Preparation method of nano-zinc oxide-doped hydroxyapatite porous ceramic

A nano-hydroxyapatite and nano-zinc oxide technology, applied in ceramic products, tissue regeneration, drug delivery, etc., can solve the problems of long-term pain at the bone graft site, mismatch between degradation and osteogenesis rate, and decreased biological activity of materials, etc. To achieve the effect of improving osteogenic induction ability, good osteogenic induction ability, and improving bone formation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

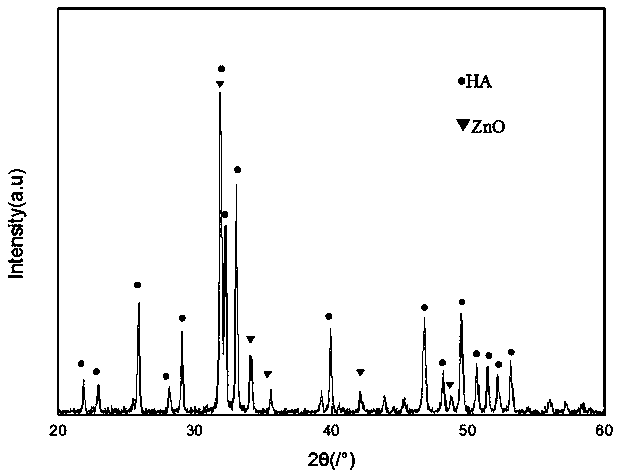

[0027] (1) Using nano-zinc oxide with a purity of ≥99.9% and a particle size of 60nm and nano-hydroxyapatite powder with a purity of ≥99.7% and a particle size of 100nm as raw materials, weigh the nano-zinc oxide according to the mass ratio of 1%:99%. Zinc and nano-hydroxyapatite powder.

[0028] (2) Put the powder raw material weighed in step (1) into an agate ball mill jar, add agate balls, absolute ethanol and dispersant polyethylene glycol (the amount of polyethylene glycol added is 0.7% of the mass of the raw material powder , the mass ratio of agate grinding balls is 3:1, the mass ratio of large, medium and small balls is 1:3:6), placed on a planetary ball mill, after 6 hours of ball milling, dried and ground in a vacuum oven at 60°C to obtain nano-oxidized Zinc doped hydroxyapatite composite powder.

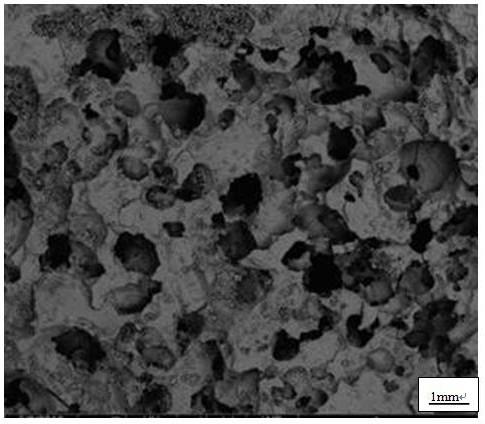

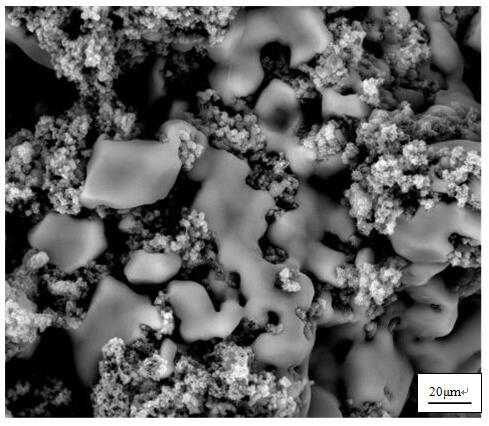

[0029] (3) The nano-zinc oxide-doped hydroxyapatite composite powder obtained in step (2) was uniformly mixed with the powder of ammonium bicarbonate, a pore-forming agen...

Embodiment 2

[0033] Using nano-zinc oxide with a purity of ≥99.9% and a particle size of 60nm and nano-hydroxyapatite powder with a purity of ≥99.7% and a particle size of 100nm as raw materials, weigh nano-zinc oxide and nano-hydroxyapatite according to a mass ratio of 3%:97%. Apatite powder, other process steps and parameters are consistent with embodiment 1.

Embodiment 3

[0035] Using nano-zinc oxide with purity ≥ 99.9% and a particle size of 60nm and nano-hydroxyapatite powder with a purity ≥ 99.7% and a particle size of 100nm as raw materials, weigh nano-zinc oxide and nano-hydroxyapatite according to a mass ratio of 5%:95%. Apatite powder, other process steps and parameters are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com