Cylindrical grinding machine for automatically grinding the middle-high curve of parabola

A parabolic and cylindrical grinding technology, which is applied in the direction of automatic grinding control device, grinding drive device, grinding/polishing safety device, etc. The effect of improving product quality and low repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

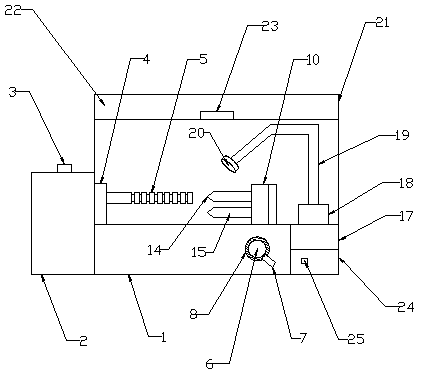

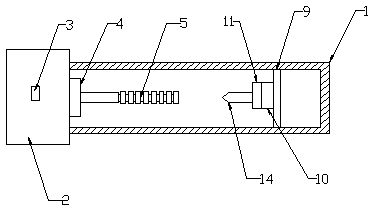

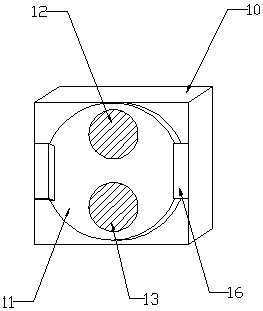

[0018] Example: such as Figure 1-3 As shown, the present invention is a device for automatic grinding of parabolic middle and high curves by cylindrical grinding, including a grinding machine body 1, a control box 2, a switch button 3, a driver 4, a workpiece shaft 5, a driving device 6, a rocker 7, and a dial 8. Ball screw 9, receiving seat 10, turntable 11, first groove 12, second groove 13, first sharpening knife 14, second sharpening knife 15, movable buckle 16, lubricating oil storage box 17, lubricating oil Oil pump 18, oil delivery pipe 19, lubricating oil nozzle 20, protective cover 21, rollable door 22, handle 23, controller 24 and fuel injection button 25, a side of grinder body 1 is equipped with control box 2, and control box 2 is provided with Switch button 3, one side of the control box 2 is provided with a driver 4, one side of the driver 4 is connected with the workpiece shaft 5, one side of the grinding machine body 1 is provided with a driving device 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com