Method for manufacturing chip oxygen sensor and chip oxygen sensor

A technology of an oxygen sensor and a manufacturing method, which is applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of uneven pressure, long activation time, poor oxygen sensitivity, etc., and achieves a good degree of integration, simple process flow, and activation time. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

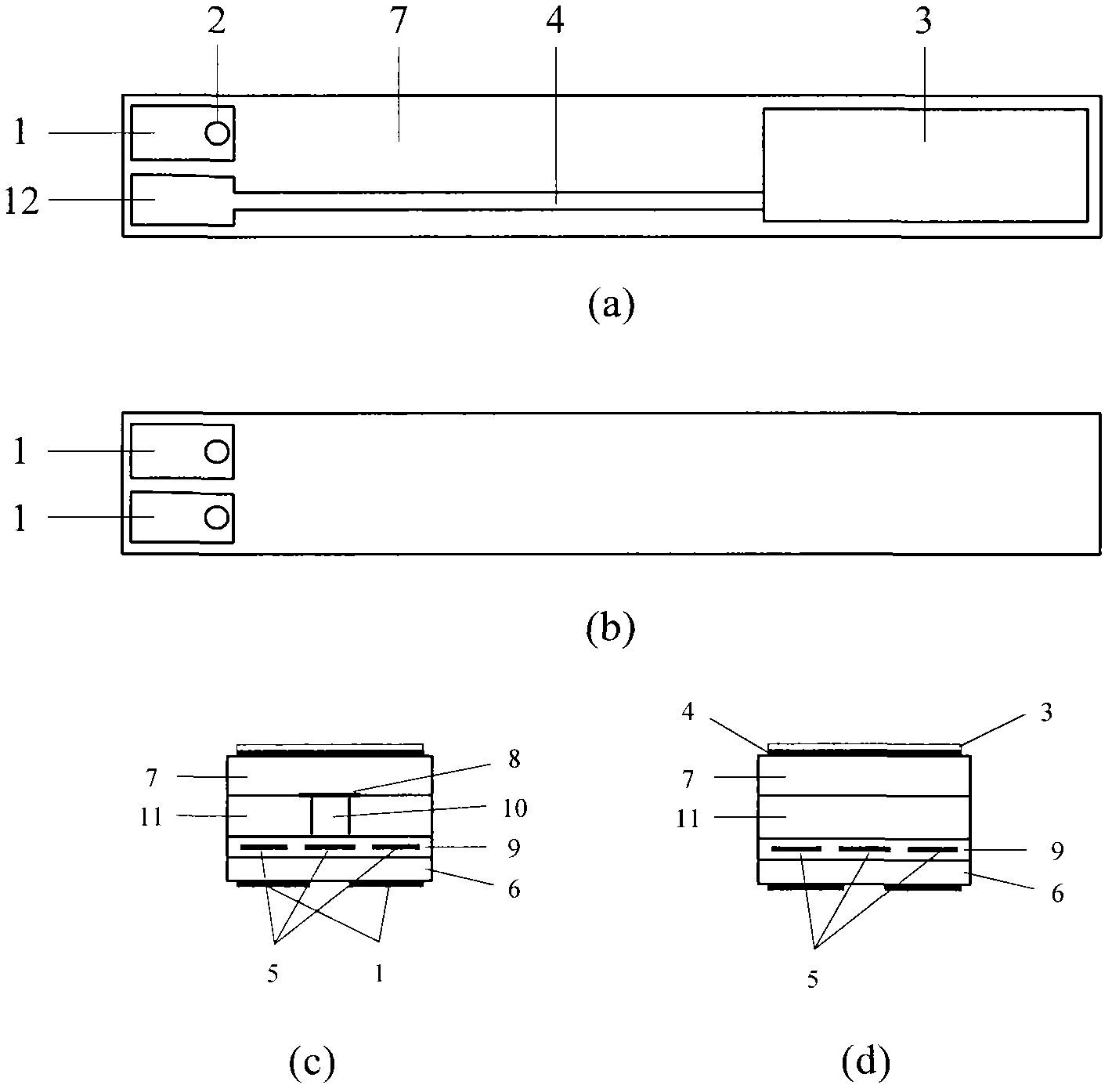

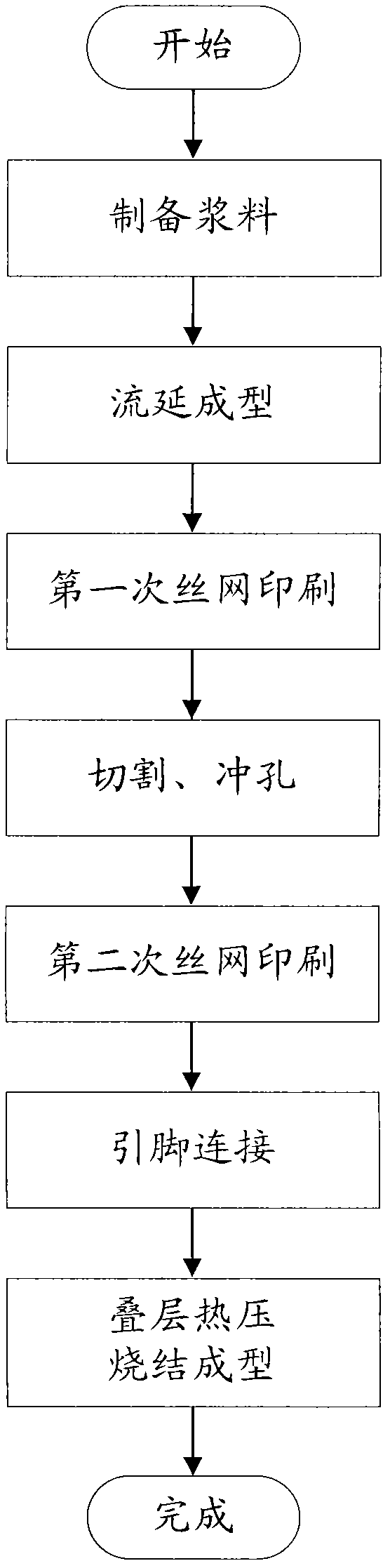

[0069] The manufacturing method of the chip oxygen sensor in this embodiment includes the following steps:

[0070] ①. Preparation of slurry:

[0071] Take by weighing 200g mole fraction of 8% yttrium oxide fully stabilized zirconia powder, place it in a ball mill jar, then add 100g ethanol, 16.67g dibutyl phthalate, 16.67g polyvinyl butyral respectively, Among them, according to mass percentage, zirconia powder accounts for 60%, ethanol accounts for 30%, dibutyl phthalate accounts for 5%, polyvinyl butyral accounts for 5%, and the materials in the ball mill tank are ball milled and mixed for 15 hours , after vacuum defoaming and sieving, a slurry with a viscosity of 906mPa·s is made;

[0072] ②. Tape casting:

[0073] Put the slurry prepared in step ① into a casting machine, use a double scraper to make a membrane with a uniform thickness from the non-water-based slurry placed on the film-forming backing belt, and place the prepared membrane in a solvent atmosphere Dry to ...

Embodiment 2

[0087] The manufacturing method of the chip oxygen sensor in this embodiment includes the following steps:

[0088] ①. Preparation of slurry:

