Preparation method and equipment of patterned electrostatic chuck

An electrostatic chuck, graphic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

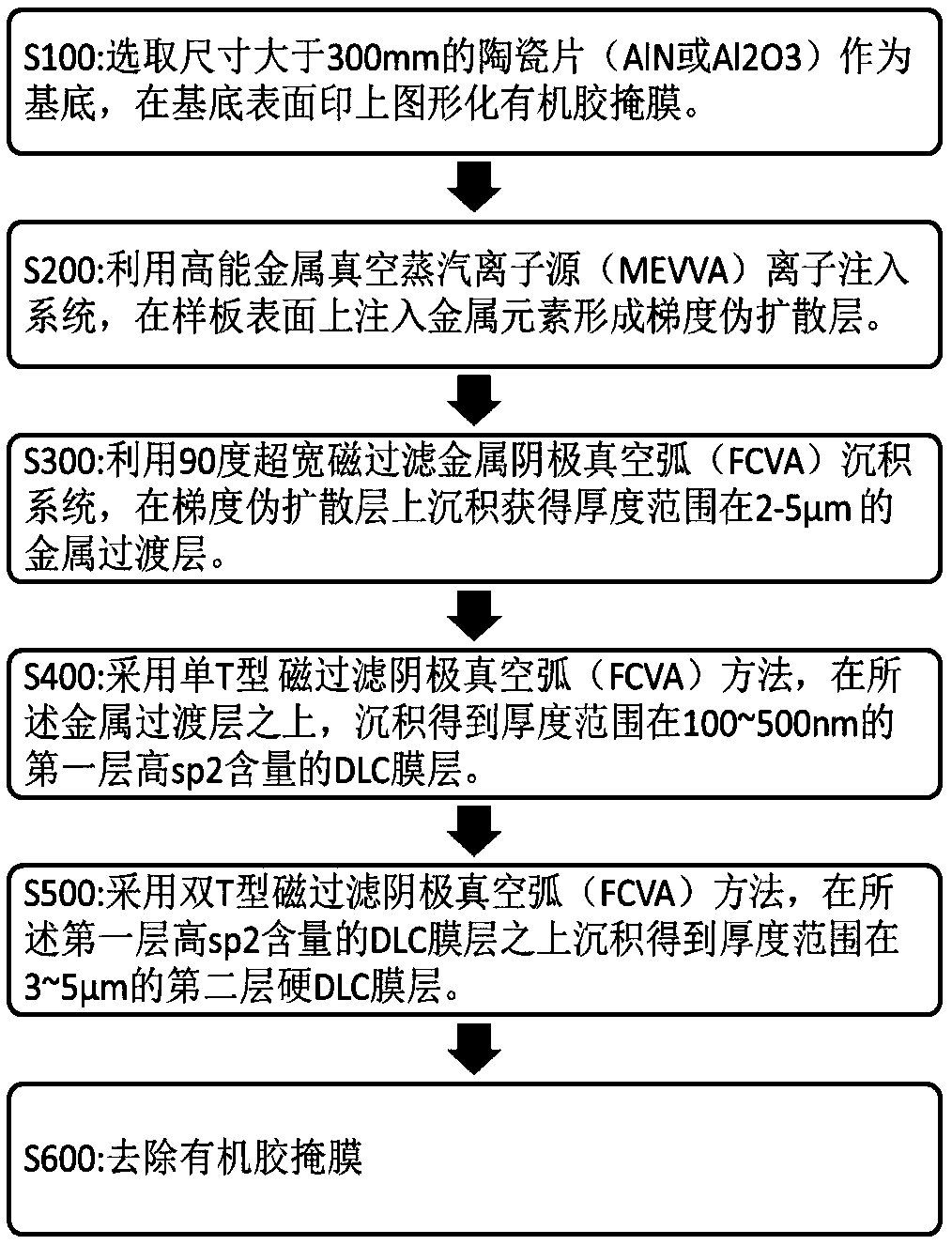

[0056] It should be noted that, in this embodiment, the DLC film is prepared by ion beam technology, and the selected base layer is super-sized (greater than 300mm) AlN or Al 2 o 3 Ceramics. refer to figure 1 , which shows the DLC film preparation method of this embodiment, the preparation method includes the following steps:

[0057] S100: Using super-sized (greater than 300mm) AlN or Al with patterned organic rubber mask printed on the surface 2 o 3 A ceramic sheet is used as the substrate.

[0058] In this step, the screen printing screen is made according to the mask design drawing. The mask glue uses temperature-resistant Japanese Silicon RTV glue, which has a temperature resistance range of 80-400°C, and does not release gas within this range, and at the same time combines with the substrate The strength is not more than 40N. Graphical organic offset printing is applied to the surface of the ceramic sheet by automatic (semi-automatic or manual) screen printing equi...

Embodiment 1

[0088] Embodiment 1: AlN ceramic sheet without DLC coating;

Embodiment 2

[0089] Embodiment 2: AlN ceramic sheet with DLC coating;

[0090] The UMT friction and wear tester is used for the experiment below. The specific settings are: use a SiC standard ball with a diameter of 4mm, the loading force is 200g, the loading time is 5min, 10min, 15min, 30min, 60min, 120min and 180min, and the friction frequency is 2Hz. Back and forth friction.

[0091] refer to Figure 7 , is the comparative data of the friction coefficient of the experimental pieces with DLC coating and without DLC coating.

[0092] from Figure 7 It can be seen that the friction coefficient of aluminum nitride with DLC coating is lower than 0.09, and the lowest reaches about 0.05, while the friction coefficient of aluminum nitride without DLC deposition is relatively large, about 0.8-0.9. The friction coefficient reflects the wear resistance of the material. The smaller the friction coefficient, the better the wear resistance of the film. The friction coefficient of aluminum nitride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com