Patents

Literature

34 results about "Improper Temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

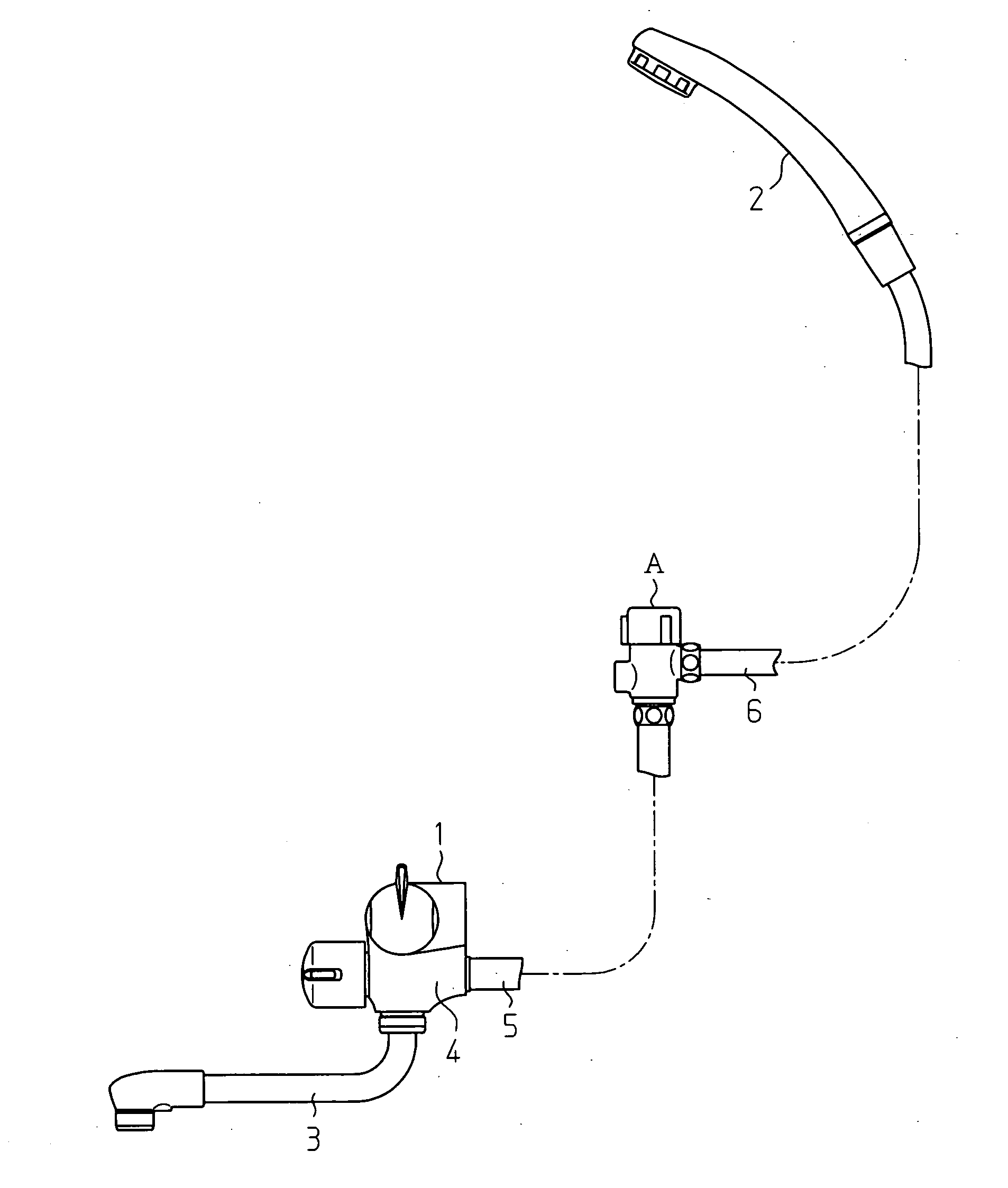

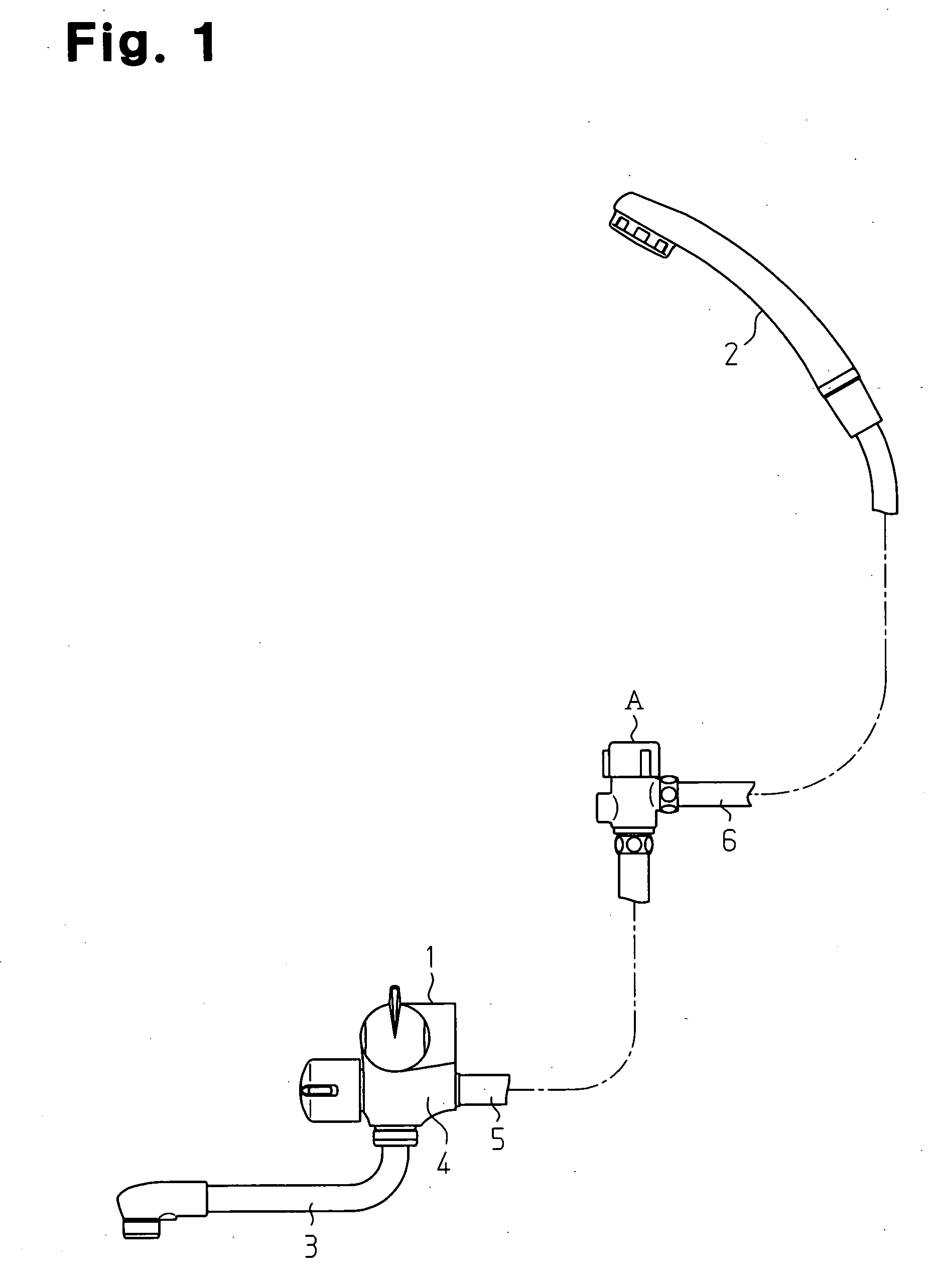

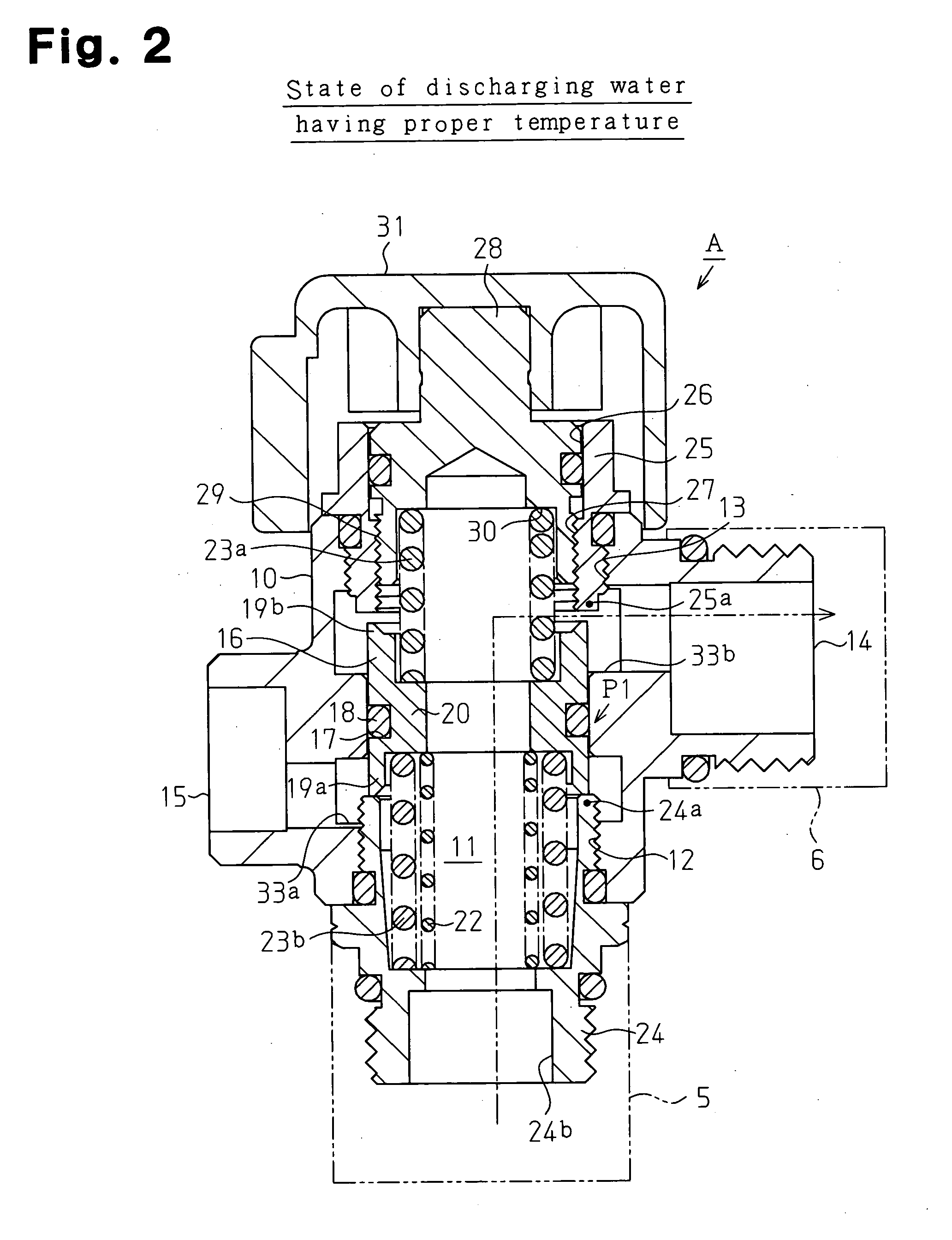

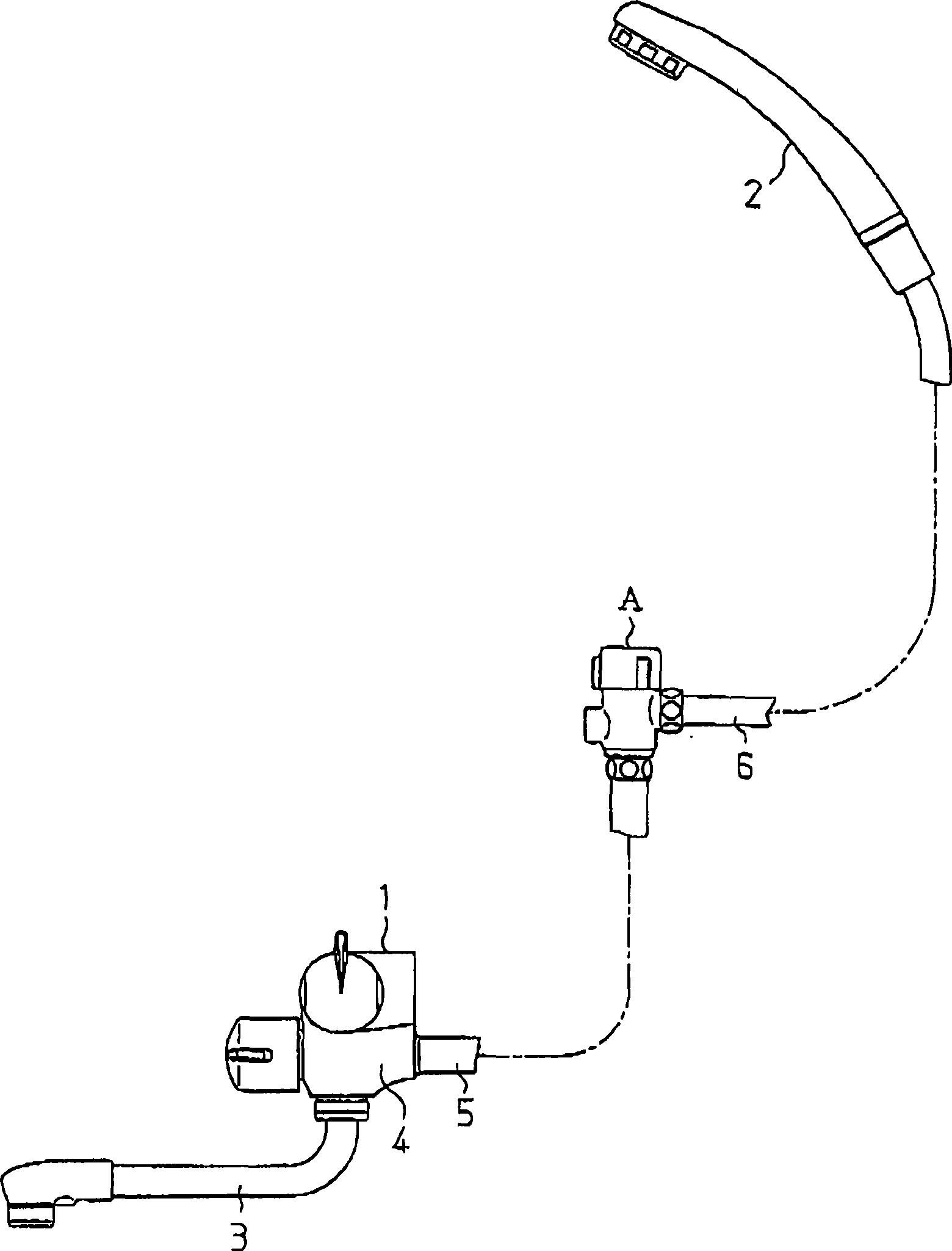

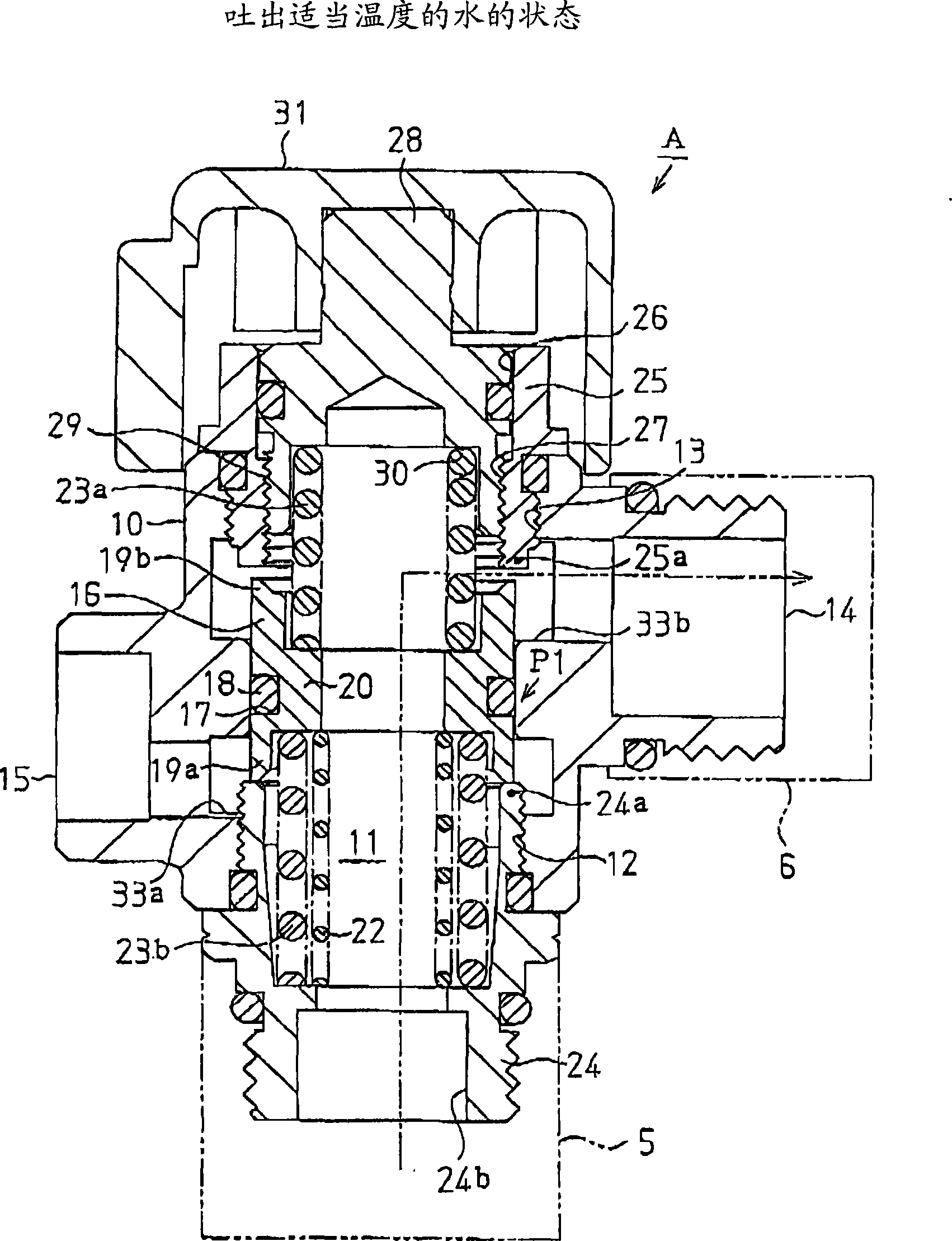

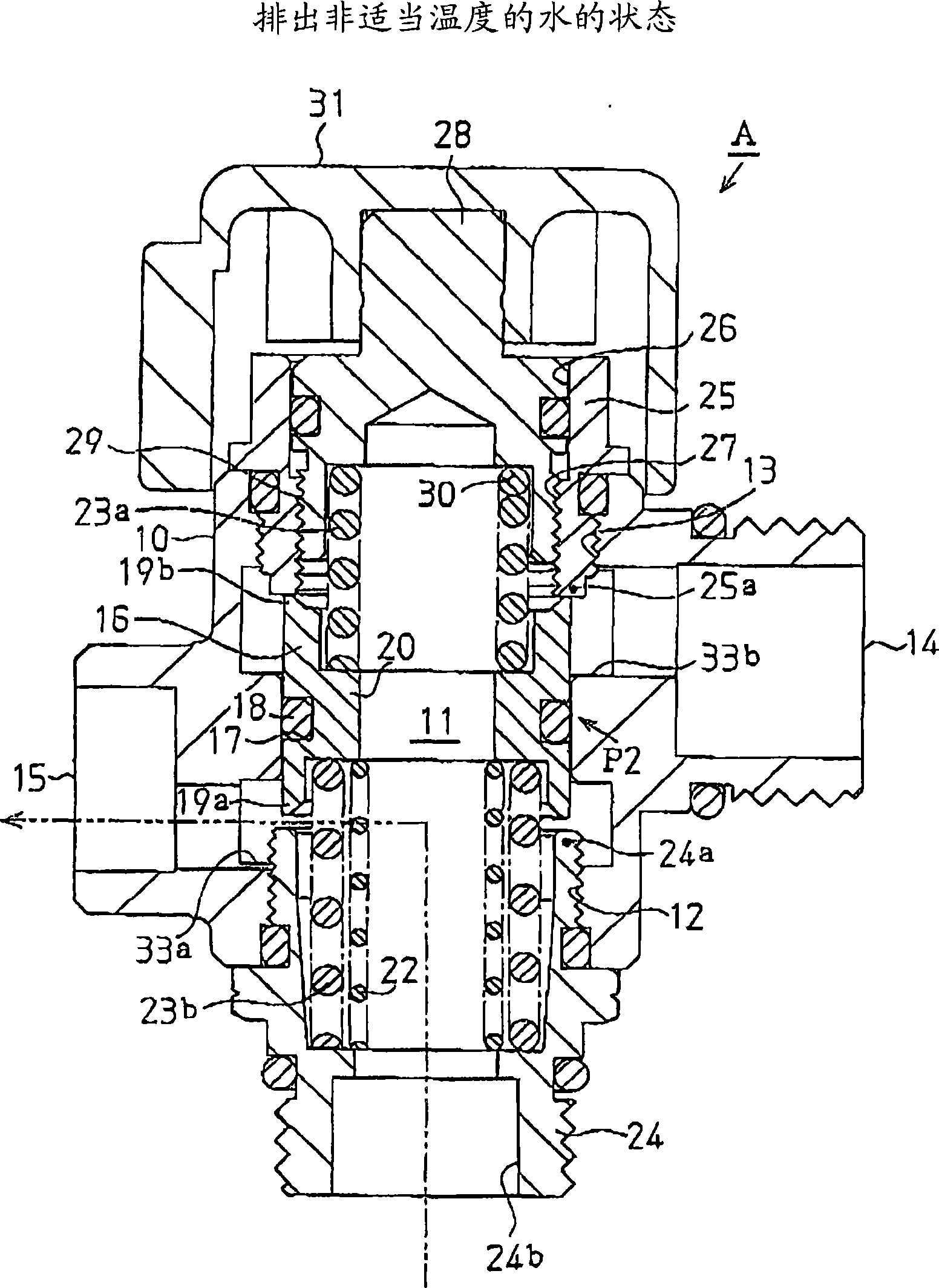

Flow channel switching valve and shower system

A channel switching valve (A) of the present invention includes a discharge hole (14) which discharges water having a proper temperature and a drain hole (15) which drains water having an improper temperature. A part of a first channel (11) extending from a hot water supply port (24b) to the discharge hole and a part of a second channel (11) extending from the hot water supply port to the drain hole are common. Therefore, the channel switching valve can be compact.

Owner:KITAMURAGOKIN IND

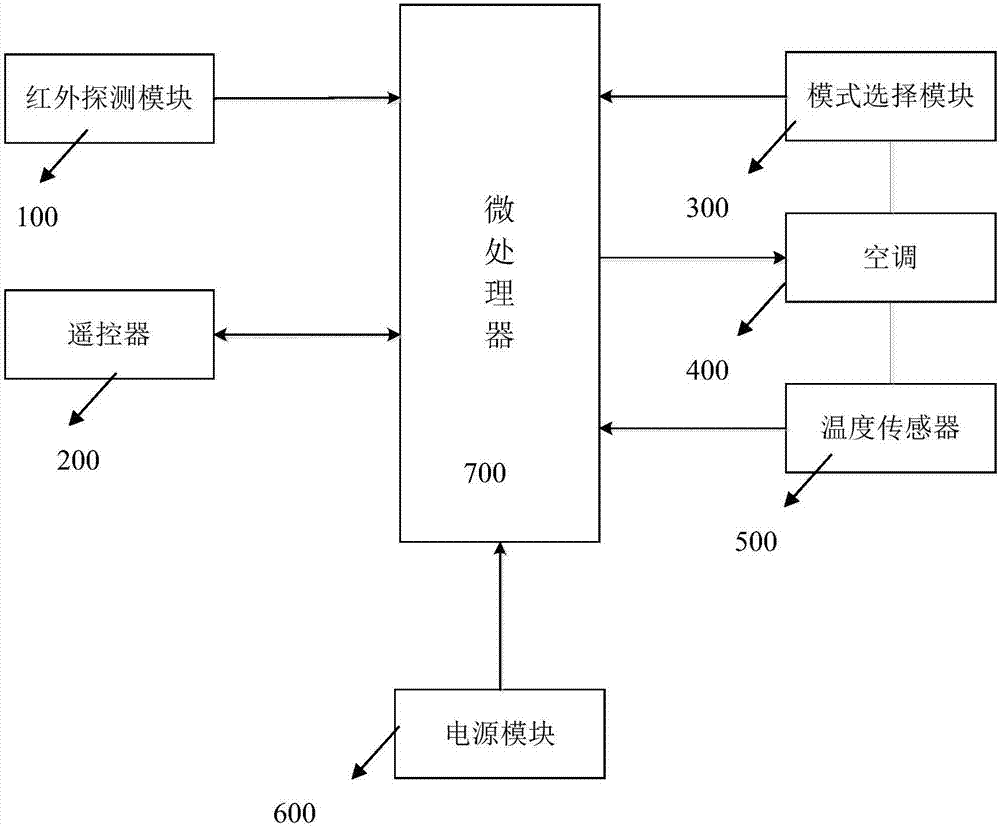

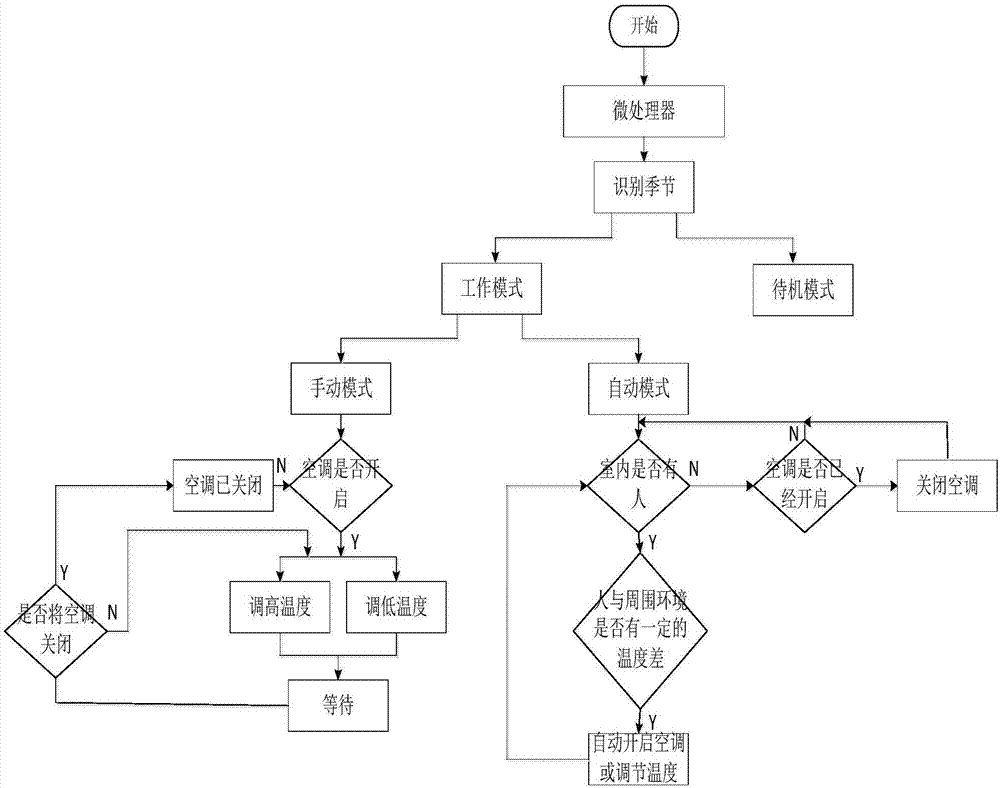

Intelligent air conditioner control device and control method based on infrared detection

InactiveCN106996621AAccurate adjustmentAutomatically judge the seasonMechanical apparatusSpace heating and ventilation safety systemsModel selectionTemperature difference

The invention discloses an intelligent air conditioner control device and a control method based on infrared detection. The device comprises a microprocessor, an infrared detecting module, an air conditioner, a remote controller, a temperature sensor, a mode selecting module and a power supply module. The control method comprises the following steps: the microprocessor is respectively connected with the remote controller, the infrared detecting module, the air conditioner, the temperature sensor, the mode selecting module and the power supply module. The model selection can be operated through the mode selecting module or the remote controller. The remote controller selects a first working mode similar to a traditional air conditioner working mode for manually adjusting an air conditioner; the remote controller selects a second working mode; and the infrared detecting device automatically identifies if a person is indoors according to thermal imaging and a surrounding temperature difference to automatically start and stop the air conditioner and to adjust indoor temperature according to the position of the person. The intelligent air conditioner control device and control method based on infrared detection largely reduce the manual operation frequency by users, can enable human bodies to feel comfortable, and prevent discomfort of bodies caused by improper temperature to a certain extent.

