Method for functionally remolding waste polystyrene

A technology of waste polystyrene and polystyrene, which is applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of low quality polystyrene, high price, complicated equipment, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

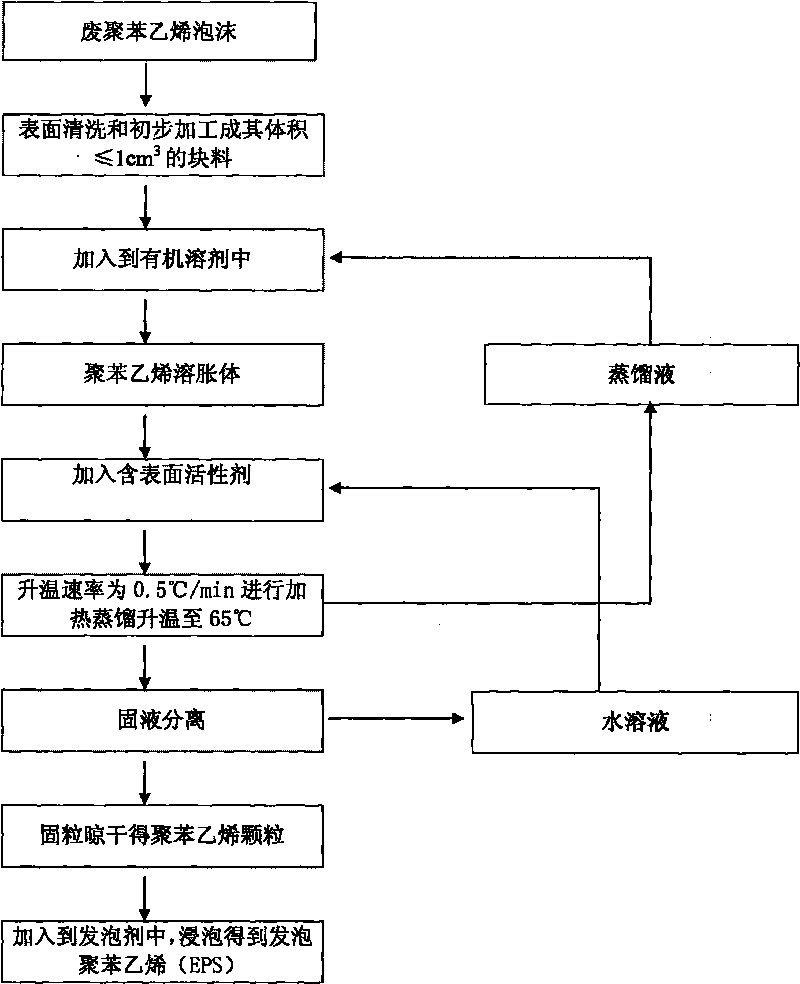

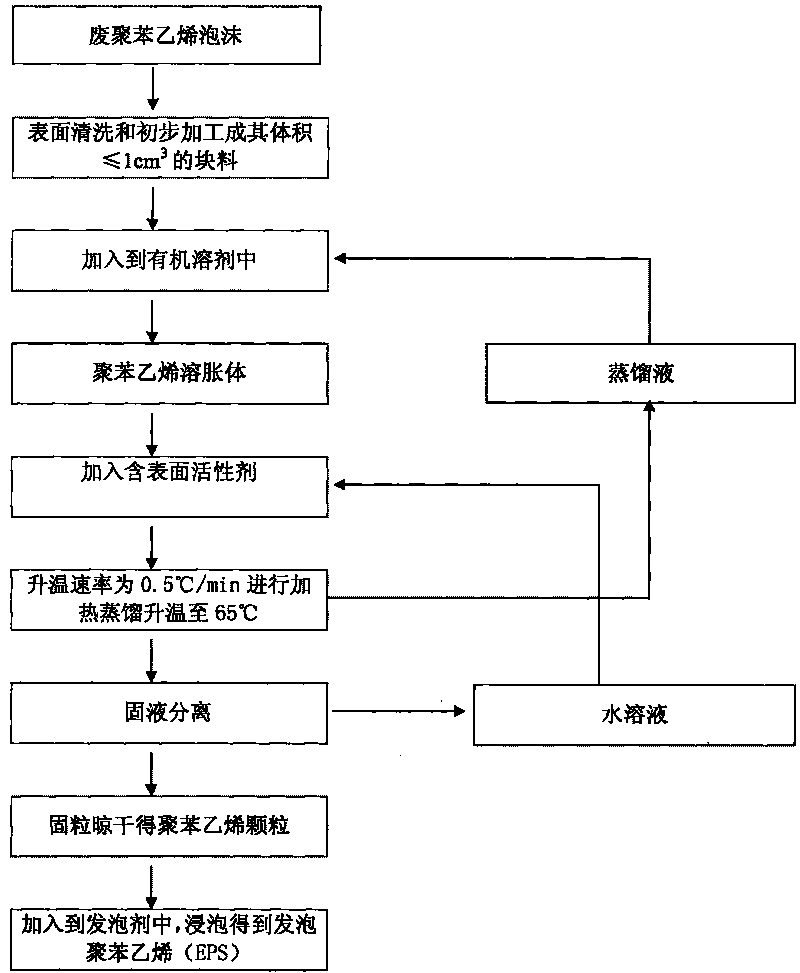

Method used

Image

Examples

Embodiment 1

[0016] a. Clean and preliminarily process the surface of waste polystyrene foam to make its volume ≤ 1cm 3 block material;

[0017] b. Add it to the chloroform solvent, the waste polystyrene foam will swell and defoam rapidly, continue to add the waste polystyrene foam until it becomes a viscous polystyrene swelling body, and place it at room temperature for 10-15 minutes;

[0018] c. Add the polystyrene swollen body into room temperature water containing sodium dodecylbenzenesulfonate at a concentration of 2.4g / liter, stir at 210rpm, start heating, and heat up at a rate of 0.5°C / min, and stop heating at 65°C Keep at constant temperature for 30 minutes;

[0019] d. Carry out solid-liquid separation by filtration, and the separated solid particles are translucent white granule finished polystyrene after drying, with a particle size of about 1mm;

[0020] e. Soak the solid polystyrene particles in propane for 10 hours to obtain expandable polystyrene particles (EPS).

[0021]...

Embodiment 2

[0023] a. Clean and preliminarily process the surface of waste polystyrene foam to make its volume ≤ 1cm 3 block material;

[0024] b. Add it into ethyl acetate solvent, the waste polystyrene foam will swell and defoam quickly, continue to add waste polystyrene foam until it becomes viscous polystyrene swelling body. Add about 7% of the treated carbon black to the swelling body, and then put it into the sonic cleaner for 15-20 minutes of ultrasonic;

