A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

An alloy material, ti-mg technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

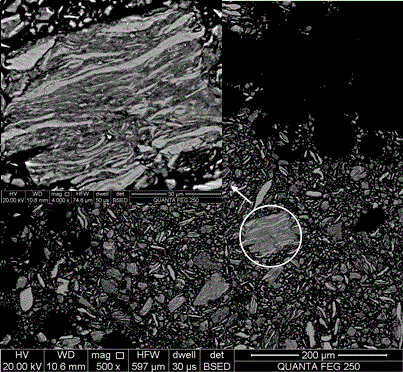

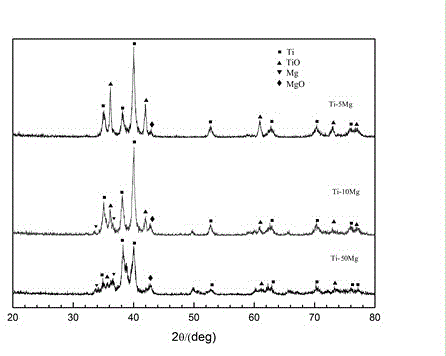

[0036] A Ti-Mg alloy material of the present invention, the alloy is a solid solution with uniform dispersion and layered composite structure, the phase composition of the alloy is Ti, Mg, TiO and MgO, and the contents of the four phases are respectively Ti 79.1%, Ti 79.1%, Mg 4.5%, TiO 12.8%, MgO 3.6%; porosity 0.56%, Vickers hardness HV406.69, compressive strength 1617.72MPa, elastic modulus 12.8GPa, self-corrosion potential -860.427mV, self-corrosion The current density is 63.71μA / cm 2 .

[0037] The powder metallurgy preparation method of the Ti-Mg alloy material of the present embodiment, the process steps are as follows:

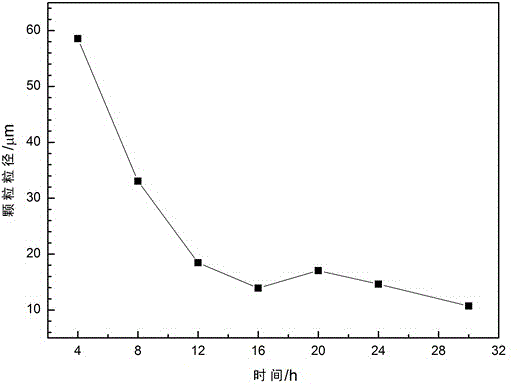

[0038] (1) The mixed powder of pure Ti powder and pure Mg powder was prepared according to the mass fraction of pure Mg powder being 10wt.%. The average particle size of pure Ti powder was 92.24 μm, and the average particle size of pure Mg powder was 206.75 μm. In addition, 4wt.% (the mass fraction of zinc stearate accounting for the sum of the mass ...

Embodiment 2

[0047] A Ti-Mg alloy material of the present invention, the alloy is a solid solution with uniform dispersion and layered composite structure, the phase composition of the alloy is Ti, TiO and MgO, and the phase contents are respectively Ti 78.3% and TiO 19.7% , MgO 2%; porosity 0.32%, Vickers hardness HV465.06, compressive strength 1690.89MPa, elastic modulus 12.4GPa, self-corrosion potential -817.814mV, self-corrosion current density 53.73μA / cm 2 .

[0048] The powder metallurgy preparation method of the Ti-Mg alloy material of the present embodiment, the process steps are as follows:

[0049] (1) The mixed powder of pure Ti powder and pure Mg powder was prepared according to the mass fraction of pure Mg powder being 5wt.%. The average particle size of Ti powder was 53.36 μm, and the average particle size of Mg powder was 152.18 μm. In addition, 4wt.% (the mass fraction of zinc stearate accounting for the sum of the mass of pure magnesium powder, pure titanium powder and zi...

Embodiment 3

[0056] A Ti-Mg alloy material of the present invention, the alloy is a solid solution with uniform dispersion and layered composite structure, the phase composition of the alloy is Ti, Mg, TiO and MgO, and the contents of the four phases are respectively Ti 76.7%, Ti 76.7%, Mg 9.9%, TiO 8.4%, MgO 5%; porosity 0.91%, Vickers hardness HV401.17, compressive strength 1603.06MPa, elastic modulus 12.1GPa, self-corrosion potential -896.209mV, self-corrosion current The density is 85.92μA / cm 2 .

[0057] The powder metallurgy preparation method of the Ti-Mg alloy material of the present embodiment, the process steps are as follows:

[0058] (1) The mixed powder of pure Ti powder and pure Mg powder was prepared according to the mass fraction of pure Mg powder being 50wt.%. The average particle size of Ti powder was 146.73 μm, and the average particle size of Mg powder was 247.13 μm. In addition, 4wt.% (the mass fraction of zinc stearate accounting for the sum of the mass of pure magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com