Method for preparing diamond coating on surface of cobalt-containing hard alloy and tool and die with diamond coating

A diamond coating and cemented carbide technology, which is applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problems affecting the bonding strength of diamond coating film base and the quality of diamond coating, so as to improve the quality of the diamond coating. Crystal uniformity, improve the bonding force of the film base, and inhibit the effect of out-diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

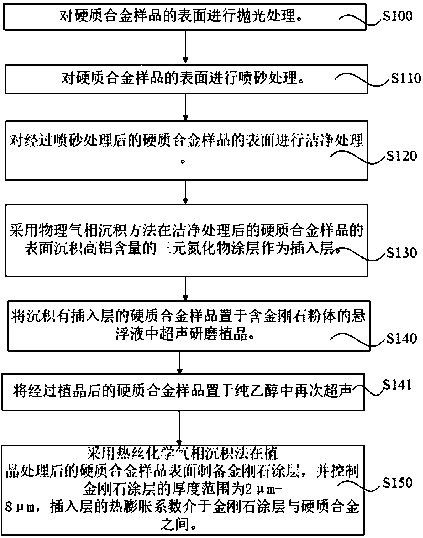

Method used

Image

Examples

Embodiment 1

[0055] Method for preparing diamond coating on the surface of YG6 cemented carbide

[0056] 1) The φ20mm*5mm YG6 cemented carbide sample after surface polishing is subjected to dry sandblasting and wet sandblasting in sequence. The distance between the nozzle of the spray gun and the surface of the YG6 cemented carbide sample is 50 mm, and the spray angle is 90 o . Dry sandblasting uses 320 mesh white corundum sand, the sandblasting pressure is 0.3MPa, and the time is 60s; wet sandblasting uses 600 mesh white corundum sand, the sandblasting pressure is 0.2MPa, and the time is 150s.

[0057] 2) Use the commercially available WIN-92 metal cleaning agent (WIN-92 is a multi-functional and efficient water-based cleaning agent, containing a variety of surfactants, alkaline additives, penetrating agents, and strong degreasing ability) for ultrasonic tank removal Oil stains and residual sand particles on the surface of YG6 cemented carbide, the ultrasonic frequency is 28KHz, the ult...

Embodiment 2

[0062] Method for preparing diamond coating on the surface of YG10 cemented carbide

[0063] 1) The φ20mm*5mm YG10 cemented carbide sample after surface polishing is subjected to dry sandblasting and wet sandblasting in sequence. The distance between the nozzle of the spray gun and the surface of the YG10 cemented carbide sample is 50mm, and the spray angle is 90°. Dry sandblasting uses 320 mesh white corundum sand, the sandblasting pressure is 0.3MPa, and the time is 120s; wet sandblasting uses 600 mesh white corundum sand, the sandblasting pressure is 0.4MPa, and the time is 90s.

[0064] 2) Use the ultrasonic tank of commercially available WIN-92 metal cleaning agent to remove the oil stain on the surface of the YG10 cemented carbide sample. The ultrasonic frequency is 28KHz, the ultrasonic intensity is 30W / L, and the ultrasonic time is 30min; after rinsing and drying, the surface roughness Ra is obtained. 0.39μm cemented carbide surface.

[0065] 3) Put the cleaned YG10 ...

Embodiment 3

[0069] Method for preparing diamond coating on the surface of YG6 cemented carbide

[0070] 1) The φ20mm*5mm YG6 cemented carbide sample after surface polishing is subjected to dry sandblasting and wet sandblasting in sequence. The distance between the nozzle of the spray gun and the surface of the YG6 cemented carbide sample is 50mm, and the spray angle is 90°. Dry sandblasting uses 320 mesh white corundum sand, the sandblasting pressure is 0.3MPa, and the time is 90s; wet sandblasting uses 600 mesh white corundum sand, the sandblasting pressure is 0.2MPa, and the time is 120s.

[0071]2) Use the ultrasonic tank of commercially available WIN-92 metal cleaning agent to remove the oil stain on the surface of the YG6 cemented carbide sample. The ultrasonic frequency is 28KHz, the ultrasonic intensity is 25W / L, and the ultrasonic time is 15min; after rinsing and drying, the surface roughness Ra is obtained. 0.33μm cemented carbide surface.

[0072] 3) Put the cleaned YG6 cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com