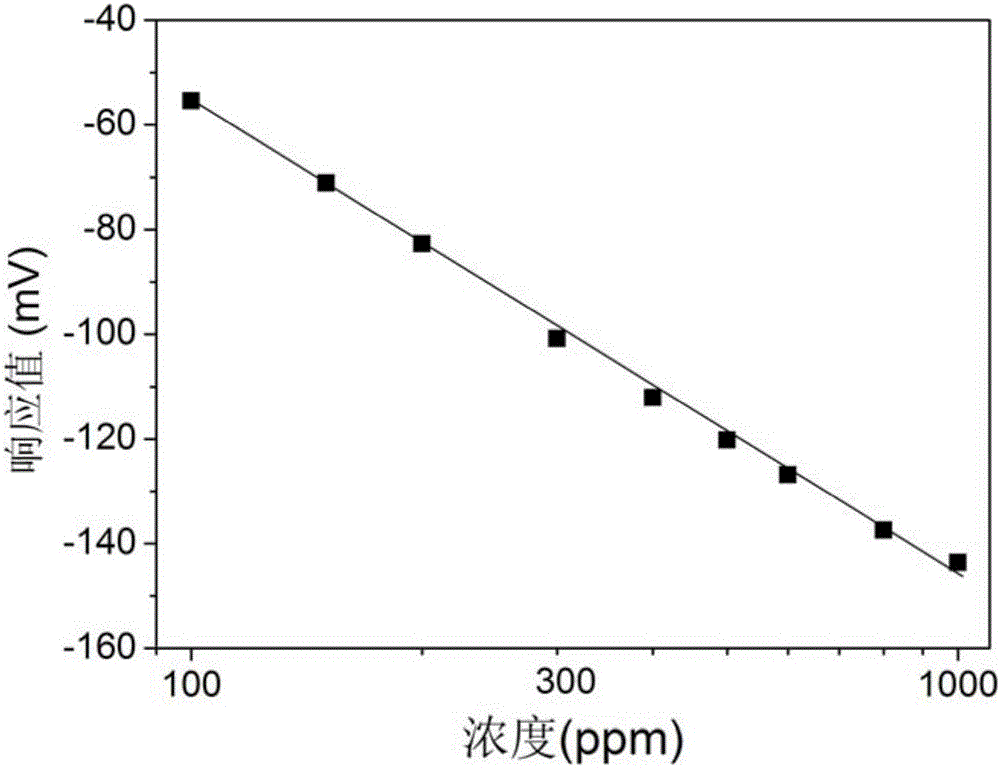

[0036] Figure 5 It is the response diagram of the LSCF / GDC / Pt sensor obtained in this example to different concentrations of hydrogen at 500°C. It can be seen from the figure that the response value of the sensor to 100ppm hydrogen is 48mV, and the sensitivity of the sensor is 86mV / decade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com