Compact type flexible substrate magneto-controlled sputter coating equipment and method

A magnetron sputtering coating and flexible substrate technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem that the ion source working gas cannot be effectively discharged, affecting the working atmosphere of the equipment, The problem of large equipment volume is achieved to prevent the mutual influence of the working atmosphere, improve the space utilization rate, and the effect of simple internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

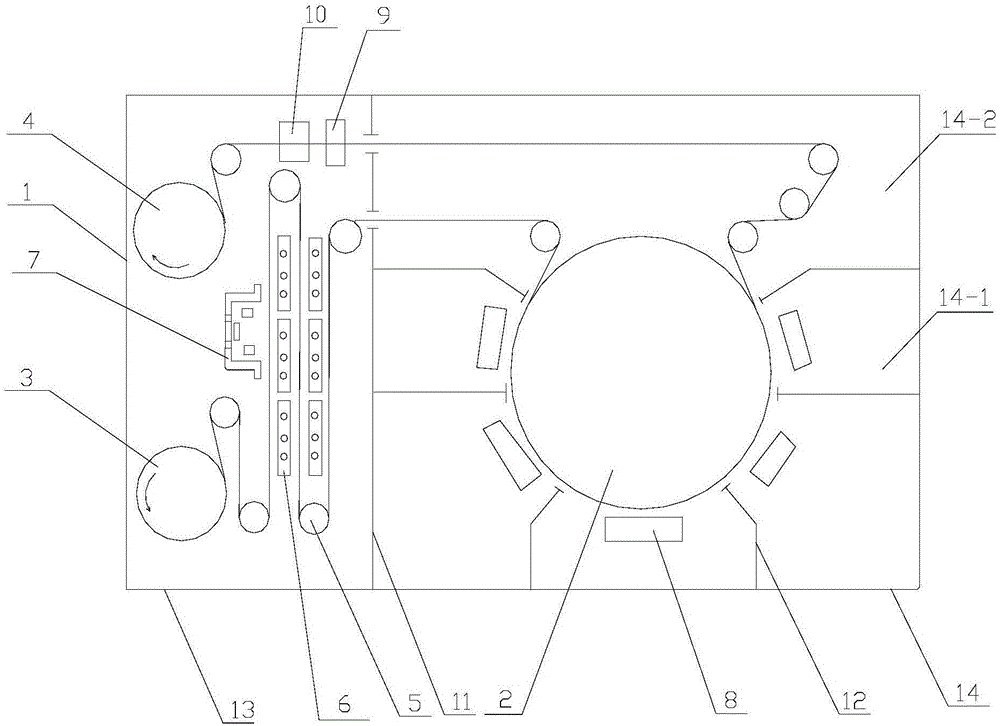

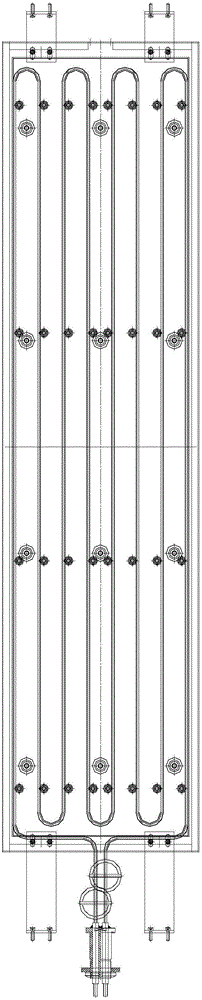

[0035] In this embodiment, a compact flexible substrate magnetron sputtering coating equipment, such as figure 1As shown, it includes a vacuum chamber, a flexible substrate winding mechanism, a magnetron sputtering device, a heater and an ion source. There is a partition partition in the vacuum chamber, and the partition partition divides the space in the vacuum chamber into a winding area and a coating area. , the partition board is provided with a through hole for the passage of the flexible substrate, the flexible substrate runs through the entire vacuum chamber, the heater and the ion source are arranged in the winding area, and the magnetron sputtering device is arranged in the coating area; A plurality of unit partitions are arranged in the coating area, and the space in the coating area is divided into a flexible substrate conveying unit and a plurality of coating units by the plurality of unit partitions. Among them, the partition partition divides the inner cavity of ...

Embodiment 2

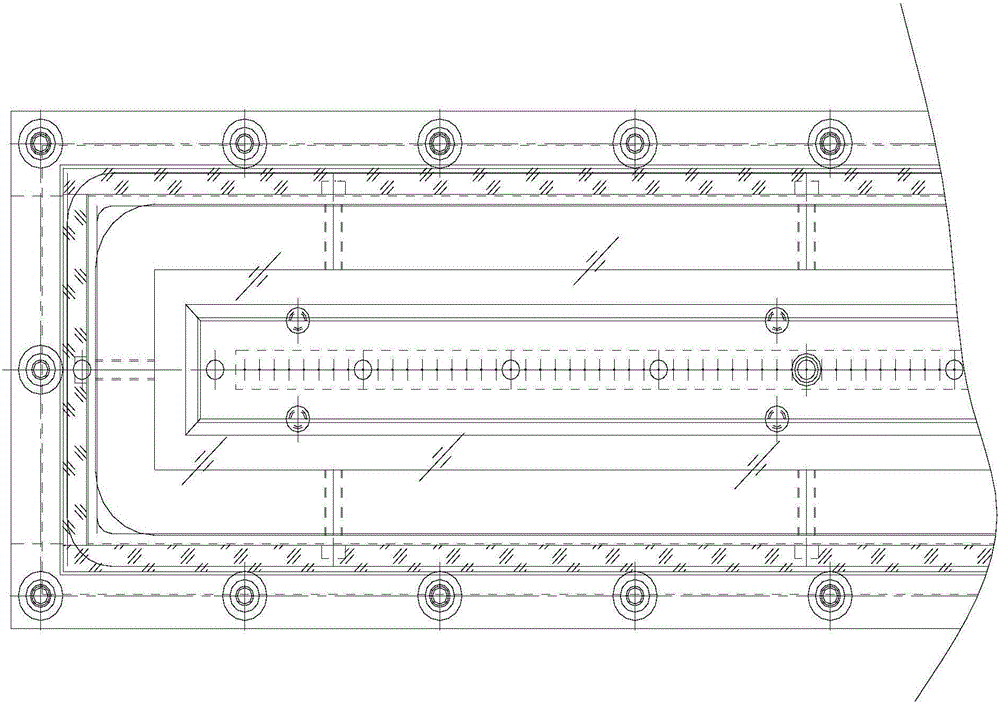

[0050] This embodiment is a compact flexible substrate magnetron sputtering coating equipment. Compared with Embodiment 1, the difference is that the vacuum chamber is a rectangular cavity structure, and the partition partitions are horizontally arranged in the vacuum chamber, and the vacuum The indoor space is divided into a winding area and a coating area in a layered structure.

[0051] According to the site requirements of the actual production line, the vacuum chamber can also be designed as a cylindrical or other shaped cavity structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com