[0025] c. Add the polystyrene swelling body to the normal temperature water containing fatty alcohol polyoxyethylene ether sodium sulfate with a concentration of 2.4g / liter, the stirring speed is 220rpm, start heating, the heating rate is 0.5°C / min, and stop heating when heated to 65°C Keep at constant temperature for 30 minutes;

[0026] d, then carry out solid-liquid separation by filtration. The separated solid particles are dried to become translucent black particles of finished polystyrene, with a particle size of about 1...

Embodiment 3

[0030] a. Clean and preliminarily process the surface of waste polystyrene foam to make its volume ≤ 1cm 3 block material;

[0031] b. Add it to acetone solvent, the waste polystyrene foam will swell and defoam quickly, continue to add waste polystyrene foam until it becomes a viscous polystyrene swelling body, and add about 1.5% of treated polystyrene foam to the swelling body Fe3iron tetroxide, and then put it into a sonic cleaner for ultrasonication for 15 to 20 minutes;

[0032] c. Add the polystyrene swollen body to room temperature water containing polyvinyl alcohol at a concentration of 2.4g / liter, stir at 220rpm, start heating at a heating rate of 0.5°C / min, stop heating at 65°C and keep the temperature constant for 30 minutes;

[0033] d. Carry out solid-liquid separation by filtration, and the separated solid particles are translucent brown granule finished polystyrene after drying, with a particle size of about 1mm;

[0034] e. Soak the solid polystyrene particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com