Grid plasma immersion ion deposition dlc method with bias regulation

A technology of ion deposition and plasma, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor bonding force, uneven deposition of DLC film, difficult control of film performance, etc. Improved binding force, stable glow discharge, and ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

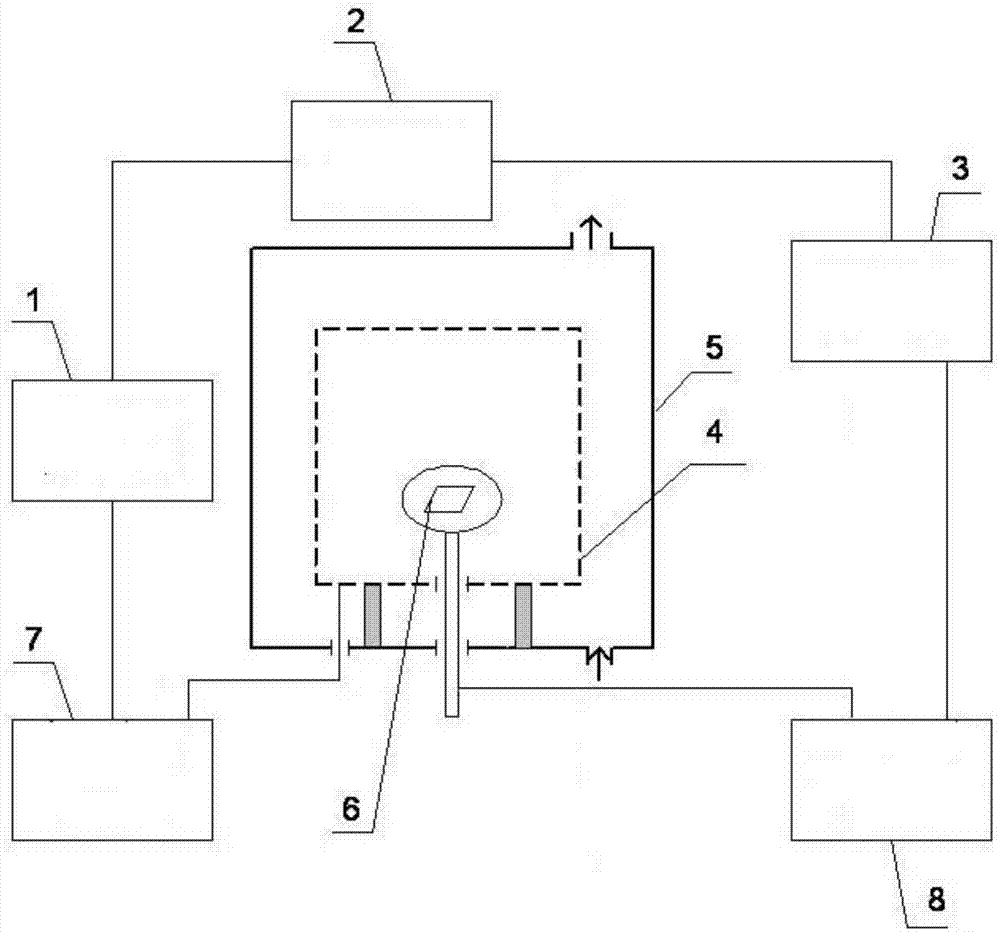

[0029] Specific implementation mode 1: In this implementation mode, the bias control grid plasma immersion ion deposition DLC method is carried out according to the following steps:

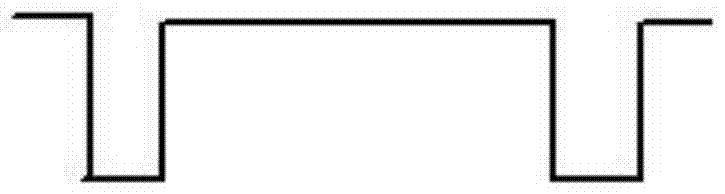

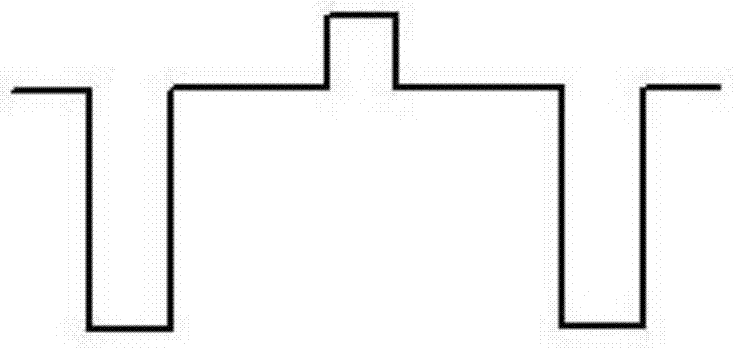

[0030] 1. Place the grid 4 in the vacuum chamber 5, and then place the workpiece on the sample holder 6 in the grid 4. The grid 4 is insulated from the workpiece, and the grid 4 passes the high-voltage pulse of the wire and the grid high-voltage pulse power supply 1. The output end is connected, and a grid high-voltage pulse waveform oscilloscope 7 is arranged between the grid 4 and the grid high-voltage pulse power supply 1; the workpiece is connected to the pulse output end of the workpiece high-voltage pulse power supply 3 through a wire, and the workpiece and the workpiece high-voltage pulse A workpiece high-voltage pulse waveform oscilloscope 8 is arranged between the power sources 3; the phase between the workpiece high-voltage pulse and the grid high-voltage pulse is controlled by the pulse...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 2, the pulse voltage of the grid high-voltage pulse outputted by the grid high-voltage pulse power supply 1 is adjusted to 2kV, the frequency is 2000Hz, and the pulse width is 20μs. Others are the same as the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the pulse voltage of the workpiece high-voltage pulse output by the workpiece high-voltage pulse power supply 3 is adjusted to 3kV, the frequency is 2000Hz, and the pulse width is 20μs. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com