Secondary temperature-decreasing water valve position self-optimizing method in main steam temperature control

A technology of main steam temperature and desuperheating water, applied in the control of superheat temperature, steam superheat, steam generation, etc., can solve the problems of large thermal stress fluctuation of pipeline, excessive main steam temperature fluctuation, loss of adjustment ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

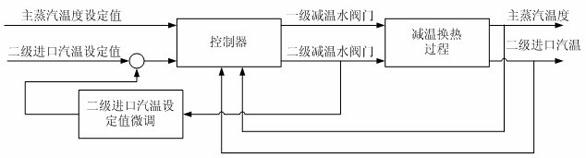

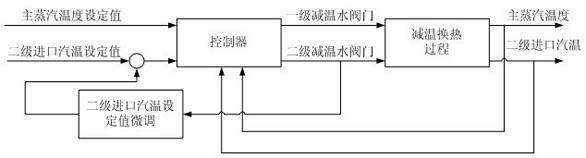

[0036] Such as figure 1 As shown, the steps of the self-optimization method for the position of the secondary desuperheating water valve in the main steam temperature control are as follows:

[0037] Step (1). Set the upper and lower limits for the optimization of the secondary desuperheating water valve.

[0038] According to the actual characteristics of the valve, the optimal upper and lower limits of the two-stage desuperheating water valve are selected in the linear working area of the valve;

[0039] Step (2). Set the filtering time of the secondary desuperheating water valve.

[0040] According to the characteristics of the main steam temperature adjustment, set the filtering time of the secondary desuperheating water valve at 3 to 5 minutes;

[0041] Step (3). Set the automatic adjustment conditions of the secondary inlet steam temperature.

[0042] 3-1. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com