Owner:YANCHENG TEACHERS UNIV

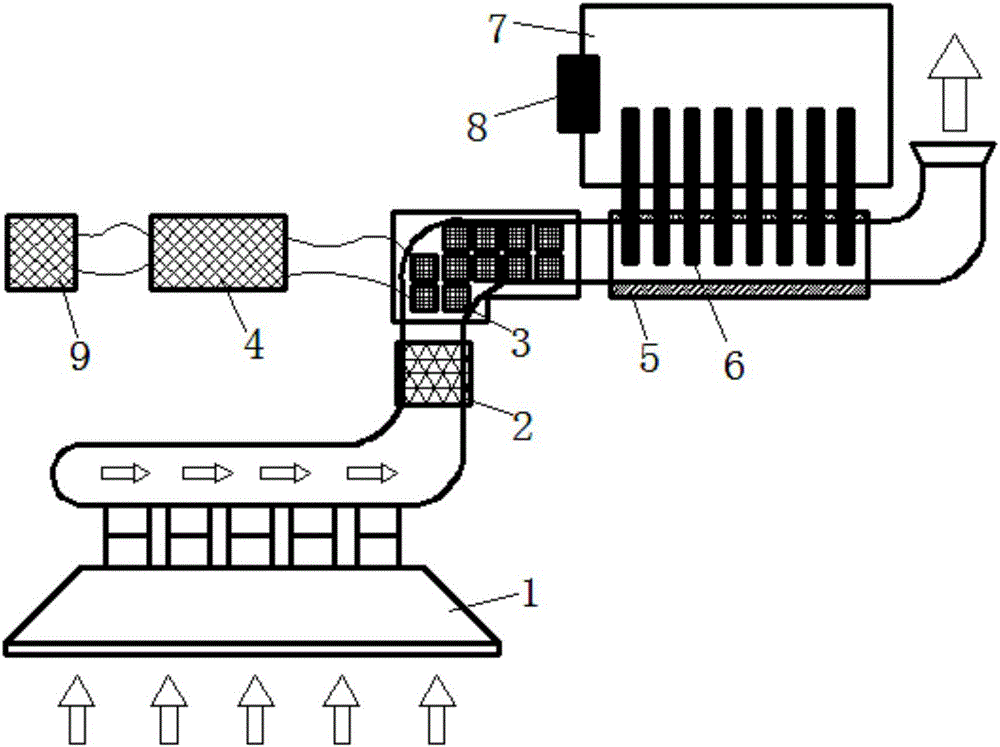

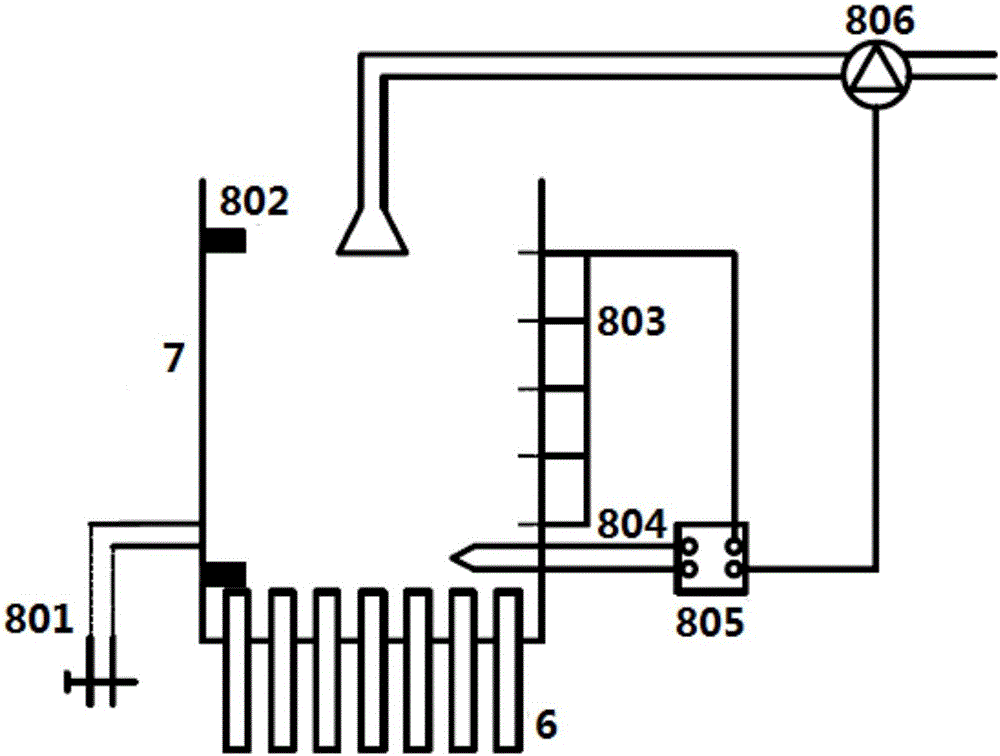

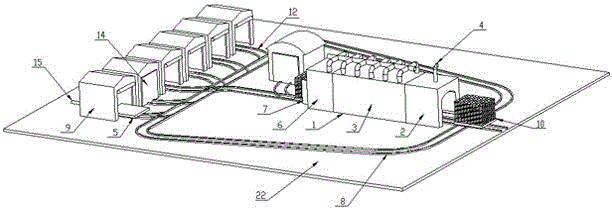

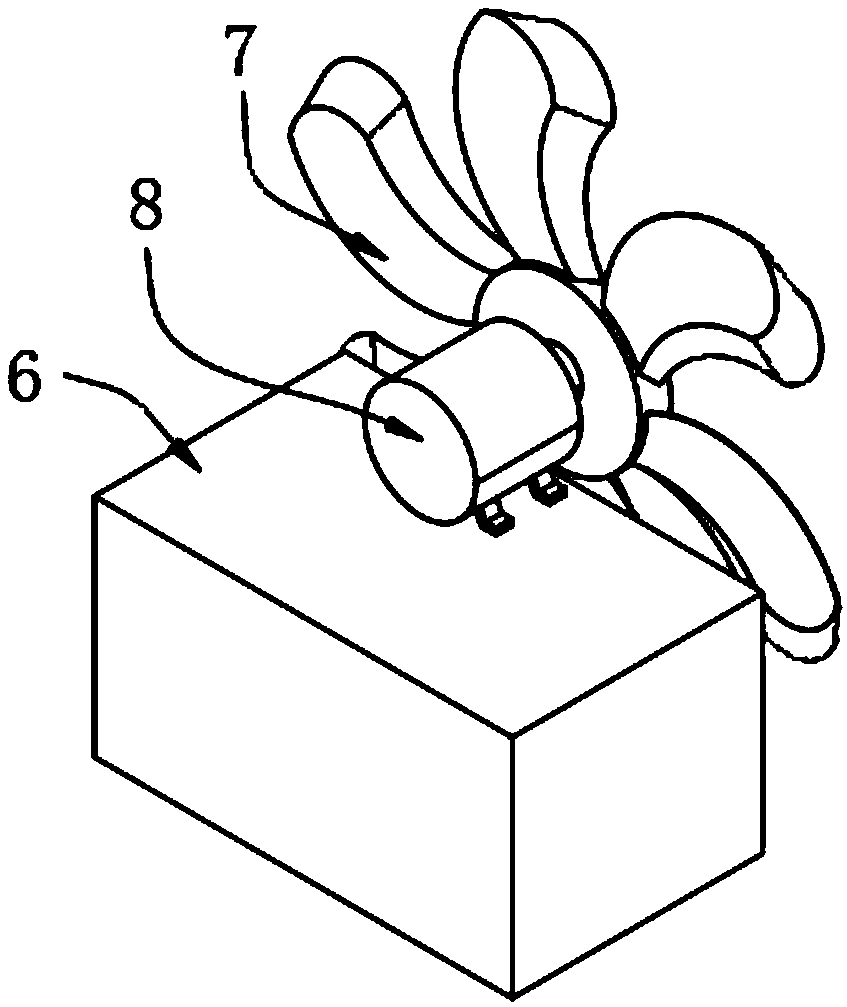

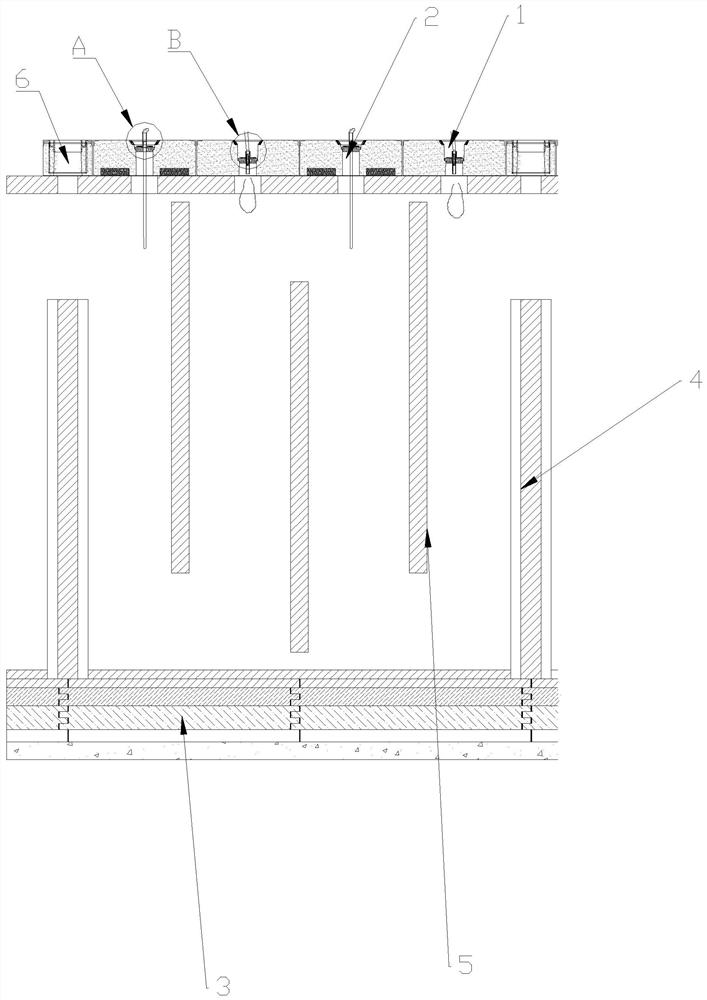

Kitchen fume waste heat recycling system

InactiveCN106196211AReduce settingsReduce layoutDomestic stoves or rangesCooking fumes removalAutomatic controlEconomic benefits

The invention discloses a kitchen fume waste heat recycling system. The system comprises a fume collecting box, a fume purifier, a temperature difference power generating piece, a storage battery, a gravity heat pipe heat exchanger, a water tank, an integrated automatic control device and an inverter. A multi-time graded treatment manner is adopted, the fume collecting box collects kitchen fume, the fume enters the fume purifier firstly to be subject to oil stain removal, the manner of one-side air cooling and one-side convection heat exchange is adopted for generating power through the temperature difference power generation module, and the storage battery is connected for electric amount storage. The cooled fume enters an outdoor heat preservation pipeline again to be subject to heat pipe waste heat recycling, heating of the automatic control water tank is combined, so that constant-temperature domestic water is obtained, and finally low-temperature fume subject to two-stage heat exchange is discharged out of a fume discharging opening. The system can sufficiently utilize the characteristics of the temperature difference power generation and heat pipe waste heat recycling, temperature difference power generation and heat pipe waste heat recycling are effectively combined, meanwhile, energy waste and unnecessary equipment arrangement caused by improper temperature during traditional fume recycling are avoided, and the utilization efficiency and economic benefits of a kitchen fume discharging system are improved.

