Mesoporous calcium magnesium silicate and polyetheretherketone composite, bone prosthesis as well as preparation method and application of composite

A technology of mesoporous calcium magnesium silicate and polyetheretherketone, applied in prosthesis, dental preparation, dental prosthesis, etc., can solve the problems of lack of biological activity, inability to bond firmly, poor mechanical compatibility, etc. Achieve the effects of simple and easy process, good biological activity and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method of mesoporous calcium magnesium silicate, comprising the steps of:

[0069] (1) Mix 6.0g of P123, 217g of water and 6g of absolute ethanol until the solution is clear, add 17mL of hydrochloric acid with a concentration of 11.9mol / L at 38°C and stir and mix, then mix 12.9g of TEOS with 8 Add dropwise / min to 20drop / min into the solution, stir until the solution turns white and turbid, then add 7.3g of calcium nitrate tetrahydrate and 7.9g of magnesium nitrate hexahydrate, and continue stirring for 1 hour to obtain a reaction solution;

[0070] (2) Aging the reaction solution at 95°C for 3 days, then removing the supernatant by suction filtration, drying the precipitate at 80°C, and sintering at 550°C for 6 hours to obtain the obtained product.

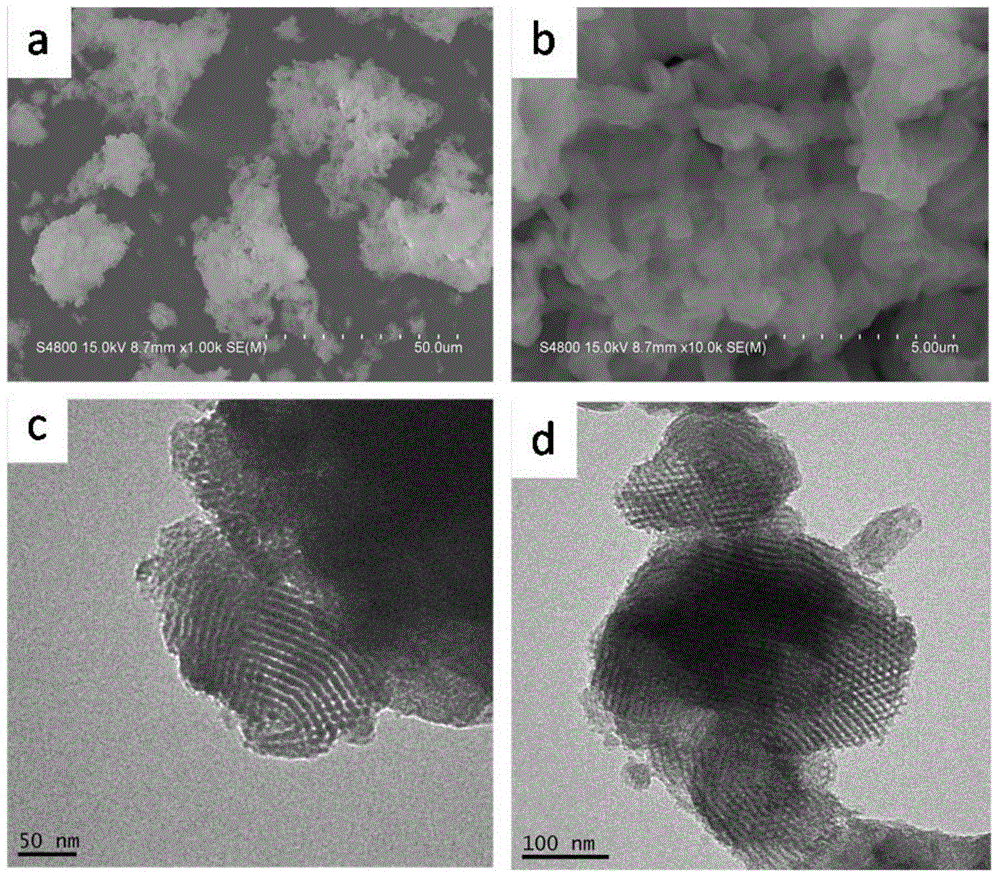

[0071] The scanning electron micrographs and transmission electron micrographs of the mesoporous calcium magnesium silicate are shown in figure 1 (a), (b) and figure 1 (c), (d); the mesoporous calcium magnes...

