Nitrogen-doped defect-rich molybdenum disulfide catalyst as well as preparation method and application thereof

A molybdenum disulfide, defect-rich technology, applied in fuel cell type half cells and primary cell type half cells, electrical components, battery electrodes, etc., can solve problems such as immature control methods and achieve excellent electrochemical catalytic activity , low cost, excellent cycle stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

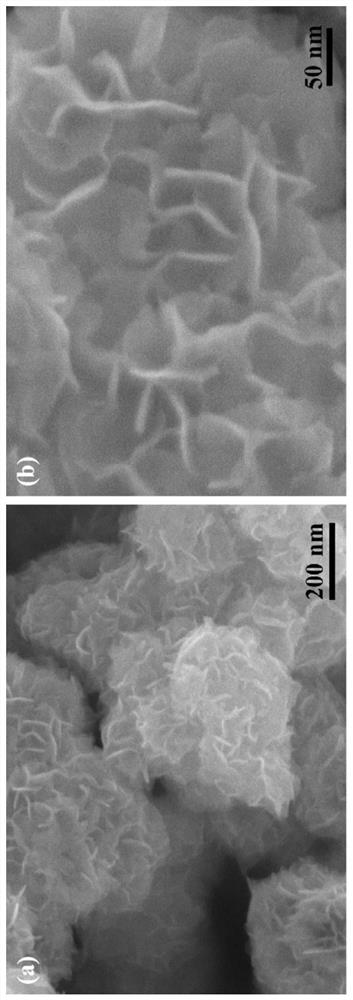

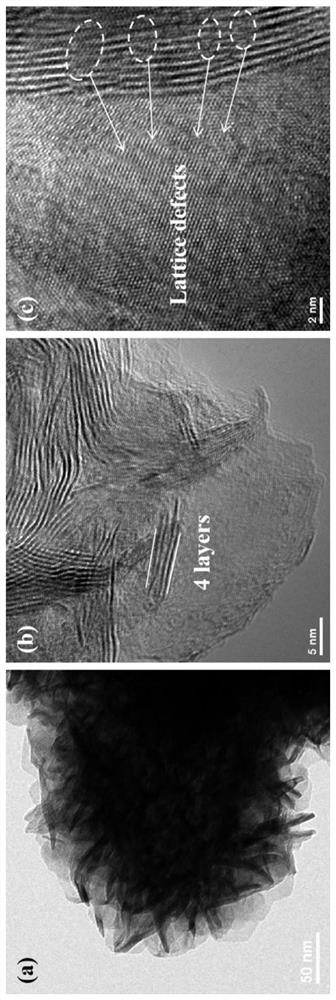

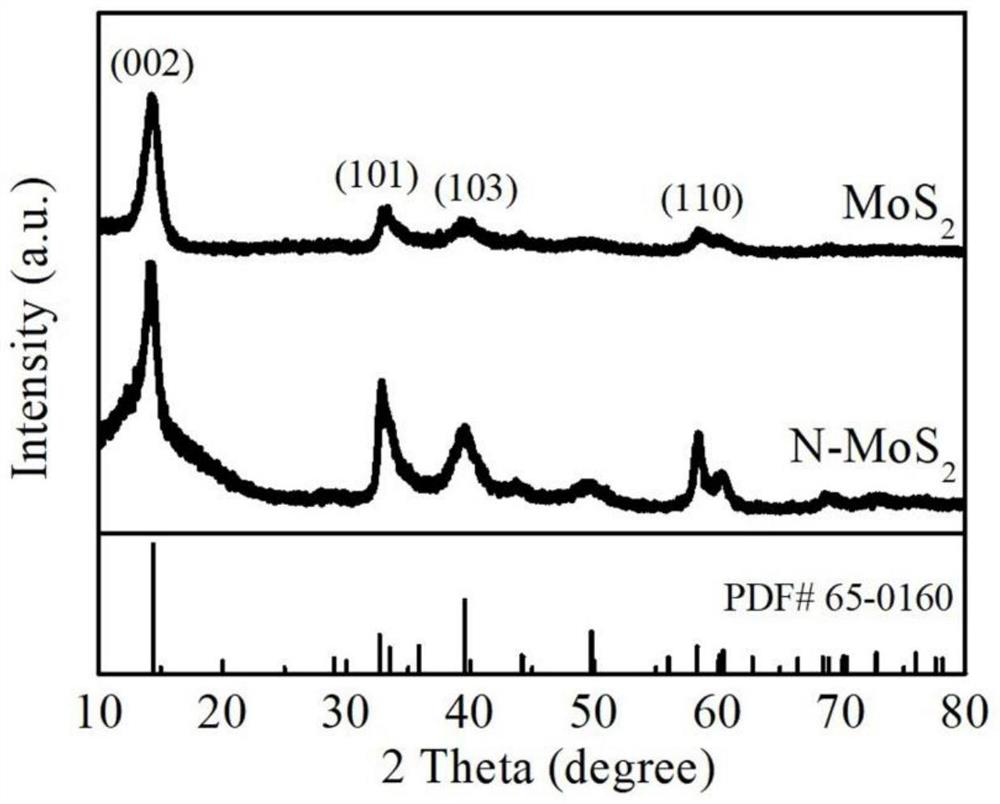

Image

Examples

Embodiment 1

[0028] 1. Precursor material preparation.

[0029] Weigh 0.08g ammonium molybdate (H 8 MON 2 o 4 ) and 0.24g thiourea (CH 4 N 2 S) Mix and add to a beaker of 60mL deionized water and stir well, dissolve evenly, and form a clear and transparent solution. Then transfer the mixed solution in the beaker to the lining of a 100mL polytetrafluoroethylene hydrothermal kettle, install the outer shell of the hydrothermal kettle, and put it in an oven at 200°C for 16 hours of reaction. After the reaction is completed, take out the inner lining of the hydrothermal kettle, and centrifuge and wash the black powder product generated in the reaction solution with deionized water and absolute ethanol for several times, and then vacuumize and dry it in an oven at 60°C to obtain the precursor material powder .

[0030] 2. N-MoS 2 Preparation of catalyst materials.

[0031] Weigh 0.2g of precursor material powder into the corundum boat, place the corundum boat in the middle of the tube fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com