Biological coating and dental arch wire coated with same

A technology of biological coating and dental arch wire, which is applied in the fields of arch wire, coating, medical science, etc., can solve the problems such as the lack of clear chemical composition, preparation process and coating characterization of metal coating, and the inability to carry out effective protection, etc. To achieve the effect of reducing the release of toxic element ions, good mechanical compatibility, and superelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using sponge titanium and niobium-titanium master alloy as raw materials, weigh 2.3 kg of sponge titanium and 2.7 kg of niobium-titanium master alloy, wherein the weight percentage of Nb in the niobium-titanium master alloy is 50%.

[0035] Mix the above-mentioned sponge titanium and niobium-titanium master alloy evenly, press 3 kg of electrodes, and smelt them into cylindrical ingots through a second vacuum consumable electric arc furnace. Milling, the diameter of the obtained granule is less than 50 μm, adopting low-energy plasma spraying method to coat biological coating on the surface of TiNi dental arch wire (the weight percentage of Ni is 55.8%), the spraying power is 10Kw, and the spraying distance is 45mm. The amount of powder is 45g / min.

[0036] The thickness of the biological coating prepared on the surface of the TiNi dental arch wire is 40 μm, the content of oxygen (O) in the biological coating is 0.05%, the content of nickel (Ni) is 0.005%, and the content...

Embodiment 2

[0038] Using sponge titanium and niobium-titanium master alloy as raw materials, weigh 2.3 kg of sponge titanium and 2.7 kg of niobium-titanium master alloy, wherein the weight percentage of Nb in the niobium-titanium master alloy is 50%.

[0039] Mix the above-mentioned sponge titanium and niobium-titanium master alloy evenly, press 3kg of electrodes, and melt them into cylindrical ingots through secondary vacuum consumable electric arc furnace. material, after annealing treatment, the grain size of the target material is less than 150 μm, and the biological coating is prepared on the surface of the TiNi dental arch wire (the weight percentage of Ni is 55.8%) by dual ion beam sputtering deposition method, and the main source emits Ar ions Beam sputtering TiNb alloy target, auxiliary source ion beam assisted bombardment growth of TiNb film to change or adjust the composition, structure and properties of the film, the main source power is 10Kw, the auxiliary source power is 10Kw...

Embodiment 3

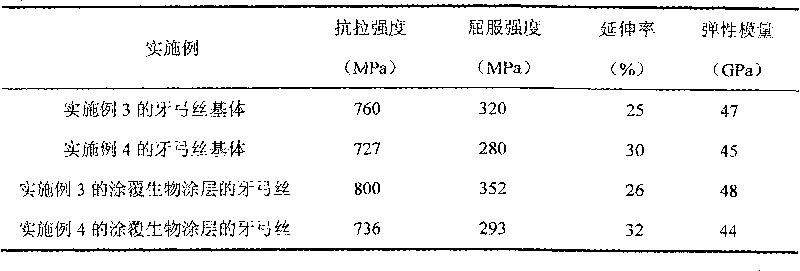

[0042] Coating the biological coating of the present invention on the base of the dental arch wire of the present invention forms a dental arch wire coated with a biological coating, wherein the base is a TiNbAl-based titanium alloy, and the coating is a TiNb homogeneous coating;

[0043] First, prepare the dental arch wire matrix:

[0044] Using sponge titanium, sponge zirconium, niobium-titanium master alloy, aluminum-titanium master alloy, aluminum-silicon master alloy, titanium-tin master alloy as raw materials, weigh 2.5 kg of sponge titanium, 0.03 kg of sponge zirconium, and 2.2 kg of niobium-titanium master alloy (niobium-titanium master alloy) The weight percentage of niobium in the master alloy is 80%), 0.1 kg of aluminum-titanium master alloy (the weight percentage of aluminum in the aluminum-titanium master alloy is 52%), 0.075 kg of aluminum-silicon master alloy (the weight percentage of aluminum in the aluminum-silicon master alloy is The weight percent content is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com