[0089] Weigh 200g of yttrium oxide fully stabilized zirconia powder with a mole fraction of 8%, place it in a ball mill jar, then add 186.67g of ethanol, 4.44g of triethanolamine, 26.67g of dibutyl phthalate, 26.67g of poly Vinyl butyral, wherein, according to mass percentage, zirconia powder accounts for 45%, ethanol accounts for 42%, triethanolamine accounts for 1%, dibutyl phthalate accounts for 6%, polyvinyl butyral accounts for 6% %, the material in the ball mill tank was ball milled and mixed for 16 hours, and after vacuum degassing and sieving, it was made into a slurry with a viscosity of 1205mPa·s;

[0090] Steps ② to ⑥ are the same as steps ② to ⑥ in Embodiment 1, and will not be repeated here.

[0091] ⑦.Laminated hot pressing, sintering molding:

[0092] Lamination hot pressing: Position and align the sensor base blanks,...

Embodiment 3

[0095] The manufacturing method of the chip oxygen sensor in this embodiment includes the following steps:

[0096] ①. Preparation of slurry:

[0097] Weigh 200g of yttrium oxide fully stabilized zirconia powder with a mole fraction of 8%, place it in a ball mill jar, then add 130.69g of ethanol, 7.92g of triethanolamine, 27.72g of dibutyl phthalate, 29.7g of poly Vinyl butyral, of which, according to mass percentage, zirconia powder accounts for 50.5%, ethanol accounts for 33%, triethanolamine accounts for 2%, dibutyl phthalate accounts for 7%, polyvinyl butyral accounts for 7.5% %, the materials in the ball mill tank were ball milled and mixed for 16 hours, and after vacuum defoaming and sieving, a slurry with a viscosity of 1100mPa·s was made;

[0098] Steps ② to ⑥ are the same as steps ② to ⑥ in Embodiment 1, and will not be repeated here.

[0099] ⑦.Laminated hot pressing, sintering molding:

[0100] Lamination hot pressing: Position and align the sensor base blanks, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com