Preparation method of TiC ceramic coating

A technology of ceramic coating and electrode, which is applied in the field of preparation of TiC ceramic coating, can solve the problems of micro cracks, limited application, poor process stability, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

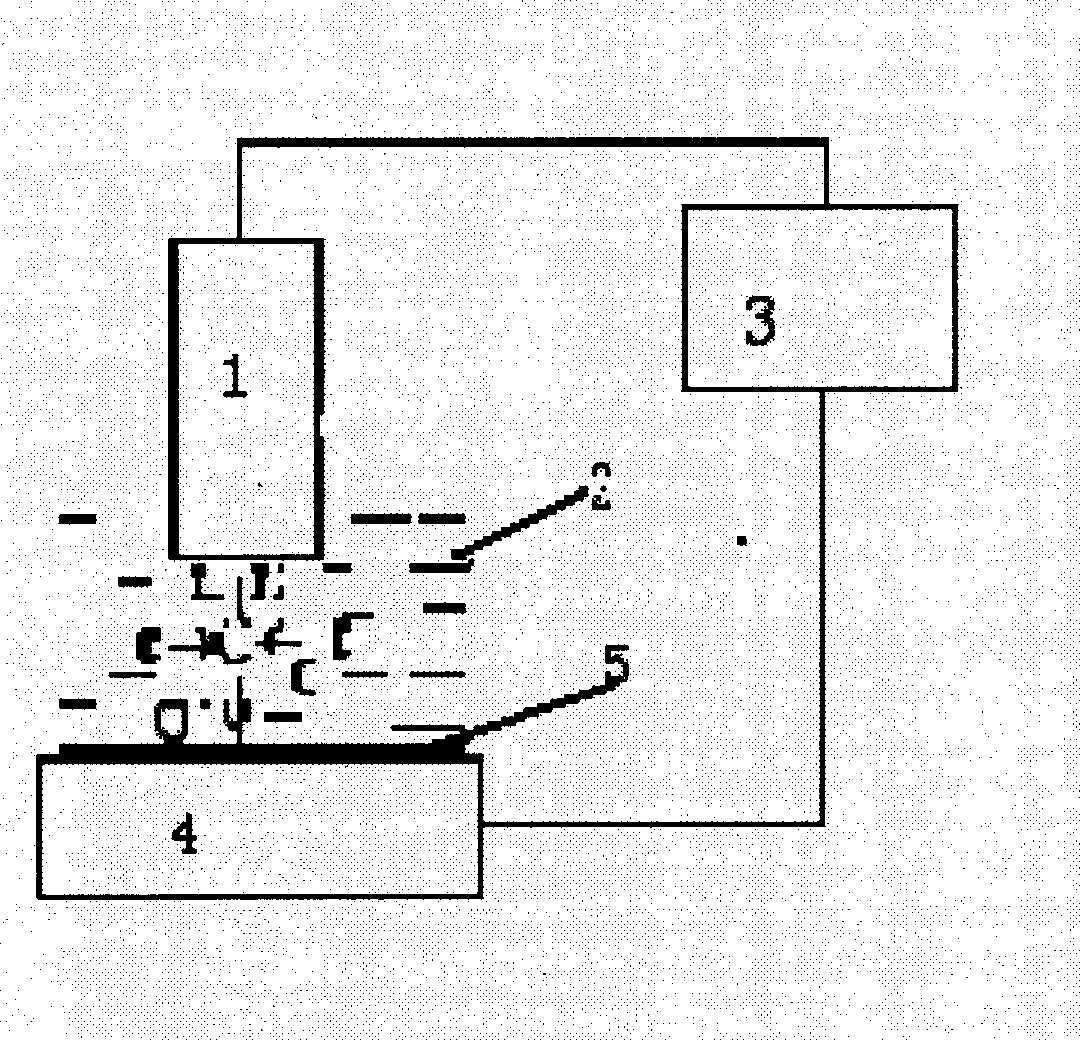

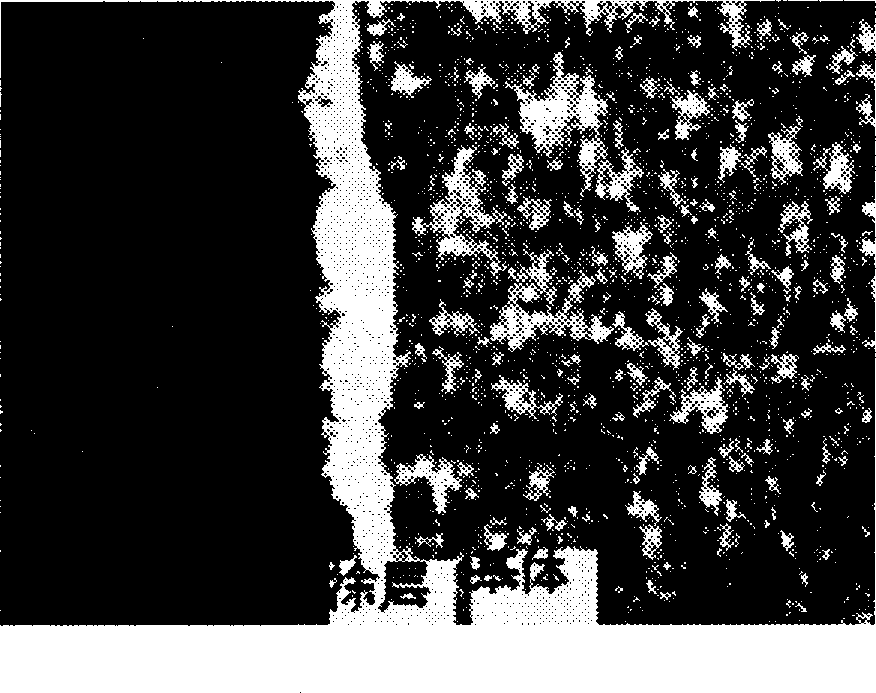

[0021] The principle diagram of the present invention is as figure 1 As shown, the preparation process is carried out on an ordinary EDM machine tool, the liquid medium is industrial aviation kerosene; the discharge electrode is a metal Ti electrode, and the substrate to be deposited, that is, the workpiece electrode (4) is 45# carbon steel. The deposition area is 80mm 2 , the preparation method of TiC ceramic coating of the present invention comprises the following steps:

[0022] 1) The bulk metal Ti electrode (1) and workpiece electrode (4) are placed in kerosene (2);

[0023] 2) connecting the anode of the pulse power supply (3) to the bulk metal Ti electrode (1), and connecting the cathode of the pulse power supply (3) to the workpiece electrode (4);

[0024] 3) Turn on the pulse power supply (3), the Ti metal ions released by the discharge of the metal Ti electrode (1) in the liquid medium and the C ions ionized in the kerosene (2) perform electrochemical reactions und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com