Owner:XI AN JIAOTONG UNIV

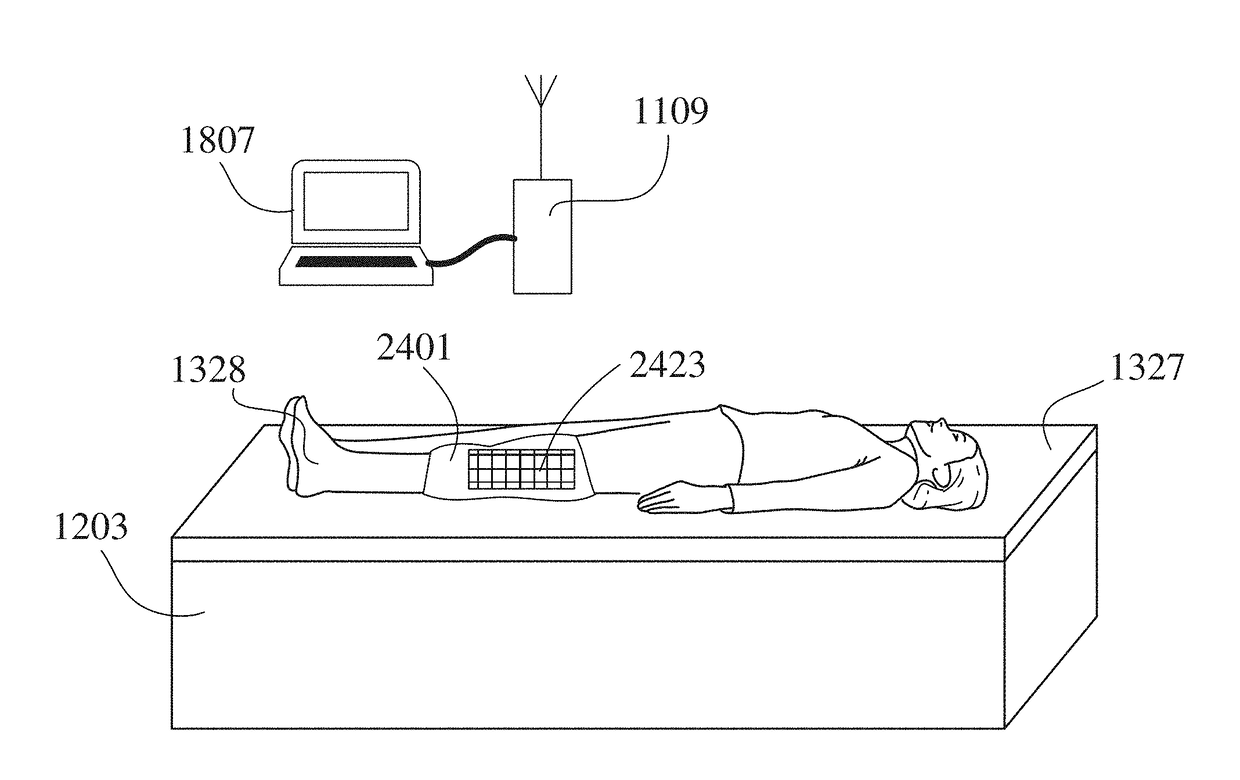

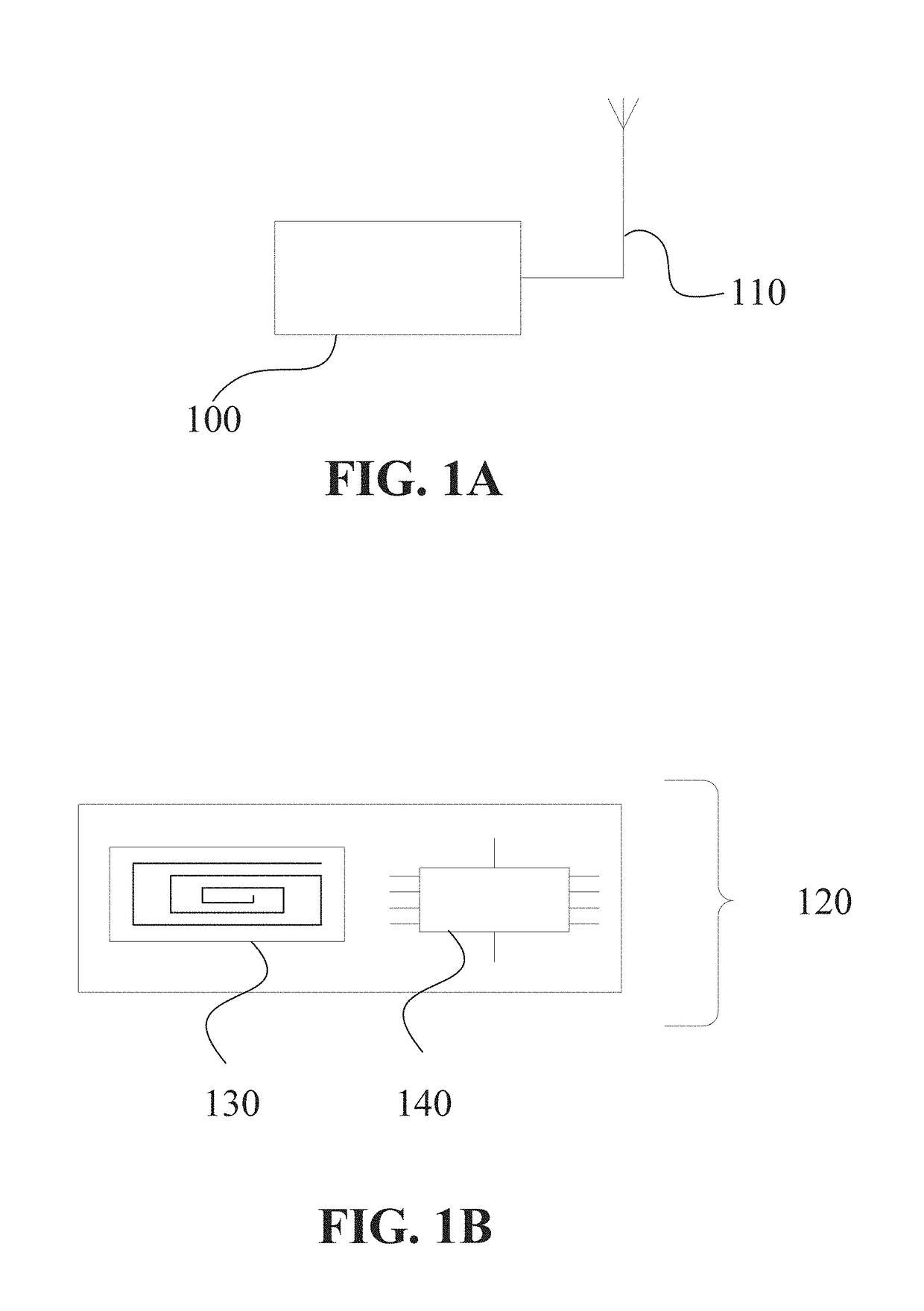

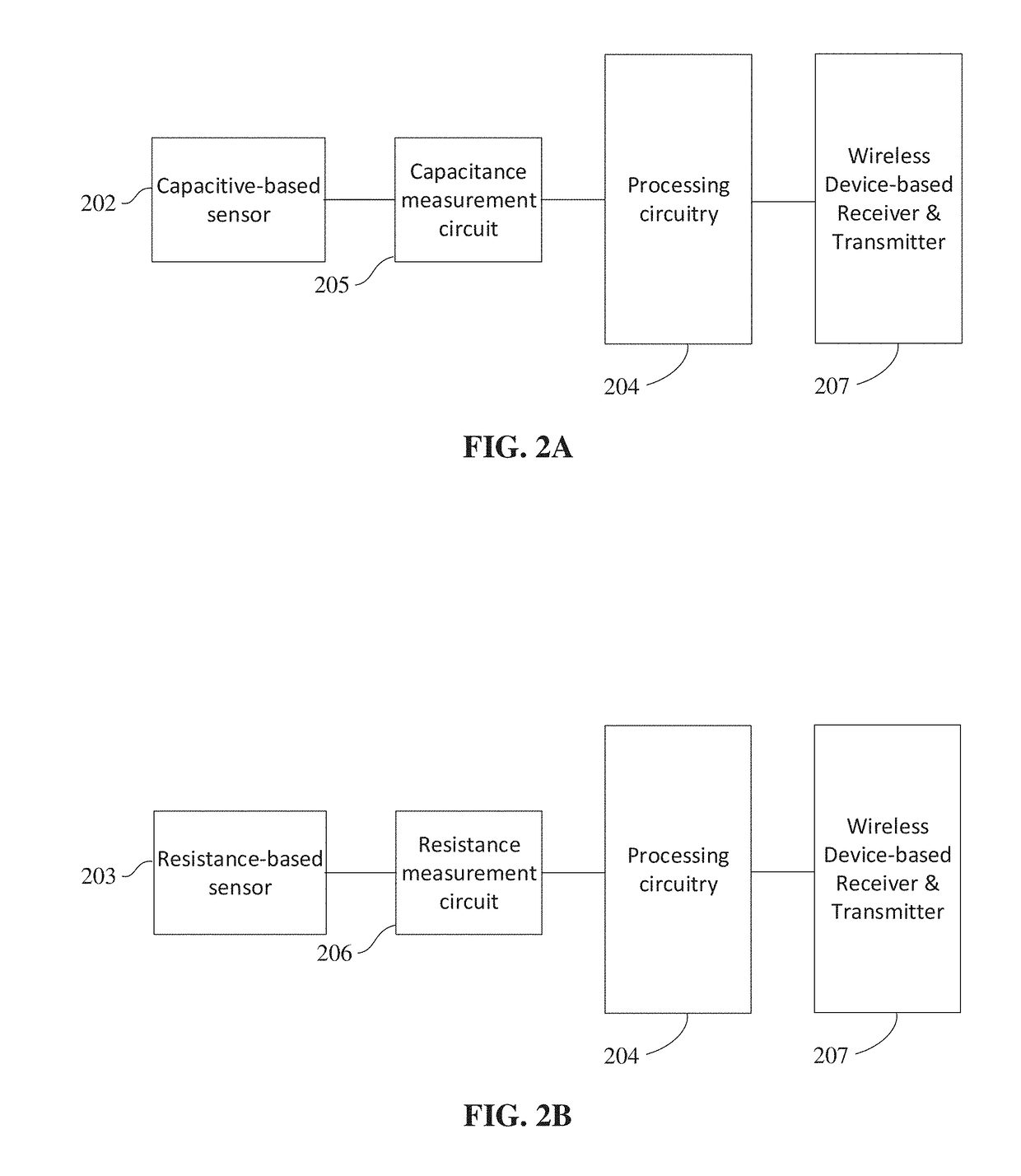

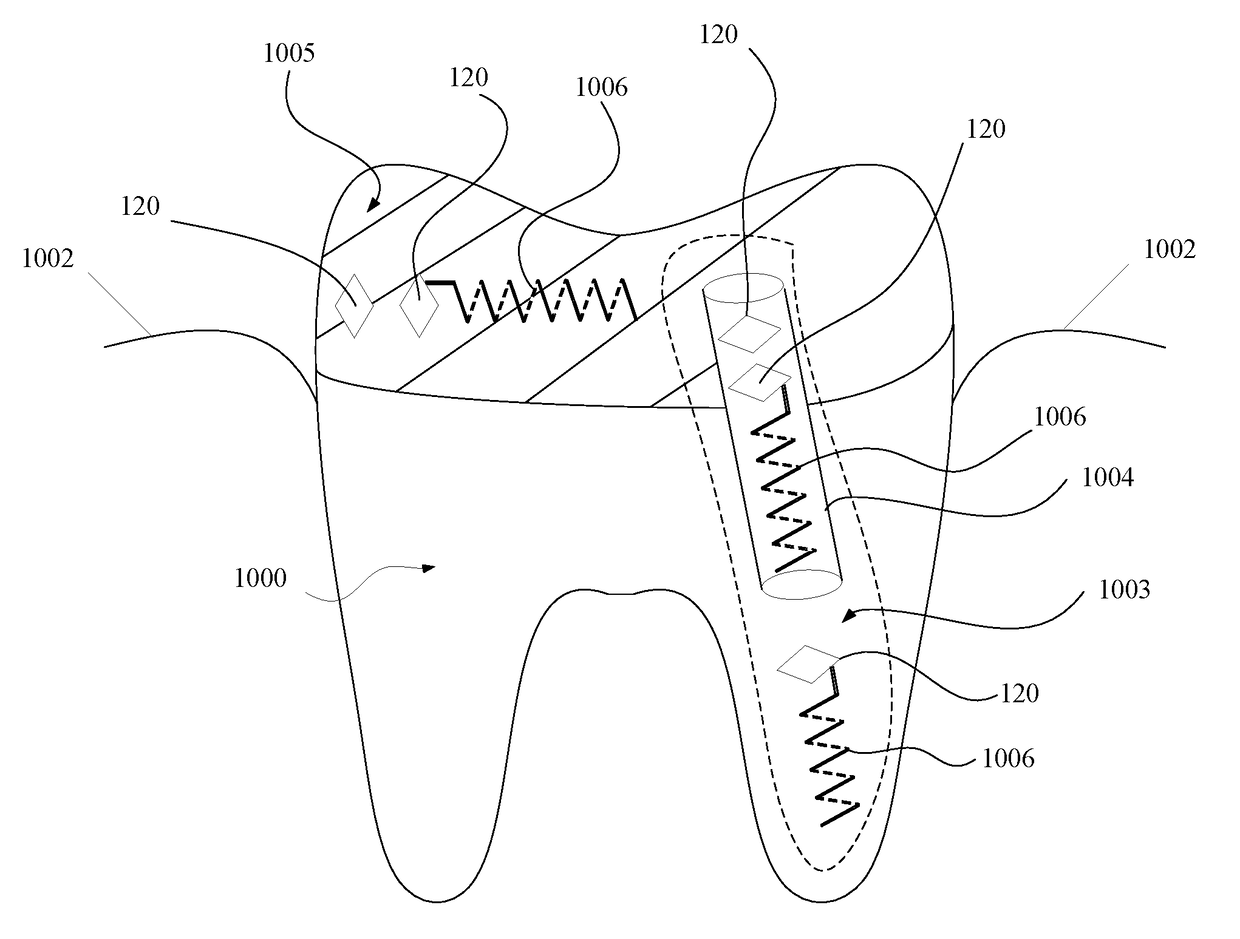

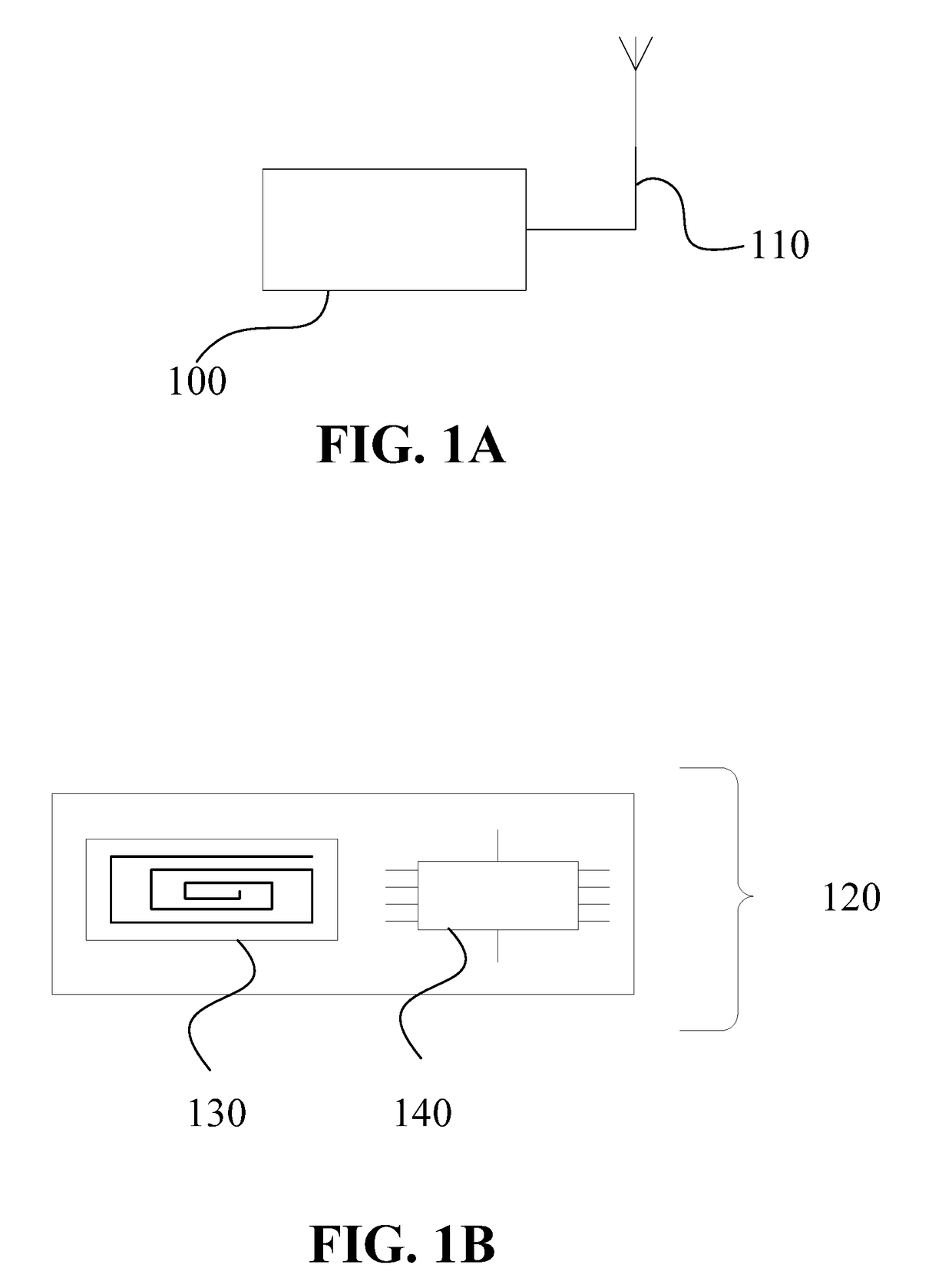

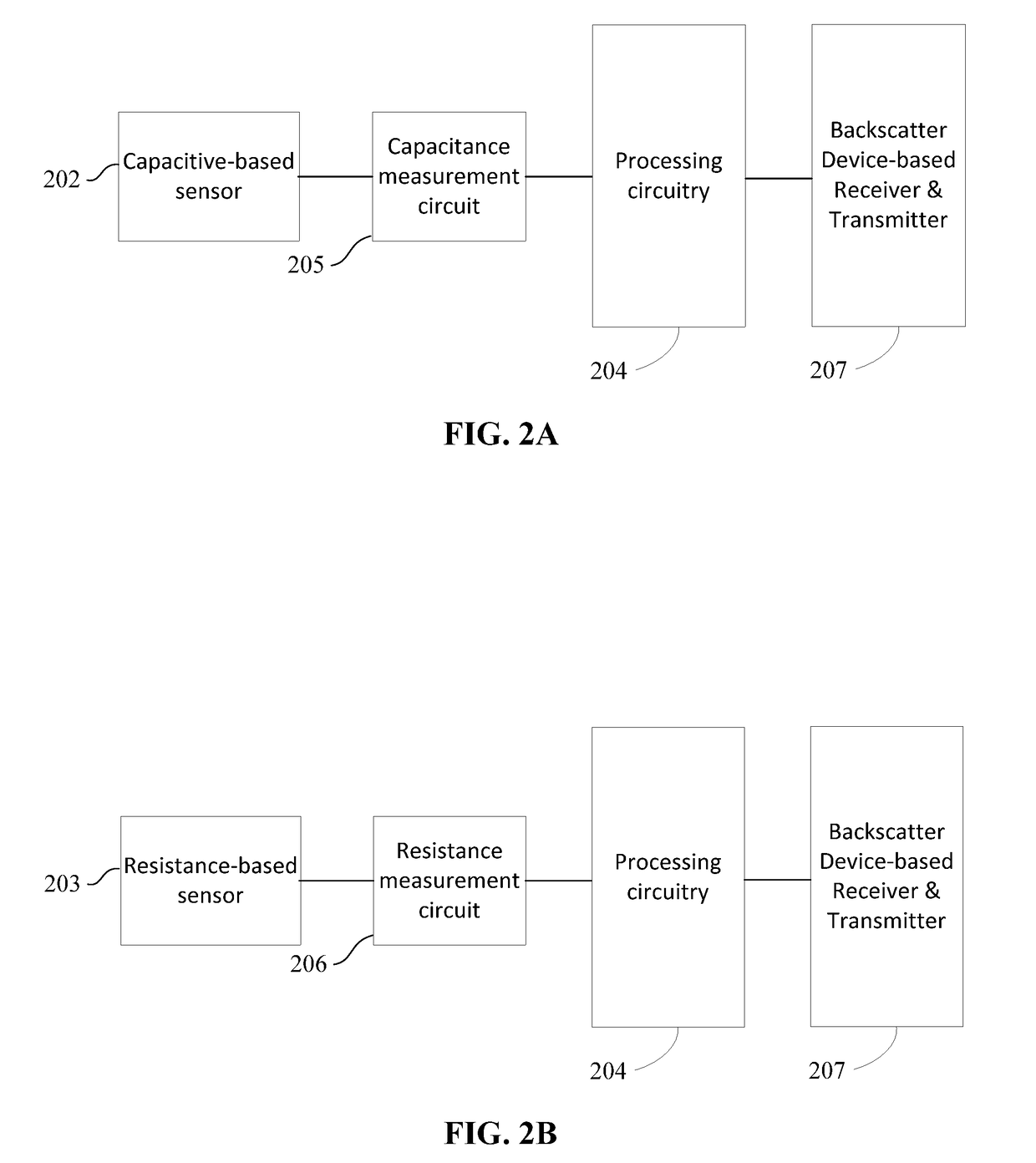

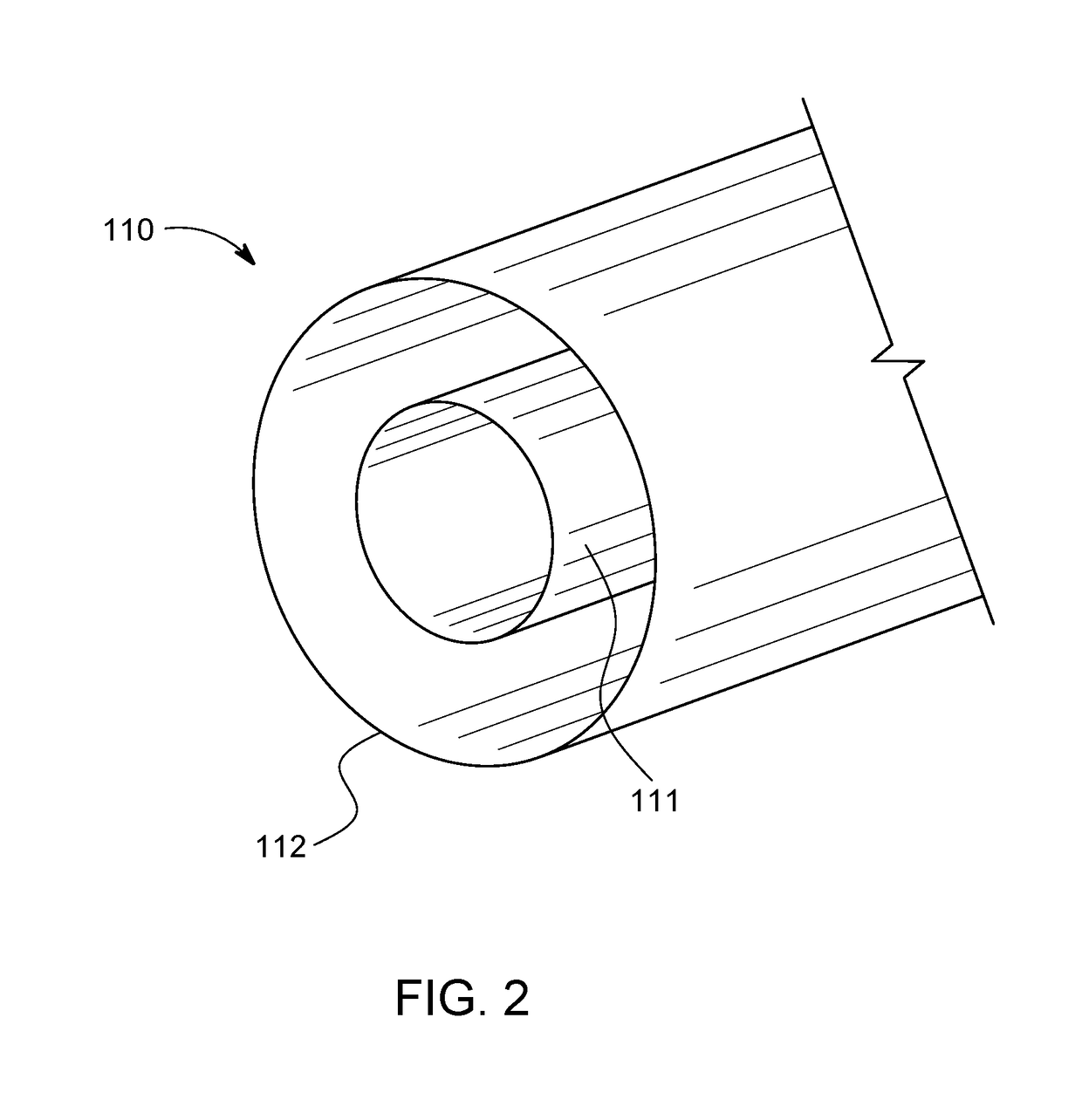

Material property monitoring and detection using wireless devices

ActiveUS20180014747A1Less-expensive to useLess-expensive to implementDental implantsArch wiresEngineeringElectromagnetic radiation

Embodiments of the present invention provide devices (tags with sensors), systems, and methods to determine states (such as, but not limited to, complex impedance) of materials-of-interest, such as tissue-of-interest, implants, and construction members, to name a few, in a non-invasive and contactless way; and using comparatively safe and / or low energy electromagnetic radiation, such as radio waves. Negligible-sized wireless-tags with sensors are implanted in such materials-of-interest. Using wireless communication and imaging technology, the states of the materials-of-interest may be monitored; which may allow non-invasive and contactless detection of problems such as cracking, bending, excessive pressure, improper temperature, and / or the like. Additionally, initially unknown locations of the implanted negligible-sized wireless-tags with sensors may be readily determined upon a given scanning (reading) session; and thus mapped to provide an effective image of the material-of-interest.

Owner:AKSELROD DAVID

Cucumber planting method

The present invention provides a cucumber planting method. The method comprises the following steps: (1) seed treatment; (2) seedling bed preparation; (3) sowing; (4) film covering; (5) temperature controlling; (6) seedling raising stage; (7) seedling strengthening stage; (8) field preparation; (9) transplanting; (10) frame mounting; (11) field fertilizing; (12) field weeding; (13) water management; and (14) diseases and pests prevention and control. According to the planting method provided by the present invention, before sowing, two times of sterilization is performed on cucumber seeds to prevent bacteria infection and rot after the cucumber seeds are planted, the germination rate of cucumber seedling is improved, and therefore the production is further increased; in addition, a seedling shed is built, and a cucumber strong seedling is cultivated in the seedling shed at first, then the strong seedling is transplanted outdoors, thereby preventing rotting caused by rainwater immersion or improper temperature control before the growth of the strong seedling, so that the germination rate of the cucumber seedling is improved.

