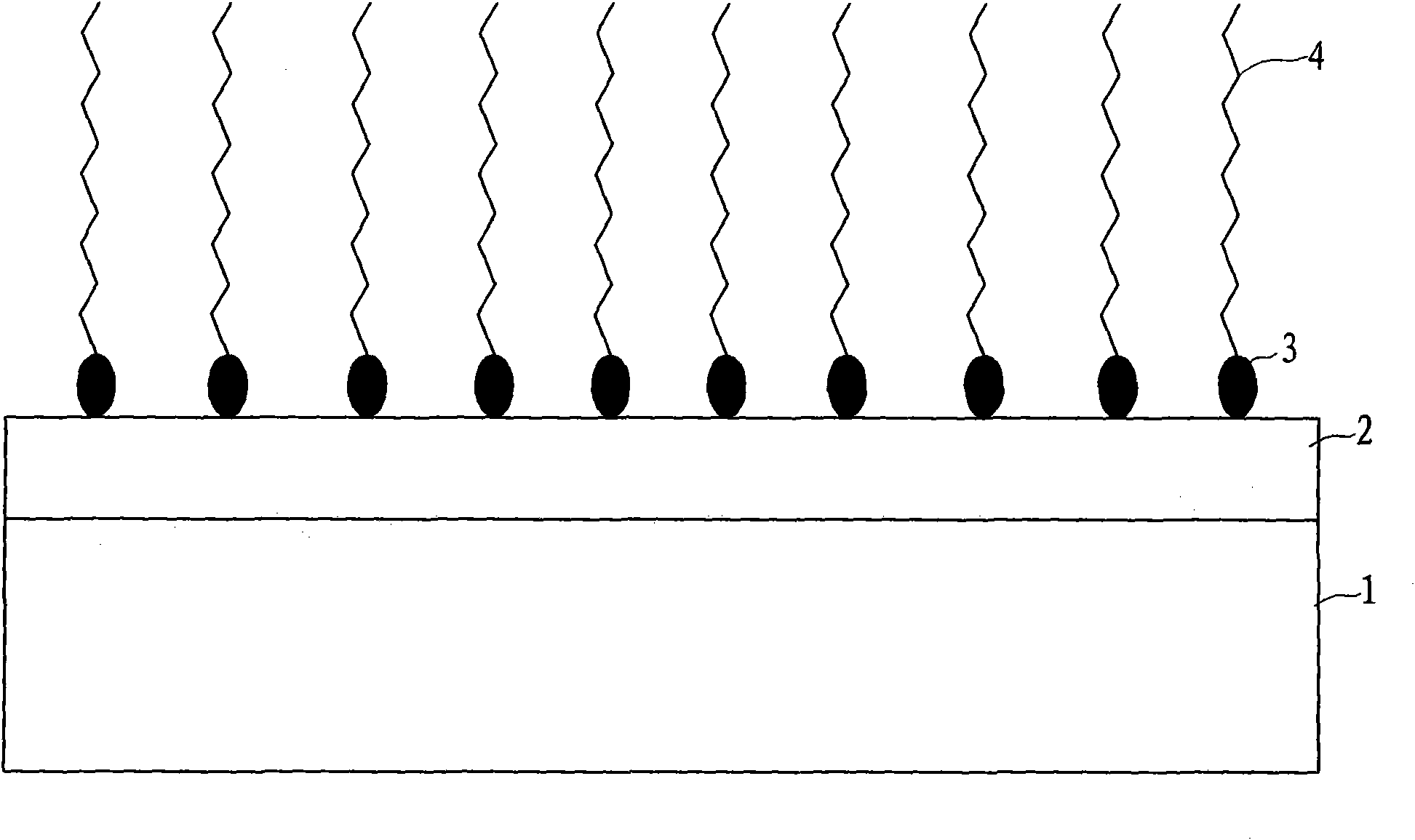

Preparation method of photovoltaic glass surface antireflection film

A technology of photovoltaic glass and anti-reflection film, applied in the field of photovoltaic glass surface treatment, can solve the problems of attenuation of anti-reflection performance, easy water absorption and deliquescence of the film layer, easy falling off of the film, etc., to increase the interaction force, improve the wiping resistance, reduce The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: 0.1mol water, 0.035mol NH 3 ·H 2 O and 5 mol of absolute ethanol were mixed, stirred and heated, and when the temperature reached the set temperature of 30°C, 0.05 mol of tetraethyl orthosilicate (TEOS) was quickly added to keep the temperature constant, and the stirring was continued for 30 hours to obtain a stable and transparent silica sol A , slowly add 0.003mol γ-aminopropyltriethoxysilane into 0.3mol absolute ethanol, and keep stirring for 5min to obtain solution B. Slowly drop solution B into sol A and stir for 5 minutes to obtain an organic-inorganic-organic hybrid silica sol, which is aged for 10 days before use.

