Solid oxide fuel cell

a fuel cell and solid oxide technology, applied in the manufacture of cell components, final product manufacturing, electrochemical generators, etc., can solve the problems of large internal resistance in the air electrode section, low proportion, and large internal resistance in the fuel electrode section, so as to improve the durability of the solid oxide fuel cell and the resistance to the exfoliation between the fuel electrode layer and the solid electrolyte layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

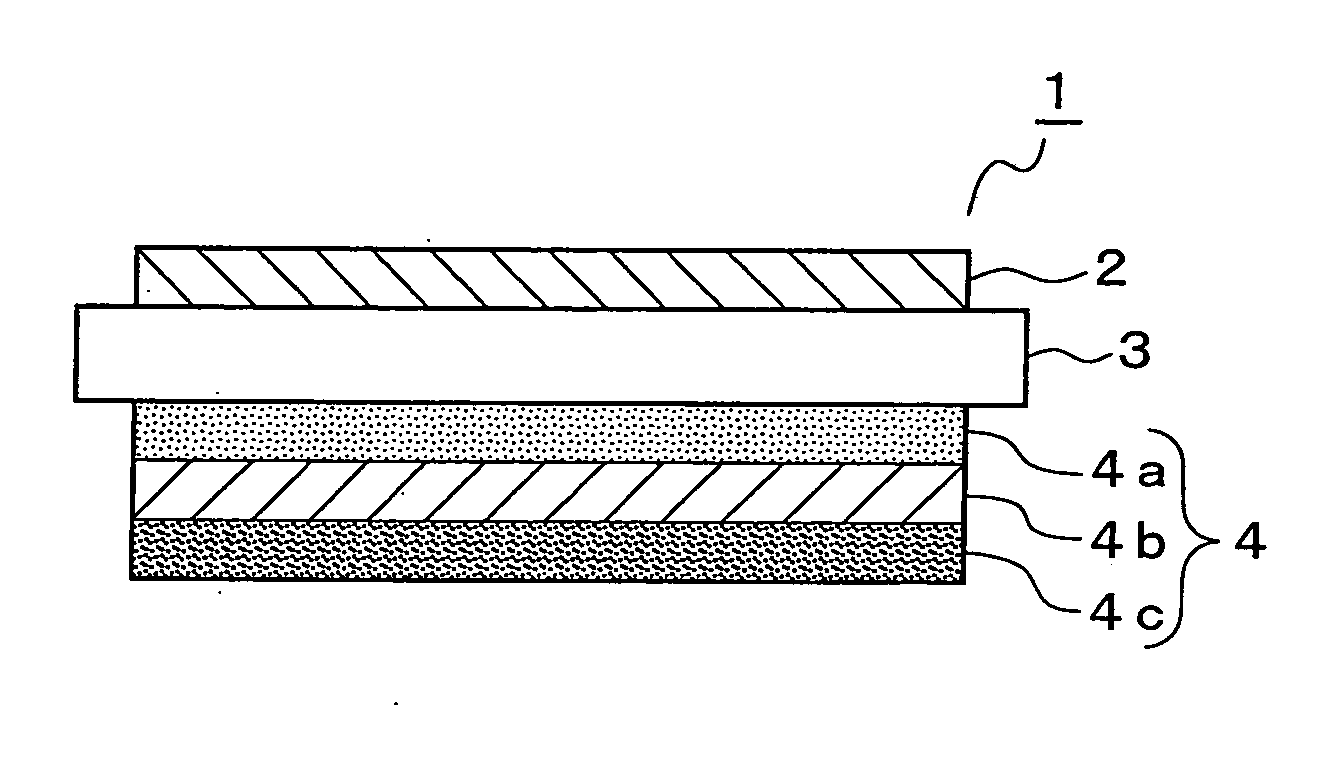

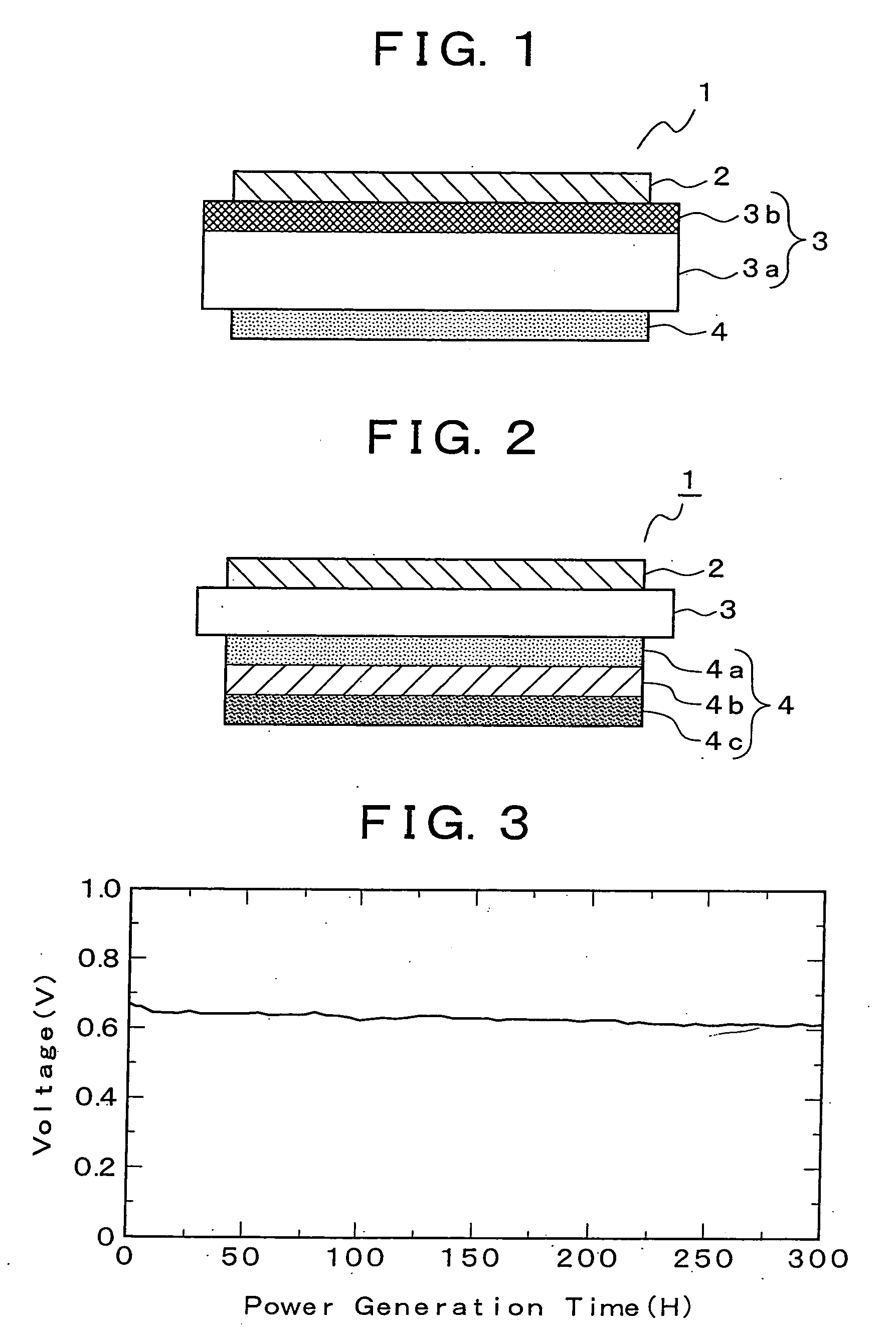

[0048] With reference to FIG. 2, the material for the air electrode layer 2 was Sm0.5Sr0.5Co0.3; the material for the solid electrolyte layer 3 was La0.8Sr0.2Ga0.8Mg0.15Co0.05O3; the composition ratio of component materials in the fuel electrode layer 4a was such that Ni(0 vol %) / Ce0.8Sm0.2O2 (100 vol %); the composition ratio of component materials in the fuel electrode layer 4b was such that Ni(10 vol %) / Ce0.8Sm0.2O2 (90 vol %); the composition ratio of component materials in the fuel electrode layer 4c was such that Ni(40 vol %) / Ce0.8Sm0.2O2 (60 vol %); and thus a power cell was formed and the obtained electric power generation property is shown in FIG. 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com