Owner:兴业县葵阳镇农业服务中心

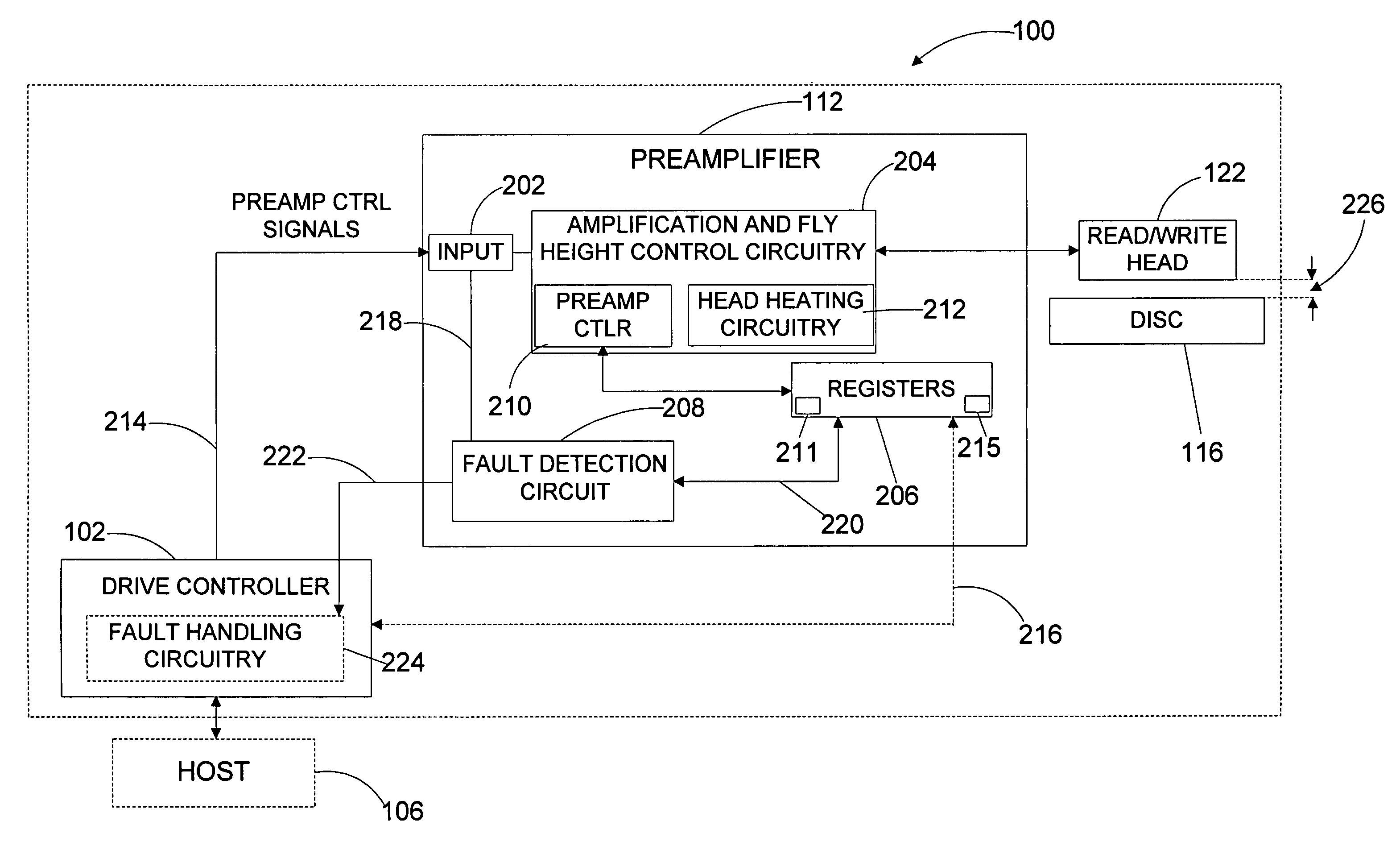

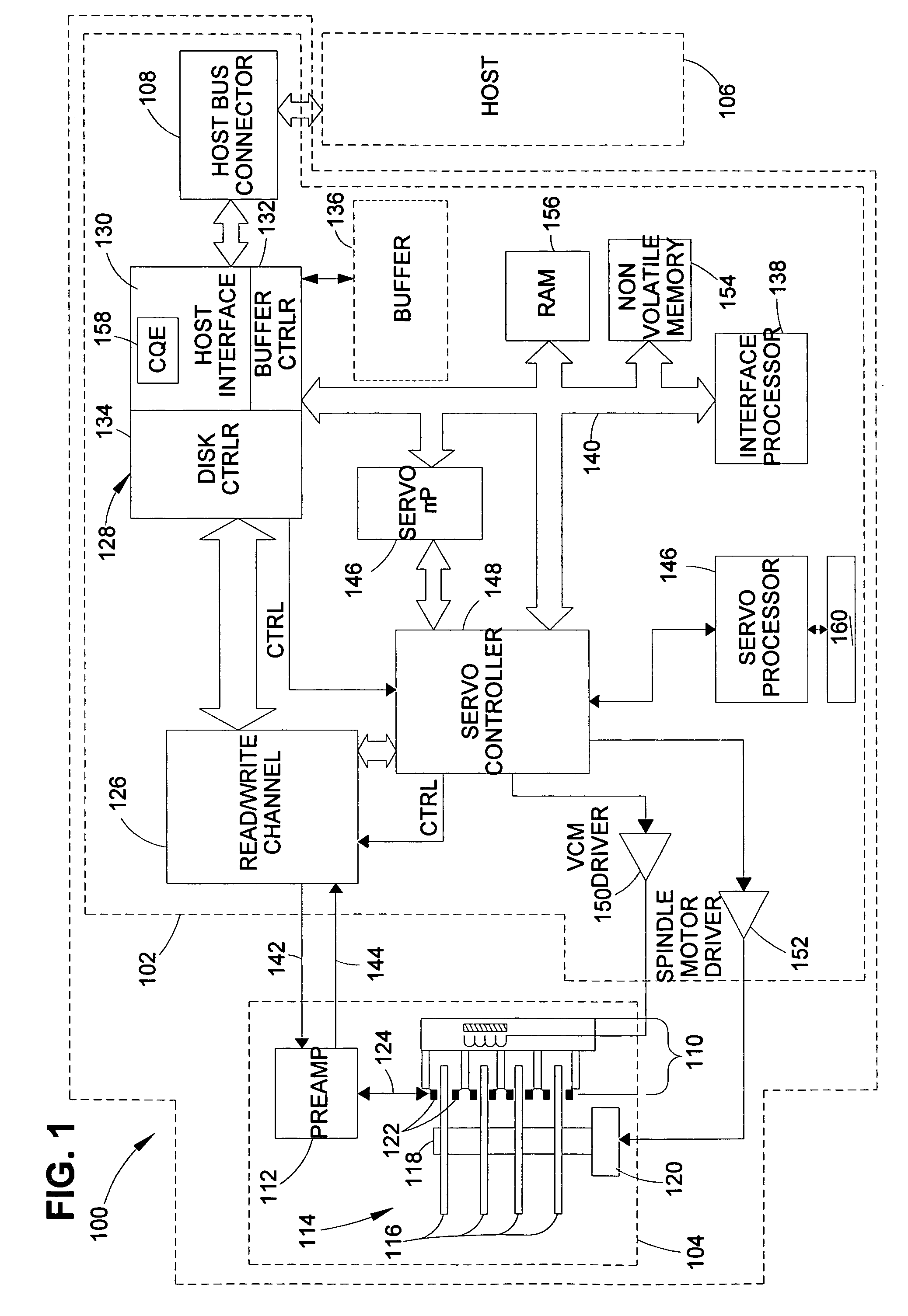

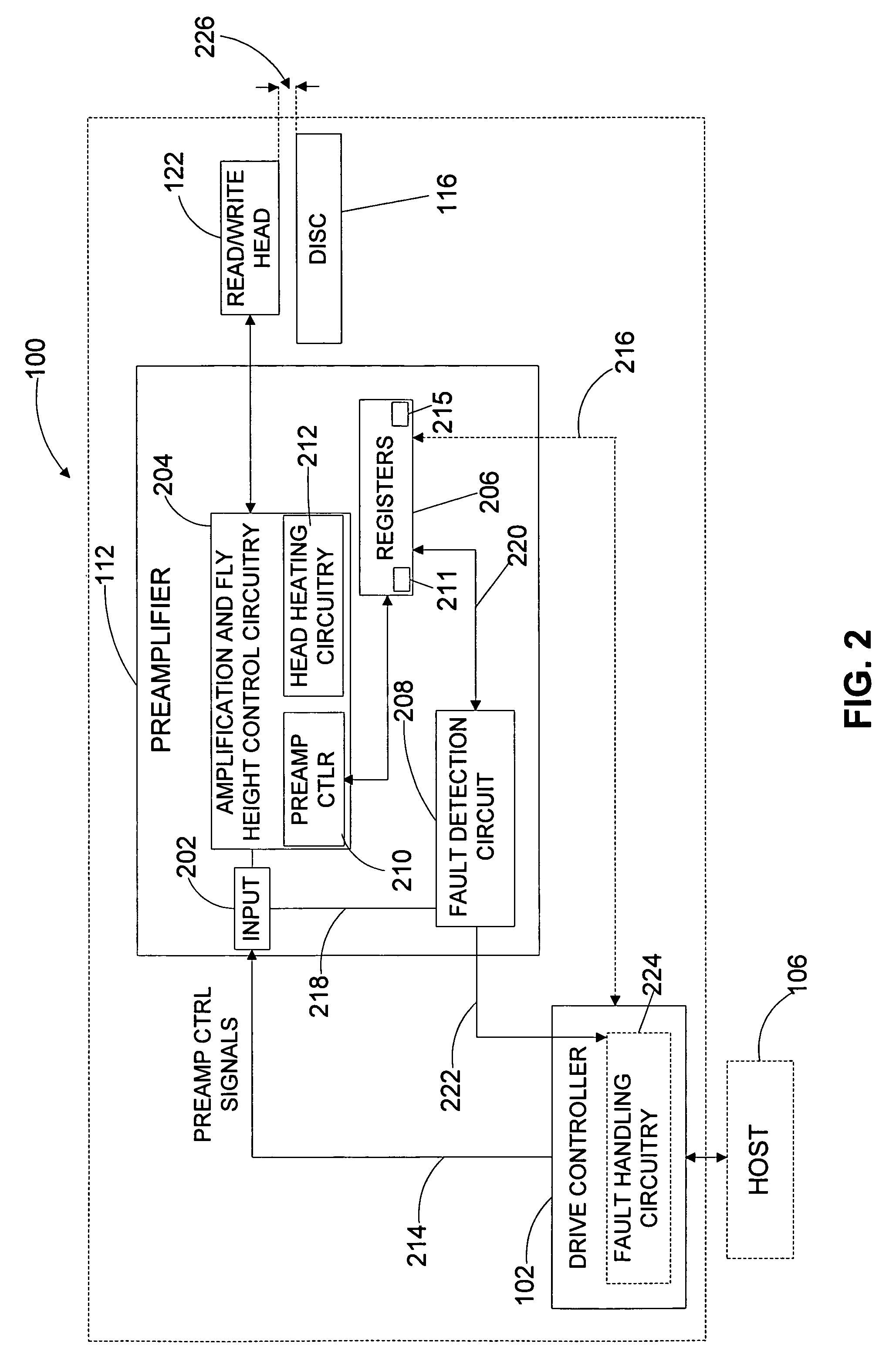

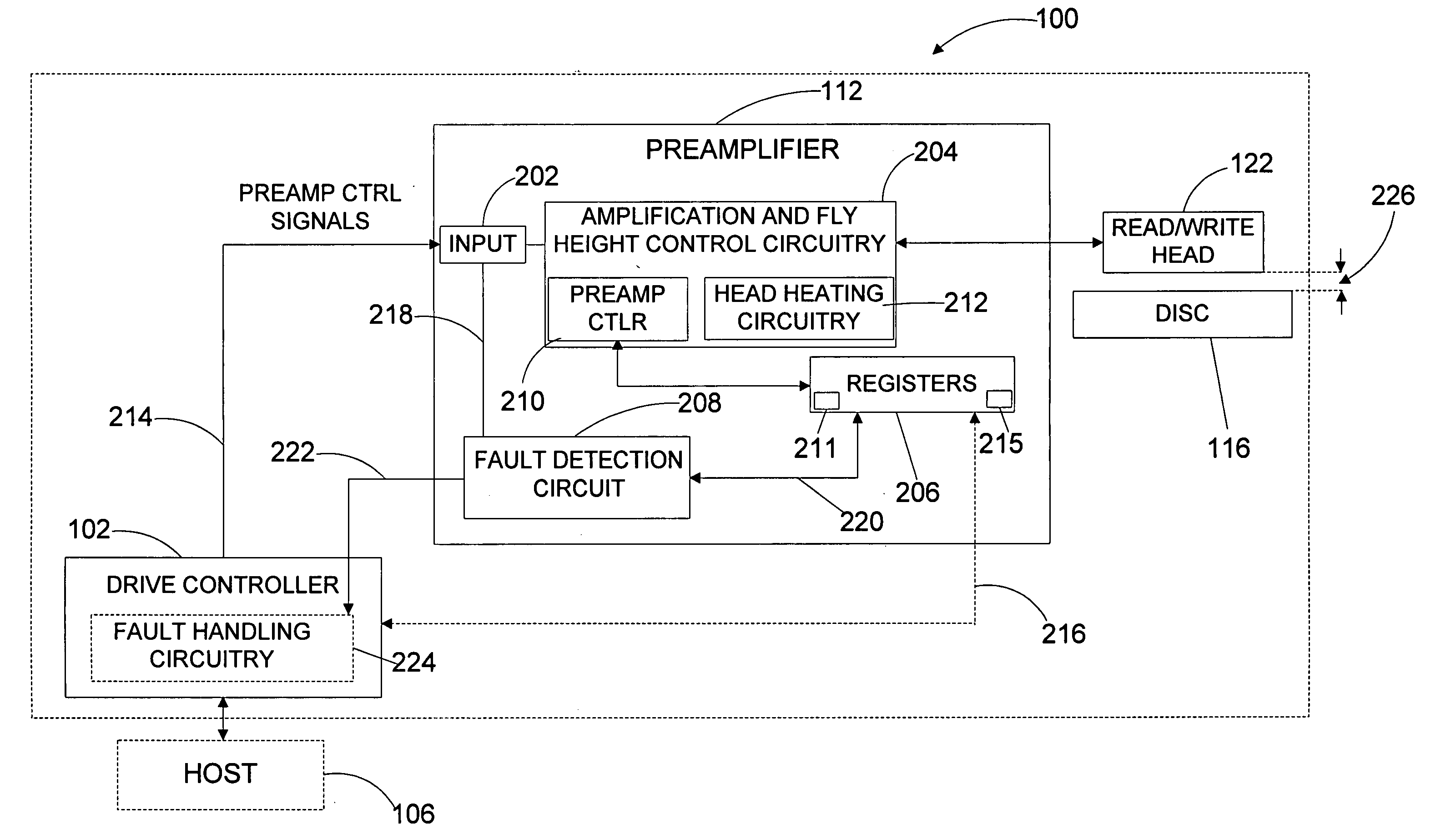

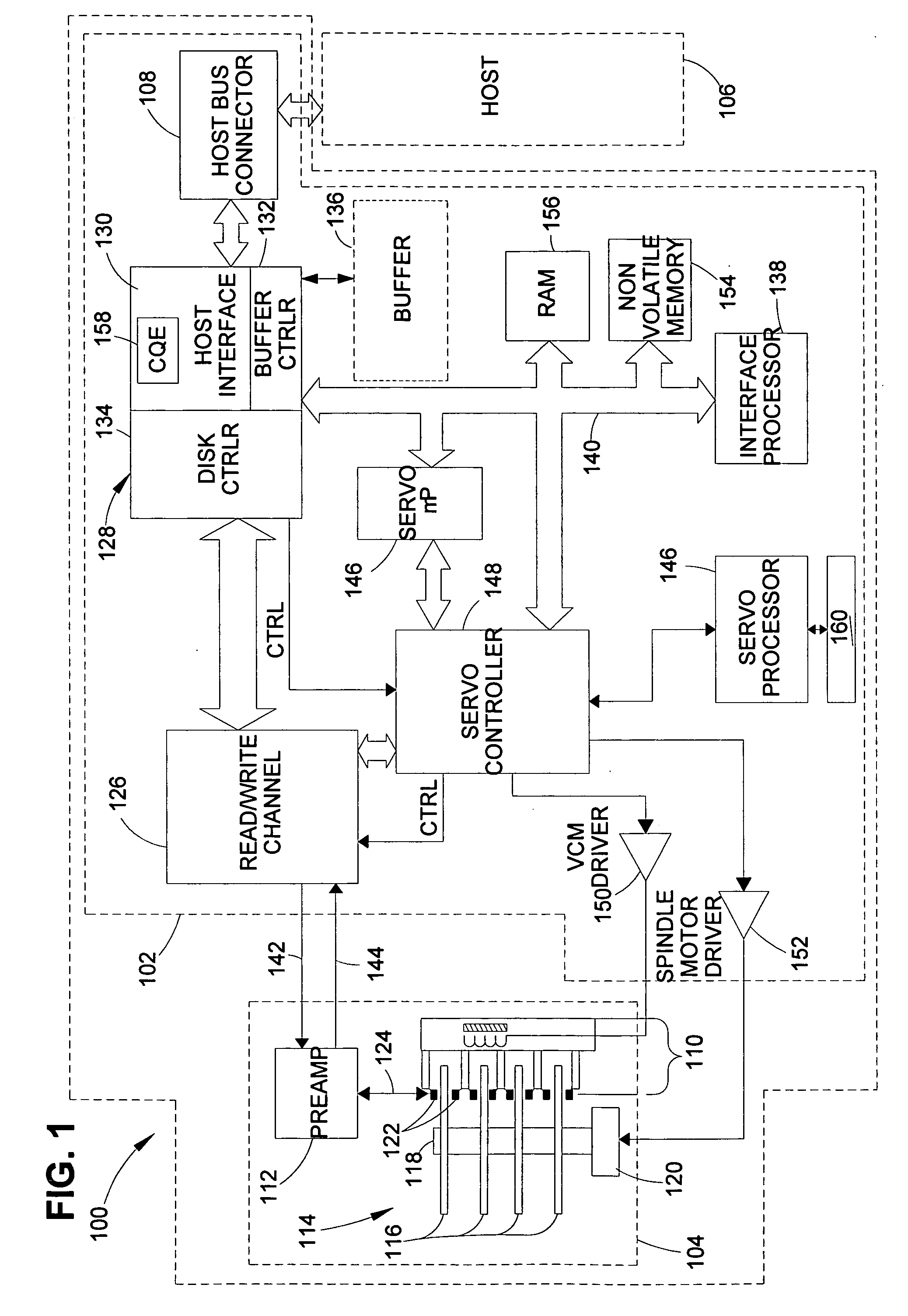

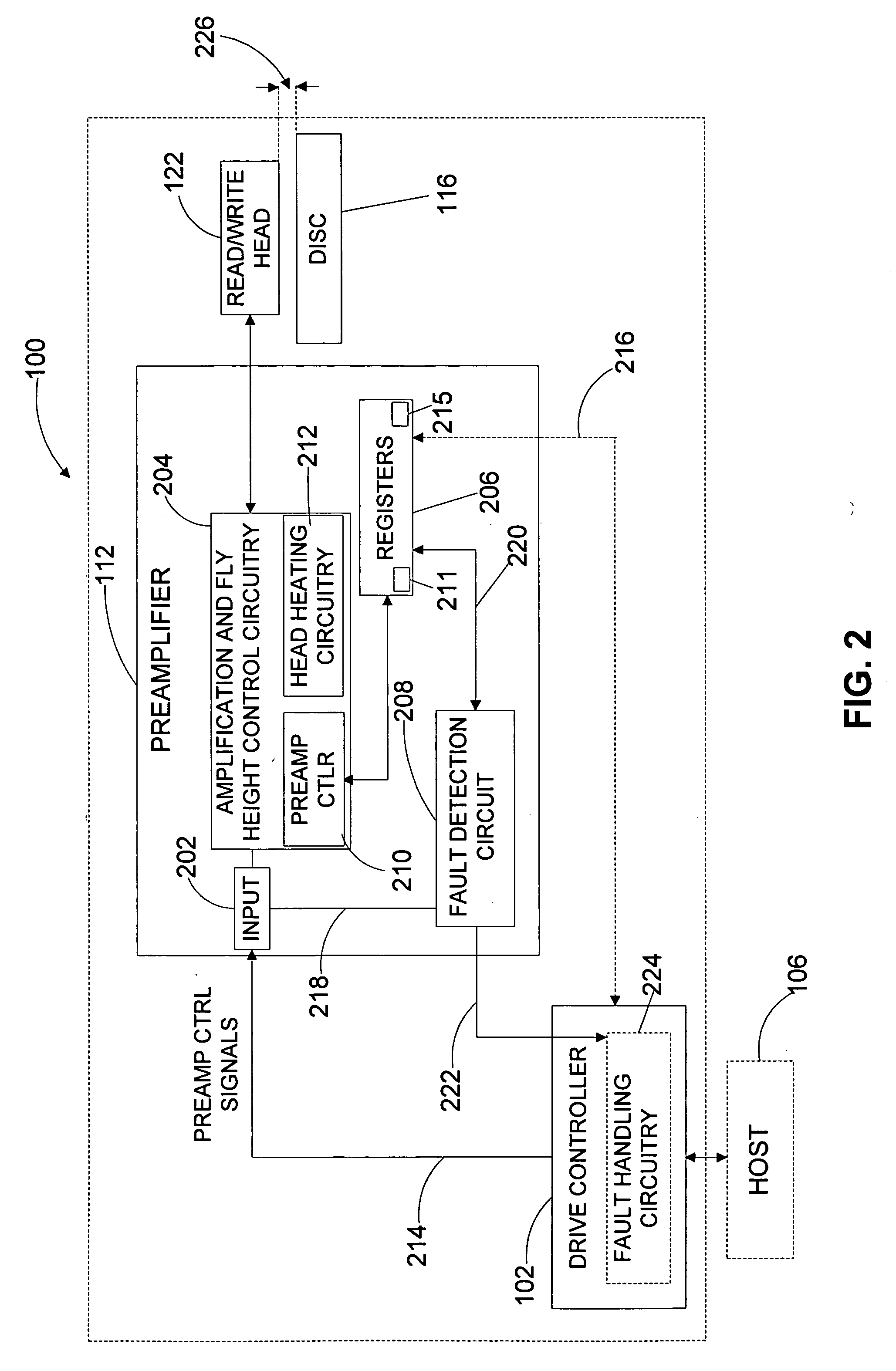

Preamplifier for use in data storage devices

A preamplifier that includes an input configured to receive a preamplifier control signal and a fault detection circuit configured to monitor the preamplifier control signal received at the input is provided. The fault detection circuit is further configured to identify a fault condition triggered by an improper temperature control signal provided by the preamplifier.

Owner:SEAGATE TECH LLC

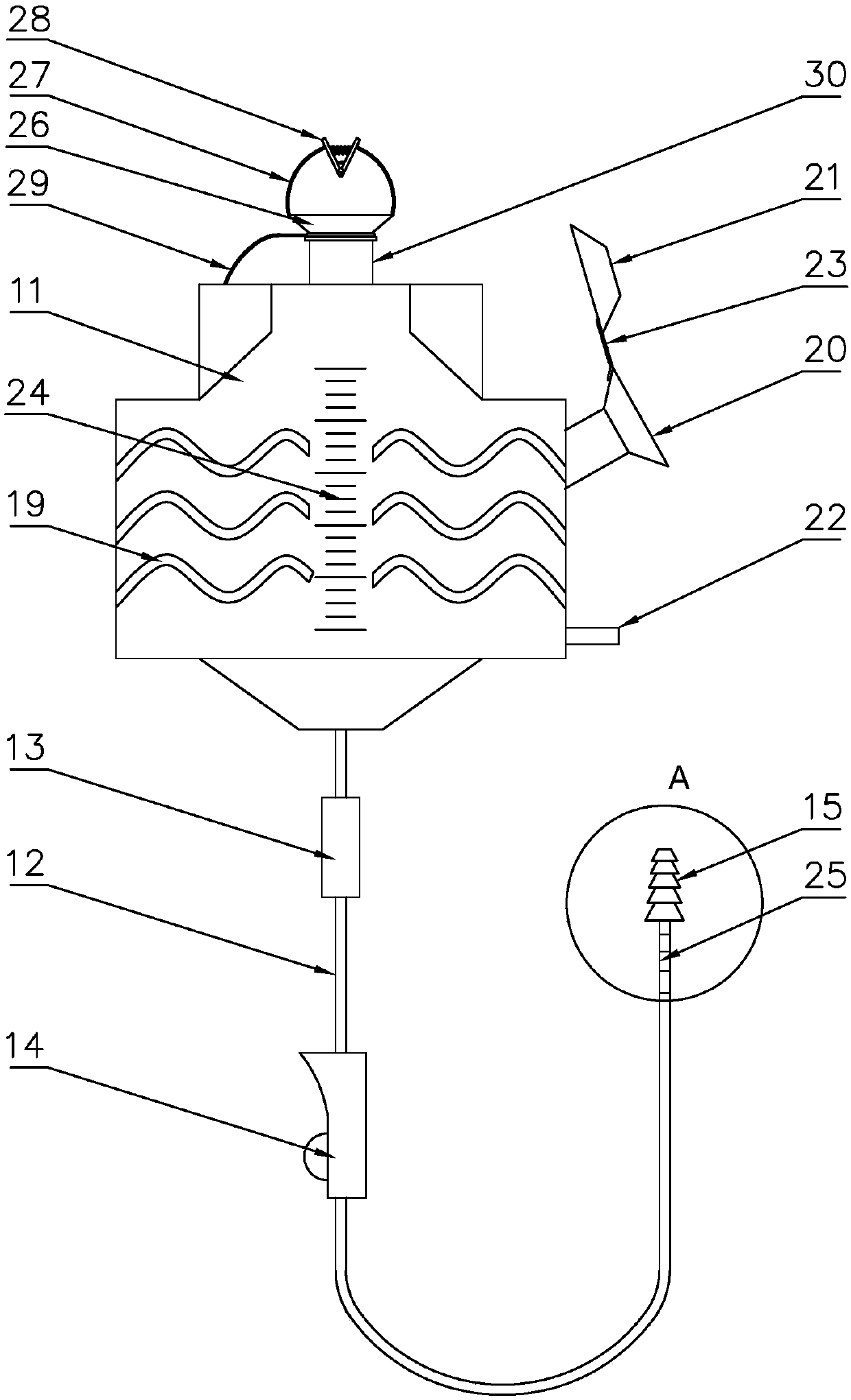

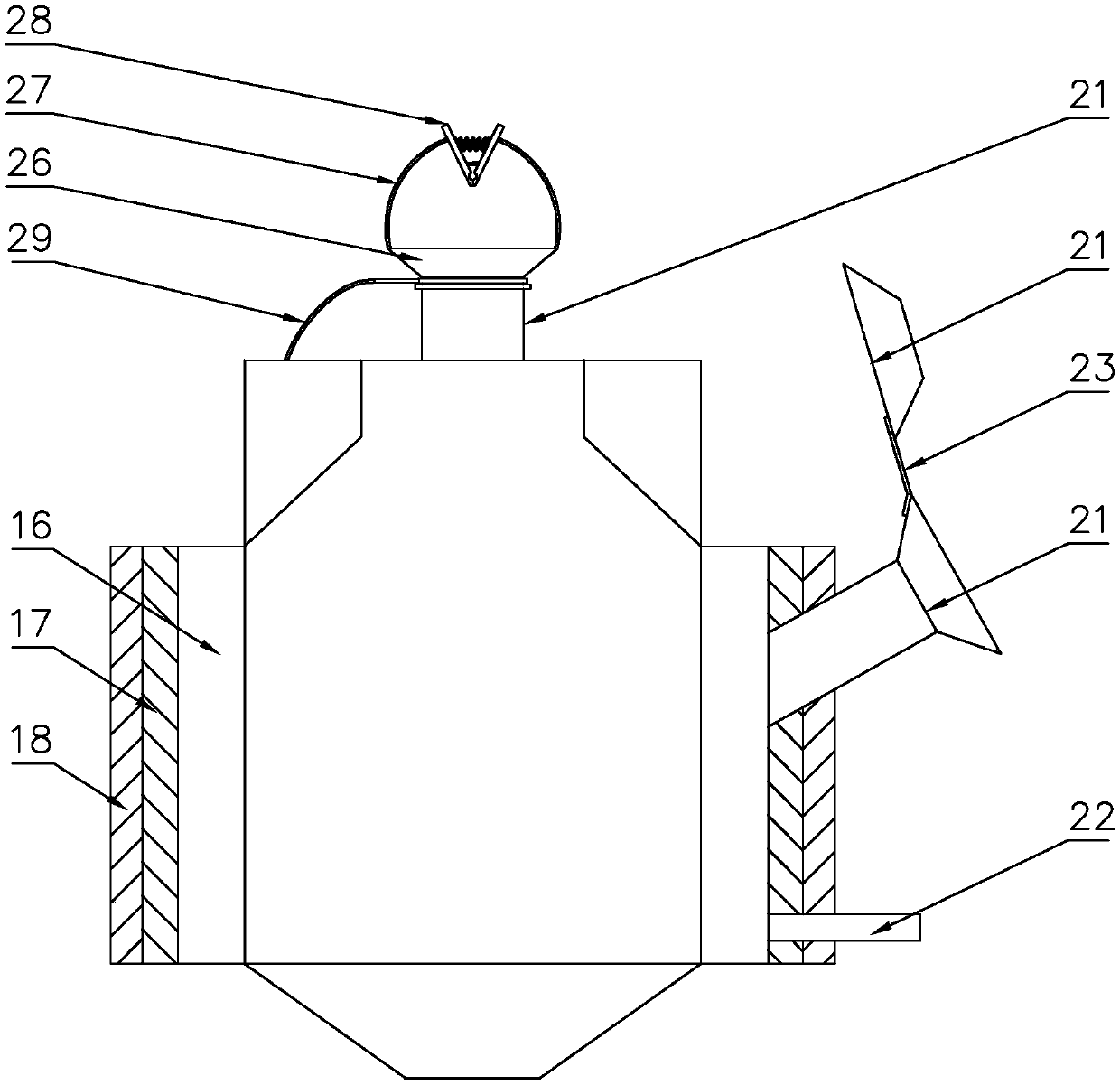

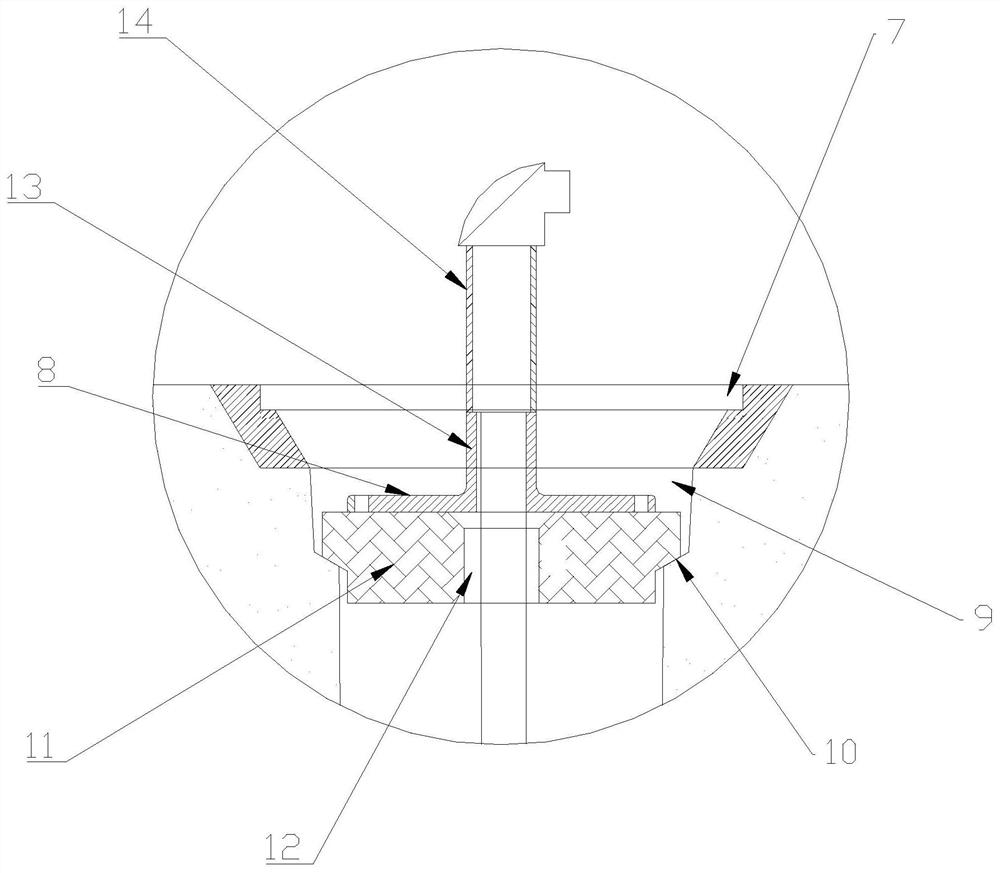

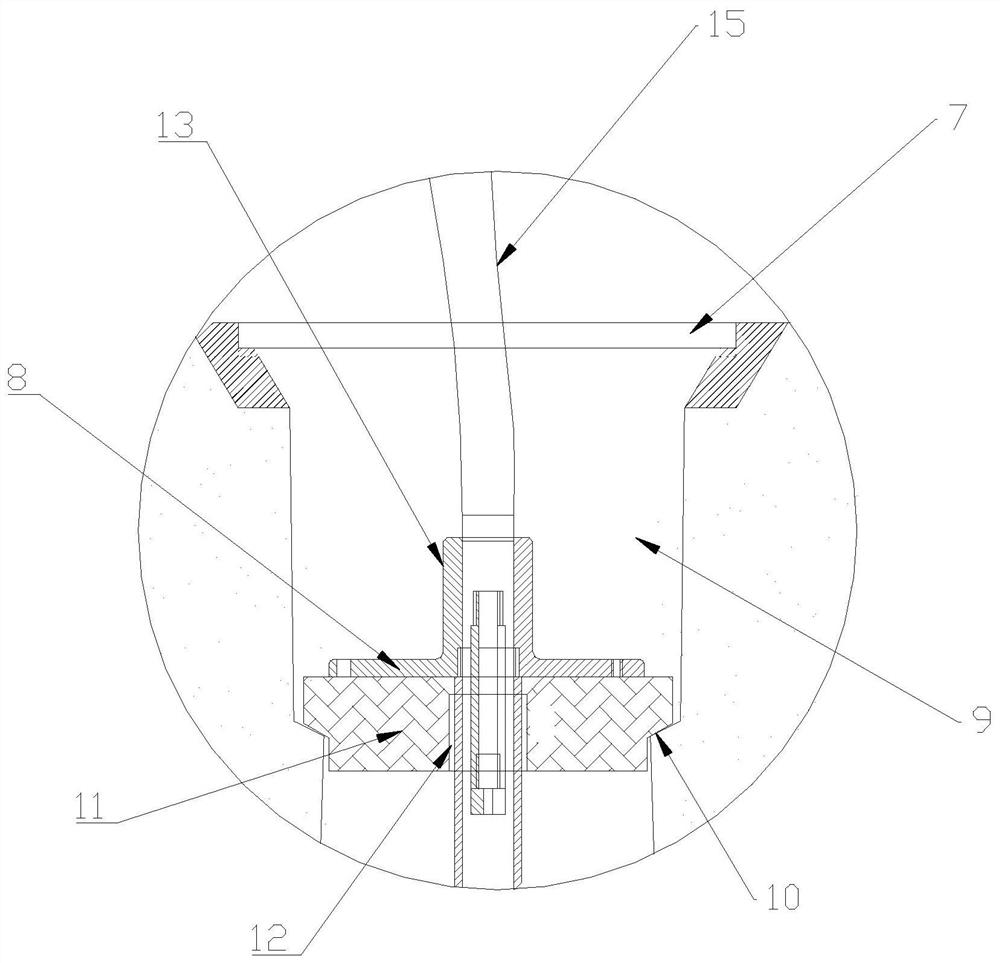

Flow channel switching valve and shower system

InactiveCN1860319AMiniaturizationOperating means/releasing devices for valvesBathsEngineeringVALVE PORT

A channel switching valve (A) of the present invention includes a discharge hole (14) which discharges water having a proper temperature and a drain hole (15) which drains water having an improper temperature. A part of a first channel (11) extending from a hot water supply port (24b) to the discharge hole and a part of a second channel (11) extending from the hot water supply port to the drain hole are common. Therefore, the channel switching valve can be compact.

