Preparation method for Mg2Si thermoelectricity material

A technology of thermoelectric materials and mixtures, applied in the direction of metal silicide, etc., can solve the problems of unsuitability for practical application, high preparation cost, expensive equipment, etc., and achieve the effect of low preparation cost, small particle size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 a kind of Mg 2 The preparation method of Si thermoelectric material, comprises the following steps:

[0027] (1) Mix Mg powder and Si powder in a molar ratio of 2.01:1 under an Ar protective atmosphere to obtain a mixture.

[0028] (2) Put the mixture into a glove box filled with an atmospheric pressure Ar, and put the glove box into a stainless steel vacuum ball mill tank, and perform intermittent ball milling at a speed of 220rpm for 10h (rest for 10min every 20min to prevent the powder from overheating with the tank) Oxidation reaction of the residual oxygen in the powder) to activate the powder surface and obtain a uniform mixed powder, in which the ball-to-material mass ratio (㎏ / ㎏) is 15:1.

[0029] (3) Pressing the mixed powder under a pressure of 15 MPa for 5 minutes for tableting to obtain Mg-Si mixed powder for tableting.

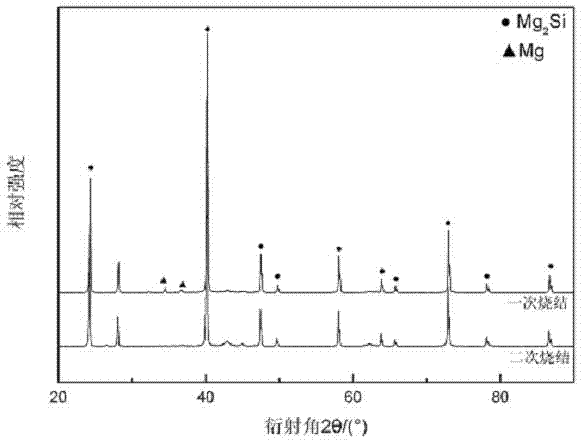

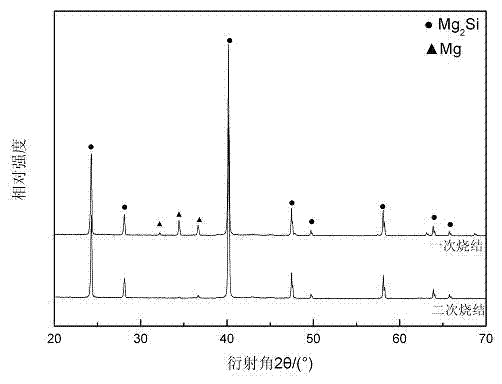

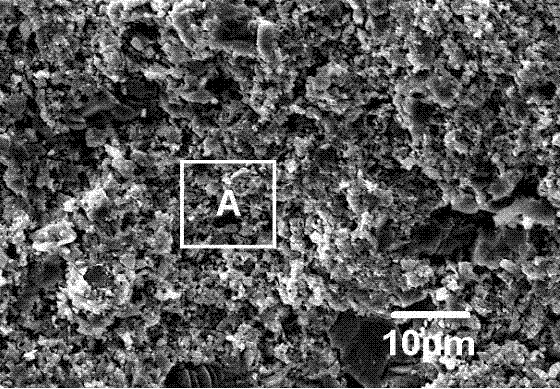

[0030] (4) Put the Mg-Si mixed powder into a graphite mold that matches its specifications, and place the graphite mold i...

Embodiment 2

[0033] Example 2 a kind of Mg 2 The preparation method of Si thermoelectric material, comprises the following steps:

[0034] (1) Mix Mg powder and Si powder uniformly in a molar ratio of 2.13:1 under an Ar protective atmosphere to obtain a mixture.

[0035] (2) Put the mixture into a glove box filled with an atmospheric pressure Ar, and put the glove box into a stainless steel vacuum ball mill tank, and perform intermittent ball milling at a speed of 220rpm for 10h (rest for 10min every 20min to prevent the powder from overheating with the tank) Oxidation reaction of the residual oxygen in the powder) to activate the powder surface and obtain a uniform mixed powder, in which the ball-to-material mass ratio (㎏ / ㎏) is 15:1.

[0036] (3) Pressing the mixed powder under a pressure of 15 MPa for 5 minutes for tableting to obtain Mg-Si mixed powder for tableting.

[0037] (4) Put the Mg-Si mixed powder into a graphite mold that matches its specifications, and place the graph...

Embodiment 3

[0040] Example 3 a kind of Mg 2 The preparation method of Si thermoelectric material, comprises the following steps:

[0041] (1) Mix Mg powder and Si powder in a molar ratio of 2.03:1 under Ar protective atmosphere to obtain a mixture.

[0042] (2) Put the mixture into a glove box filled with an atmospheric pressure Ar, and put the glove box into a stainless steel vacuum ball mill tank, and perform intermittent ball milling at a speed of 220rpm for 10h (rest for 10min every 20min to prevent the powder from overheating with the tank) Oxidation reaction of the residual oxygen in the powder) to activate the powder surface and obtain a uniform mixed powder, in which the ball-to-material mass ratio (㎏ / ㎏) is 15:1.

[0043] (3) Pressing the mixed powder under a pressure of 15 MPa for 5 minutes for tableting to obtain Mg-Si mixed powder for tableting.

[0044] (4) Put the Mg-Si mixed powder into a graphite mold that matches its specifications, and place the graphite mold in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com