High-hardness and low-stress multi-element composite diamond-like coating and preparation method thereof

A diamond coating and multi-component compounding technology, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems of hardness reduction and performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

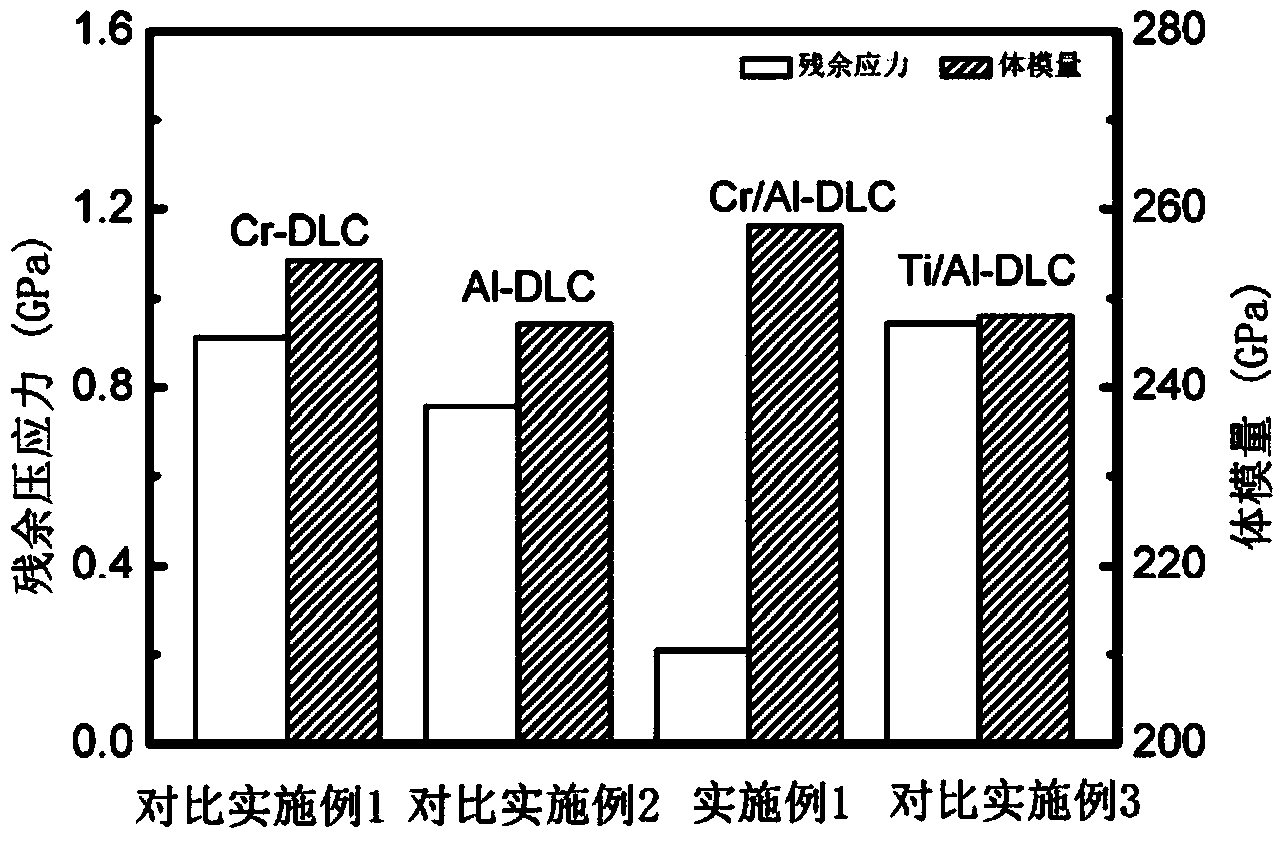

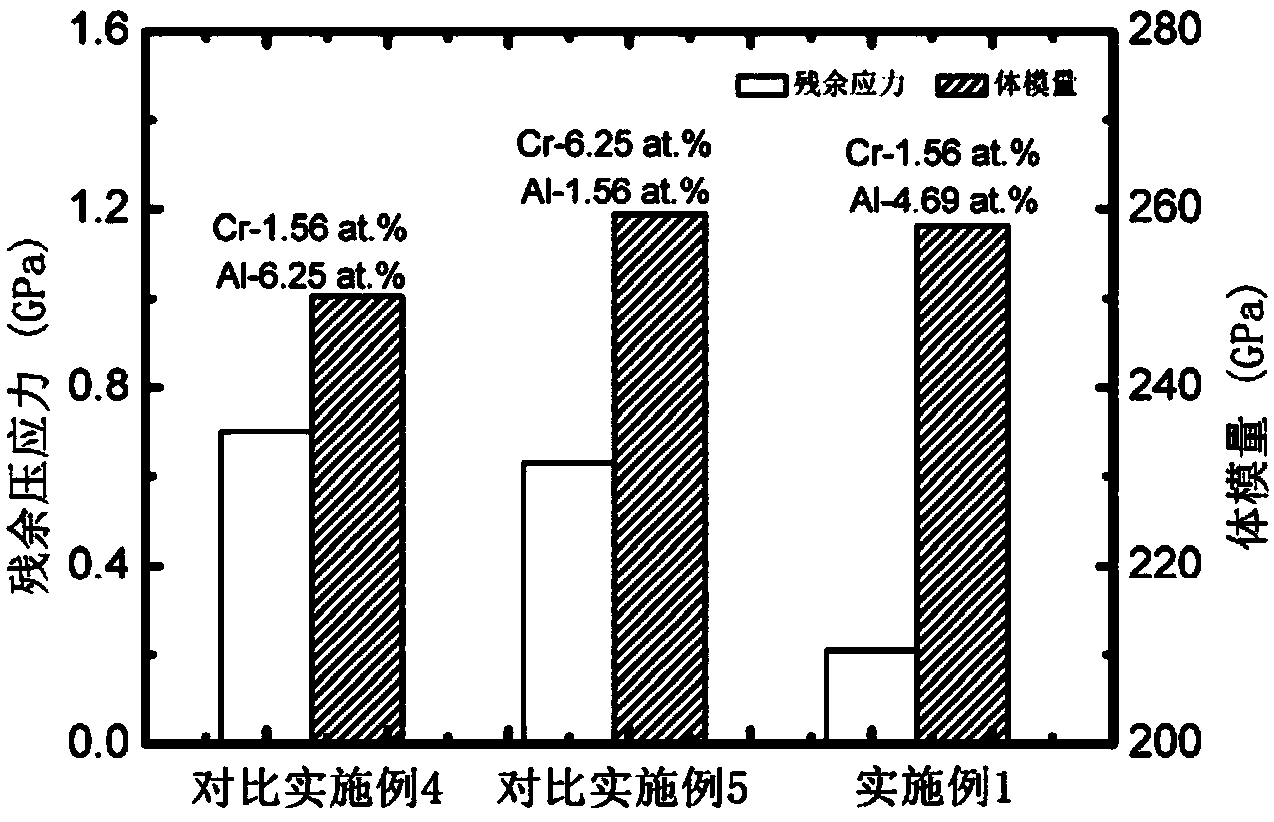

[0039] In Example 1, the coating on the surface of the Si substrate is a multi-component composite diamond-like coating. The multi-component composite diamond-like coating is composed of diamond-like, the first doping element Al and the second doping element is Cr element, referred to as Cr / Al multi-component composite diamond-like coating; and, in the multi-component composite diamond-like coating In the layer, the atomic percentage content of Al element is 4.69%, and the atomic percentage content of Cr element is 1.56%.

[0040] The above-mentioned Cr / Al multi-component composite diamond-like coating is prepared by using a linear ion beam composite magnetron sputtering coating equipment, which includes a vacuum chamber, a linear ion source, a magnetron sputtering source and a workpiece bracket , including the following steps:

[0041] Step 1. Clean the Si substrate:

[0042] Place the Si substrate on the workpiece holder of the vacuum chamber, and adjust the vacuum chamber a...