Owner:MYM CORP

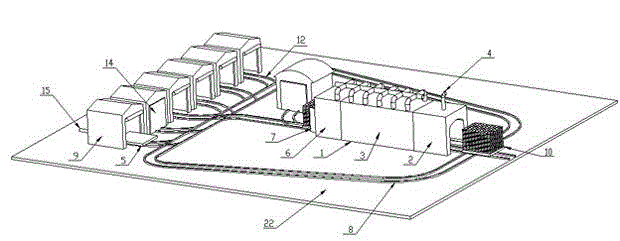

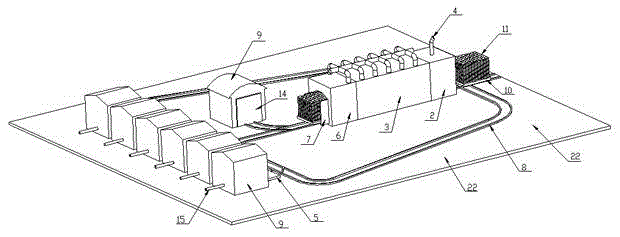

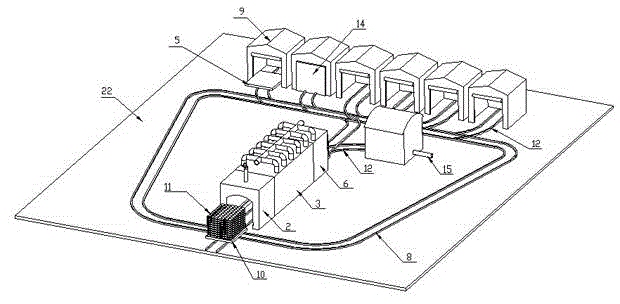

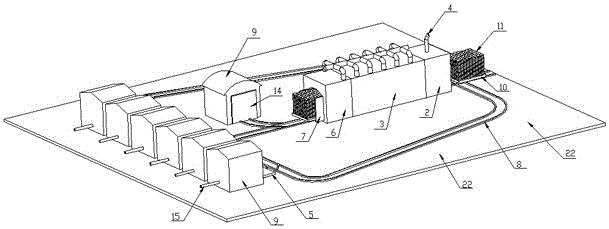

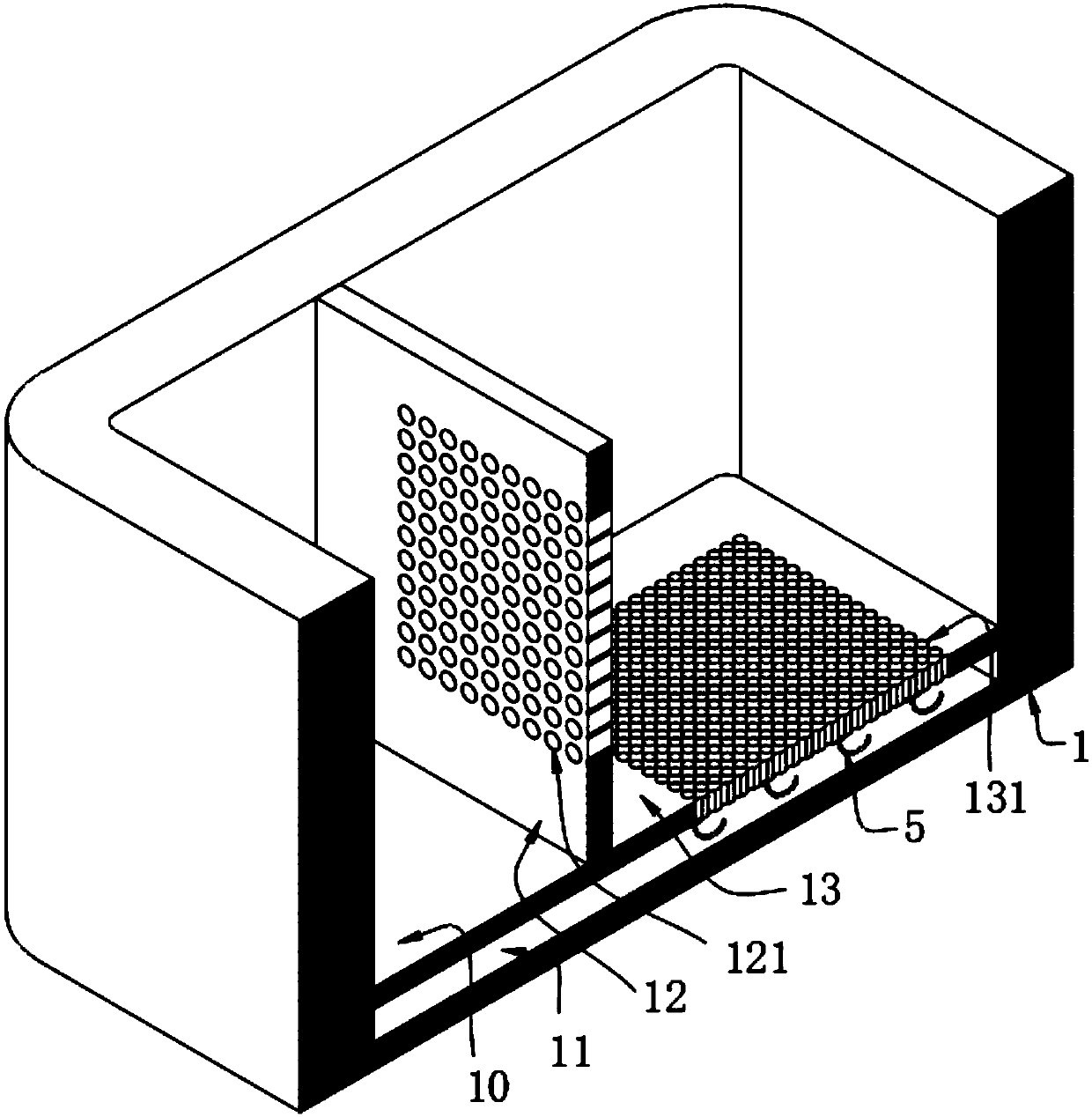

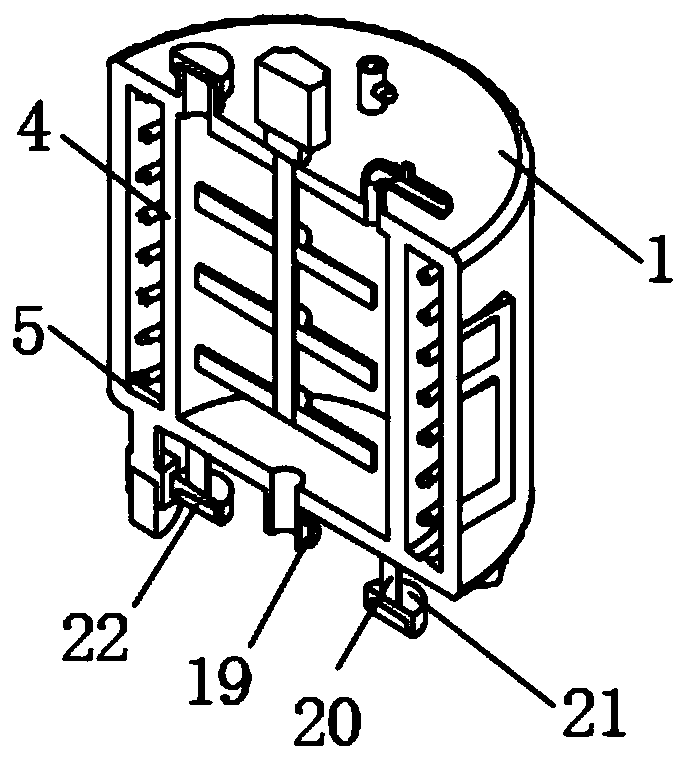

Split type tunnel kiln

The invention discloses a split type tunnel kiln. A kiln body (1) is divided into a preheating chamber (2) and a sintering chamber (3) in the moving direction of a trolley (10). Cooling chambers (9) of the tunnel kiln are arranged around the kiln body (1) and separated from the sintering chamber (3). Sintered products (11) coming out of the sintering chamber (3) are conveyed to the cooling chambers (9) through a transfer trolley (5) which moves back and forth between a transfer chamber (6) and the cooling chambers (9). The split type tunnel kiln can improve production efficiency greatly, products of different technological requirements are sent to different cooling chambers for cooling, so that the situation that the baking process of the whole tunnel kiln is changed completely due to different technological requirements of different products is avoided, cold breakage or hot breakage caused by improper temperature control is avoided, the qualified rate of the products is improved, investment is saved, and the application range is wide.

Owner:彭州市半陶陶瓷有限责任公司

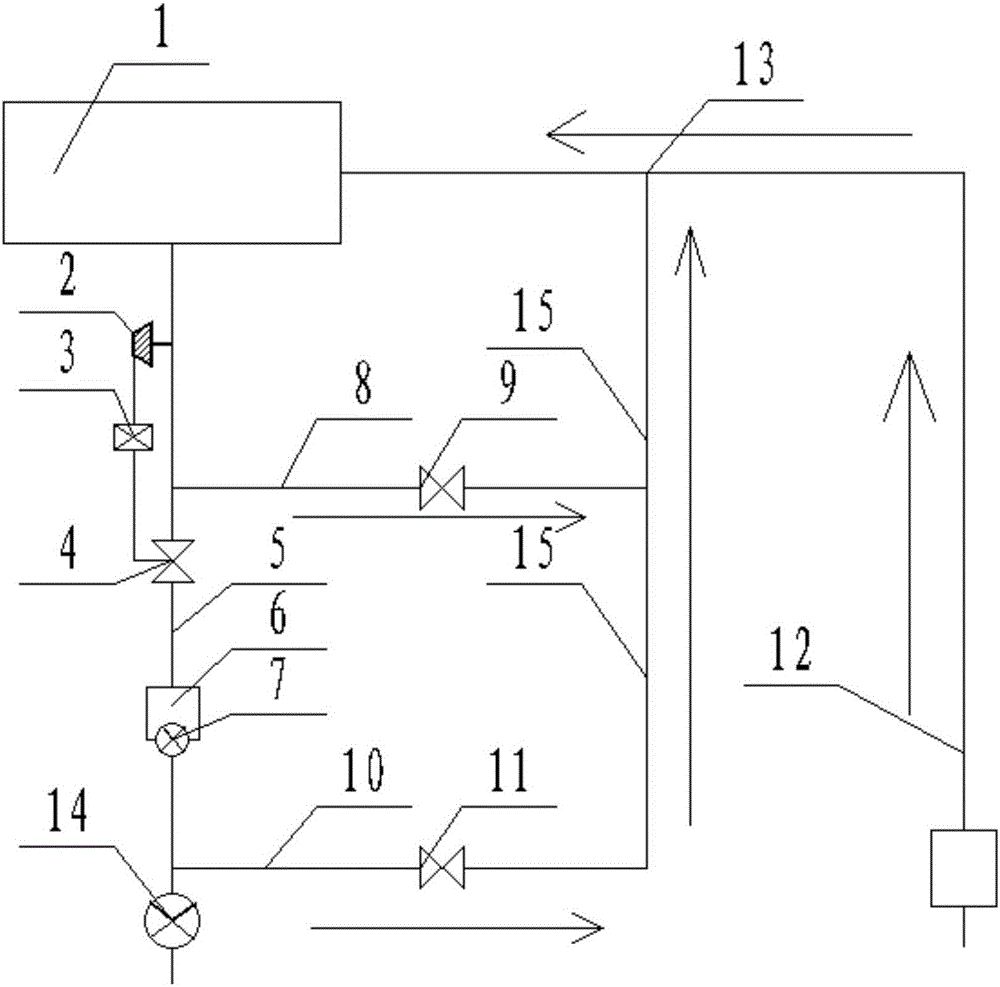

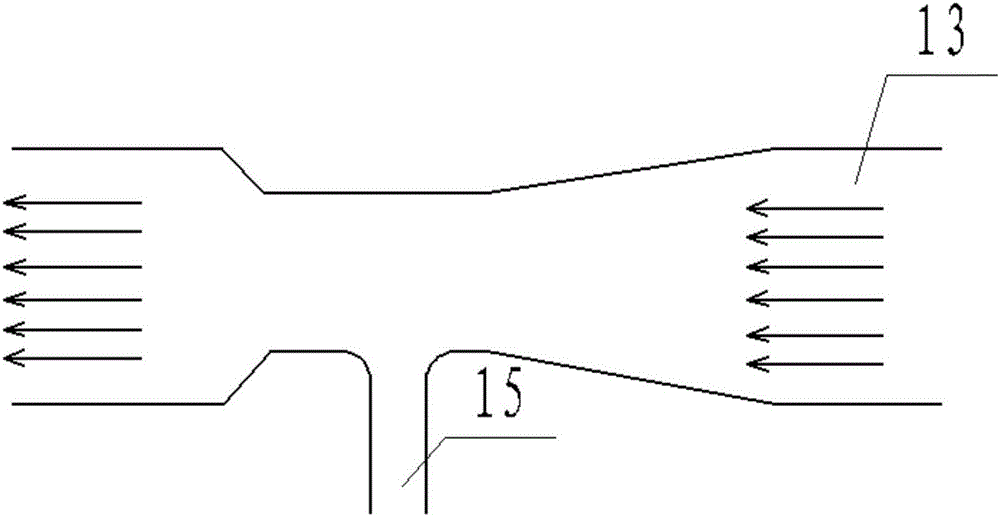

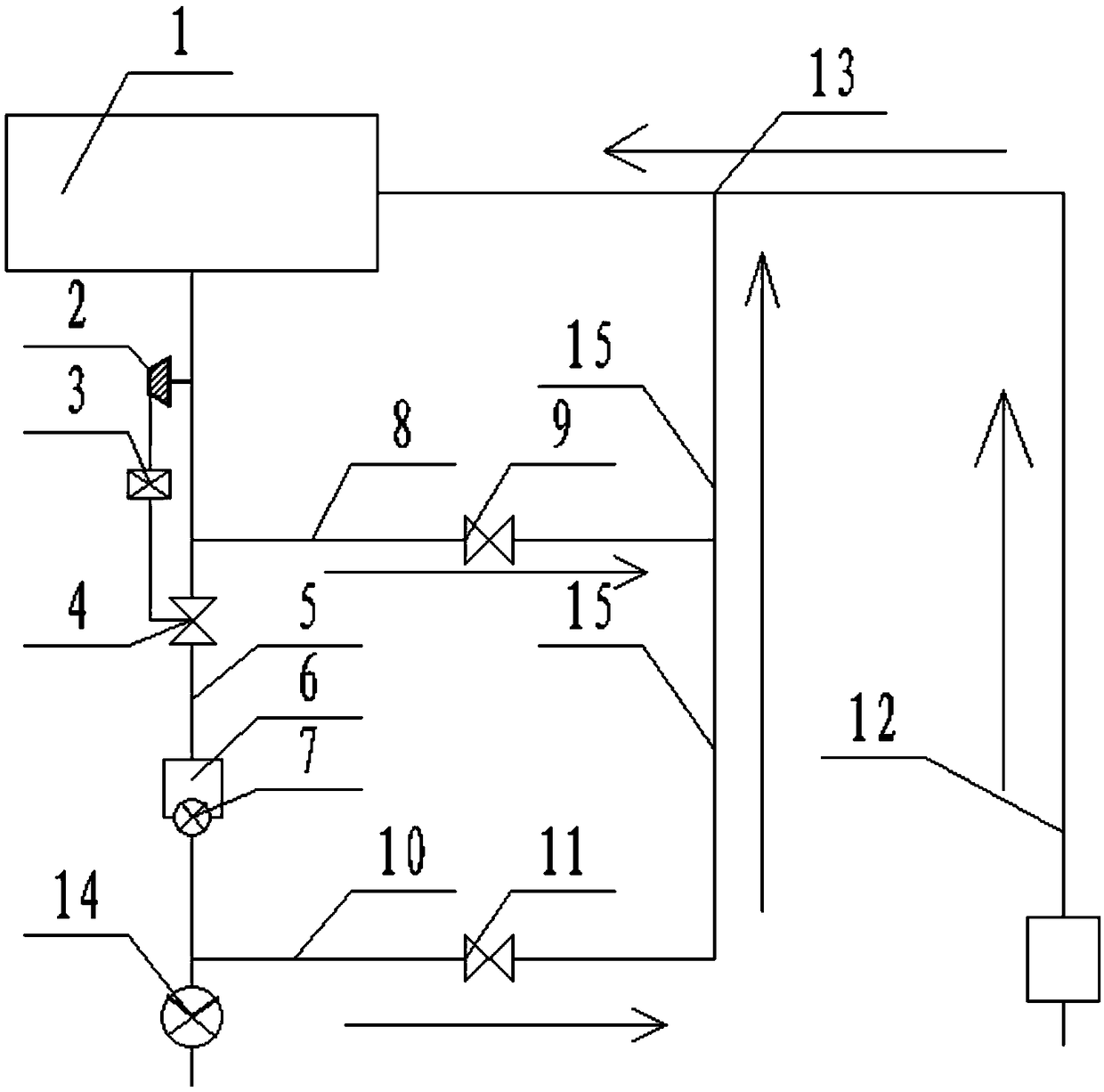

Efficient water-saving temperature control device

ActiveCN106247627AGuaranteed continuous supplyControl water temperatureFluid heatersTemperature controlWater saving

The invention provides an efficient water-saving temperature control device. The efficient water-saving temperature control device comprises a water heater, a temperature sensor, a controller, an electric valve, a hot water pipeline, an infusion type water tank, a valve, a first backflow pipeline, a first check valve, a second backflow pipeline, a second check valve, a water heater water inlet pipeline, a Venturi tube, a main valve and a main backflow pipe. According to the efficient water-saving temperature control device, through the arrangement of the sensor, the electric control device, the backflow pipelines and the Venturi tube, recycling of improper-temperature flow flowing out of a water heater is achieved, the problem of waste caused by retardance of valve closing and water cutting-off is solved, and the effects of controlling the water temperature and ensuring continuous supply of hot water can further be achieved to a certain extent.

Owner:常熟市铜业总公司有限公司

Material property monitoring using backscatter devices

ActiveUS20180017512A1Less-expensive to useLess-expensive to implementFastening prosthesisDiagnostic markersEngineeringElectromagnetic radiation

Embodiments of the present invention provide devices (tags), systems, and methods to determine structural integrity and other states of materials-of-interest, such as dental fillings, implants, and root canal posts, to name a few, in a non-invasive and contactless way; and using comparatively safe and / or low energy electromagnetic radiation, such as radio waves. Negligible-sized backscatter-tags with sensors are implanted in such materials-of-interest. Using backscatter imaging technology, the structural integrity and other states of the materials-of-interest may be monitored; which may allow non-invasive and contactless detection of problems such as cracking, bending, excessive pressure, improper temperature, and / or the like. Additionally, initially unknown locations of the implanted negligible-sized backscatter-tags with sensors may be readily determined upon a given scanning (reading) session; and thus mapped to provide an effective image of the material-of-interest.

Owner:AKSELROD DAVID

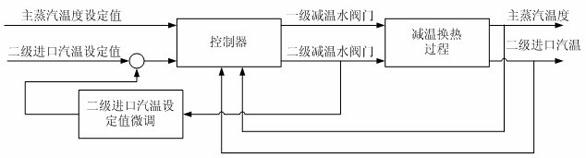

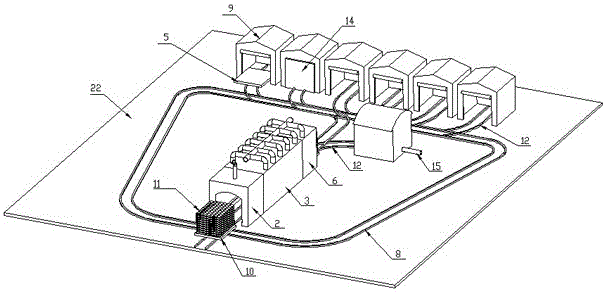

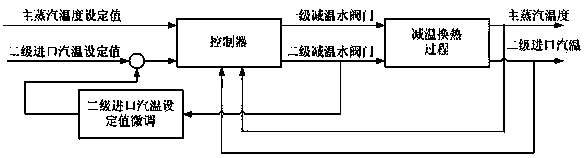

Secondary temperature-decreasing water valve position self-optimizing method in main steam temperature control

InactiveCN102588949AStable temperatureAdequate means of adjustmentSuperheating controlAuto regulationLower limit

The invention discloses a secondary temperature-decreasing water valve position self-optimizing method in main steam temperature control. For the existing main steam temperature closed-loop control process, the improper temperature setting value of a secondary inlet regularly causes a too low or too high working point of the secondary temperature-decreasing water valve, so that the secondary temperature-decreasing water valve loses the adjusting capacity in the subsequent time. The secondary temperature-decreasing water valve position self-optimizing method overcomes the existing disadvantages through the following steps of: (1) setting upper limit and the lower limit for the optimization of the secondary temperature-decreasing water valve; (2) setting the filter time for the secondary temperature-decreasing water valve; (3) setting the automatic steam temperature adjusting condition for the secondary inlet; and (4) setting a maximum offset of the automatic steam temperature adjustment for the secondary inlet. According to the method provided by the invention, the secondary temperature-decreasing water valve is enabled to be always in a proper position so as to ensure enough adjusting margin on the up stroke and the down stroke, and sufficient adjusting means are guaranteed in case of unexpected disturbance; in a varying load process, the function can more easily enable the main steam temperature to be stable.

Owner:ZHEJIANG UNIV

Preamplifier for use in data storage devices

InactiveUS20070053092A1Record information storageAnalogue recordingAudio power amplifierControl signal

A preamplifier that includes an input configured to receive a preamplifier control signal and a fault detection circuit configured to monitor the preamplifier control signal received at the input is provided. The fault detection circuit is further configured to identify a fault condition triggered by an improper temperature control signal provided by the preamplifier.

Owner:SEAGATE TECH LLC

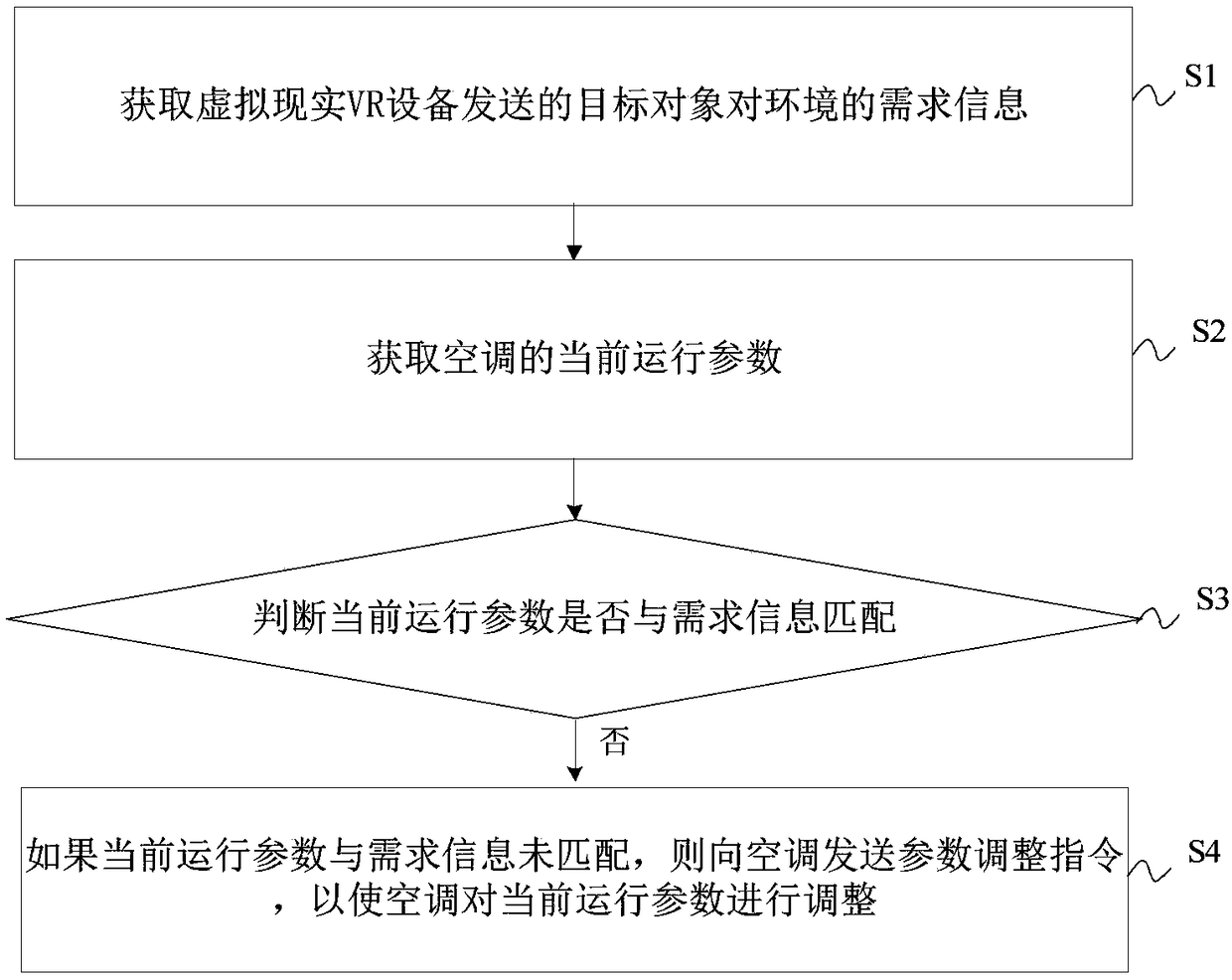

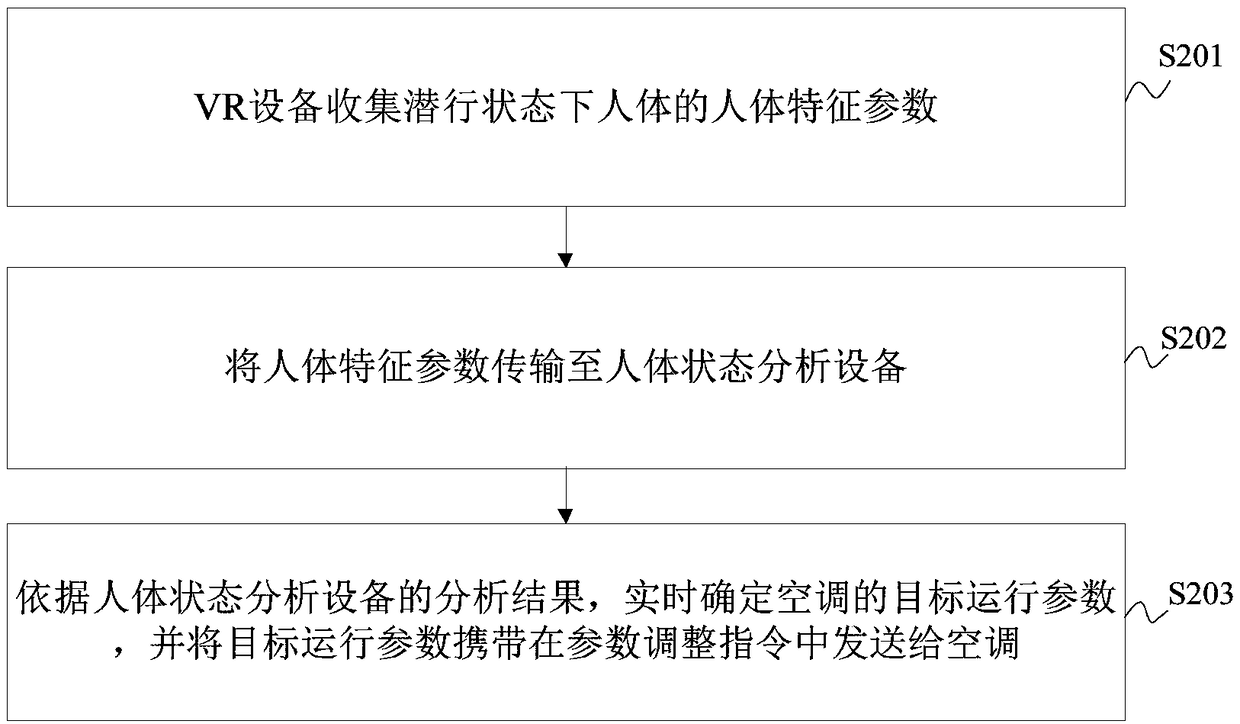

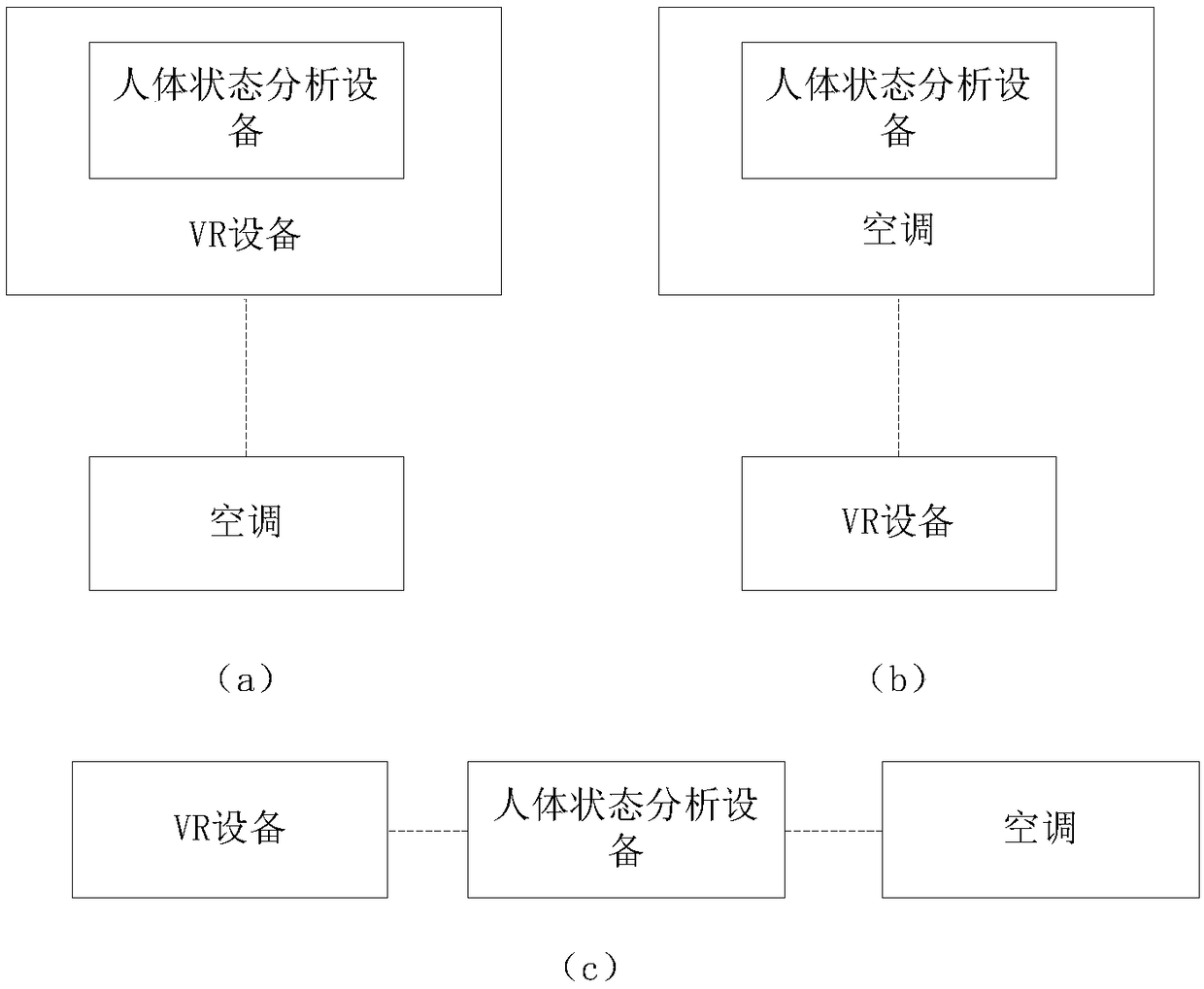

Air conditioner control method, device and system

InactiveCN109282438AImprove perceptionImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusSimulationImproper Temperature

