Vacuum cavity isolating mechanism

A technology of vacuum cavity and isolation mechanism, which is applied in the direction of vacuum evaporation plating, electric solid devices, semiconductor devices, etc. It can solve problems such as unstable performance, large stress, and unclean components, and achieve firm and reliable connection, high performance Stable, Pure Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

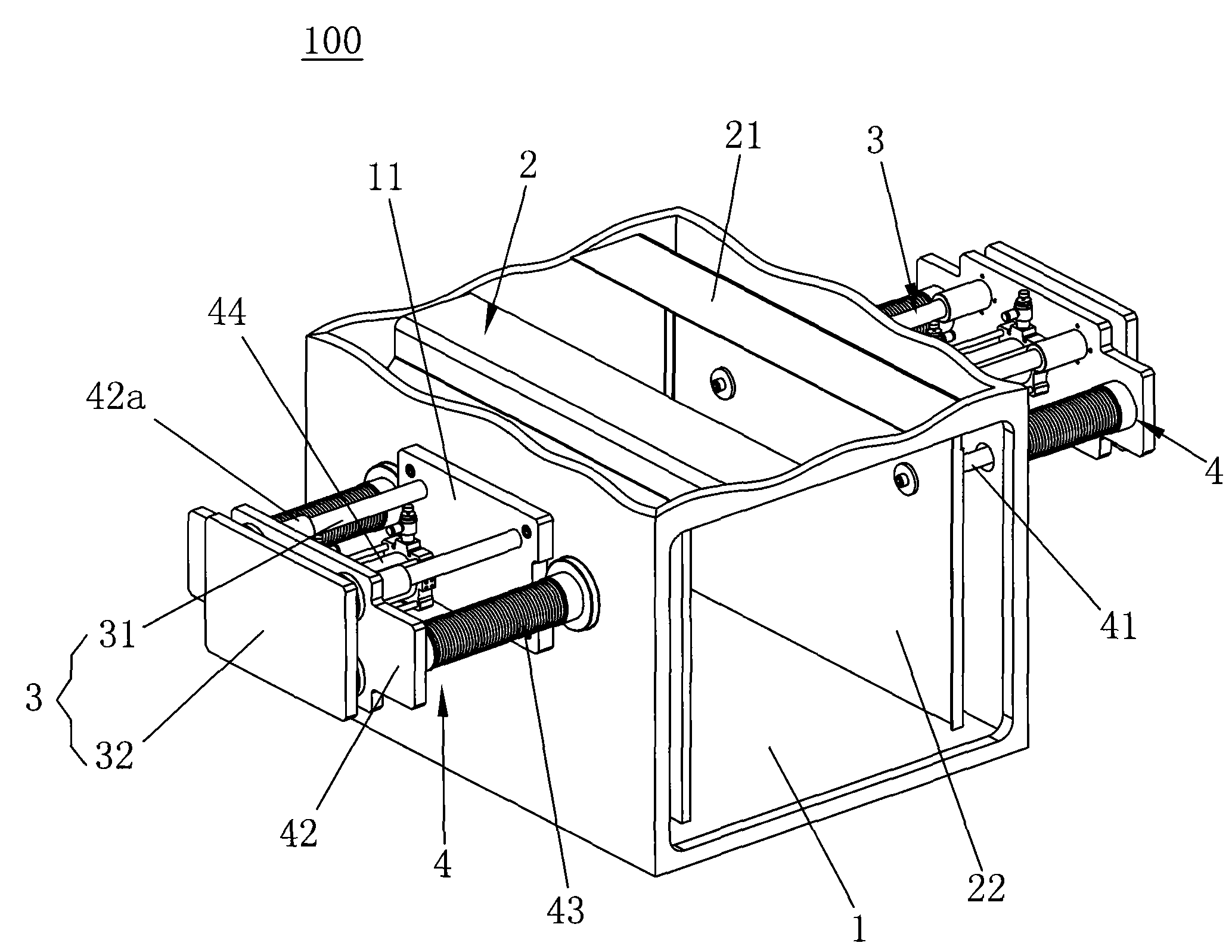

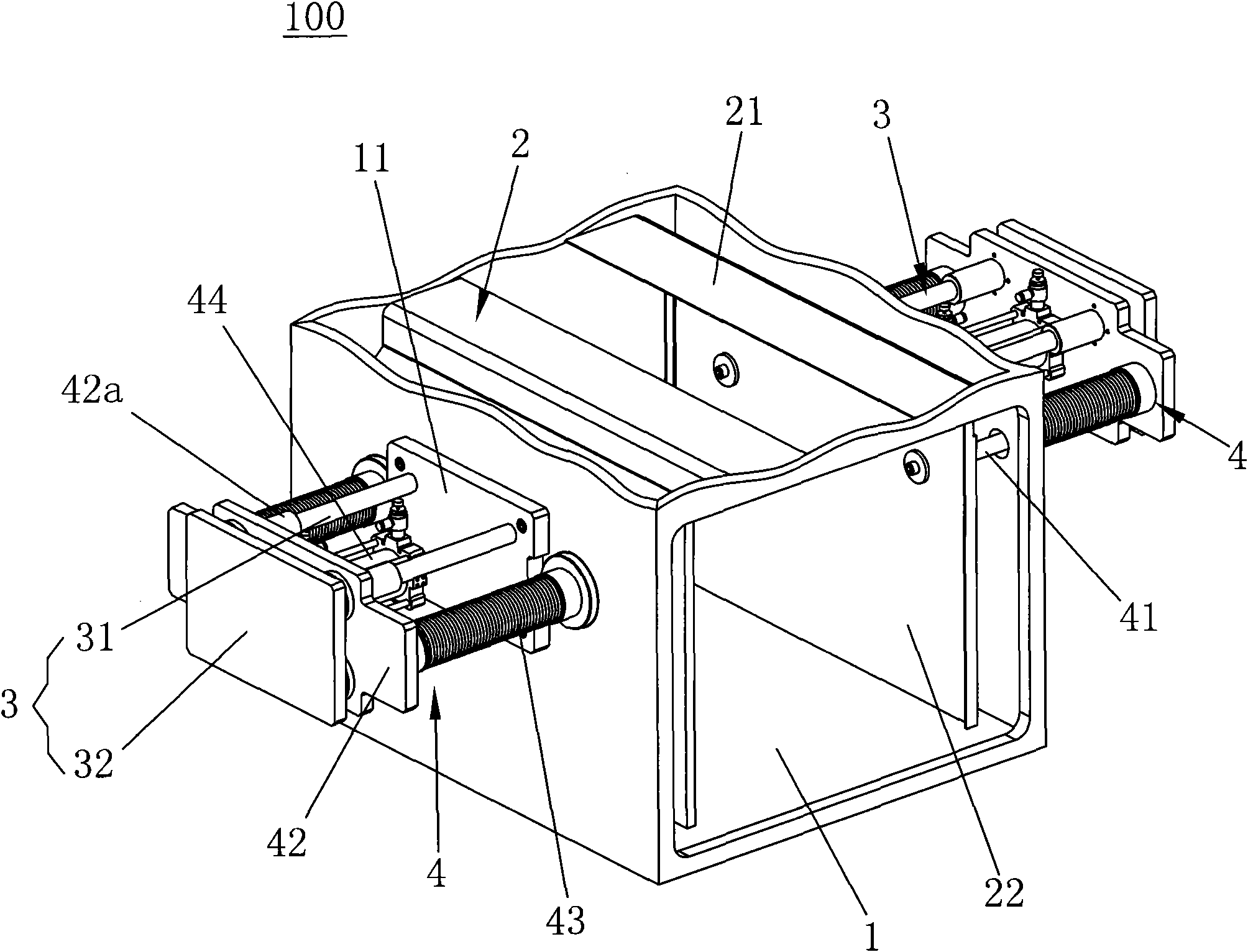

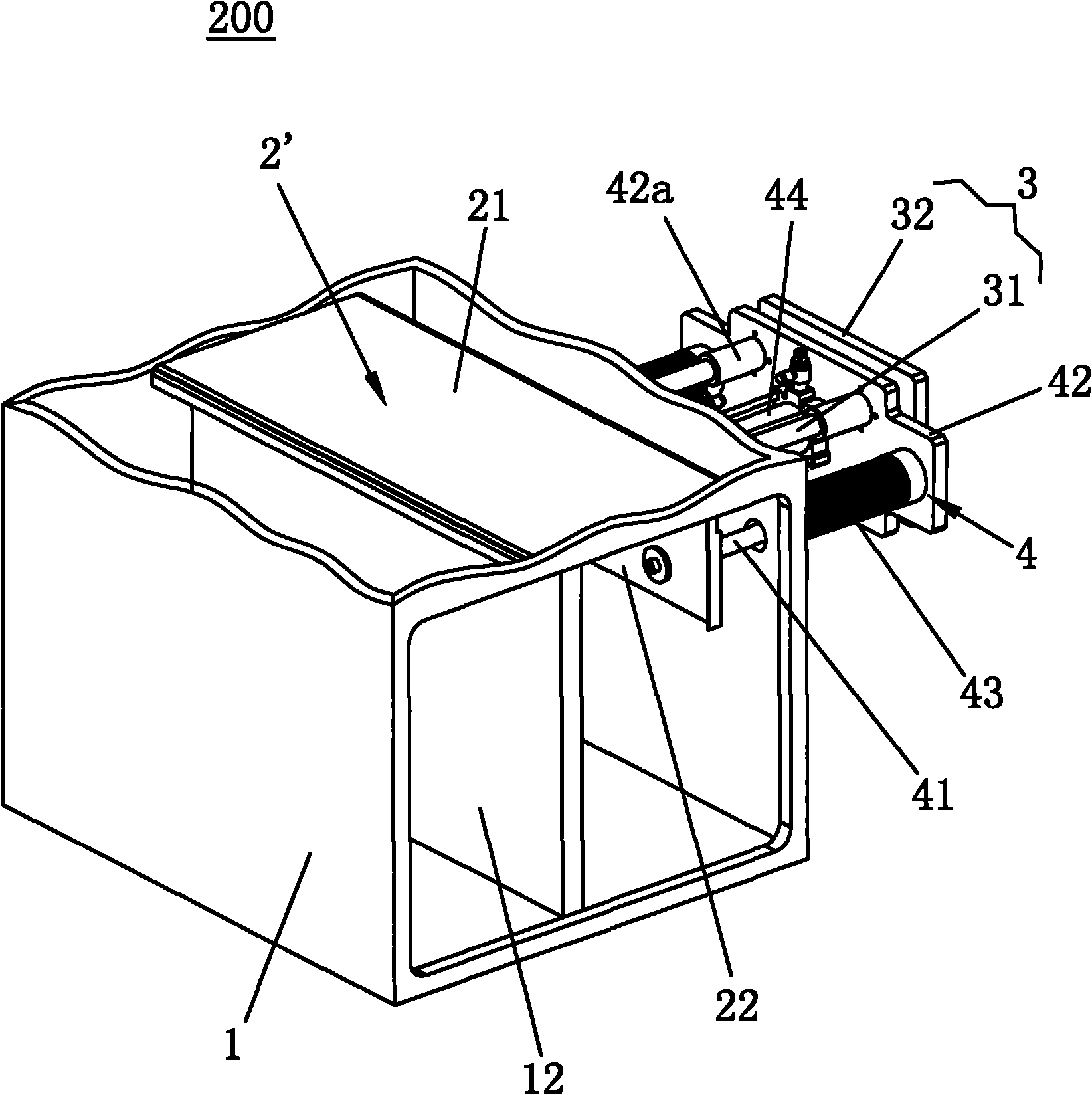

[0022] As shown in Figure 1 is the first embodiment of the present invention, as shown in the figure, the vacuum chamber isolation mechanism 100 includes a vacuum chamber 1, two blocking covers 2, two guiding mechanisms 3 and two control mechanisms 4, two blocking covers 2. The two guide mechanisms 3 and the two control mechanisms 4 are respectively arranged on both sides of the vacuum chamber 1, the vacuum chamber 1 is a hollow and sealed structure, and the evaporation source (not shown in the figure) is connected to the A processing plate (not shown in the figure) is arranged in the vacuum chamber 1, and the processing plate is located above the evaporation source, and the blocking cover 2 is made of a metal material, or can be made of two kinds of materials. It is made by welding or bolt fastening, and has a butt plate 21 and a mounting plate 22. The butt plate 21 is vertically fixedly connected to the mounting plate 22, and the mounting plate 22 is connected to the two cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com