Submicron silicon nitride hollow microspheres and preparation method

A submicron silicon nitride technology, which is applied in the field of submicron silicon nitride hollow microspheres and its preparation, can solve the problems of large particle size and uneven particle size of silicon nitride hollow microspheres, and achieve uniform particle size, Low cost, uniform and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

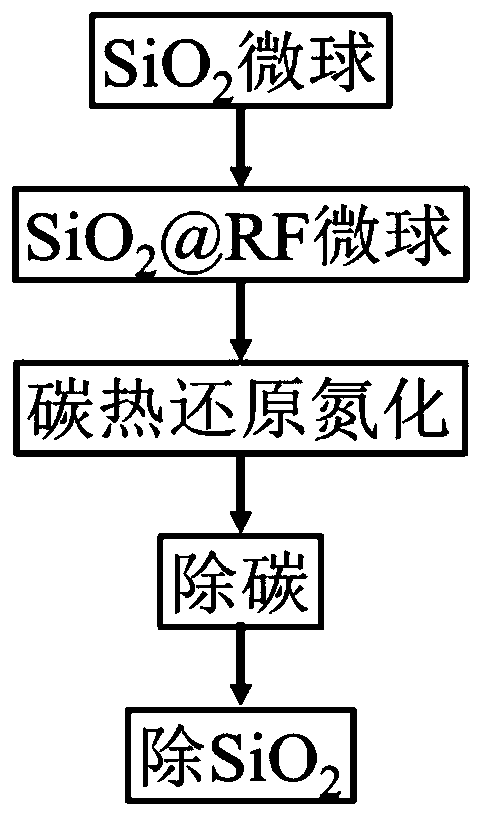

Method used

Image

Examples

Embodiment 1

[0038] Step 1. Preparation of monodisperse SiO by modified Stober method 2 Microspheres

[0039] Step 1.1, mix 24ml of deionized water, 100ml of absolute ethanol and 14ml of concentrated ammonia water, then stir at 30°C for 20min, and obtain solution A after stirring.

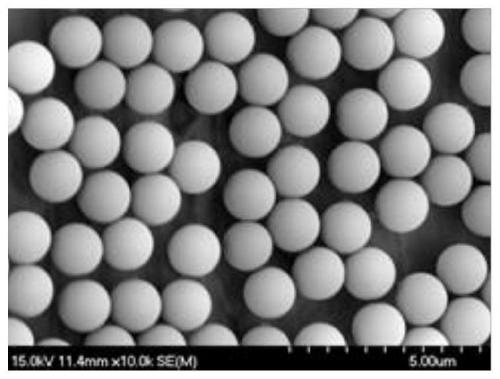

[0040] Step 1.2, suck 6ml tetraethyl orthosilicate into the syringe, add it dropwise into solution A at a rate of 3.75ml / h, stir at 30°C for 12h, collect the final solution by centrifugation and wash it three times with absolute ethanol. Insulate in an oven at 80°C for 24 hours to obtain monodisperse SiO 2 Microspheres.

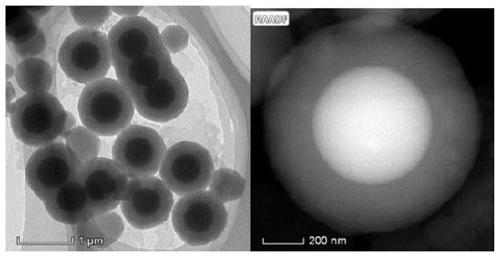

[0041] Step 2. Preparation of phenolic resin-coated silica core-shell powder SiO by polycondensation reaction of resorcinol and formaldehyde 2 @RF(Resorcinol-formaldehyde resin)

[0042] The monodisperse SiO prepared in step 1 2Put the microspheres into the Erlenmeyer flask, add a mixed solution of distilled water and absolute ethanol, then add concentrated ammonia water, cetyltrimethylam...

Embodiment 2

[0051] Step 1. Preparation of monodisperse SiO by modified Stober method 2 Microspheres

[0052] Step 1.1, mix 24ml of deionized water, 100ml of absolute ethanol and 14ml of concentrated ammonia water, then stir at 30°C for 20min, and obtain solution A after stirring.

[0053] Step 1.2, suck 6ml tetraethyl orthosilicate into the syringe, add it dropwise to solution A at a rate of 1ml / h, stir at 30°C for 12h, collect the final solution by centrifugation and wash it three times with absolute ethanol. ℃ in the oven for 24h, that is, monodisperse SiO 2 Microspheres.

[0054] Step 2. Preparation of phenolic resin-coated silica core-shell powder SiO by polycondensation reaction of resorcinol and formaldehyde 2 @RF(Resorcinol-formaldehyde resin)

[0055] The monodisperse SiO prepared in step 1 2 Put the microspheres into the Erlenmeyer flask, add a mixed solution of distilled water and absolute ethanol, then add concentrated ammonia water, cetyltrimethylammonium bromide, and res...

Embodiment 3

[0064] Step 1. Preparation of monodisperse SiO by modified Stober method 2 Microspheres

[0065] Step 1.1, mix 24ml of deionized water, 100ml of absolute ethanol and 14ml of concentrated ammonia water, then stir at 30°C for 20min, and obtain solution A after stirring.

[0066] Step 1.2, suck 6ml tetraethyl orthosilicate into the syringe, add it dropwise into solution A at a rate of 3.75ml / h, stir at 30°C for 12h, collect the final solution by centrifugation and wash it three times with absolute ethanol. Insulate in an oven at 80°C for 24 hours to obtain monodisperse SiO 2 Microspheres.

[0067] Step 2. Preparation of phenolic resin-coated silica core-shell powder SiO by polycondensation reaction of resorcinol and formaldehyde 2 @RF(Resorcinol-formaldehyde resin)

[0068] The monodisperse SiO prepared in step 1 2 Put the microspheres into the Erlenmeyer flask, add a mixed solution of distilled water and absolute ethanol, then add concentrated ammonia water, cetyltrimethyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com