The invention discloses an air conditioner control method, device and system. The method comprises the following steps: acquiring environment demand information, of a target object, sent by a VR device; acquiring current running parameters of an air conditioner; determining whether the current running parameters are matched with the demand information; and if the current running parameters are notmatched with the demand information, sending a parameter adjusting instruction to the air conditioner in order to adjust the current running parameters through the air conditioner. According to the method, the current running parameters of the air conditioner can be adjusted based on the environment demand information of the target object when the current running parameters of the air conditionerare not matched with the environment demand information of the target object, so that the sensing ability of a user in a VR world to the environment can be improved; the comfort of the user can be effectively improved; and the damage of diving in an environment with improper temperature and humidity for a long time to body health can be avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

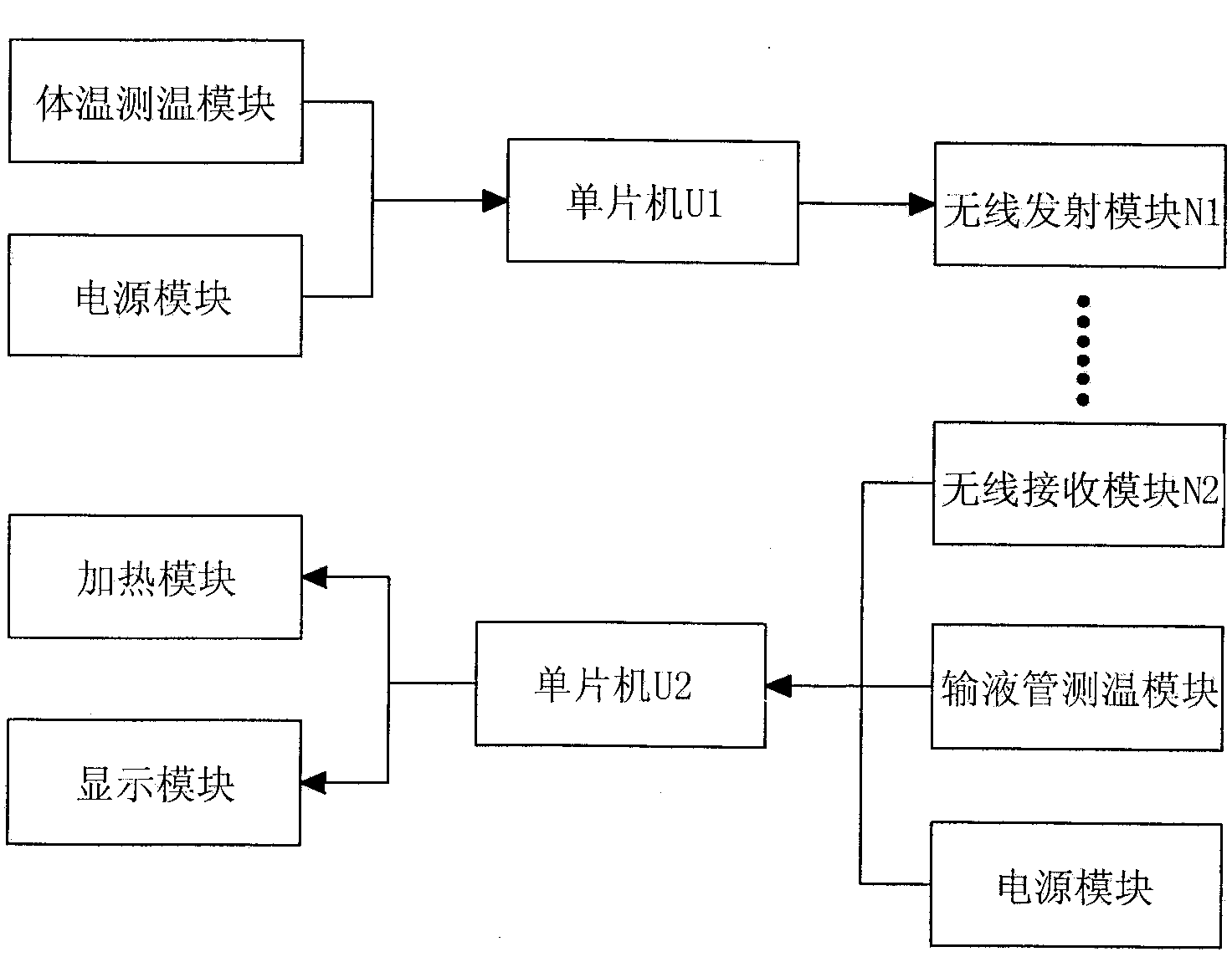

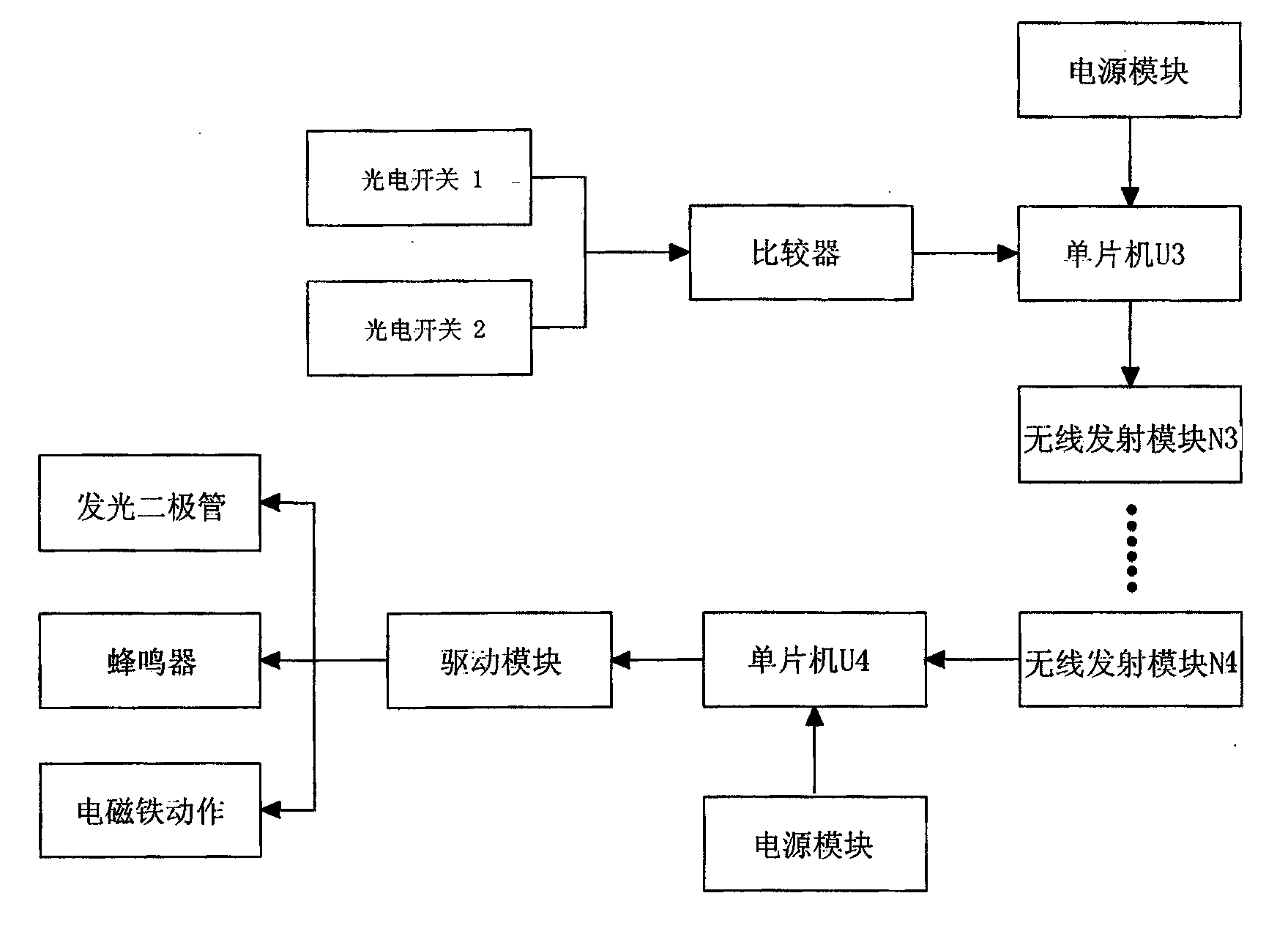

Transfusion method, transfusion pipe heating method and system

ActiveCN104288875AAvoid adverse reactionsAdd comparison functionMedical devicesFlow monitorsBody temperature measureEngineering

The invention provides a transfusion method and a transfusion pipe heating method and system. A body temperature measuring module is utilized to measure the temperature of a human body, meanwhile a transfusion pipe temperature measuring module is utilized to measure the temperature of fluid at the outlet end of the transfusion pipe, then a single chip microcomputer controls the transfusion pipe heating system to heat the transfusion pipe according to the temperature difference to enable the fluid temperature at the outlet end of the transfusion pipe to change with the temperature of a human body to achieve the effect that the temperature of the fluid at the outlet end of the transfusion pipe, and the problem that a transfusion patient has adverse reaction caused by improper temperature in the transfusion treatment process is solved.

Owner:魏峥

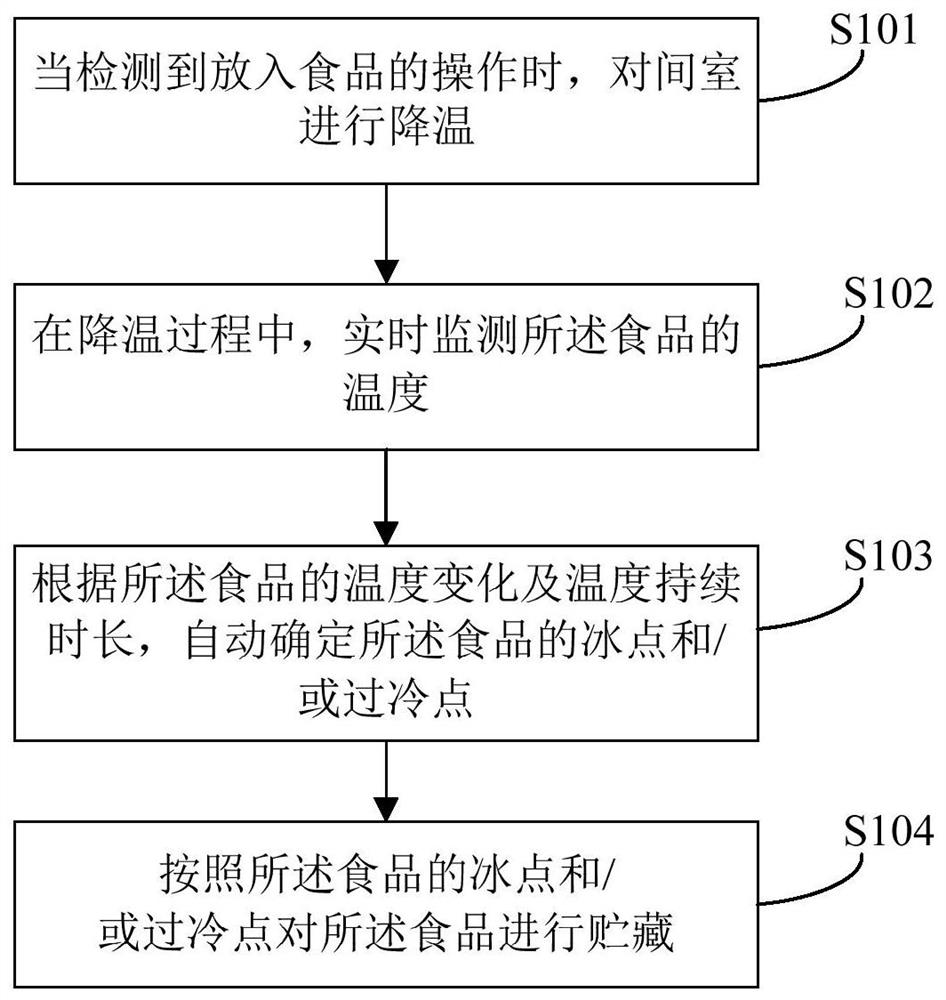

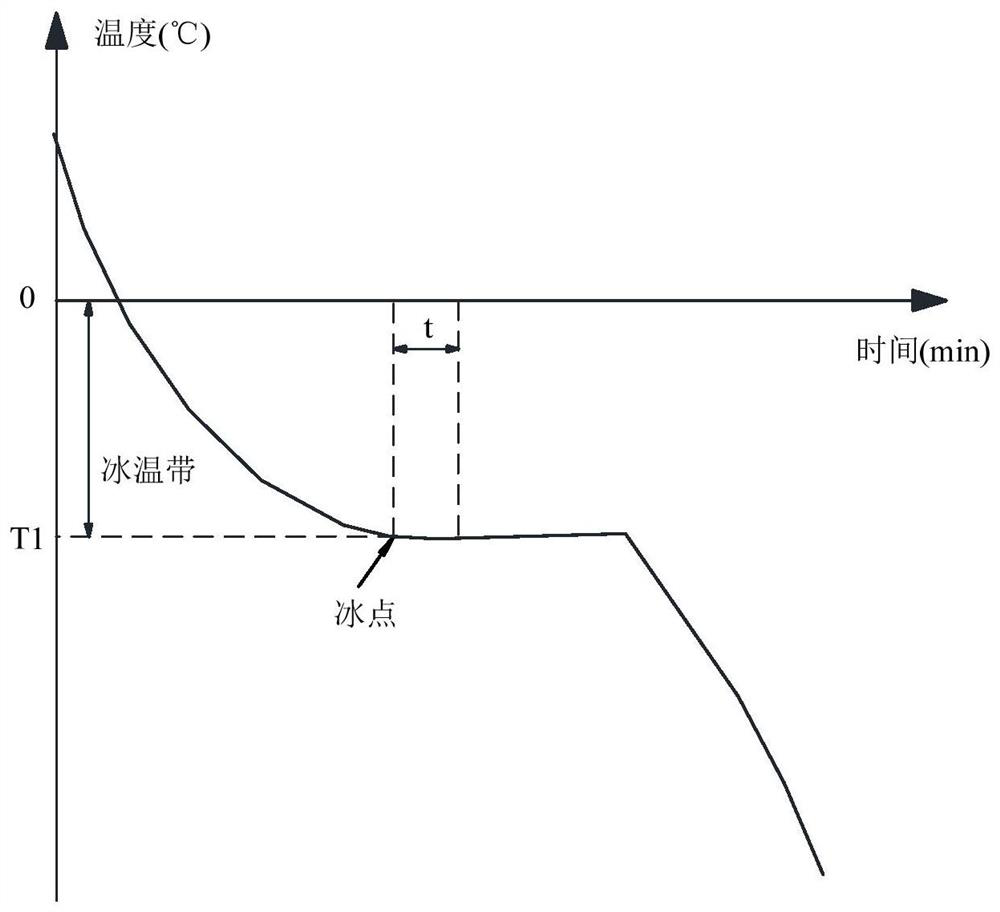

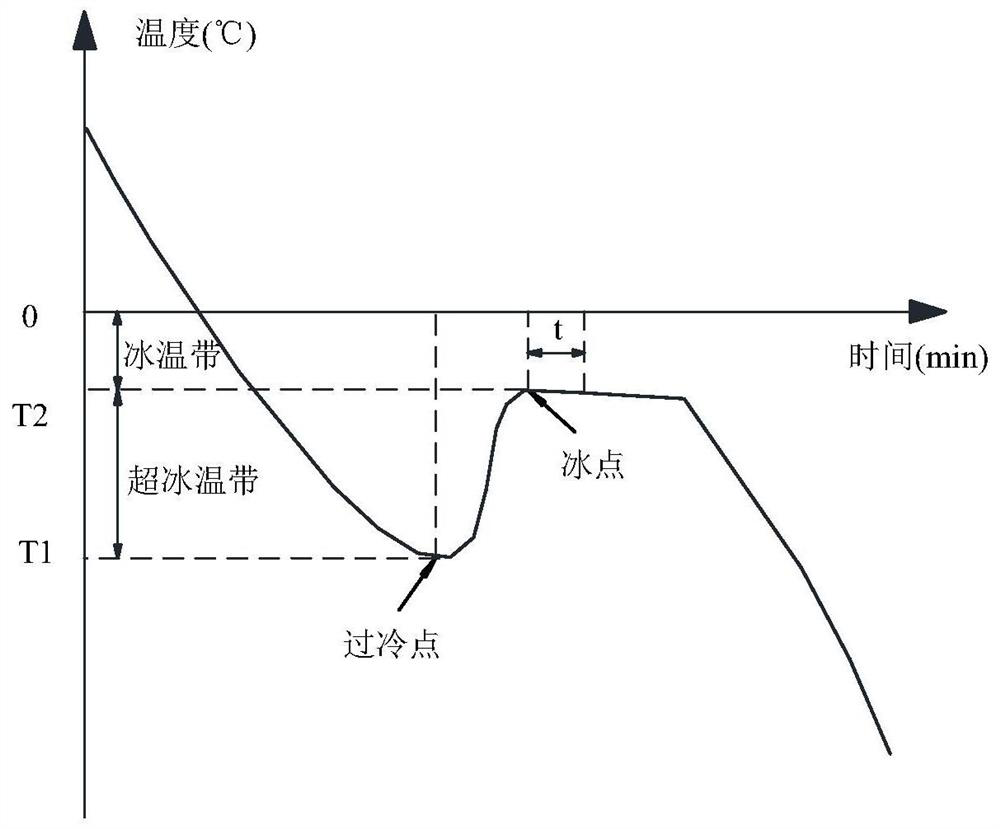

Food preservation control method and device, and refrigerator

InactiveCN112923651AFully automatedRealize intelligenceLighting and heating apparatusCooling fluid circulationIce bindingProcess engineering

The invention discloses a food preservation control method and device, and a refrigerator. The method comprises the following steps: when the operation of putting a food is detected, cooling a compartment; monitoring the temperature of the food in real time in the cooling process; automatically determining a freezing point and / or a supercooling point of the food according to the temperature change and the temperature duration of the food; and storing the food according to the freezing point and / or the supercooling point of the food. According to the invention, based on the temperature change and the temperature duration of the food in the cooling process for the compartment, the freezing point and / or the supercooling point of the food placed in the compartment can be automatically determined, the temperature of the compartment is further automatically controlled to be the proper temperature for food storage, and automation and intelligence of ice temperature or super-ice temperature storage for the food are realized; and a user does not need to manually input the storage temperature or the name of the food, the operation difficulty of the user is simplified, the situation that the preservation period is affected by food freezing due to an improper temperature input by the user is avoided, and the user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

