Preparation method of multi-metal doping hydrogen-free diamond carbon film

A multi-element metal and diamond thin film technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of reducing the internal stress of the film, poor thermal stability, poor bonding force of the film base, etc., to achieve optional Strong performance, strong process operability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

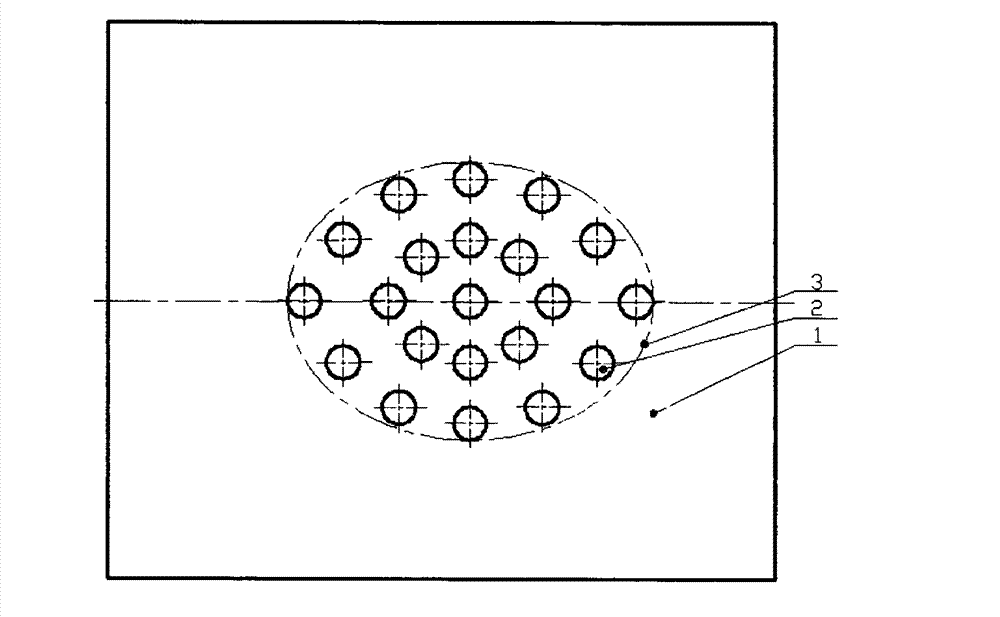

Image

Examples

Embodiment 1

[0025] 1. Use tungsten and molybdenum mosaic target (tungsten is used as the basic target material, mosaic block material is molybdenum);

[0026] 2. Ultrasonic clean the stainless steel sheet, after drying, fix it on the workpiece rack in the vacuum chamber of the ion beam assisted deposition coating equipment and vacuumize it, and pre-vacuumize it to 2.0×10 -4 Pa;

[0027] 3. Connect the sputtering ion source and the auxiliary source gas source, pass the argon gas into the vacuum chamber, and keep the air pressure lower than 1.4×10 -2 Pa, the sputtering source uses an ion beam with a voltage of 2.7KV and a current of 100mA to bombard the target; the auxiliary source uses a voltage of 0.2KV and a beam of 100mA to bombard and clean the sample and activate the surface; the bombardment time is 10min.

[0028] 4. The sputtering source uses an ion beam with a voltage of 2.7KV and an ion beam current of 75mA to bombard the graphite target; an ion beam with a voltage of 2.2KV and a...

Embodiment 2

[0032] 1. Titanium chromium mosaic target is used (titanium is used as the basic target material, and the mosaic block material is chromium);

[0033] 2. Ultrasonic clean the high-speed steel mold piece, after drying, fix it on the workpiece rack in the vacuum chamber of the ion beam assisted deposition coating equipment and vacuumize it, and pre-vacuumize it to 2.0×10 -4 Pa;

[0034] 3. Connect the sputtering ion source and the auxiliary source gas source, pass the argon gas into the vacuum chamber, and keep the air pressure lower than 1.5×10 -2 Pa, the sputtering source uses an ion beam with a voltage of 2.7KV and a current of 100mA to bombard the target; the auxiliary source uses a voltage of 0.2KV and a beam of 100mA to bombard the sample for cleaning and surface activation; the bombardment time is 10min.

[0035] 3. The sputtering source uses an ion beam with a voltage of 2.5KV and an ion beam current of 80mA to bombard the graphite target; an ion beam with a voltage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com