Embodiment 2

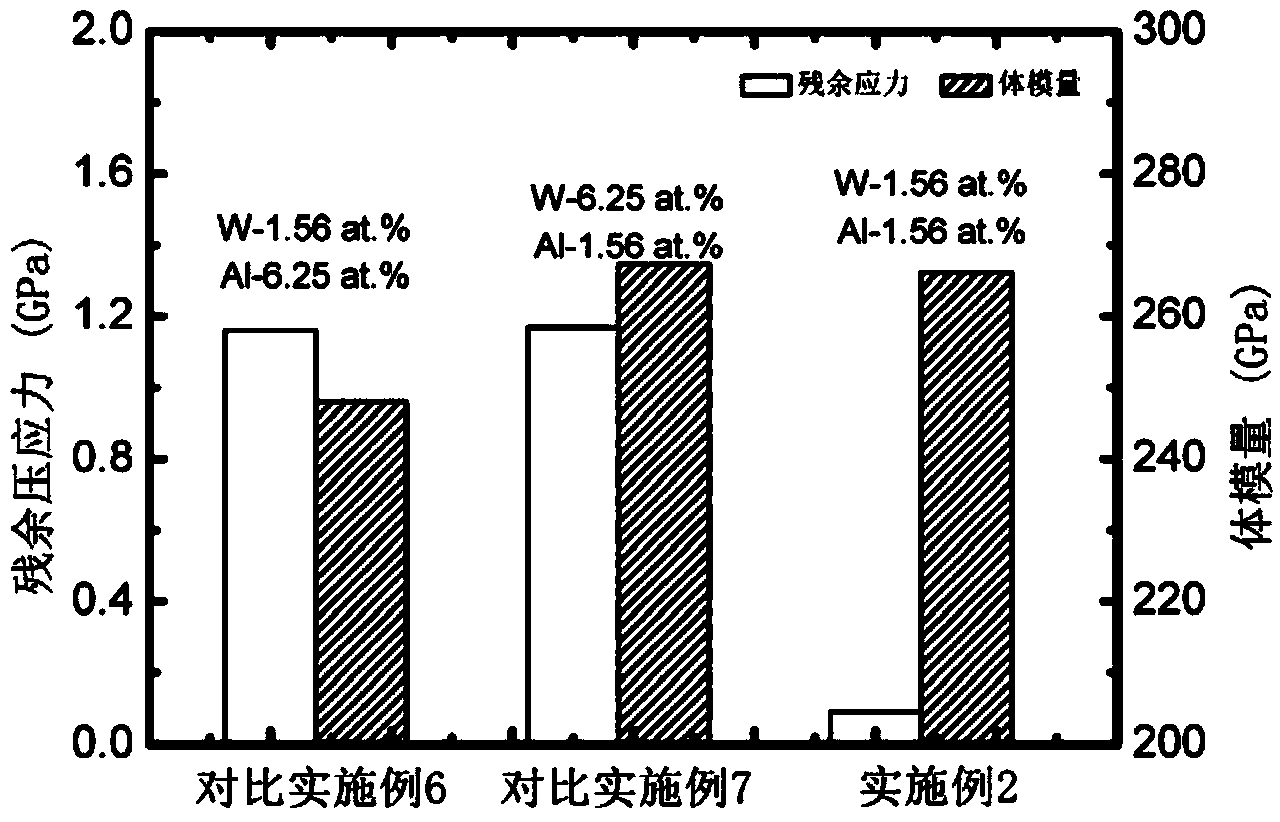

[0077] In Example 2, the coating on the surface of the Si substrate is a multi-component composite diamond-like coating. The multi-component composite diamond-like coating is composed of diamond-like, the first doping element Al and the second doping element is W element, referred to as W / Al multi-component composite diamond-like coating; and, in the multi-component composite diamond-like coating In the layer, the atomic percent content of Al element is 1.56%, and the atomic percent content of W element is 1.56%.

[0078] The above-mentioned W / Al multi-component composite diamond-like coating is prepared by using a linear ion beam composite magnetron sputtering coating equipment, which includes a vacuum chamber, a linear ion source, a magnetron sputtering source and a workpiece bracket , including the following steps:

[0079] Step 1. Clean the Si substrate:

[0080] Place the Si substrate on the workpiece holder of the vacuum chamber, and adjust the vacuum chamber air press...

Embodiment 3

[0096] In Example 2, the coating on the surface of the Si substrate is a multi-component composite diamond-like coating. The multi-component composite diamond-like coating is composed of diamond-like, the first doping element Cu, and the second doping element is Cr element, referred to as Cr / Cu multi-component composite diamond-like coating; and, in the multi-component composite diamond-like coating In the layer, the atomic percentage content of Cu element is 1.56%, and the atomic percentage content of Cr element is 1.56%.

[0097] The above-mentioned Cr / Cu multi-component composite diamond-like coating is prepared by using a linear ion beam composite magnetron sputtering coating equipment, which includes a vacuum chamber, a linear ion source, a magnetron sputtering source and a workpiece bracket , including the following steps:

[0098] Step 1. Clean the Si substrate:

[0099] Place the Si substrate on the workpiece holder of the vacuum chamber, and adjust the vacuum chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual stress | aaaaa | aaaaa |

| Residual stress | aaaaa | aaaaa |

| Residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com