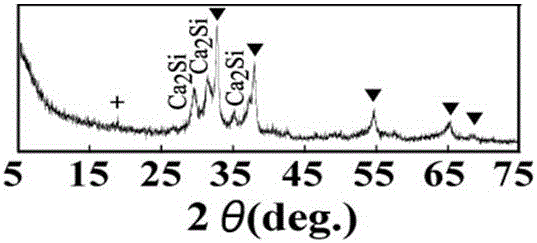

Cubic-phase Ca2Si thermoelectric material and preparation method thereof

A technology of thermoelectric materials and cubic phase, which is applied in the field of cubic phase Ca2Si thermoelectric materials and its preparation, can solve the problems that thermoelectric materials have not been reported, and achieve the effects of easy operation, low reaction temperature and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

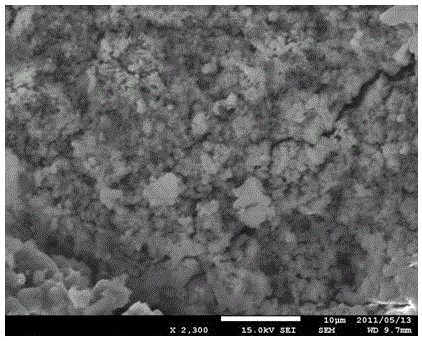

Embodiment 1

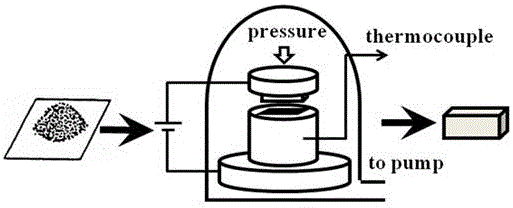

[0026] A cubic phase Ca 2 The preparation method of Si thermoelectric material, comprises the following steps:

[0027] (1) Mix Ca powder and Si powder at a molar ratio of 2.0:1 under an Ar protective atmosphere to obtain a mixture;

[0028] (2) Put the mixture obtained in step (1), grinding balls, stainless steel ball milling tank and electronic balance into a glove box filled with an atmospheric pressure Ar, in which the mass ratio of balls to materials is 3:1, and accurately weigh in the glove box Finally, put into the ball mill jar, seal the ball mill jar well, avoid oxygen from entering, then take out the ball mill jar from the glove box;

[0029] (3) Put the ball mill pot prepared in step (2) into the ball mill for 5 h at a speed of 2000 rpm to fully react the powder;

[0030] (4) Take out the reacted powder in step (3), put it into a stainless steel mold with an inner hole diameter of 10 mm, use vacuum plasma sintering, heat up to 300 °C under a pressure of 300 MPa an...

Embodiment 2

[0033] A cubic phase Ca 2 The preparation method of Si thermoelectric material, comprises the following steps:

[0034] (1) Mix Ca powder and Si powder at a molar ratio of 2.3:1 under an Ar protective atmosphere to obtain a mixture;

[0035] (2) Put the mixture obtained in step (1), the grinding balls, the stainless steel ball milling tank and the electronic balance into a glove box filled with an atmospheric pressure Ar, wherein the mass ratio of the ball to material is 16:1, and accurately weigh in the glove box After measuring, put into the ball mill jar, seal the ball mill jar well to prevent oxygen from entering, and then take out the ball mill jar from the glove box;

[0036] (3) Put the ball mill pot prepared in step (2) into the ball mill for 100 h at a speed of 500 rpm to fully react the powder;

[0037] (4) Take out the reacted powder in step (3), put it into a stainless steel mold with a hollow size of 12 mm×6 mm, use vacuum plasma sintering, and heat up to 500 °C...

Embodiment 3

[0040] A cubic phase Ca 2 The preparation method of Si thermoelectric material, comprises the following steps:

[0041] (1) Mix Ca powder and Si powder at a molar ratio of 2.5:1 under an Ar protective atmosphere to obtain a mixture;

[0042](2) Put the mixture, grinding balls, stainless steel ball milling tank and electronic balance into a glove box filled with an atmospheric pressure Ar, wherein the mass ratio of balls to materials is 8:1. After accurate weighing in the glove box, put Put into the ball mill jar, seal the ball mill jar well to prevent oxygen from entering, then take out the ball mill jar from the glove box;

[0043] (3) Put the stainless steel vacuum ball mill tank prepared in step (2) into a ball mill for 50 h at a speed of 2000 rpm to fully react the powder;

[0044] (4) Take out the reacted powder in step (3), put it into a hollow 10 mm×10 mm stainless steel mold, adopt vacuum plasma sintering method, heat up to 100 °C under a pressure of 600 MPa and keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com