Environment-friendly wax oil and preparation method thereof

A kind of wood wax oil and environmental protection technology, applied in the field of coatings, can solve the problems of insufficient mechanical strength, narrow application range, poor dry rate of paint film, etc., achieve ideal durability effect, easy brushing construction, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

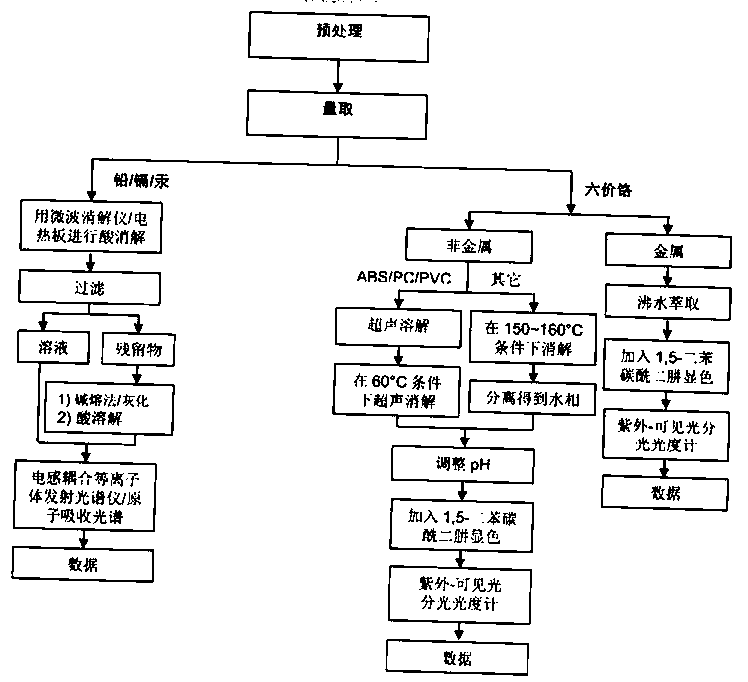

Method used

Image

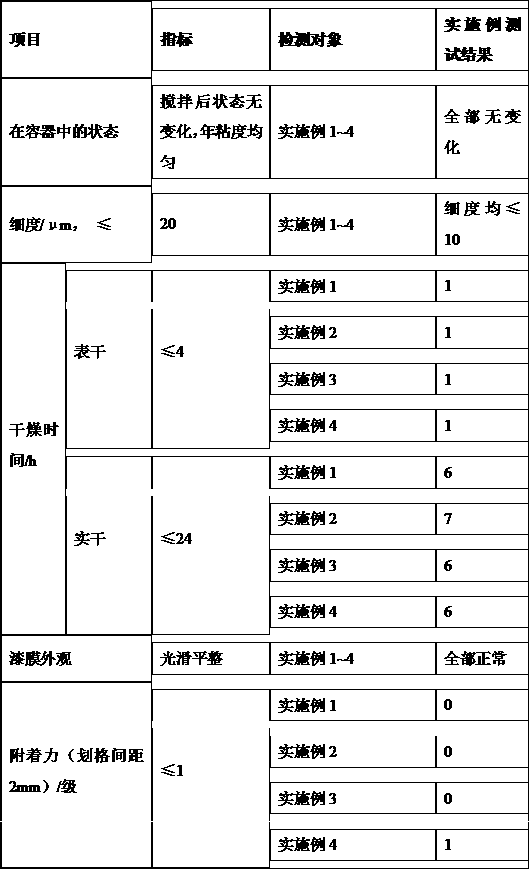

Examples

Embodiment 1

[0072] Embodiment 1: Preparation and use of environment-friendly wood wax oil

[0073] (1) Prepare the raw materials required for the preparation of environmentally friendly wood wax oil according to the following proportions by weight.

[0074] Isocyanate modified long oil alkyd resin 30g;

[0075] 200 g linseed oil;

[0076] Tung oil 150 g;

[0077] Carnauba Wax 100 g

[0078] Beeswax 100 g;

[0079] PTFE wax 80 g;

[0080] Rosin resin 100 g;

[0081] Rare earth catalyst 50 g;

[0082] Fatty alcohol polyoxyethylene methyl-terminated polyether 6 g;

[0083] Free radical absorber 1 g;

[0084] HALS 6 g.

[0085] (2) Environmentally friendly wood wax oil is prepared according to the following steps:

[0086] Step 1): Add the raw material isocyanate-modified alkyd resin and vegetable oil into the mixer in batches, mix evenly, and stir for 40 minutes at a speed of 1200 r / min;

[0087] Step 2): Prepare the raw material biological wax and natural resin according to the w...

Embodiment 2

[0091] Embodiment 2: the preparation and use of environment-friendly wood wax oil

[0092] Isocyanate modified long oil alkyd resin 300 g;

[0093] 100 g linseed oil;

[0094] Tung oil 100 g;

[0095] Carnauba wax 50 g;

[0096] 150 g beeswax;

[0097] PTFE wax 80 g;

[0098] Rosin resin 120 g;

[0099] Rare earth catalyst 50 g;

[0100] Fatty alcohol polyoxyethylene methyl-terminated polyether 6 g;

[0101] Free radical absorber 1 g;

[0102] HALS 6 g.

[0103] (2) Environmentally friendly wood wax oil is prepared according to the following steps:

[0104] Step 1): Add the raw material isocyanate-modified alkyd resin and vegetable oil into the mixer in batches, mix evenly, and stir for 60 minutes at a speed of 2000 r / min;

[0105] Step 2): Prepare the raw material bio-wax and natural resin according to the weight ratio, add them into the reaction kettle, raise the temperature to 100°C-120°C, stir for 120 minutes, and cool down;

[0106] Step 3): Add the mixture pre...

Embodiment 3

[0110] Embodiment 3: the preparation and use of environment-friendly wood wax oil

[0111] Isocyanate modified long oil alkyd resin 350 g;

[0112] 200 g linseed oil;

[0113] Tung oil 150 g;

[0114] Carnauba wax 150 g;

[0115] Beeswax 100 g;

[0116] PTFE wax 80 g;

[0117] Rosin resin 100 g;

[0118] Rare earth catalyst 60 g;

[0119] Fatty alcohol polyoxyethylene methyl-terminated polyether 6 g;

[0120] Free radical absorber 2 g;

[0121] HALS 6 g.

[0122] (2) Environmentally friendly wood wax oil is prepared according to the following steps:

[0123] Step 1): Add the raw material isocyanate-modified alkyd resin and vegetable oil into the mixer in batches, mix evenly, and stir for 40 minutes at a speed of 3000 r / min;

[0124] Step 2): Prepare the raw material biological wax and natural resin according to the weight ratio, add them into the reaction kettle, raise the temperature to 110°C~120°C, stir for 90 minutes, and cool down;

[0125] Step 3): Add the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com