A high-temperature carbonized ceramic-based molecular sieve membrane oxygen generator and its application method

A technology of high temperature carbonization and oxygen generation device, applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problem of poor oxygen production efficiency, poor recyclability, and low purity problem, to achieve high affinity and avoid the effect of reducing oxygen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

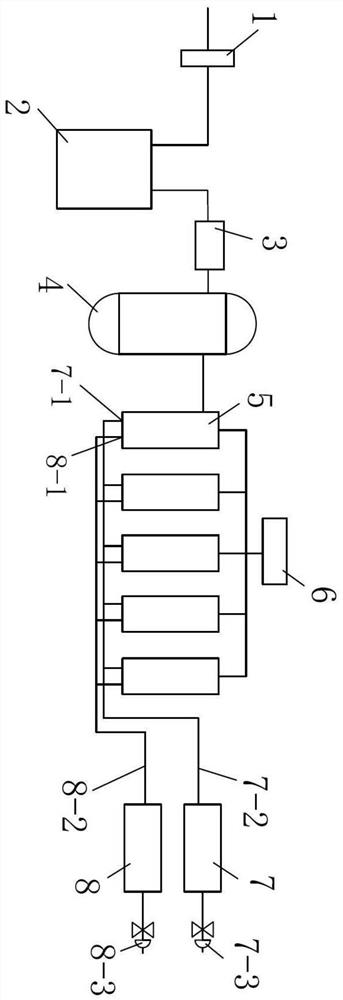

[0053] Such as figure 1 As shown, a high-temperature carbonized ceramic-based molecular sieve membrane oxygen production device provided in this embodiment includes an air source inlet 1, an air compressor 2, a C-level filter 3, and 4 and 5 air storage tanks connected in sequence. High-temperature carbonized ceramic-based molecular sieve adsorption unit 5, vacuum pump 6, oxygen gas storage tank 7, nitrogen gas storage tank 8, the end of the oxygen gas storage tank 7 is provided with a first stop valve 7-3, and the end of the nitrogen gas storage tank 8 is provided with a second Two check valves 8-3;

[0054] The vacuum pump 6 is set in the high-temperature carbonized ceramic-based molecular sieve adsorption unit 5, the high-temperature carbonized ceramic-based molecular sieve adsorption unit 5 communicates with the oxygen gas storage tank 7 through the oxygen shunt pipeline 7-2, and the high-temperature carbonized ceramic-based molecular sieve adsorption unit 5 communicates wi...

Embodiment 2

[0083] The only structural difference between this embodiment and Embodiment 1 is that the device provided by this embodiment contains four high-temperature carbonized ceramic-based molecular sieve adsorption units 5 .

[0084] The raw materials for the preparation of the oxygen-ion conductive carbonized ceramic-based molecular sieve membrane used in the molecular sieve in the adsorption tower of the device provided in this embodiment include the following components in parts by weight:

[0085]

[0086] The diameter of the nano carboxymethyl cellulose sodium with a degree of polymerization of 500 used in this embodiment is 65 nm.

[0087] Among them, the Sr 0.3 Ce 0.7 co 0.2 Al 0.8 The preparation method of O hollow fiber membrane, comprises the following steps:

[0088] S1: Add 17.5 parts by weight of EDTA to an aqueous solution of ammonium hydroxide with a mass fraction of 26% to form a water-soluble EDTA ammonium salt solution with a concentration of 3.3M;

[0089]...

Embodiment 3

[0111] The structural difference between this example and Example 1 is only that the device provided by this example contains three high-temperature carbonized ceramic-based molecular sieve adsorption units 5 .

[0112] The raw materials for the preparation of the oxygen-ion conductive carbonized ceramic-based molecular sieve membrane used in the molecular sieve in the adsorption tower of the device provided in this embodiment include the following components in parts by weight:

[0113]

[0114] The nano lignosulfonate with a degree of polymerization of 480 used in this example has a diameter of 80 nm.

[0115] Sr 0.1 Ce 0.9 co 0.1 Al 0.9 o 0.5 The preparation method of hollow fiber membrane comprises the following steps:

[0116] S1: Add 15 parts of EDTA to an aqueous ammonium hydroxide solution with a mass fraction of 25% to form a water-soluble EDTA ammonium salt solution with a concentration of 3M;

[0117] S2: Mix SrCl according to the molar ratio of 1:9:1:9 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com