Low-temperature curing adhesive for forming medicine-carrying winding composite shell and preparation method

A shell forming and adhesive technology, applied in the direction of adhesive, adhesive type, adhesive additive, etc. The connection performance, the preparation process are convenient, and the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] According to the second aspect of the present invention, there is provided a method for preparing a low-temperature curing adhesive for forming a wound composite shell with medicine, which is used to prepare the low-temperature curing adhesive for forming a wound composite shell with medicine described in the first aspect, including:

[0057] The curing catalyst and the plasticizer are prepared into a solution according to the mass ratio;

[0058] Mix the coupling agent, reinforcing filler and tackifying resin according to the mass ratio;

[0059] At room temperature, add the composition of adhesive, chain extender, crosslinking agent, curing catalyst and plasticizer solution, reinforcing filler, coupling agent and tackifying resin into the mixing container according to the mass ratio, and Stir well after each addition;

[0060] Stir evenly after adding the curing agent, vacuum degassing, preferably degassing for 10 to 20 minutes, to prepare a low-temperature curing ad...

Embodiment 1

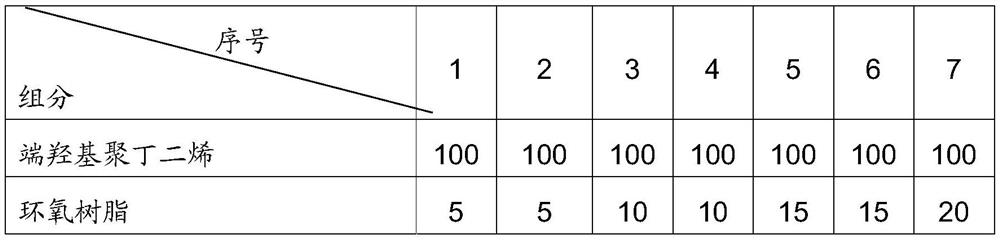

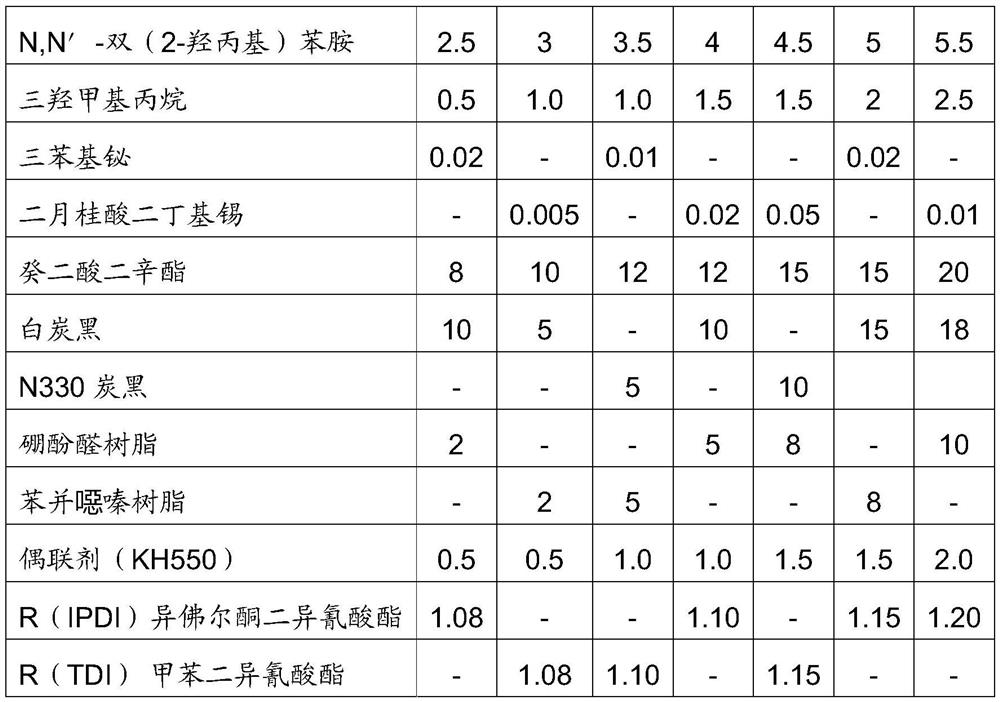

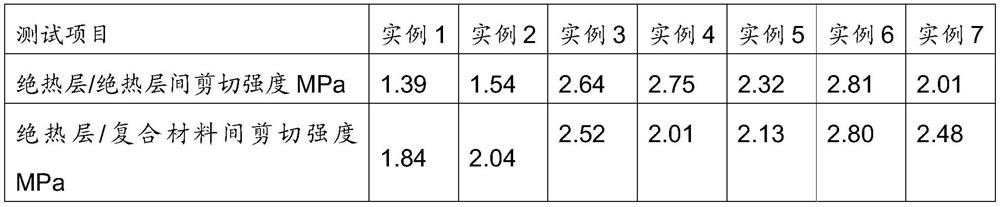

[0069] At room temperature, 100g of hydroxyl-terminated polybutadiene, 5g of epoxy resin E51, 2.5g of N,N'-bis(2-hydroxypropyl)aniline, 0.5g of trimethylolpropane, 8.02g of triphenyl Bismuth dioctyl sebacate solution, (0.5g coupling agent, 10g white carbon black and 2g boron phenolic resin) composition was added into the mixing container, and fully stirred evenly after each addition. Stir and disperse for 10 minutes, then bake at 60°C for 10 minutes. Then add an IPDI curing agent with a curing parameter R=1.08 at room temperature, stir evenly and then vacuum degas for 15 minutes to obtain a low-temperature curing adhesive. The adhesive of the present invention was used to make shear samples of the thermal insulation layer and the thermal insulation layer, and the thermal insulation layer and the shell material resin sheet, and cured at 70° C. for 5 days. The measured shear strength results are listed in Table 2.

Embodiment 2

[0071] Repeat the method of Example 1 according to the content of each component specified in Table 1, but replace triphenylbismuth with dibutyltin dilaurate, polyoxazine resin replaces boron phenolic resin, TDI replaces IPDI, wherein N, N'- The consumption of bis(2-hydroxypropyl)aniline is 3g, the consumption of trimethylolpropane is 1.0g, the consumption of dibutyltin dilaurate is 0.005g, the consumption of dioctyl sebacate is 10g, white carbon black 5g, the amount of polyoxazine resin is 2g, and the TDI curing parameter R is 1.08. The test results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com