CS (calcium silicate)/PEEK (poly(ether-ether-ketone)) composite bone repair material, bone repair body as well as preparation method and application of material

A polyetheretherketone and bone prosthesis technology, applied in the field of medical biomaterials, can solve the problems of poor osteogenic performance, easy falling off of the coating, loosening of the PEEK implant, etc., and achieve the effect of improving the bonding speed and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

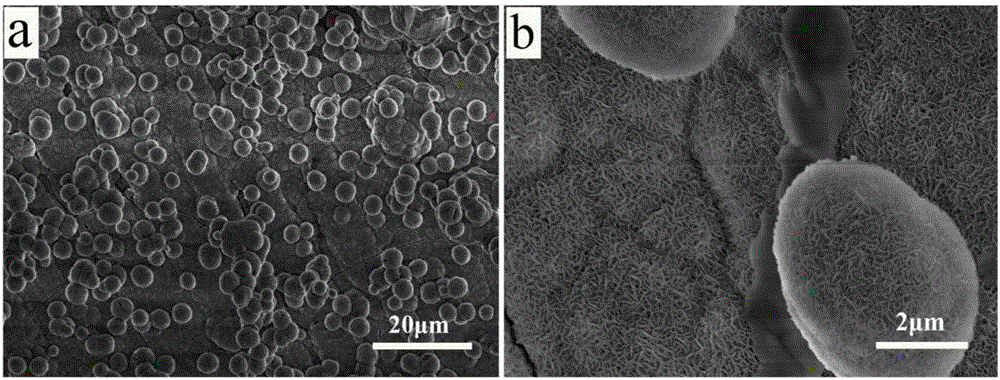

[0070] A calcium silicate / polyetheretherketone composite bone repair material is made by mixing 45% calcium silicate and 55% polyetheretherketone. The ketone is in powder form (particle size is 30 μm).

[0071] The preparation method of the calcium silicate / polyetheretherketone composite material comprises the following steps:

[0072] Mix 4.5kg calcium silicate powder (particle size is 20μm) and 5.5kg polyetheretherketone powder (particle size is 30μm) in a mixer to obtain mixed powder; then mix powder with twin-screw extruder at high temperature After melt blending, extrusion and granulation are performed, and the temperature of the melt extrusion is 370°C to 380°C; the pressure of the twin-screw extruder is 80 MPa to 100 MPa.

Embodiment 2

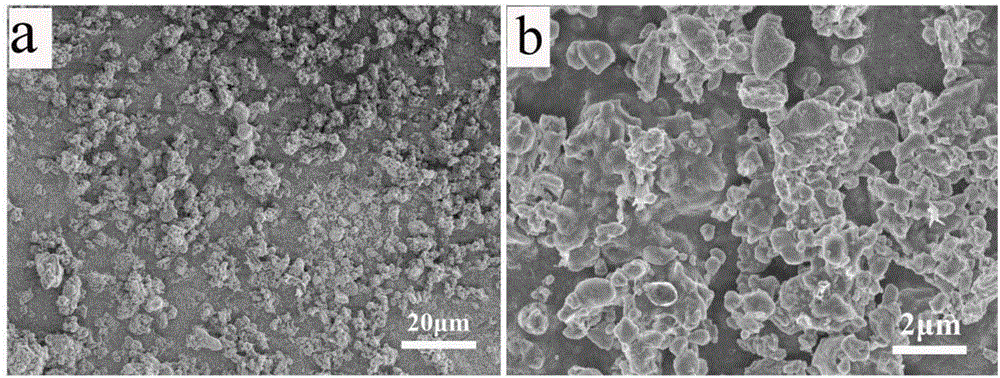

[0074]A calcium silicate / polyetheretherketone composite bone repair material is made of 45% calcium silicate and 55% polyetheretherketone, the calcium silicate is powder (with a particle size of 20 μm), and the polyetheretherketone is Powder (particle size of 30 μm), calcium silicate powder was pretreated with an ethanolic solution of polyethylene glycol 4000.

[0075] The preparation method of the calcium silicate / polyetheretherketone composite material comprises the following steps:

[0076] 4.5kg of calcium silicate powder (particle size is 20 μm) is treated with an ethanol solution of polyethylene glycol 4000, and the amount of polyethylene glycol 4000 is 1% to 4% of the amount of calcium silicate. Dry in the oven. 5.5 kg of polyether ether ketone powder (with a particle size of 30 μm) was washed three times with an ethanol solution, and the washed PEEK powder was dried in an oven. The treated calcium silicate and PEEK powder are uniformly mixed in a mixer to obtain a mi...

Embodiment 3

[0078] A calcium silicate / polyetheretherketone composite bone repair material is made of 50% calcium silicate and 50% polyetheretherketone, the calcium silicate is powder (with a particle size of 30 μm), and the polyetheretherketone is Powder (40 μm particle size), calcium silicate powder was pretreated with an aqueous solution of sodium carboxymethylcellulose.

[0079] The preparation method of the calcium silicate / polyetheretherketone composite material comprises the following steps:

[0080] 5kg of calcium silicate powder (with a particle size of 30 μm) is treated with an aqueous solution of sodium carboxymethyl cellulose, and the amount of sodium carboxymethyl cellulose is 2% to 3% of the amount of calcium silicate. Dry in the oven. 5 kg of polyether ether ketone powder (40 μm in particle size) was washed three times with ethanol solution, and the washed PEEK powder was dried in an oven. The treated calcium silicate and PEEK powder are uniformly mixed in a mixer to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com