Code spraying spinning machine

A spinning machine and coding technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problem of inability to distinguish whether the product is qualified or not, and achieve good use effect and quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

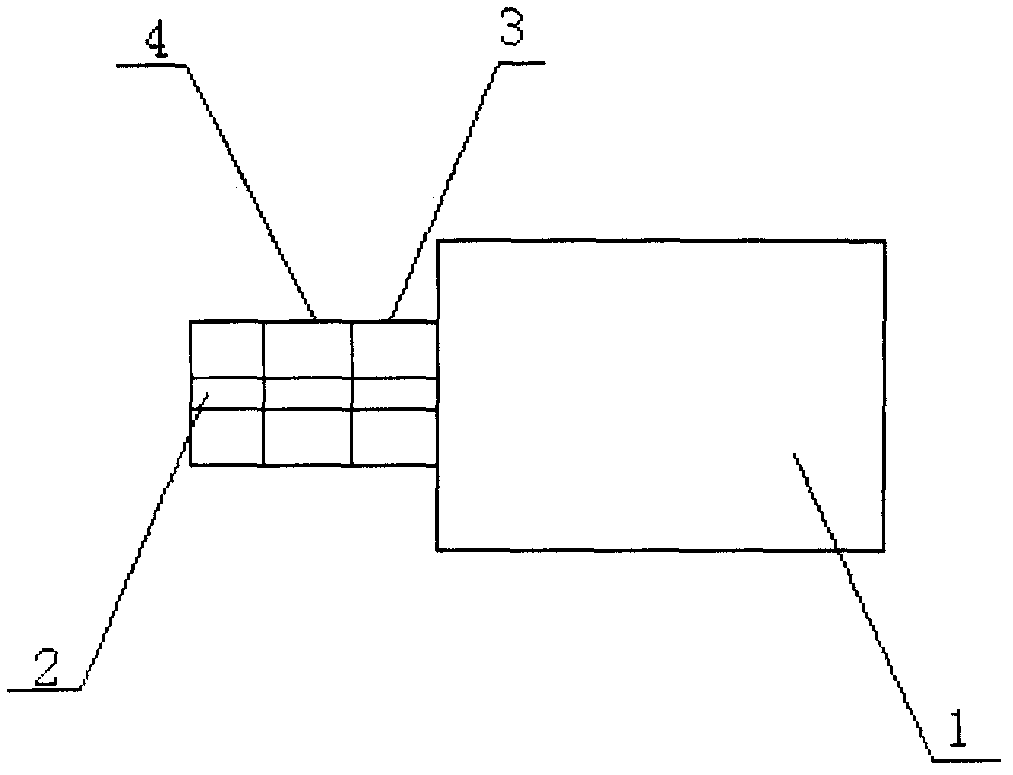

[0009] like figure 1 It is a structural schematic diagram of the present invention, a code-jetting spinning machine, comprising a spinning machine 1 and a spinning port 2, the left end of the spinning machine 1 is provided with a spinning port 2, and the spinning machine 1 and the spinning port are A temperature measurement area 3 and a coding area 4 are arranged between the 2, and the coding area 4 is on the left side of the temperature measurement area 3.

[0010] This coding spinning machine is equipped with a coding area 4 on the right side of the silk outlet 2, and a temperature measuring area 3 is installed on the right side of the coding area 4. When working, the temperature measuring area 3 will measure the temperature of the silk thread. After detection, it will feed back to the coding area 4, and the coding area 4 will spray codes on the silk threads with abnormal temperature according to whether the temperature of the silk threads is suitable, so as to distinguish q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com