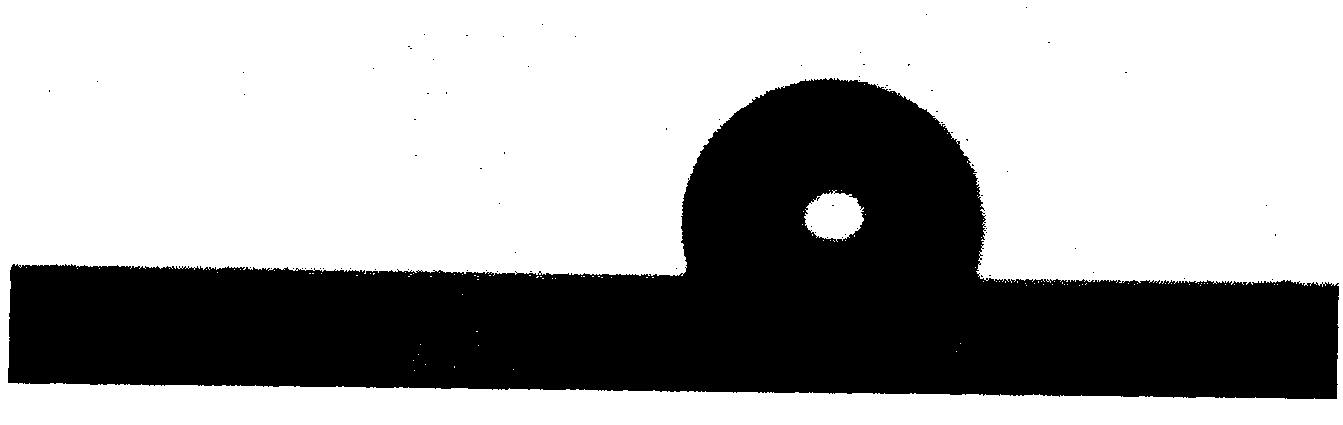

[0024] The film is coated by the pulling method, the pulling speed is 2mm / s, the number of pulling is 3 times, and the transparent silica gel film can be obtained after natural drying after the pulling. The gel film prepared above was treated in an atmosphere of tridecafluorooctyltriethoxysilane at a temperature of 50-150° C., and the...

Embodiment 2

[0026] Embodiment 2: 0.1mol water, 0.035mol NH 3 ·H 2 O and 5mol ethylene glycol were mixed and stirred and heated. When the temperature reached the set temperature of 30°C, 0.05mol tetraethyl orthosilicate (TEOS) and 0.05mol γ-aminopropyltriethoxysilane were quickly added and mixed and stirred for 30 hours to obtain a stable Transparent inorganic-organic hybrid silica sol. Aging for 10 days for use.

[0027] Coating the aged organic-inorganic hybrid silica sol with the pulling method, the pulling speed is 2mm / s, the number of pulling is 3 times, and the transparent silica gel film can be obtained by natural drying after pulling. The gel film prepared above was treated in an atmosphere of tridecafluorooctyltriethoxysilane at a temperature of 50-150° C., and the treatment pressure was 2 atm. After the atmosphere treatment, the sample was heat-treated in the air at 300°C for 0.5 hours, and a silica-based anti-reflection film with high transmittance, good adhesion to the film ...

Embodiment 3

[0028] Embodiment 3: 0.25mol water, 0.078mol NH 3 ·H 2O and 5 mol of absolute ethanol were mixed, stirred and heated, and when the temperature reached the set temperature of 40°C, 0.05 mol of tetraethyl orthosilicate (TEOS) was quickly added to keep the temperature constant, and the stirring was continued for 30 hours to obtain a stable and transparent silica sol A , slowly add 0.02 mol of tridecafluorooctyltriethoxysilane into 0.3 mol of absolute ethanol, and keep stirring for 5 minutes to obtain solution B. Solution B was slowly dropped into sol A, and stirred for 5 minutes to obtain an inorganic-organic hybrid silica sol, which was aged for 10 days before use.

[0029] Coating the aged inorganic-organic hybrid silica sol with the pulling method, the pulling speed is 2mm / s, and the number of pulling times is 3 times. After the pulling is completed, it can be dried naturally to obtain a transparent silica gel film. The gel film prepared above was treated in a hexamethyldisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com