Doped multilayer gradient coating for metal bipolar plates of fuel cell

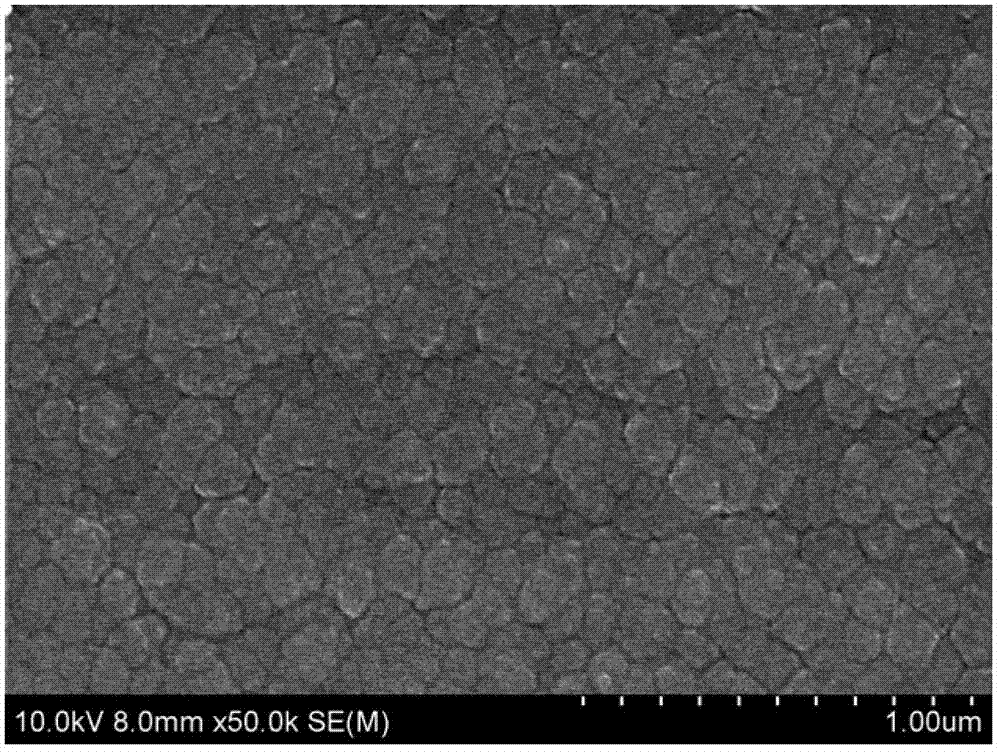

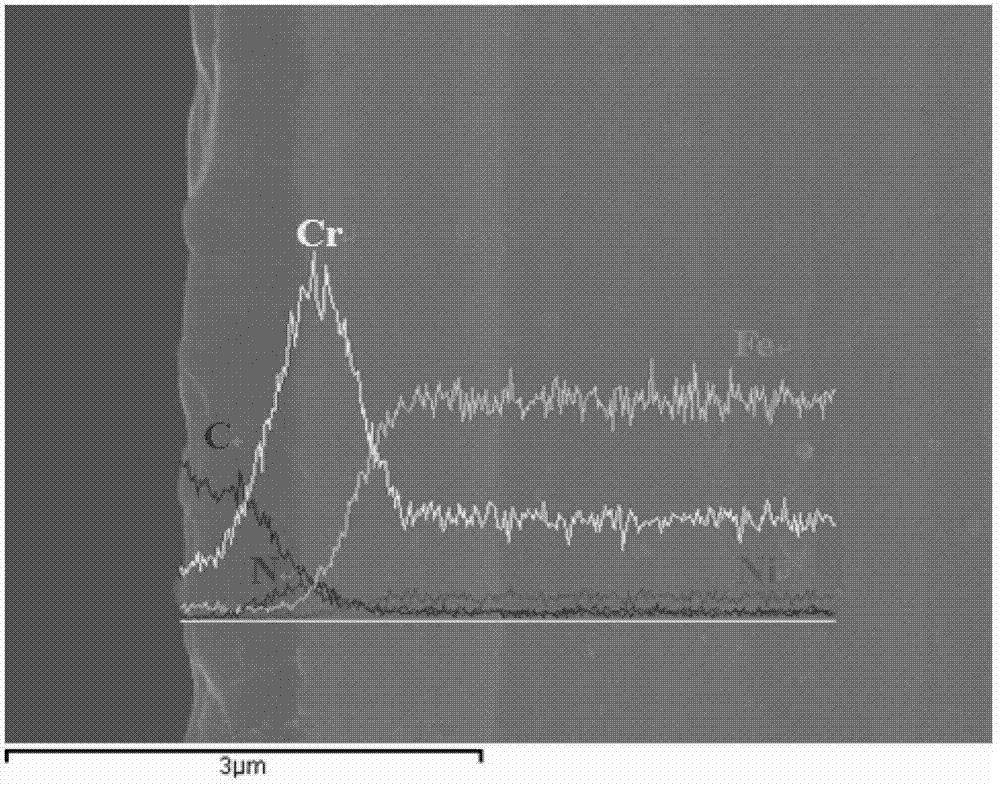

A metal bipolar plate and fuel cell technology, which is applied to fuel cell parts, battery electrodes, metal material coating technology, etc., can solve the problem of large difference in physical properties between the carbon film and the stainless steel substrate, poor bonding force of the film base, and deposition Long time and other problems, to achieve the effect of improving the stacking performance and service life, low porosity, and improving the binding force of the membrane base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1, ion sputtering cleaning;

