Split type tunnel kiln

A tunnel kiln and split-type technology, applied in the field of tunnel kiln, can solve the problems of inability to realize continuous mass production, excessive one-time investment, cold or hot frying of products, etc. The effect of improving the utilization of the site and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

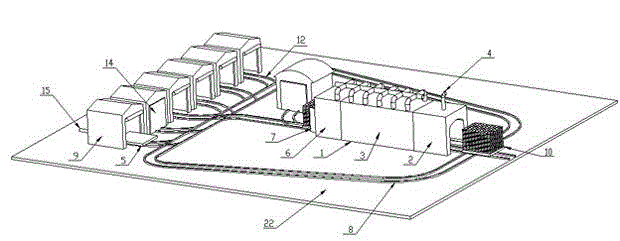

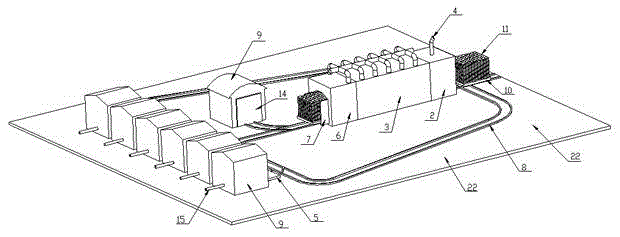

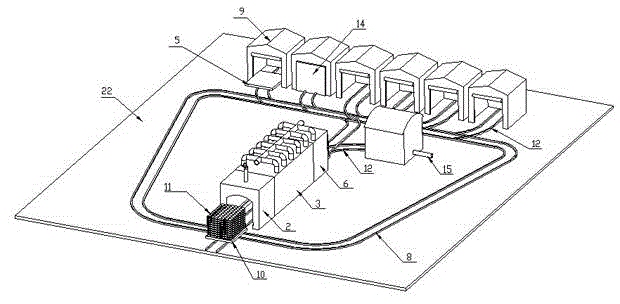

[0019] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

[0020] Such as Figure 1 to Figure 3 As shown, a split-type tunnel kiln includes: a kiln body 1 arranged on an earth foundation 22, the kiln body 1 is connected by walls on both sides and a vault on the top, and the kiln body 1 is based on a platform The running direction of the car 10 is sequentially divided into a preheating chamber 2 and a firing chamber 3, wherein a flue 4 for releasing smoke is arranged above the preheating chamber 2, and a heating device is arranged in the firing chamber 3, and the firing The upper part of the chamber 3 is a high-temperature zone, and the lower part is a low-temperature zone. A section of the kiln tail part of the kiln body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com