SnO2/Ag nanometer composite powder and preparation method thereof

A nanocomposite powder and composite powder technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy aggregation of nanoparticles, complex preparation process, poor crystallinity, etc., to achieve Good dispersibility, low preparation temperature and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Dissolve 2.265g of stannous chloride in 100 ml of deionized water to make a transparent solution of 0.1mol / L stannous chloride;

[0028] 2) Dissolve 1.699g of silver nitrate in 100 ml of deionized water to make a 0.1mol / L silver nitrate solution; then slowly add the silver nitrate solution into the transparent stannous chloride solution and keep stirring to obtain a milky white precipitate;

[0029] 3) Slowly add ammonia water with a mass percentage of 10% to the milky white precipitate at a rate of 1ml / s and keep stirring. After the reaction, the pH of the system is 12, and a brown precipitate is obtained;

[0030] 4) The tan precipitate obtained in step 3) was alternately washed three times with deionized water and absolute ethanol, and the obtained product was dried at 80°C to obtain the precursor powder;

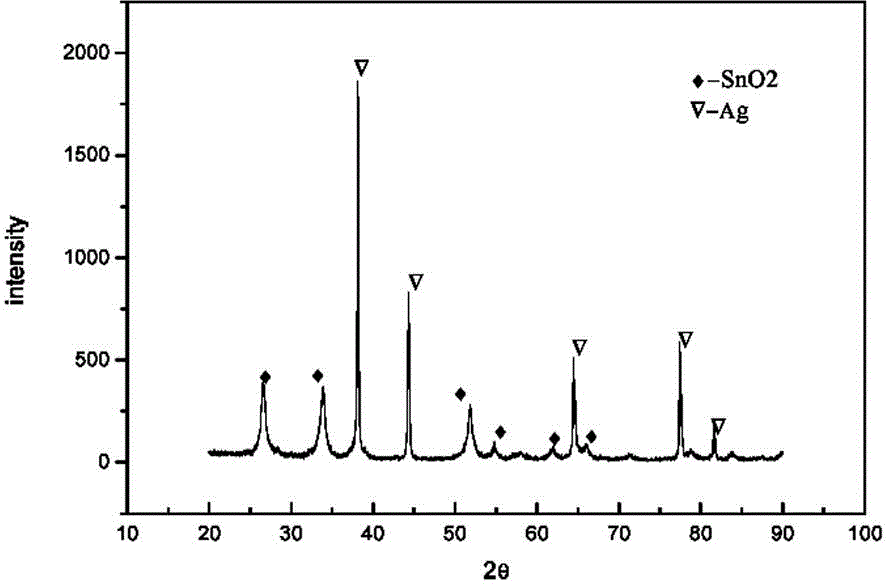

[0031] Sinter the precursor powder obtained in step 4) at 700°C for 3h in an air atmosphere to obtain SnO 2 / Ag nanocomposite powder.

[0032] The above prep...

Embodiment 2

[0038] 1) Dissolve 1.132g of stannous chloride in 100 ml of deionized water to make a transparent solution of 0.05mol / L stannous chloride;

[0039] 2) Dissolve 1.699g of silver nitrate in 100 ml of deionized water to make a 0.1mol / L silver nitrate solution; then slowly add the silver nitrate solution into the transparent stannous chloride solution and keep stirring to obtain a milky white precipitate;

[0040] 3) Slowly add ammonia water with a mass percentage of 10% to the milky white precipitate at a rate of 1ml / s and keep stirring. After the reaction, the pH of the system is 9, and a brown precipitate is obtained;

[0041] 4) The tan precipitate obtained in step 3) was alternately washed three times with deionized water and absolute ethanol, and the obtained product was dried at 80°C to obtain the precursor powder;

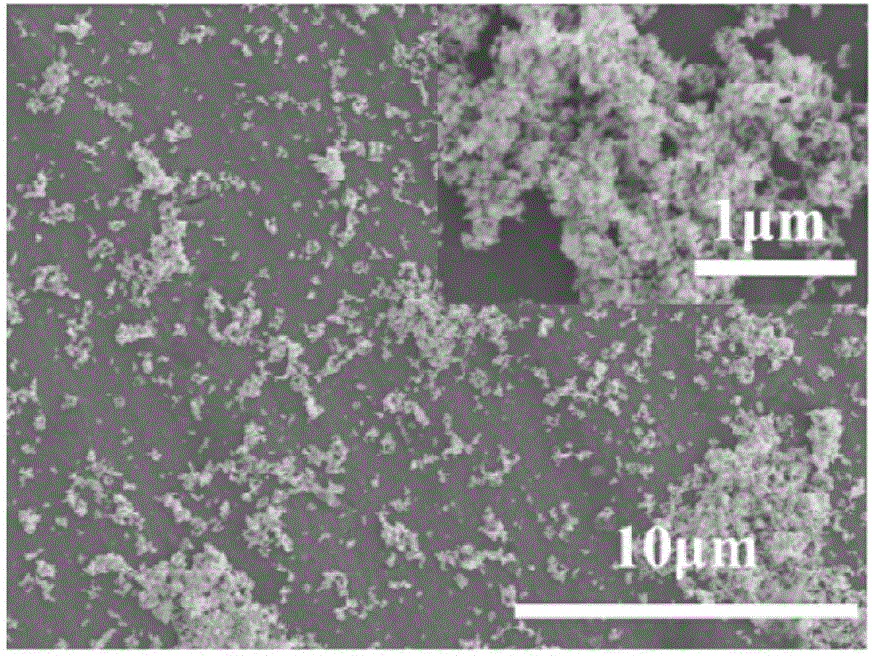

[0042]The precursor powder obtained in step 4) was sintered at 600 °C for 3 hours in an air atmosphere to obtain SnO with an average particle size of 35 nm and...

Embodiment 3

[0048] 1) Dissolve 2.13 g of sodium stannate in 100 ml of deionized water to make a transparent solution of 0.1mol / L sodium stannate;

[0049] 2) Dissolve 2.016g of silver nitrate in 126ml of deionized water to make a 0.1mol / L silver nitrate solution; then slowly add the silver nitrate solution into the transparent sodium stannate solution and keep stirring to obtain a yellow-brown precipitate;

[0050] 3) Slowly add ammonia water with a mass percentage of 5% to the yellow-brown precipitate at a rate of 1ml / s and keep stirring. After the reaction, the pH of the system is 8, and a tan precipitate is obtained;

[0051] 4) The tan precipitate obtained in step 3) was alternately washed three times with deionized water and absolute ethanol, and the obtained product was dried at 80°C to obtain the precursor powder;

[0052] The precursor powder obtained in step 4) was sintered in an air atmosphere at 600°C for 3 hours to obtain a dispersedly distributed nanocomposite powder with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com