Low-temperature solid oxide fuel cell cathode in a core-shell nanofiber structure and preparation method thereof by electrospinning

A technology of solid oxides and nanofibers, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve unfavorable cathode batch production and large-scale application, surface adsorption poisoning and high thermal expansion coefficient, unfavorable cathode oxygen surface exchange process, etc. problems, to achieve the effect of promoting oxygen surface exchange and bulk diffusion rate, improving structure and performance stability, and improving the ability to resist CO2 surface adsorption and poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further description will be made below through specific examples.

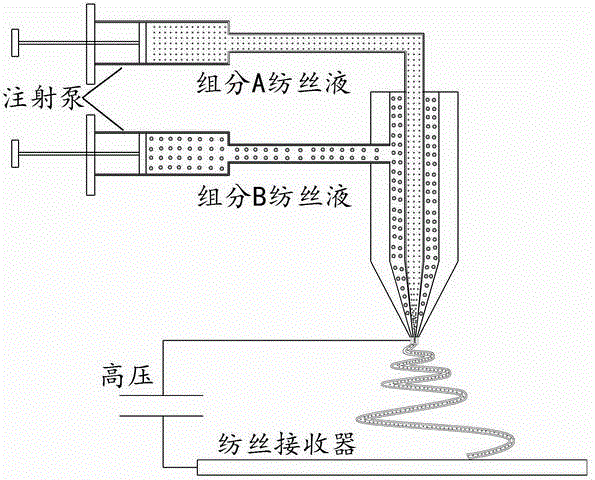

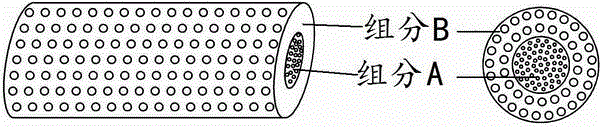

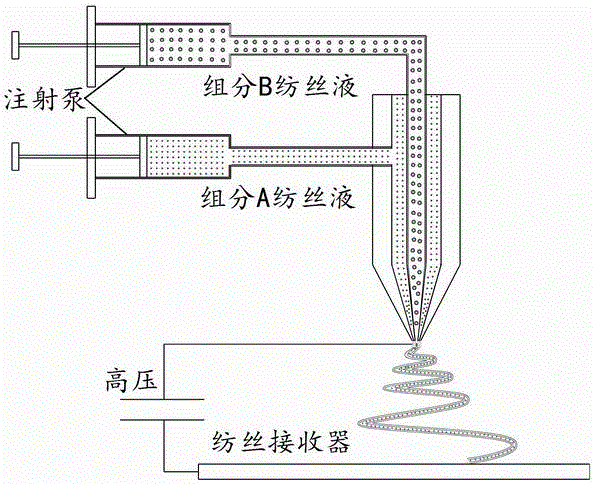

[0025] Preparation of perovskite oxide PrBa by electrospinning 0.92 co 2 o 6-δ (δ is the amount of oxygen deficiency) and electrolyte Gd 0.1 Ce 0.9 o 1.95 Low-temperature SOFC cathode material with core-shell nanofiber structure

[0026] Step 1, prepare PrBa respectively 0.92 co 2 o 6-δ Spinning precursor solution and Gd 0.1 Ce 0.9 o 1.95 Spinning Precursor Solution

[0027] PrBa 0.92 co 2 o 6-δ Spinning precursor solution preparation process:

[0028] According to the synthesis of 0.4mmol PrBa 0.92 co 2 o 6-δ The metal ion stoichiometric ratio accurately weighs Pr(NO 3 ) 3▪ 6H 2 O0.174g, Ba(NO 3 ) 2 0.0961g, Co(Ac) 2▪ 4H 2 O 0.199g, put into a mixed solvent composed of 0.2ml deionized water, 0.5ml alcohol and 6ml N,N-dimethylformamide, magnetically stir at room temperature until the above reagents are completely dissolved and mixed evenly; then 1.0g Polyvinylpyrrolidone was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com