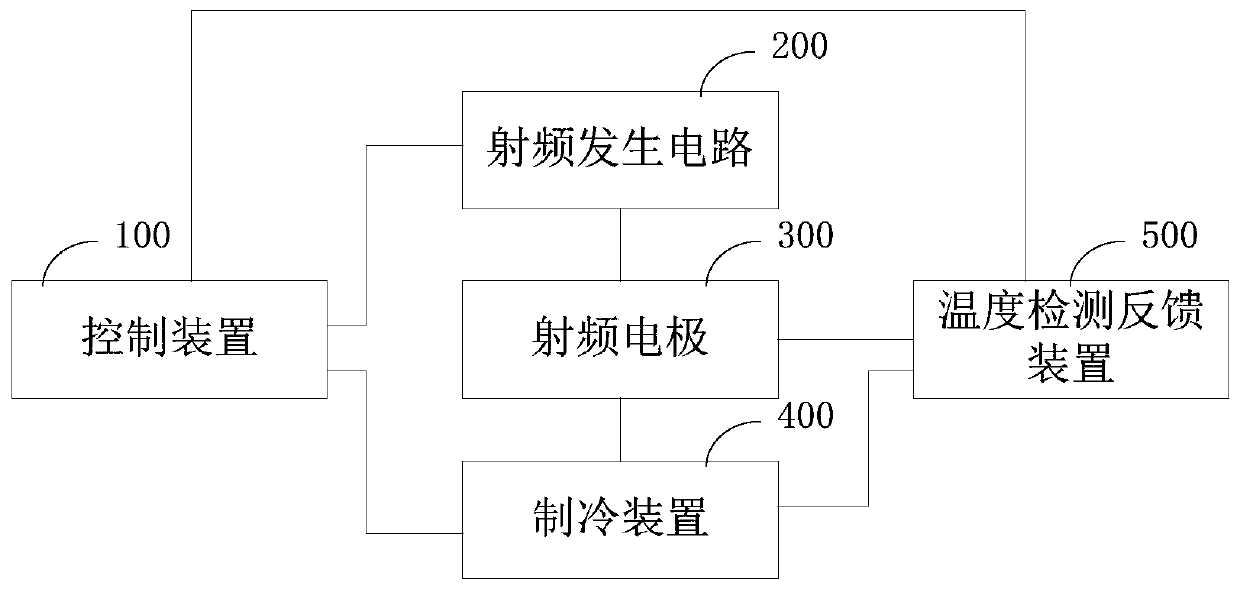

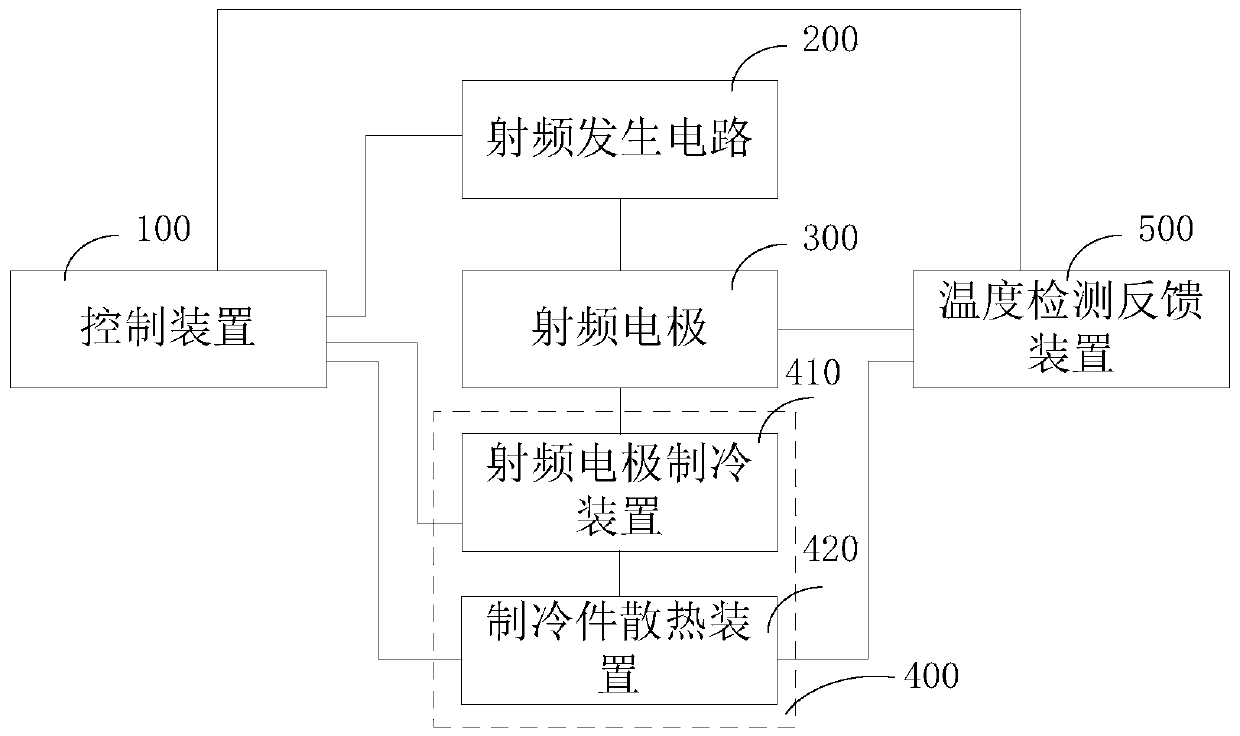

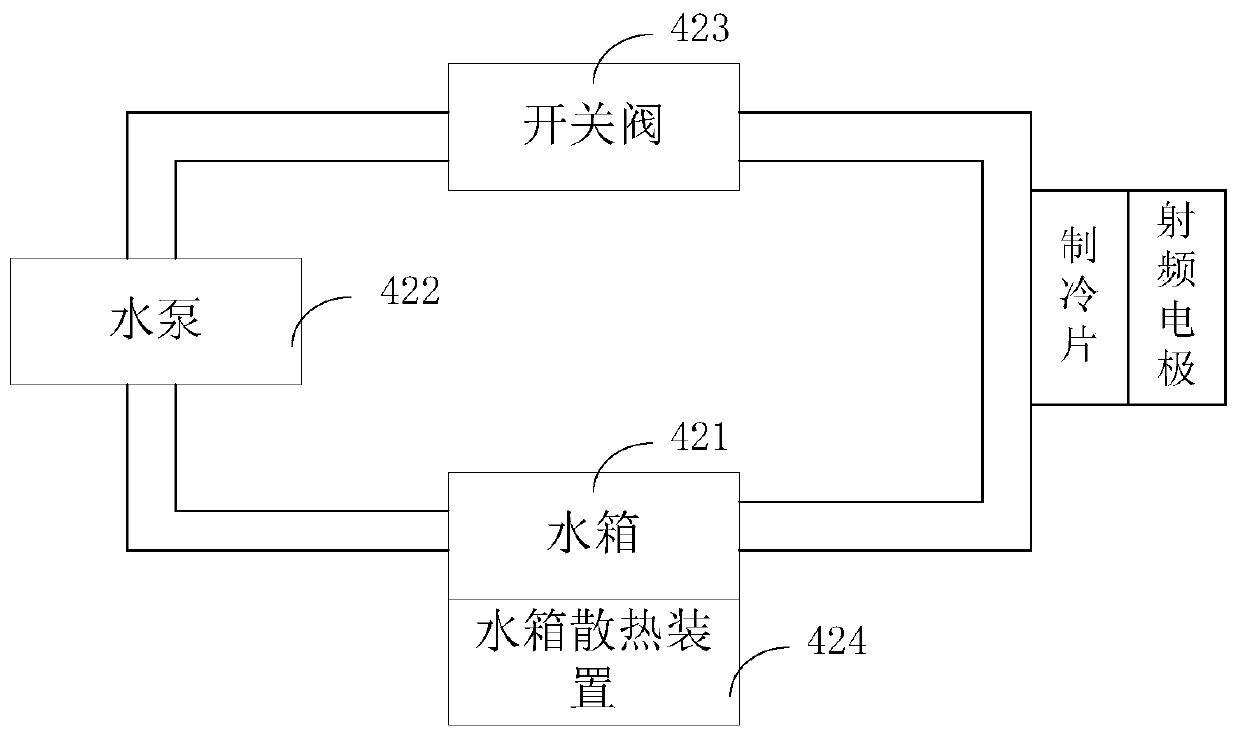

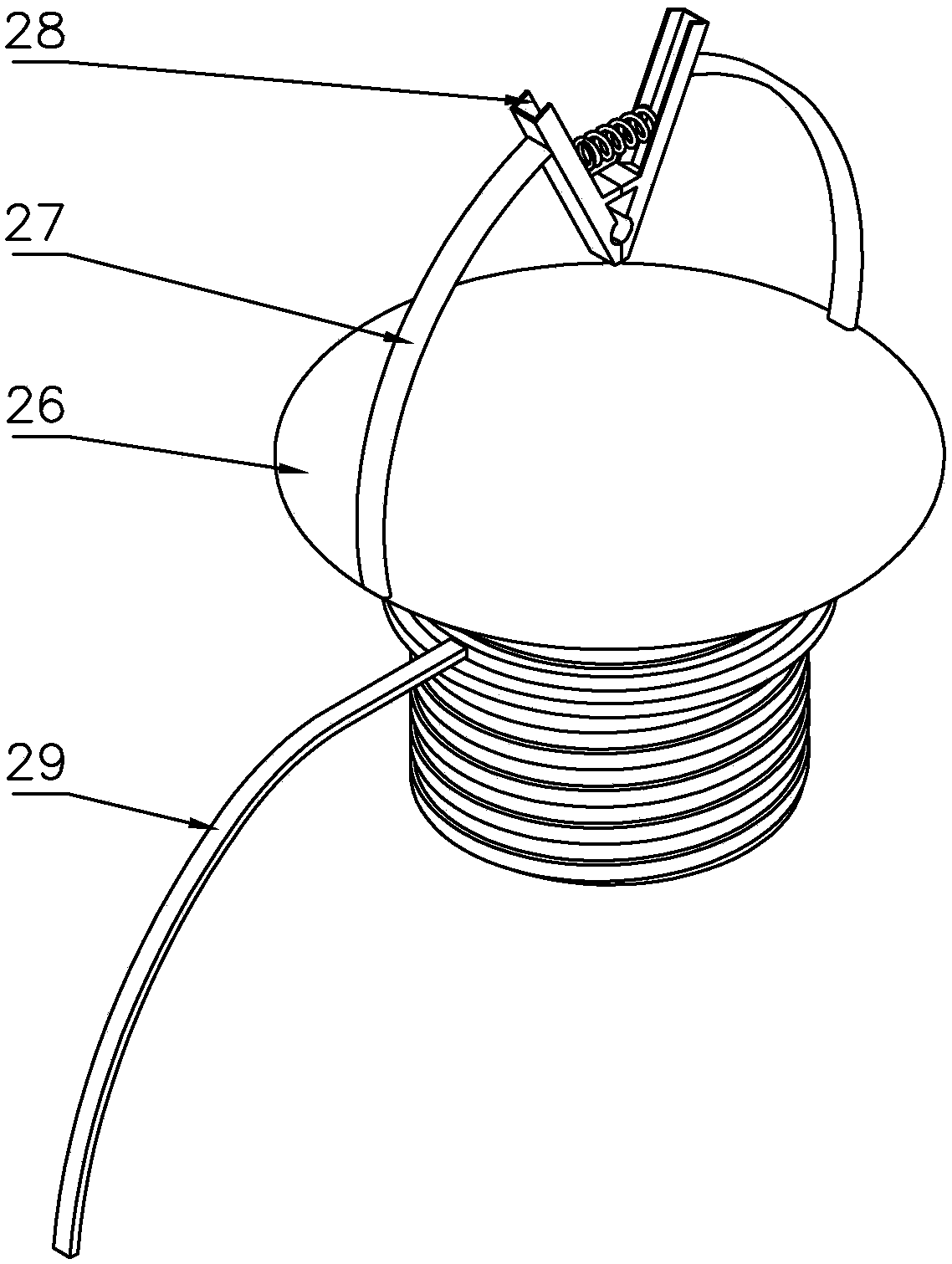

Radio frequency fat reduction equipment

ActiveCN109998667AImprove use reliabilityReduce adverse effectsSurgical instruments for heatingPower flowControl signal

The invention relates to radio frequency fat reduction equipment. The equipment comprises a control device, a radio frequency generating circuit, a radio frequency electrode, a refrigerating device and a temperature detecting feedback device; the radio frequency generating circuit is connected with the radio frequency electrode and used for generating radio frequency current according to a controlsignal sent by the control device and transmitting the radio frequency current to the radio frequency electrode, the refrigerating device is used for reducing the temperature of the radio frequency electrode, the temperature detecting feedback device is connected with the radio frequency electrode and the refrigerating device and used for detecting the temperature of the refrigerating device andthe radio frequency electrode to generate a temperature feedback signal and feeding back the temperature feedback signal to the control device, the control device is connected with the radio frequencygenerating circuit, the refrigerating device and the temperature detecting feedback device and used for controlling the intensity of radio frequency current generated by the radio frequency generating circuit and the work of the refrigerating device according to the temperature feedback signal, the refrigerating temperature is reasonably and precisely controlled, the temperature of the radio frequency electrode is adjusted accordingly, the adverse influence of improper temperature on a receiving object is avoided, and the use reliability of the radio frequency fat reduction equipment is improved.

Owner:深圳易美医学科技有限公司

Disposable feeding bag for clinical care

InactiveCN107811868ARelieve painReduce heat lossFeeding-bottlesDomestic articlesInsulation layerTemperature monitoring

The invention discloses a disposable feeding bag for clinical nursing, which comprises a bag body, a diversion tube, a dropper, a water storage layer, and a thermal insulation layer. Head II, the upper side of the plug II is provided with a hanging ring; the outer side of the bag is provided with a water storage layer, the upper side of the water storage layer is provided with a water inlet, and the other end of the water inlet is provided with a plug I; the water inlet There is an outlet pipe on one side of the lower part of the mouth; an insulation layer is arranged on the outside of the water storage layer; There is a matching joint at the end; there is a temperature display card on the side of the matching joint. In the present invention, a water storage layer is arranged on the outside of the bag body, and an insulation layer is arranged on the outside of the water storage layer, and the food in the feeding bag is kept warm by injecting hot water; in addition, a temperature display card is arranged on the side of the fitting joint, which can be used to It is suitable for detecting the temperature of food, reducing the suffering of patients caused by improper temperature.

Owner:王磊

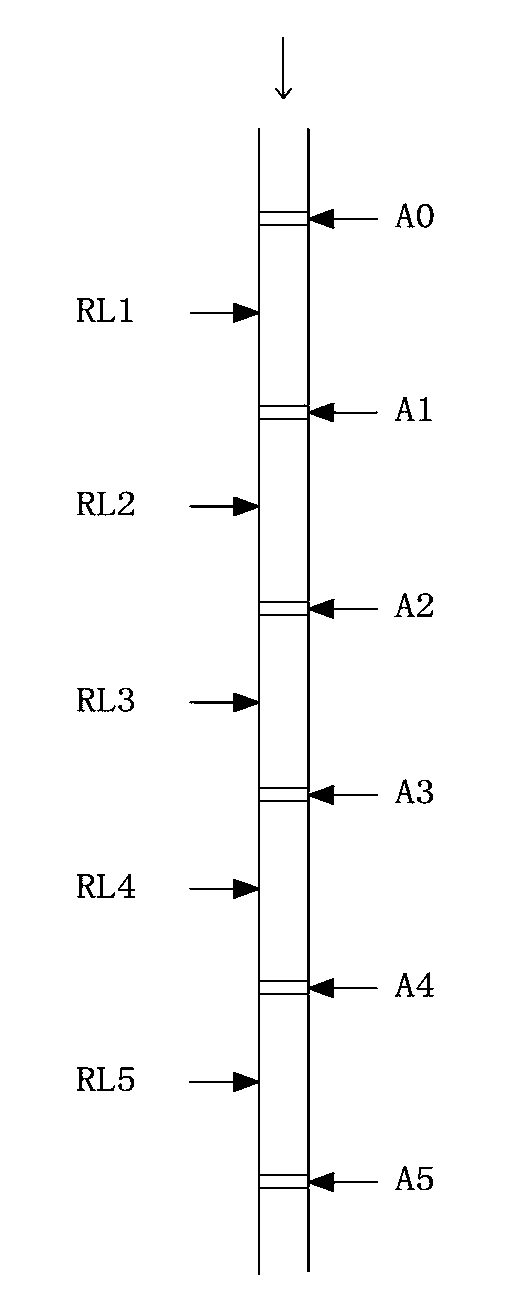

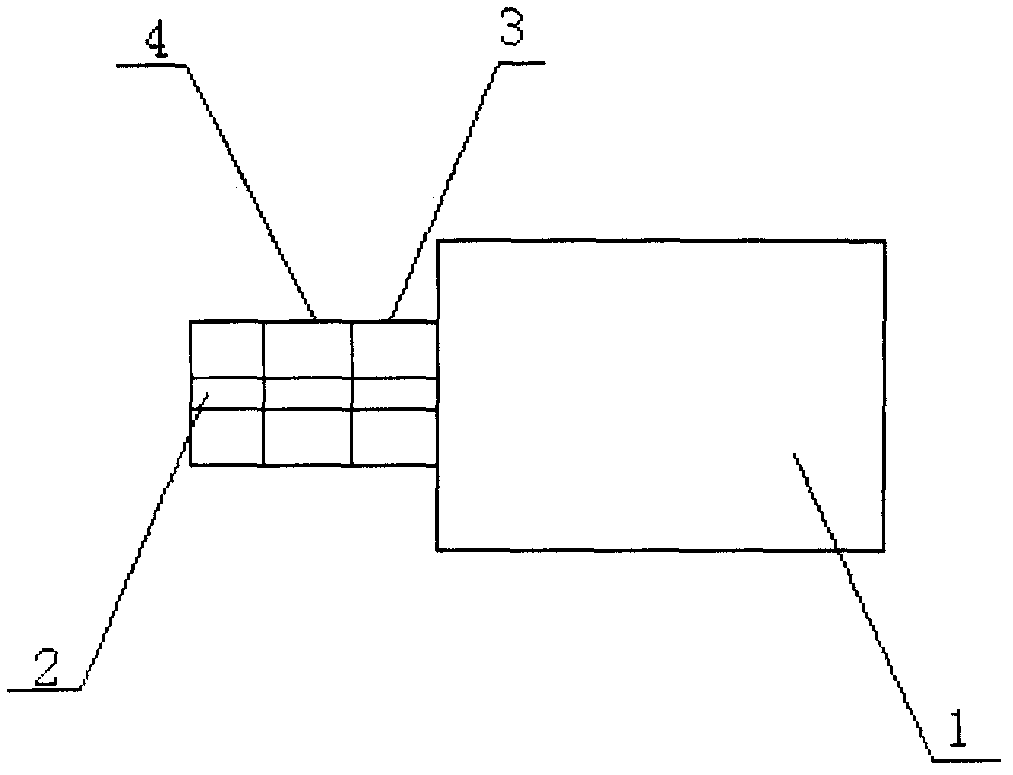

Code spraying spinning machine

InactiveCN102995144AQuality assuranceEasy to useArtificial thread manufacturing machinesFilament/thread formingPulp and paper industryLine segment

The invention relates to the technical field of spinning, in particular to a code spraying spinning machine, which comprises a spinning machine and a spinning orifice. The spinning orifice is formed in the left end of the spinning machine. A temperature measurement area and a code spraying area are arranged between the spinning machine and the spinning orifice. The code spraying area is on the left side of the temperature measurement area. According to the code spraying spinning machine, the temperature measurement area is additionally arranged at the spinning orifice to detect the temperature of silk threads at a silk thread outlet, whether the temperature is proper or not is judged according to a condition, and silk thread segments at improper temperature are subjected to code spraying treatment to represent defective product areas, so that a function of distinguishing qualified products from defective products can be realized, the quality of outgoing products can be ensured, and a good using effect can be achieved.

Owner:常州市夏华布业有限公司

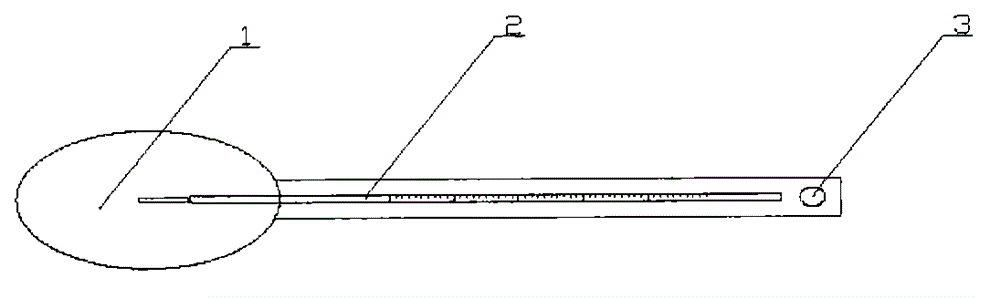

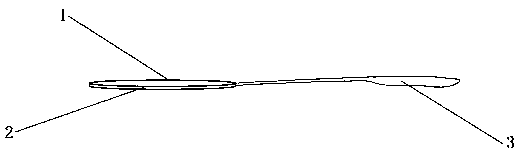

Temperature measurement spoon for babies

The invention discloses a temperature measurement spoon for babies, and the temperature measurement spoon can avoid the circumstance that babies are burned by food which is too high in temperature or the circumstance of diarrhea in the babies when the food is too low in temperature. When the temperature is about 40 DEG C suitable for the babies, an indicator lamp can display green, and yellow is displayed when the temperature is too low while red is displayed when the temperature is too high, so that a user can judge food temperature. The temperature measurement spoon comprises a spoon, wherein a thermometer and the indicator lamp are arranged on the spoon. The head of the thermometer is arranged on one side of the head of the spoon and the tail of the thermometer is arranged on one side of the indicator lamp. With the adoption of the structures, the user can directly observe the food temperature by virtue of the indicator lamp, so that bad influence on the small babies due to improper temperature is avoided. Parents, who feed the babies, are unnecessary to sense the temperature, so that the temperature measurement spoon is quite rapid and convenient.

Owner:罗家华

A split tunnel kiln

The invention discloses a split type tunnel kiln. A kiln body (1) is divided into a preheating chamber (2) and a sintering chamber (3) in the moving direction of a trolley (10). Cooling chambers (9) of the tunnel kiln are arranged around the kiln body (1) and separated from the sintering chamber (3). Sintered products (11) coming out of the sintering chamber (3) are conveyed to the cooling chambers (9) through a transfer trolley (5) which moves back and forth between a transfer chamber (6) and the cooling chambers (9). The split type tunnel kiln can improve production efficiency greatly, products of different technological requirements are sent to different cooling chambers for cooling, so that the situation that the baking process of the whole tunnel kiln is changed completely due to different technological requirements of different products is avoided, cold breakage or hot breakage caused by improper temperature control is avoided, the qualified rate of the products is improved, investment is saved, and the application range is wide.

Owner:彭州市半陶陶瓷有限责任公司

Secondary temperature-decreasing water valve position self-optimizing method in main steam temperature control

InactiveCN102588949BStable temperatureAdequate means of adjustmentSuperheating controlAuto regulationLower limit

The invention discloses a secondary temperature-decreasing water valve position self-optimizing method in main steam temperature control. For the existing main steam temperature closed-loop control process, the improper temperature setting value of a secondary inlet regularly causes a too low or too high working point of the secondary temperature-decreasing water valve, so that the secondary temperature-decreasing water valve loses the adjusting capacity in the subsequent time. The secondary temperature-decreasing water valve position self-optimizing method overcomes the existing disadvantages through the following steps of: (1) setting upper limit and the lower limit for the optimization of the secondary temperature-decreasing water valve; (2) setting the filter time for the secondary temperature-decreasing water valve; (3) setting the automatic steam temperature adjusting condition for the secondary inlet; and (4) setting a maximum offset of the automatic steam temperature adjustment for the secondary inlet. According to the method provided by the invention, the secondary temperature-decreasing water valve is enabled to be always in a proper position so as to ensure enough adjusting margin on the up stroke and the down stroke, and sufficient adjusting means are guaranteed in case of unexpected disturbance; in a varying load process, the function can more easily enable the main steam temperature to be stable.

Owner:ZHEJIANG UNIV

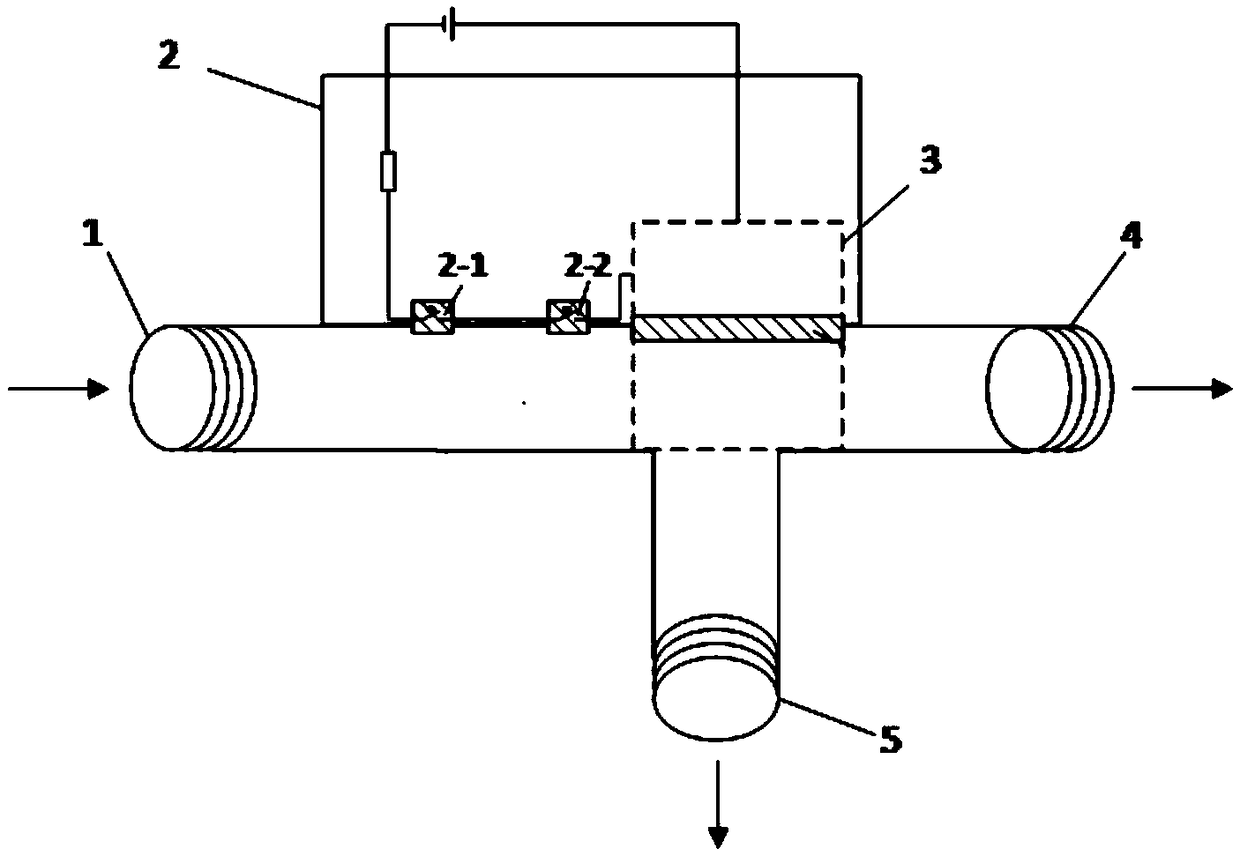

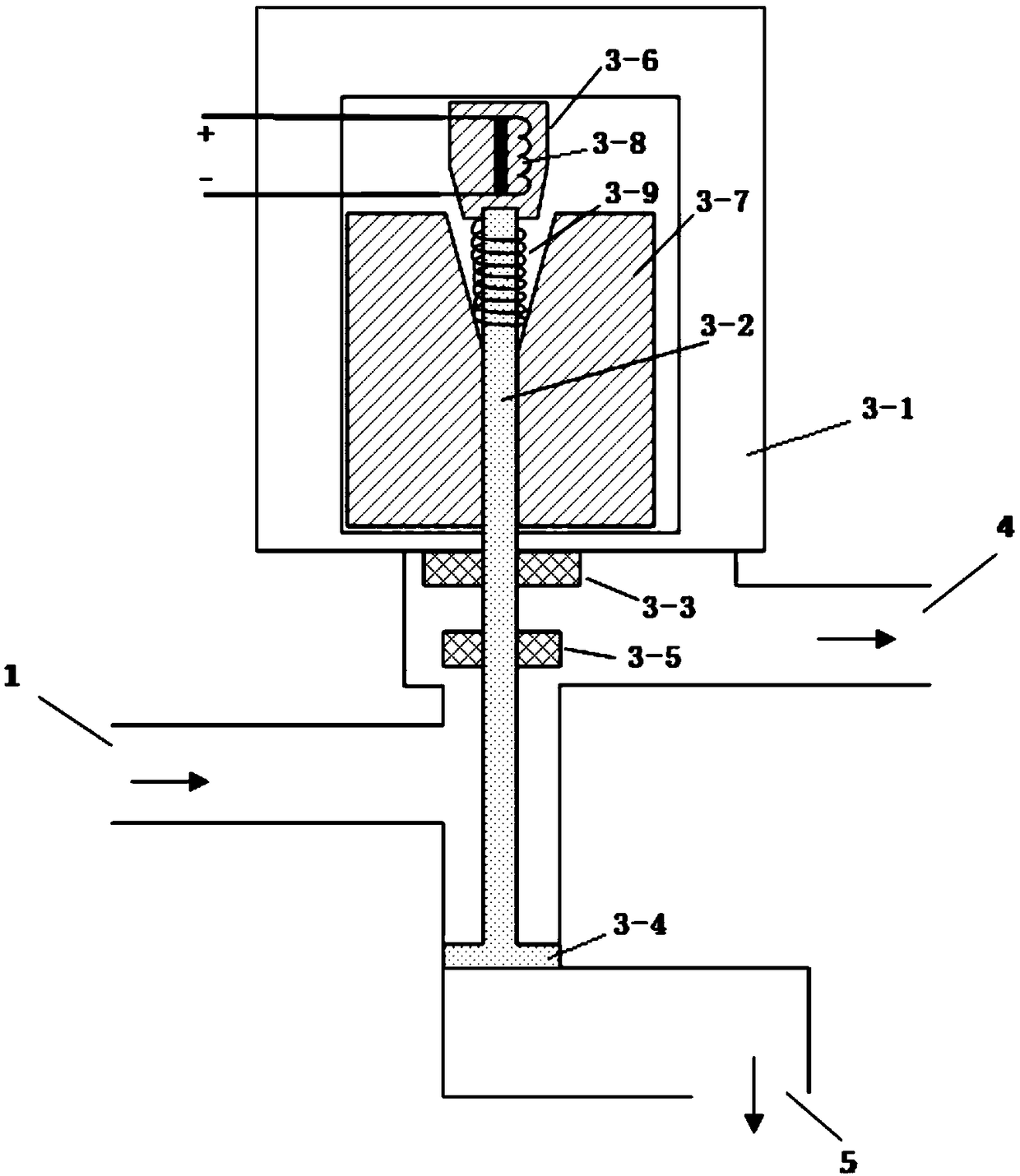

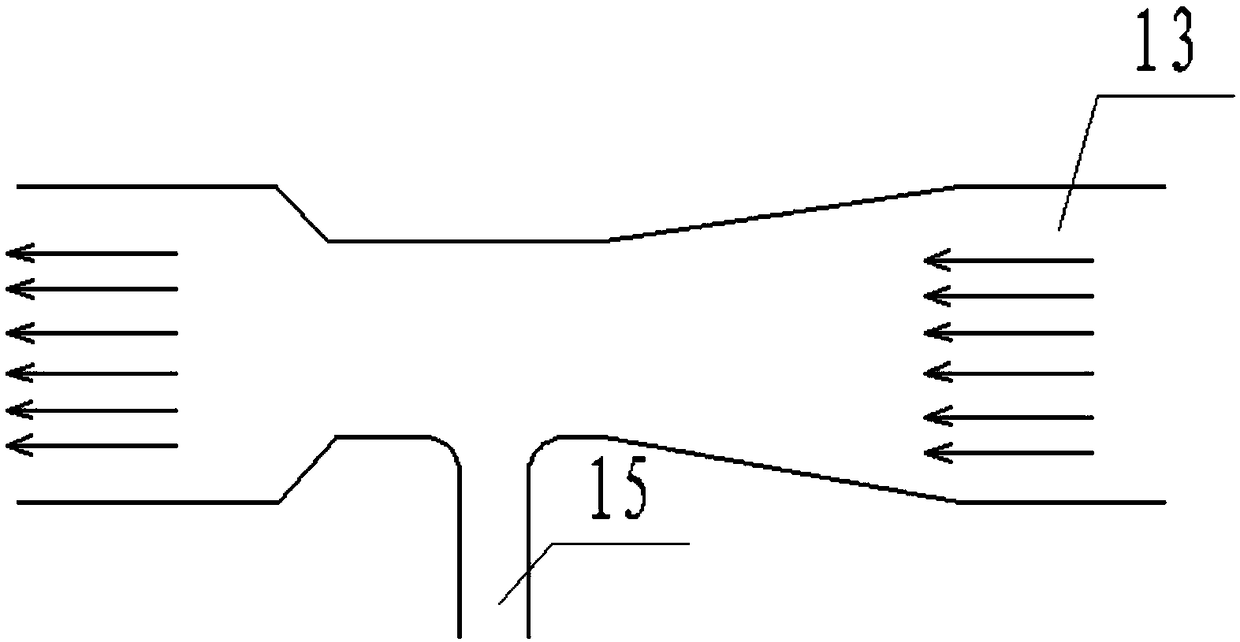

Water flow dividing device based on temperature control

ActiveCN109140025ATo achieve the effect of intelligent water savingOperating means/releasing devices for valvesWater savingTemperature control

The invention discloses a water flow dividing device based on temperature control. The water flow dividing device comprises a water inlet pipe, a temperature induction module, an electromagnetic control module, a first water outlet pipe and a second water outlet pipe. The water inlet pipe communicates with the first water outlet pipe and the second water outlet pipe through the electromagnetic control module. The temperature induction module inducts the temperature of the water body in the water inlet pipe, and switching signals are generated to control the electromagnetic control module to conduct flow dividing on the water body. According to the water flow dividing device based on temperature control, the water with the improper temperature is automatically collected through a first water outlet, the water with the proper temperature automatically flows out of a second water outlet to be used, and the effect of intelligent water saving is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

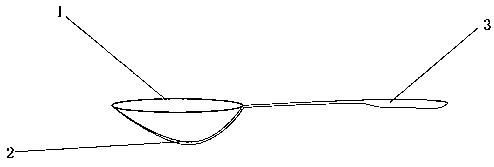

Variant spoon

The invention discloses a variant spoon which comprises an induction spoon surface, a telescopic spoon bottom and a spoon handle. The variant spoon is characterized in that physical reaction can be performed according to temperature, and a user is informed of proper temperature or improper temperature by changing forms.

