Hyaluronic acid supramolecular hydrogel for three-dimensional culture of chondrocytes, and preparation and application of hyaluronic acid supramolecular hydrogel

A technology of supramolecular hydrogel and hyaluronic acid, which is applied in the direction of cell culture support/coating, bone/connective tissue cells, animal cells, etc., can solve the problem of limiting chondrocyte proliferation, cartilage matrix secretion, and poor mechanical biocompatibility and other problems, to improve mechanical compatibility, prevent cell leakage, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A method for preparing a hyaluronic acid supramolecular gel for three-dimensional culture of chondrocytes, comprising the steps of:

[0067] (1) Add 0.1g of methacrylic anhydride-modified hyaluronic acid (HAMA) into 180mL of deionized water, and stir at room temperature to dissolve completely;

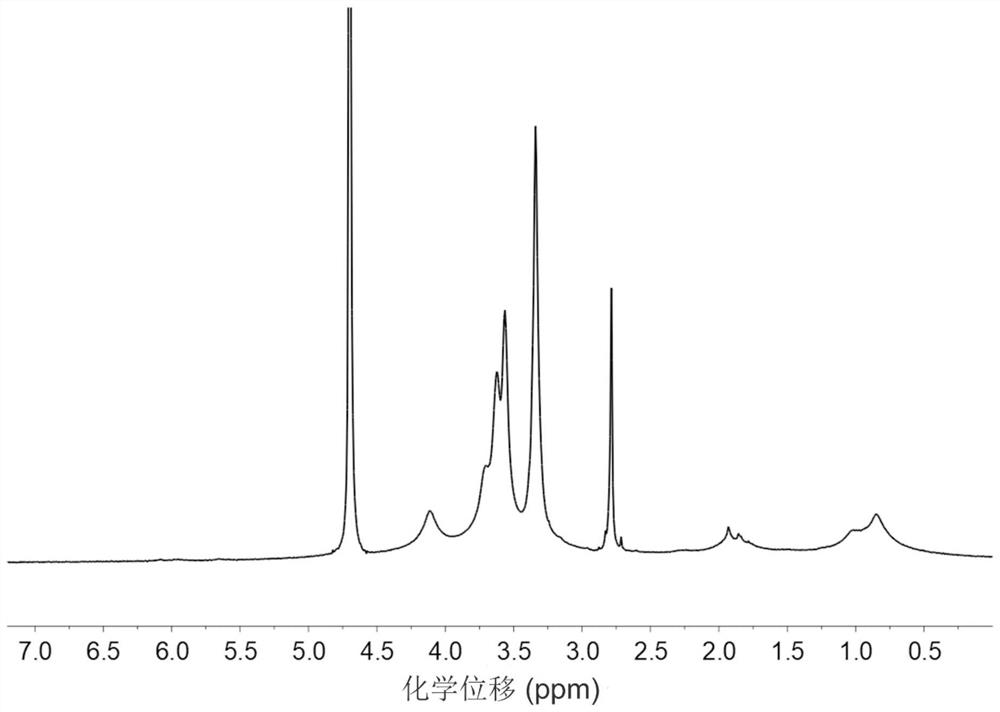

[0068] (2) Add 0.1 g of double bond functionalized UPy macromonomer (UPyMA) to 5 mL of deionized water, add 200 μL of 5M sodium hydroxide solution, stir to dissolve completely, and add to step (1);

[0069] (3) 0.3 g of 2-(2-methoxyethoxy) ethyl methacrylate (DEGMA, purchased from Aladdin Co., Ltd.) was dissolved in 5 mL of deionized water, and added to step (2);

[0070] (4) Dissolve 20 mg of potassium persulfate (KPS) in 5 mL of deionized water and add to step (3);

[0071] (5) Nitrogen deoxygenation in the reaction solution of step (4) was carried out for 40min;

[0072] (6) Dissolve 100 μL of tetramethylethylenediamine (TEMED) in 5 mL of deionized water, and add to step (5...

Embodiment 2

[0078] A method for preparing a hyaluronic acid supramolecular gel for three-dimensional culture of chondrocytes, comprising the steps of:

[0079] (1) Add 0.4 g of methacrylic anhydride-modified hyaluronic acid (HAMA) into 180 mL of deionized water, and stir at room temperature to dissolve completely;

[0080] (2) Add 0.1 g of double bond functionalized UPy macromonomer (UPyMA) to 5 mL of deionized water, add 200 μL of 5M sodium hydroxide solution, stir to dissolve completely, and add to step (1);

[0081] (3) 0.6 g of 2-(2-methoxyethoxy) ethyl methacrylate (DEGMA, purchased from Aladdin Co., Ltd.) was dissolved in 5 mL of deionized water, and added to step (2);

[0082] (4) Dissolve 40 mg of potassium persulfate (KPS) in 5 mL of deionized water and add to step (3);

[0083] (5) Nitrogen deoxygenation in the reaction solution of step (4) was carried out for 40min;

[0084] (6) Dissolve 200 μL of tetramethylethylenediamine (TEMED) in 5 mL of deionized water, and add to step ...

Embodiment 3

[0090] A method for preparing a hyaluronic acid supramolecular gel for three-dimensional culture of chondrocytes, comprising the steps of:

[0091] (1) Add 0.2 g of methacrylic anhydride-modified hyaluronic acid (HAMA) into 180 mL of deionized water, and stir at room temperature to dissolve completely;

[0092] (2) Add 0.1 g of double bond functionalized UPy macromonomer (UPyMA) to 5 mL of deionized water, add 200 μL of 5M sodium hydroxide, stir to dissolve completely, and add to step (1);

[0093] (3) 0.5 g of 2-(2-methoxyethoxy) ethyl methacrylate (DEGMA, purchased from Aladdin Co., Ltd.) was dissolved in 5 mL of deionized water and added to step (2);

[0094] (4) Dissolve 40 mg of potassium persulfate (KPS) in 5 mL of deionized water and add to step (3);

[0095] (5) Nitrogen deoxygenation in the reaction solution of step (4) was carried out for 40min;

[0096] (6) Dissolve 200 μL of tetramethylethylenediamine (TEMED) in 5 mL of deionized water, and add to step (5) after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com