Design method of muffle furnace heating system

A heating system and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems that consume a lot of time, manpower, and material resources, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

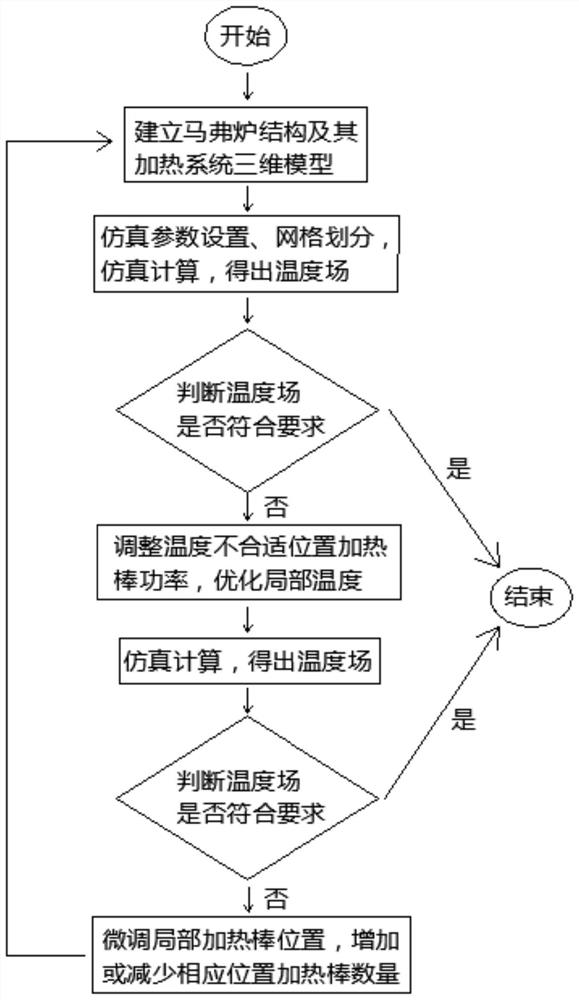

[0034] Such as figure 1 Shown, the design method of muffle furnace heating system of the present invention comprises the following steps:

[0035] Step 1. Based on the muffle furnace structure and heating system of the existing liquid crystal glass production line, adjust the heating system appropriately according to the size change of the muffle furnace;

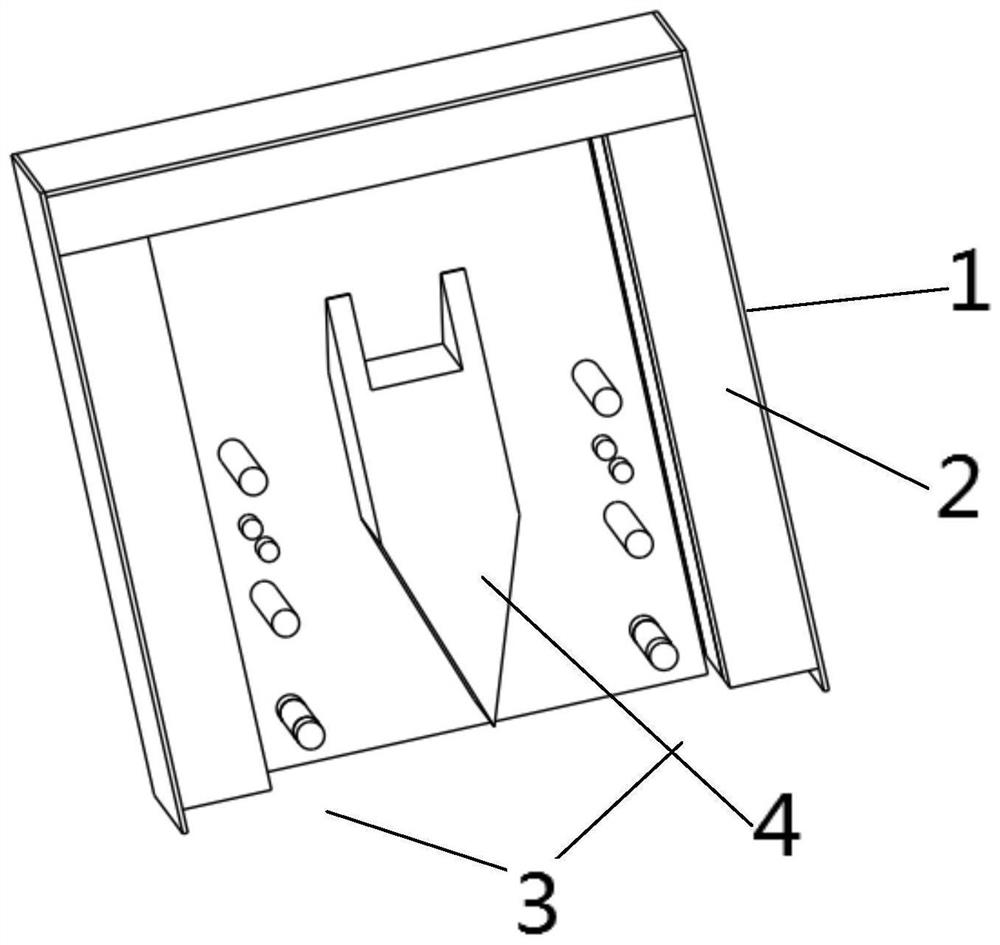

[0036] Step 2, using Croe 3D modeling software to establish a simulation model of the muffle furnace and its heating system.

[0037] Step 3, import the simulation model into the FloEFD thermal simulation software for simulation parameter setting, grid division, and then perform simulation numerical calculation to obtain the simulation calculation result, that is, the temperature field distribution inside the entire muffle furnace.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com