Owner:俞倩

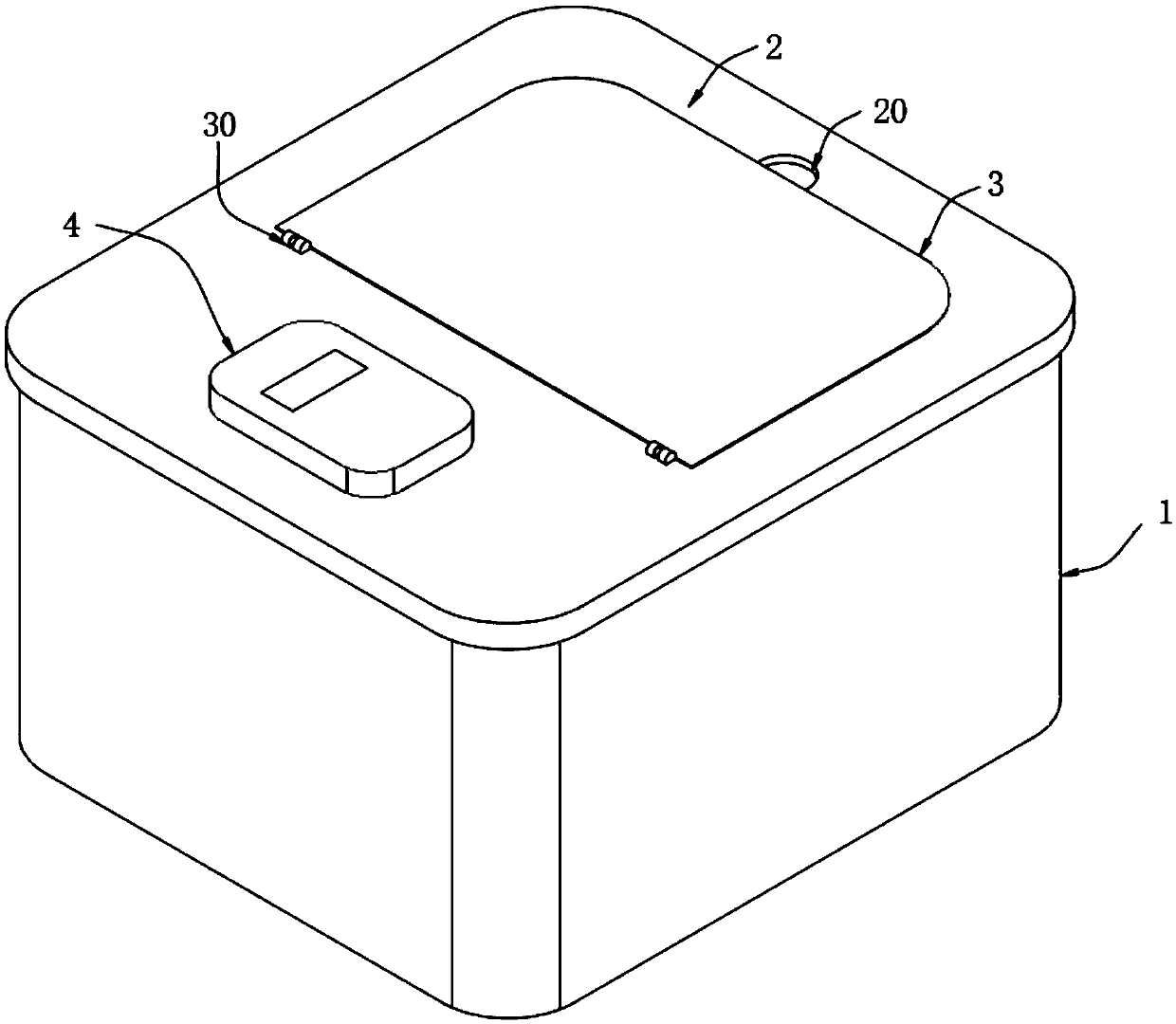

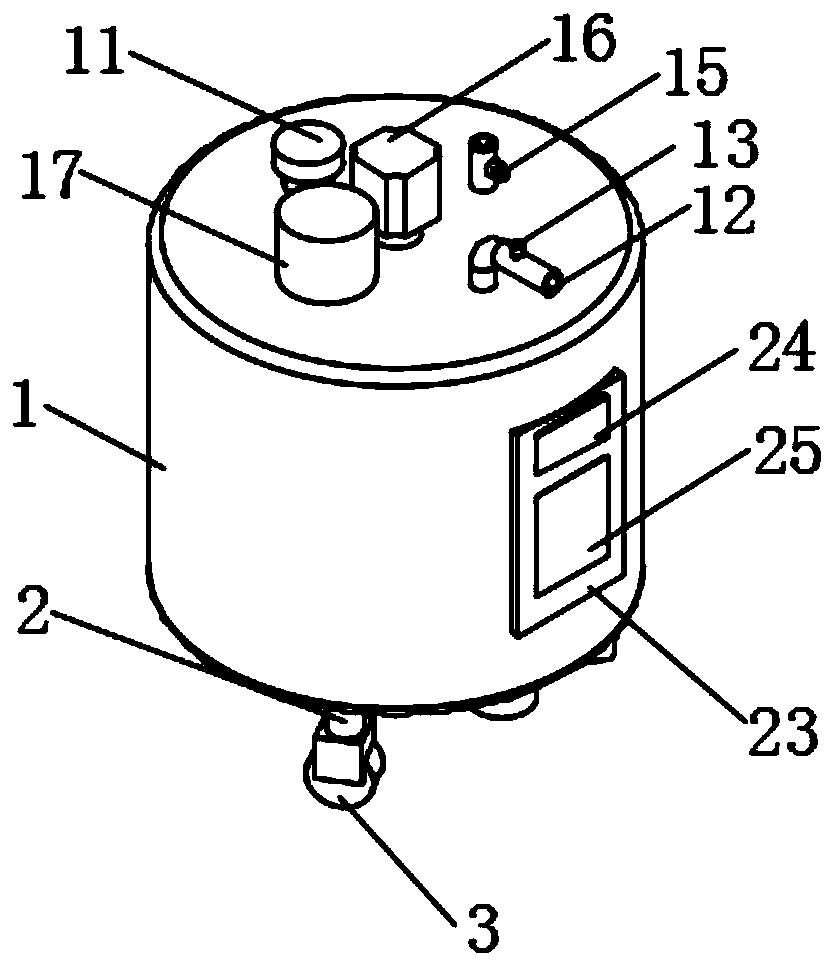

Special milk warming device for neonatal wards

PendingCN109549499ADisplay temperatureSuitable temperatureWarming devicesMedical wardLiquid-crystal display

The invention relates to the technical field of a milk warming device, in particular to a special milk warming device for neonatal wards. The special milk warming device for neonatal wards comprises amilk warming box, wherein a separation plate is arranged inside the milk warming box; an equipment cabin and a milk warming cabin are formed in two sides of the separation plate; a control module isarranged in the equipment cabin; a cavity is formed in the bottom of the milk warming box; a plurality of electric heating wires are arranged at one side, near the milk warming cabin, of the cavity atequal intervals; a box cover is arranged on the top of the milk warming cabin; and a control mainboard is arranged at one side of the movable plate. The temperature in the milk warming cabin can be clearly shown through a liquid crystal display screen arranged on the control mainboard; the temperature in the milk warming cabin can be conveniently regulated in a later stage; secondly, a fan can becontrolled through a bridge driver arranged on the control module, and the electric heating wires can be controlled by an intermediate relay arranged on the control module, so that the temperature ofmilk is enabled to always maintain the proper temperature; the problem of neonatal diarrhea due to improper temperature is effectively solved; on the other hand, the workload of nursing personnel isreduced; the work efficiency is improved; and the physical and metal stress of the nursing personnel can be reduced at the same time.

Owner:XUZHOU MATERNITY & CHILD HEALTH CARE HOSPITAL

Intelligent air conditioner control system

InactiveCN111829131AAvoid sick situationsMechanical apparatusSpace heating and ventilation safety systemsData controlControl system

The invention belongs to the technical field of intelligent air conditioners, and particularly relates to an intelligent air conditioner control system. The intelligent air conditioner control systemcomprises a user terminal and a control terminal. The user terminal is used for collecting physical sign data of a user. The control terminal is used for inputting a temperature value, is used for analyzing the input temperature value and the physical sign data of the user by using a preset model after the temperature value is input, and correcting the input temperature value to obtain a correctedtemperature value when the analysis result is that the input temperature value has pathogenic risks to the user, and is also used for controlling air supply of an air conditioner after the correctedtemperature value is obtained. By using the system, when the user subjectively judges that the temperature has a problem, the control terminal can correct the input temperature and then control the air supply of the air conditioner. Compared with the prior art, occurrence of diseases caused by improper temperature subjectively judged by the user can be avoided as much as possible.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

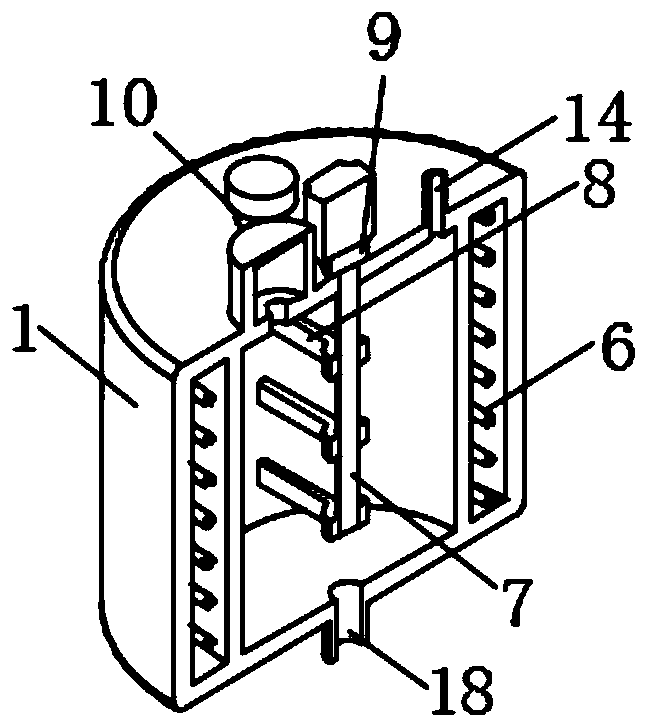

Efficient biological purification device for water pollution control

InactiveCN110204055AKeep aliveDischarge in timeWater treatment temperature conditionsBiological water/sewage treatmentCouplingEnzyme

The invention discloses an efficient biological purification device for water pollution control. The device comprises an outer shell, the lower end surface of the outer shell is provided with supportlegs, a universal wheel is arranged at the lower end of every support leg, an inner shell is arranged in the outer shell, a cavity is arranged between the outer shell and the inner shell, a spiral heating tube is arranged in the cavity, the bottom end surface of the cavity is provided with a temperature sensor, a shaft coupling is arranged on the upper end surface of the outer shell, and a motor is arranged at the upper end of the shaft coupling. The invention has a simple structure, is convenient to use, can control the temperature in the biological purification process in order to avoid theadverse effect of improper temperature on the biological purification process and ensure the activity of a biological enzyme and the high-efficiency proceeding of the purification process, can timelydischarge a gas generated in the biological purification process in order to avoid damages of the accumulation of the gas in the device to the device, and can be moved to meet the special use requirements of users and realize humanization.

Owner:刘姣

A high-efficiency water-saving temperature control device

ActiveCN106247627BGuaranteed continuous supplyControl water temperatureFluid heatersTemperature controlWater saving

The invention provides an efficient water-saving temperature control device. The efficient water-saving temperature control device comprises a water heater, a temperature sensor, a controller, an electric valve, a hot water pipeline, an infusion type water tank, a valve, a first backflow pipeline, a first check valve, a second backflow pipeline, a second check valve, a water heater water inlet pipeline, a Venturi tube, a main valve and a main backflow pipe. According to the efficient water-saving temperature control device, through the arrangement of the sensor, the electric control device, the backflow pipelines and the Venturi tube, recycling of improper-temperature flow flowing out of a water heater is achieved, the problem of waste caused by retardance of valve closing and water cutting-off is solved, and the effects of controlling the water temperature and ensuring continuous supply of hot water can further be achieved to a certain extent.

Owner:常熟市铜业总公司有限公司

Low-nitrogen roasting furnace and control method thereof

PendingCN112944928AEasy to controlReduce generationControl devices for furnacesWaste heat treatmentTemperature controlNitrogen oxides

The invention discloses a low-nitrogen roasting furnace and a control method thereof. The low-nitrogen roasting furnace comprises a plurality of heating units which are adjacently communicated, each heating unit comprises at least one heating part and at least one temperature measuring part, at least one temperature measuring part is arranged behind each heating part, each heating part and the adjacent temperature measuring part located at the downstream portion of flue gas flow form a control base point, and the average temperature corresponding to the control base points in the flue gas flowing direction is gradually reduced. According to the low-nitrogen roasting furnace, the heating parts and the temperature measuring parts are arranged in a matched mode, and the power of the heating parts is controlled through one-to-one correspondence of the temperature measuring parts and the heating parts, so that the temperature is controlled more accurately, and generated thermal nitrogen oxides caused by improper temperature control are reduced.

Owner:山东平阴丰源炭素有限责任公司

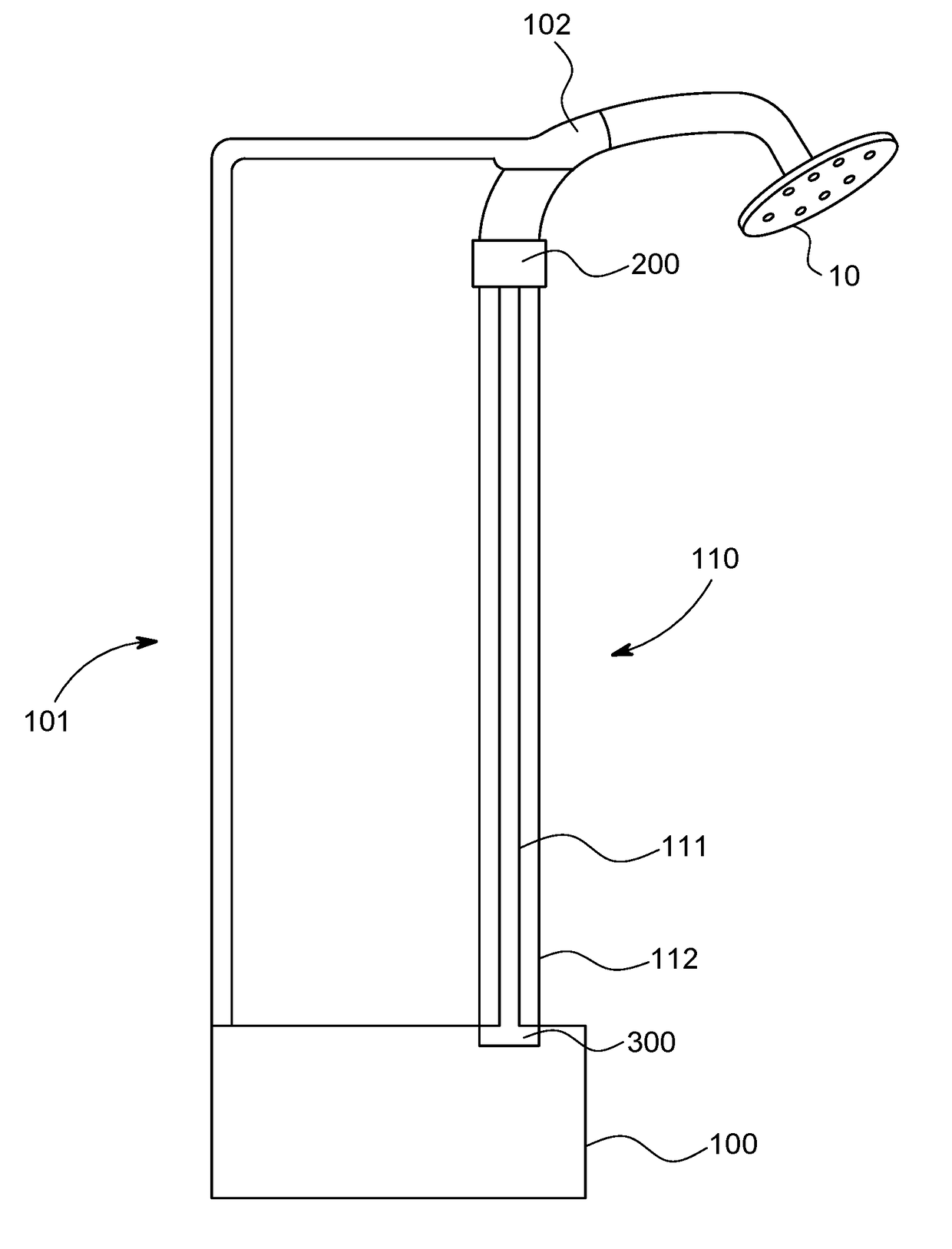

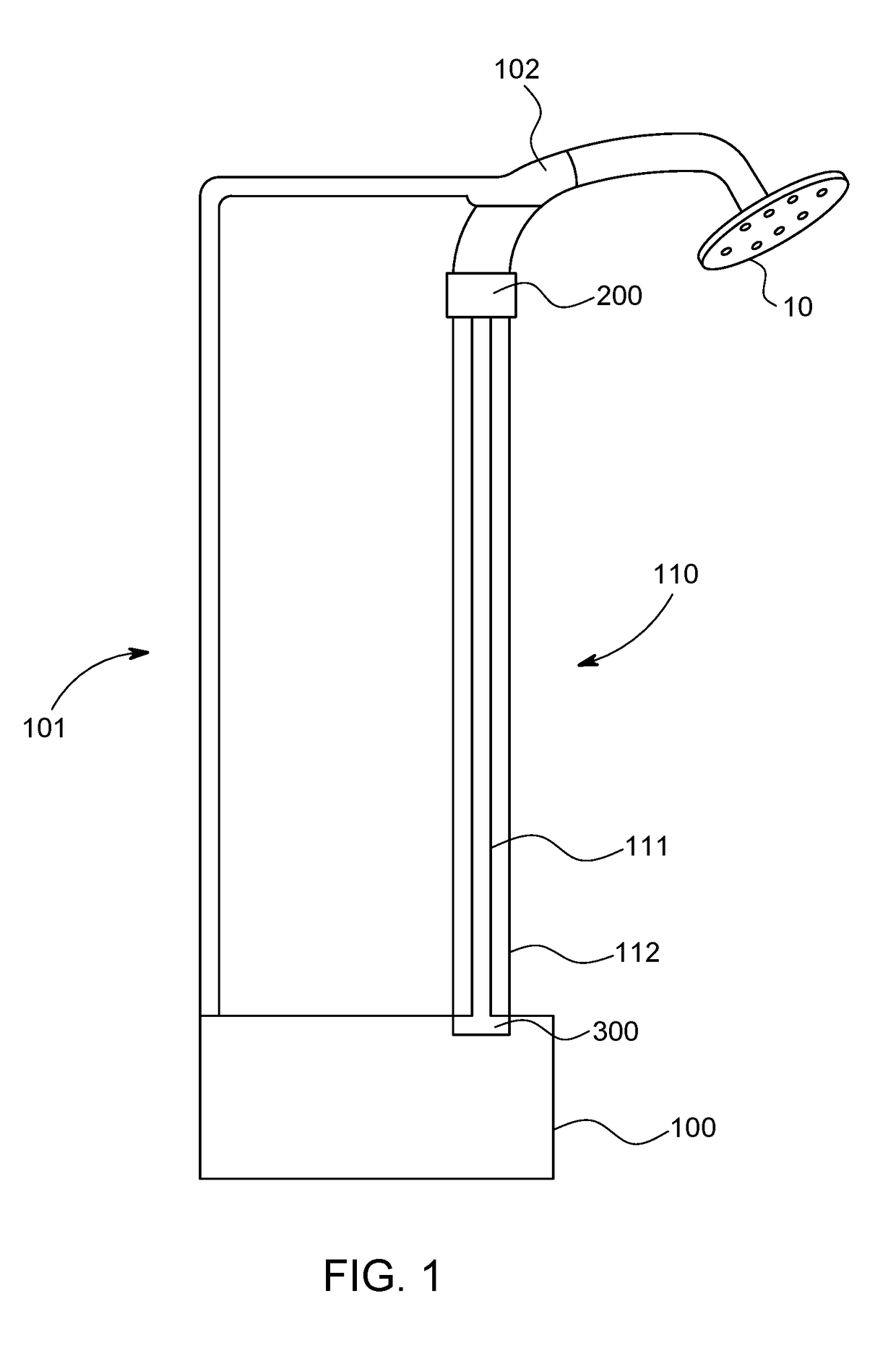

Apparatus and Method for Conserving Water by Diverting Water of Improper Temperature

InactiveUS20180291592A1Prevent heat lossEasy to getTemperature control without auxillary powerOperating means/releasing devices for valvesWater sourceEngineering

A water conservation apparatus that conserves water by diverting water of an undesired temperature away from the faucet and back to the hot water source for additional heating by way of a nested water pipe design.

Owner:SPIRO YURI

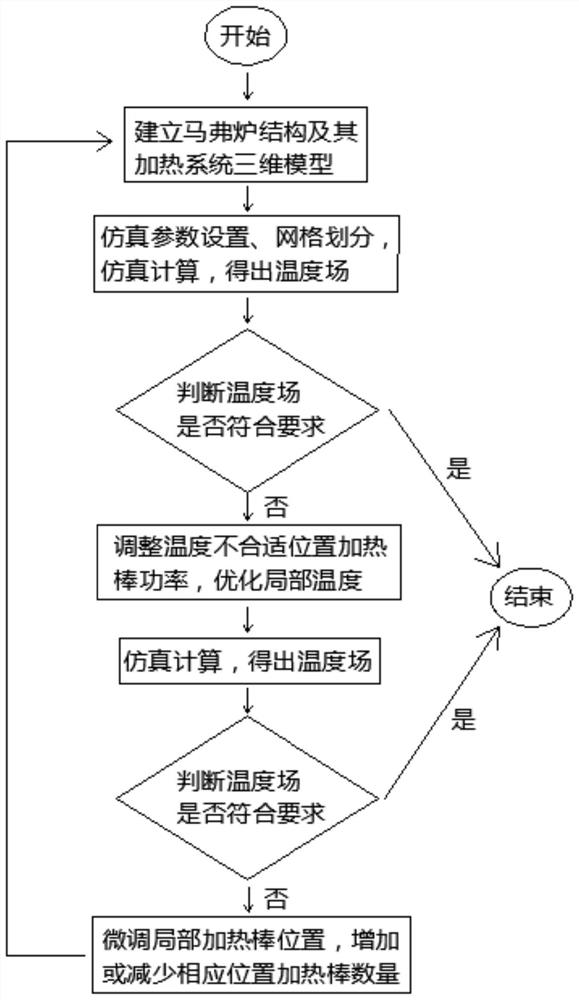

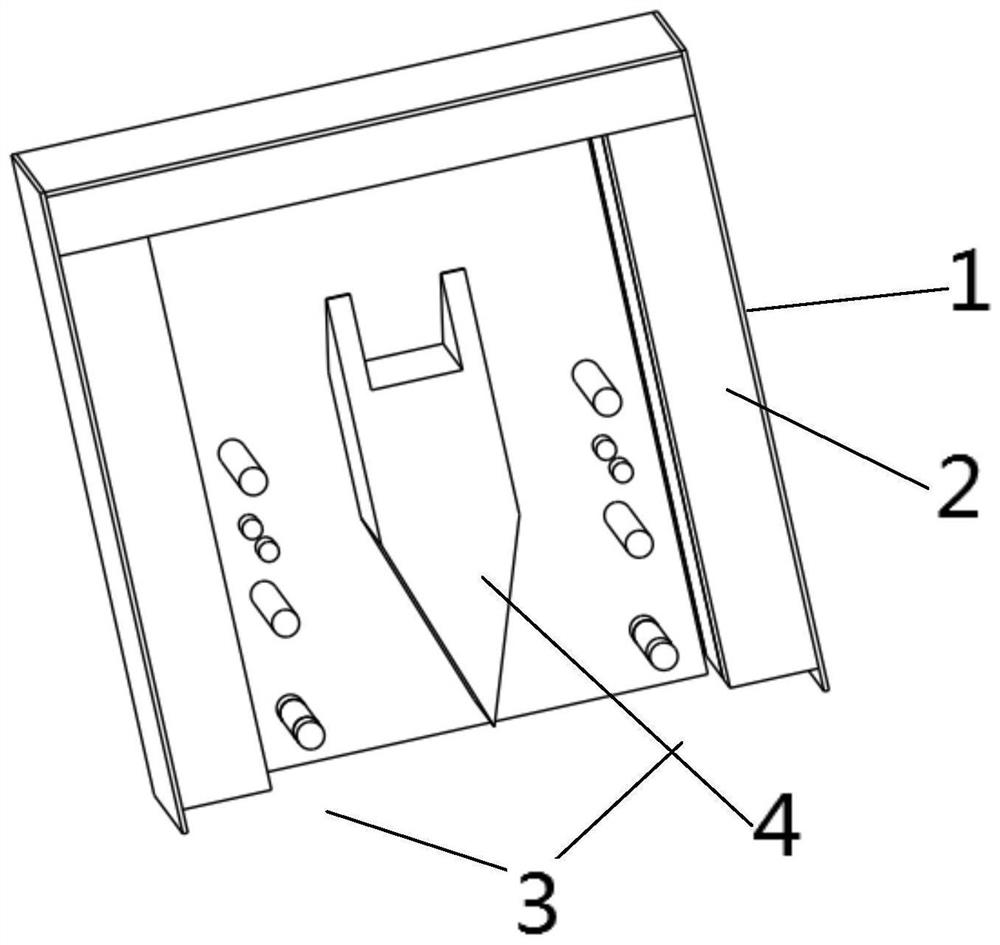

Design method of muffle furnace heating system

PendingCN112733338ASimple designShorten the timeDesign optimisation/simulationSpecial data processing applicationsHeater RodProcess engineering

The invention discloses a design method of a muffle furnace heating system. The design method comprises the steps of 1, designing an initial heating system based on the structure of a muffle furnace; 2, establishing simulation models of the muffle furnace and the heating system; 3, performing simulation numerical calculation according to the simulation models; 4, judging whether the heating system meets the requirement or not according to a simulation calculation result, and if the requirement is met, ending the design task; if not, entering the step 5; 5, adjusting the power of the heating rod at the position with the improper temperature, and calculating a simulation numerical value; 6, judging whether the heating system meets the requirement or not according to the simulation calculation result obtained in the step 5, and if the requirement is met, ending the design task; if not, entering the step 7; 7, finely adjusting the positions of the heating rods at the inappropriate temperature positions and / or changing the number of the heating rods at the corresponding positions; and 8, returning to the step 2. Optimization and improvement of the muffle furnace heating system can be quickly achieved, and time, manpower and material resources are greatly saved.

Owner:IRICO DISPLAY DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com