Embodiment 2

[0073] The preparation method of mesoporous calcium magnesium silicate / polyether ether ketone composite material, it comprises the following steps:

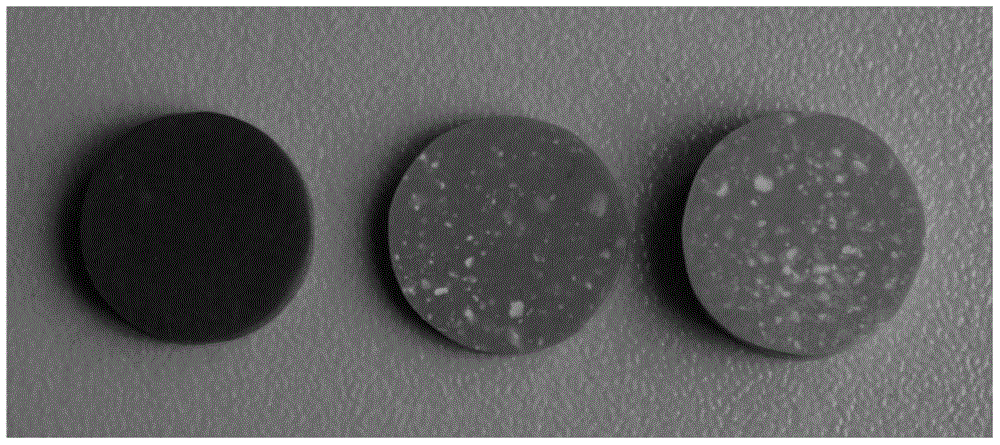

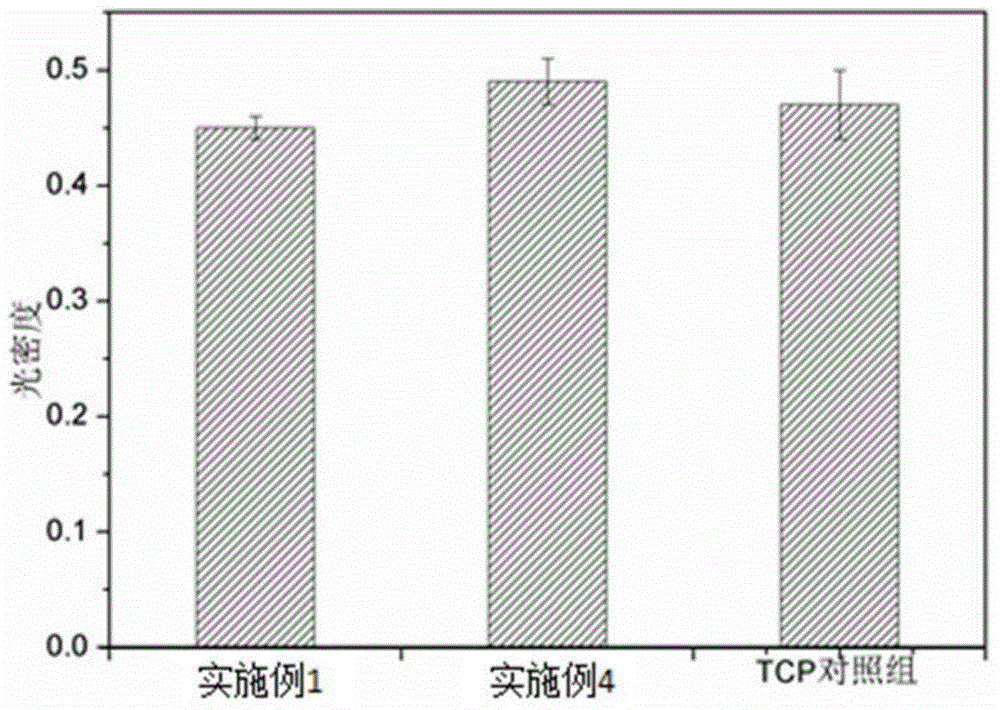

[0074] 2kg (20wt%) of the mesoporous calcium magnesium silicate powder prepared in Example 1 and 8kg (80wt%) of polyetheretherketone powder (10 μm in particle size) were uniformly mixed in a mixer to obtain a mixed powder; the mixed powder Mix with absolute ethanol, ultrasonically disperse with 60W power for 15min, and then place in a 60°C oven to evaporate absolute ethanol to obtain a composite powder; then use a mold to compress the composite powder (use a mold for a non-bone prosthetic product), and then Raise the temperature in a sintering furnace, sinter and shape it, and obtain it; wherein, the sintering temperature is 355° C.; the heating rate of the sintering furnace is 1° C. / min; and the holding time is 2 hours. The mechanical properties of the mesoporous calcium magnesium silicate / polyether ether ketone composite are sh...

Embodiment 3

[0076] A method for preparing a bone prosthesis, comprising the steps of:

[0077] 4kg (40wt%) of the mesoporous calcium magnesium silicate powder prepared in Example 1 and 5kg (50wt%) of polyetheretherketone powder (10 μm in particle size) were uniformly mixed in a mixer to obtain a mixed powder; Mix the mixed powder with absolute ethanol, ultrasonically disperse for 30 minutes with a power of 90W, and then place it in an oven at 58°C to evaporate absolute ethanol to obtain a composite powder; then use a mold to press the composite powder into shape (use a mold for non-bone prosthesis products) , and then heated up in a sintering furnace, and sintered to form a final product; wherein, the sintering temperature is 360° C.; the heating rate of the sintering furnace is 2° C. / min; the holding time is 2.5 hours. The mechanical properties of the bone restoration are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com