Preparation method of electron beam radiation crosslinking composite polymer hydrogel dressing

An electron beam irradiation and composite polymer technology is applied in the field of composite polymer materials to prepare hydrogel dressings, which can solve the problems of weak irradiation cross-linking force and influence on mechanical properties, etc. Pure ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

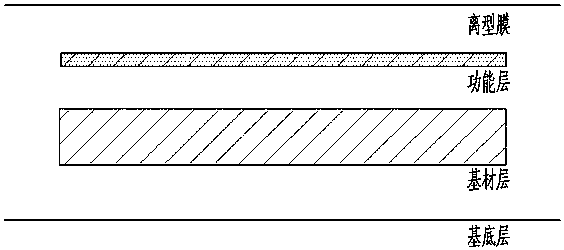

Image

Examples

Embodiment 1

[0021] Weigh a certain mass of polyvinyl alcohol, polyvinylpyrrolidone, and gelatin solid powder, respectively, and add them into deionized water to make three aqueous solutions. %; respectively dissolved in a high-pressure steam container at a temperature of 120°C for 2 hours; after complete dissolution, the three solutions were mixed according to a certain volume ratio, and an appropriate amount of deionized water was added as needed to prepare a substrate layer mixed solution. The mass fraction of polyvinyl alcohol in the substrate layer mixed solution is 1 wt%, the mass fraction of polyvinylpyrrolidone is 1 wt%, and the mass fraction of gelatin is 4 wt%.

[0022] Take part of the above-mentioned substrate layer solution, add a certain amount of low-molecular chondroitin sulfate and low-molecular hyaluronic acid solid powder, and fully stir and mix. The mass fractions of low-molecular chondroitin sulfate and low-molecular hyaluronic acid are respectively 2wt%, to prepare a ...

Embodiment 2

[0026] Adopt exactly the same steps as Example 1, the only difference is the mass fraction in the mixed solution of the preparation substrate layer, the mass fraction of polyvinyl alcohol is 3wt%, the mass fraction of polyvinylpyrrolidone is 3wt%, the mass fraction of gelatin Fraction 18wt%.

[0027] The hydrogel dressing obtained by testing is sterile, and the tensile strength measured by an electronic tensile testing machine is 0.024MPa, the elongation at break is 97.45%, the ability to absorb deionized water is 17.49g / g, and the ability to absorb normal saline is 4.82g / g.

Embodiment 3

[0029] Adopt exactly the same steps as Example 1, the only difference is the mass fraction in the mixed solution of the preparation substrate layer, the mass fraction of polyvinyl alcohol is 2wt%, the mass fraction of polyvinylpyrrolidone is 2wt%, the mass fraction of gelatin Fraction 15wt%.

[0030] The hydrogel dressing obtained by testing is sterile, and the tensile strength measured by an electronic tensile testing machine is 0.026MPa, the elongation at break is 275.13%, the ability to absorb deionized water is 100.50g / g, and the ability to absorb normal saline is 9.99% g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com