[0039] First, put the ultrasonically cleaned stainless steel bipolar plate in the UDP650 closed-field unbalanced magnetron sputtering ion coating equipment, and start vacuuming to make the background vacuum degree lower than 5×10 -6 Torr, start feeding argon to keep the vacuum at 2×10 -2 Torr;

[0040] Secondly, apply the bias voltage to -500V, turn on the chromium target current, control it at 0.5A, and clean the stainless steel bipolar plate for 30 minutes to remove the oxide film, passivation film, etc. that may remain on the surface of the stainless steel, and obtain a certain surface roughness ;

[0041] Step 2, depositing a pure chromium transition layer;

[0042] Adjust substrate bias to -70V, chromium target current 7A, deposit Cr transition layer for 15 minutes.

[0043] Step 3, depositing the CrN coating and controlling the doping structure at the same time;

[0044] Control the bias voltage at -60V, maintain the chromiu...

Embodiment 2

[0053] In this embodiment, the first, second, and third steps are exactly the same as those in Embodiment 1. The difference is that when implementing the fourth, fifth, and sixth steps in this embodiment, while other parameters are consistent with those in Embodiment 1, the Ti target and The Al target is subjected to element doping and tissue regulation, and the target current of both the Ti target and the Al target is kept at 2A, and is gradually reduced to 0 during the fifth step.

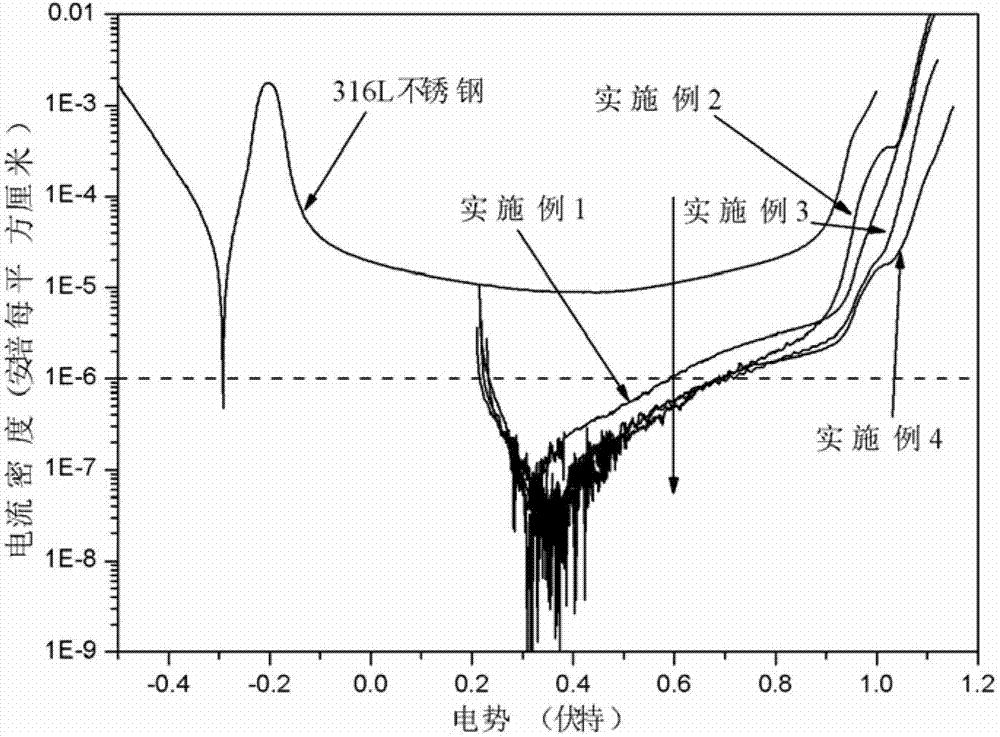

[0054] The same test method as in Example 1 is used to detect the sample of Example 2. Such as image 3 As shown in the curve of Example 2, in the simulated fuel cell corrosion solution, the corrosion potential of the sample prepared in Example 2 is 0.382V, and the corrosion current density is 8.7×10 -8 A / cm 2 , the current density at 0.6V is 4.2×10 -7 A / cm 2 . Such as Figure 4 As shown in Example 2, the surface contact resistance of the sample under the pressure condition of a typical fuel ...

Embodiment 3

[0056] In this embodiment, the first step is exactly the same as Embodiment 1, the difference is:

[0057] The second step is to control the bias voltage at -50V, the chromium target current is 5A, and deposit the Cr transition layer for 30 minutes;

[0058] The third step is to keep the chromium target current at 5A, control the bias voltage at -70V, feed nitrogen gas at a gas rate of 20SCCM, turn on the Mo target and the W target at the same time, control the Mo target current at 0.5A, and the W target current at 1A. Depositing a CrN coating doped with Mo and W elements for 45 minutes;

[0059] The fourth step, control the bias voltage at -50V, turn on the graphite target, gradually increase the current from 0A to 6A, and gradually reduce the current of the chromium target, Mo target and W target to 0A, and deposit the chromium-carbon-nitrogen transition layer for 15 minutes;

[0060] The fifth step is to close the chromium target, Mo target and W target, control the bias v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com