Doped sulfide composite film, preparing method of doped sulfide composite film and workpiece comprising doped sulfide composite film

A composite film and sulfide technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of low hardness of sulfide film, complicated preparation method, high friction coefficient, and achieve enhanced mechanical properties , The effect of inhibiting rapid growth and high crystalline strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The doped sulfide composite thin film of this embodiment is composed of doping elements and sulfides, the doping elements are Ce and Al, and the sulfides are WS 2 , the mass percentage of doping element Ce is 13.2%, the mass percentage of doping element Al is 2.08%, and the balance is sulfide.

Embodiment 2-14

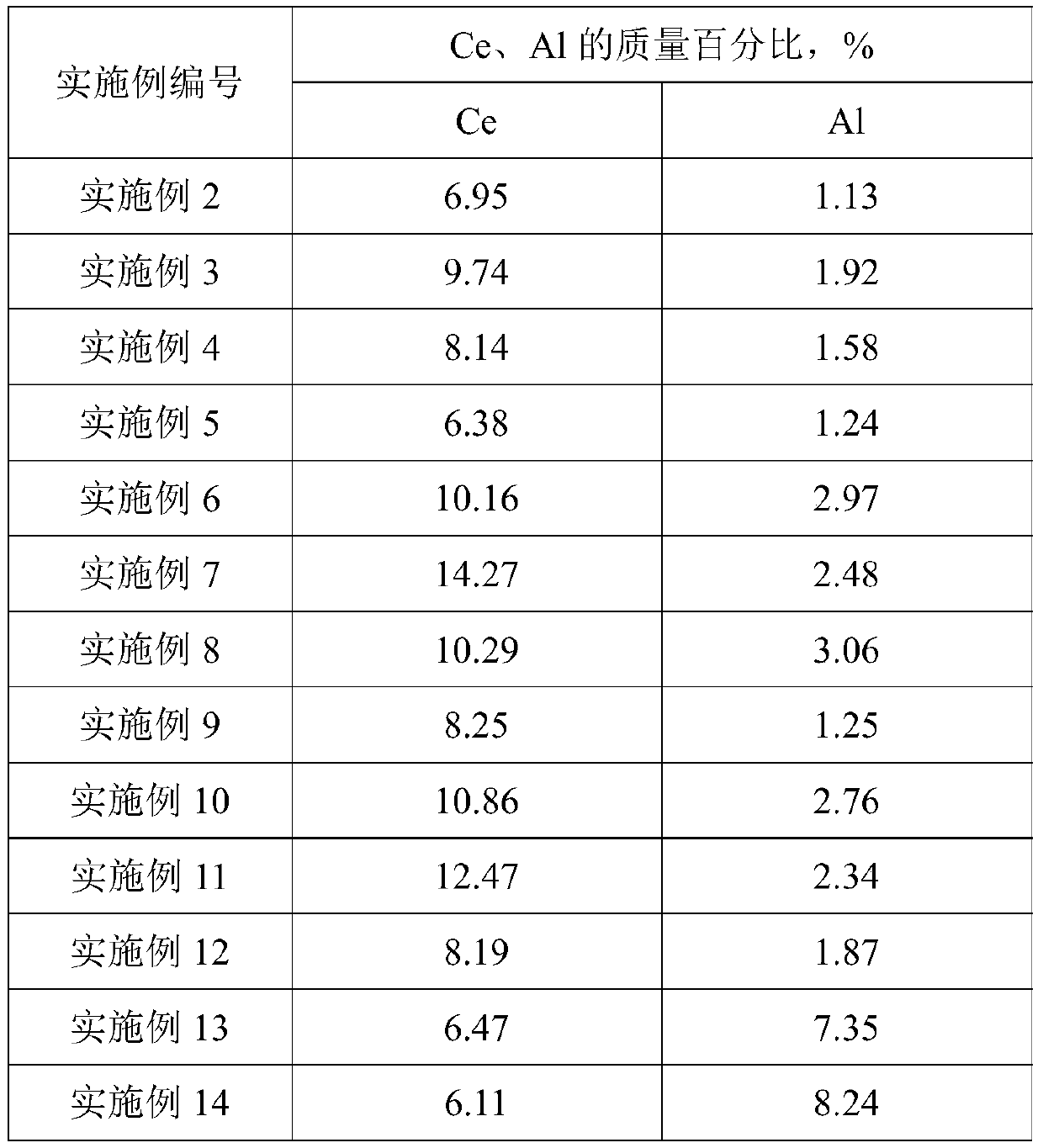

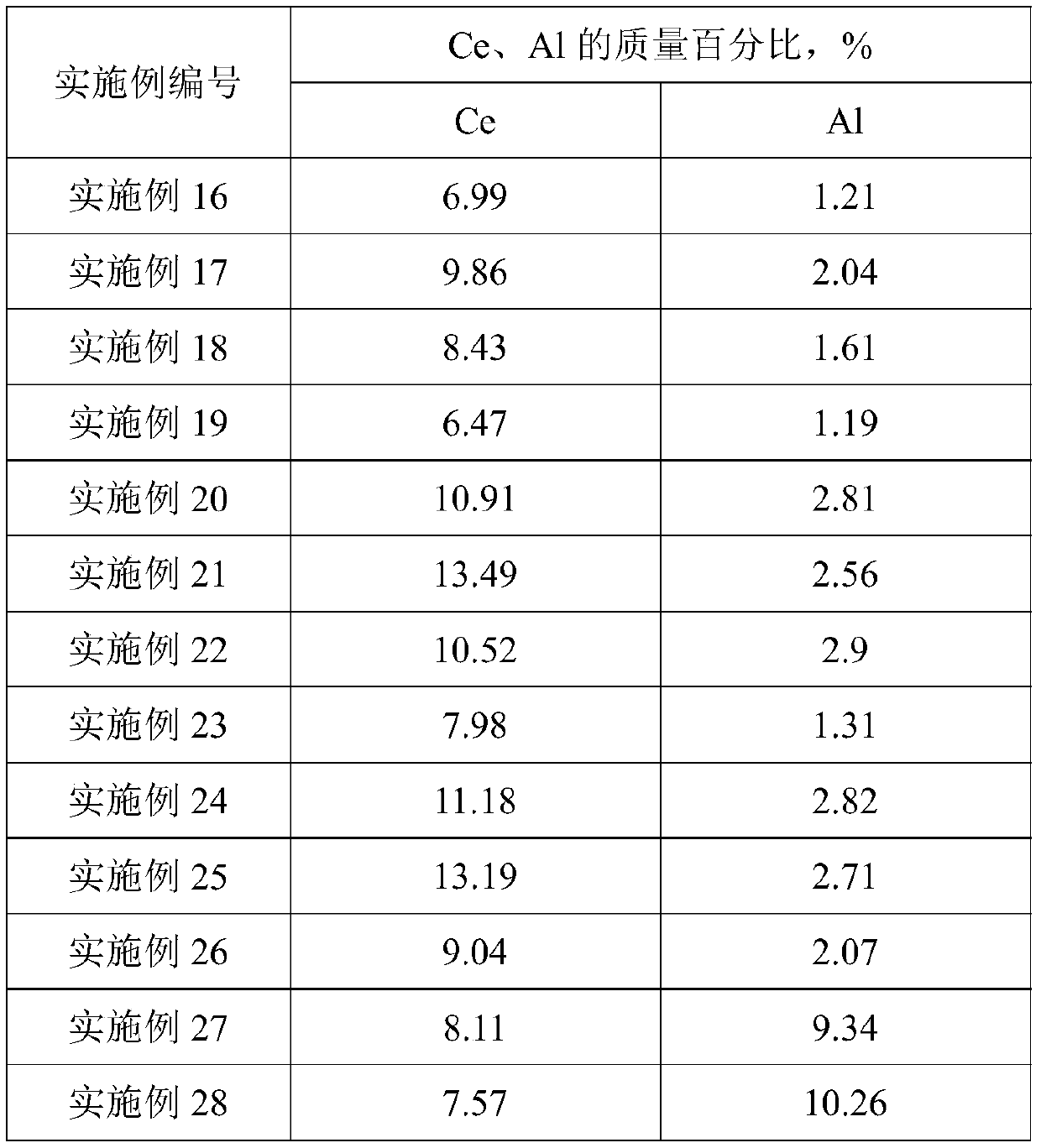

[0032] The doped sulfide composite thin film of embodiment 2-14 is composed of doping elements and sulfides, the doping elements are Ce and Al, and the sulfides are WS 2 ; The contents of each component are listed in Table 1.

[0033] The doped sulfide (WS) of table 1 embodiment 2-13 2 ) composition of the composite film

[0034]

Embodiment 15

[0036] The doped sulfide-based composite thin film of this embodiment is composed of doping elements and sulfides, the doping elements are Ce and Al, and the sulfides are MoS 2 , the mass percentage of doping element Ce is 12.98%, the mass percentage of doping element Al is 2.12%, and the balance is sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com