Infrared heating furnace device

An infrared heating furnace and infrared heating technology, which are used in measuring devices, lighting and heating equipment, furnaces, etc., can solve the problems of unstable heating at low-end temperature and difficulty in completing temperature-changing experiments, and achieve good heating effect, uniform heating and control. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

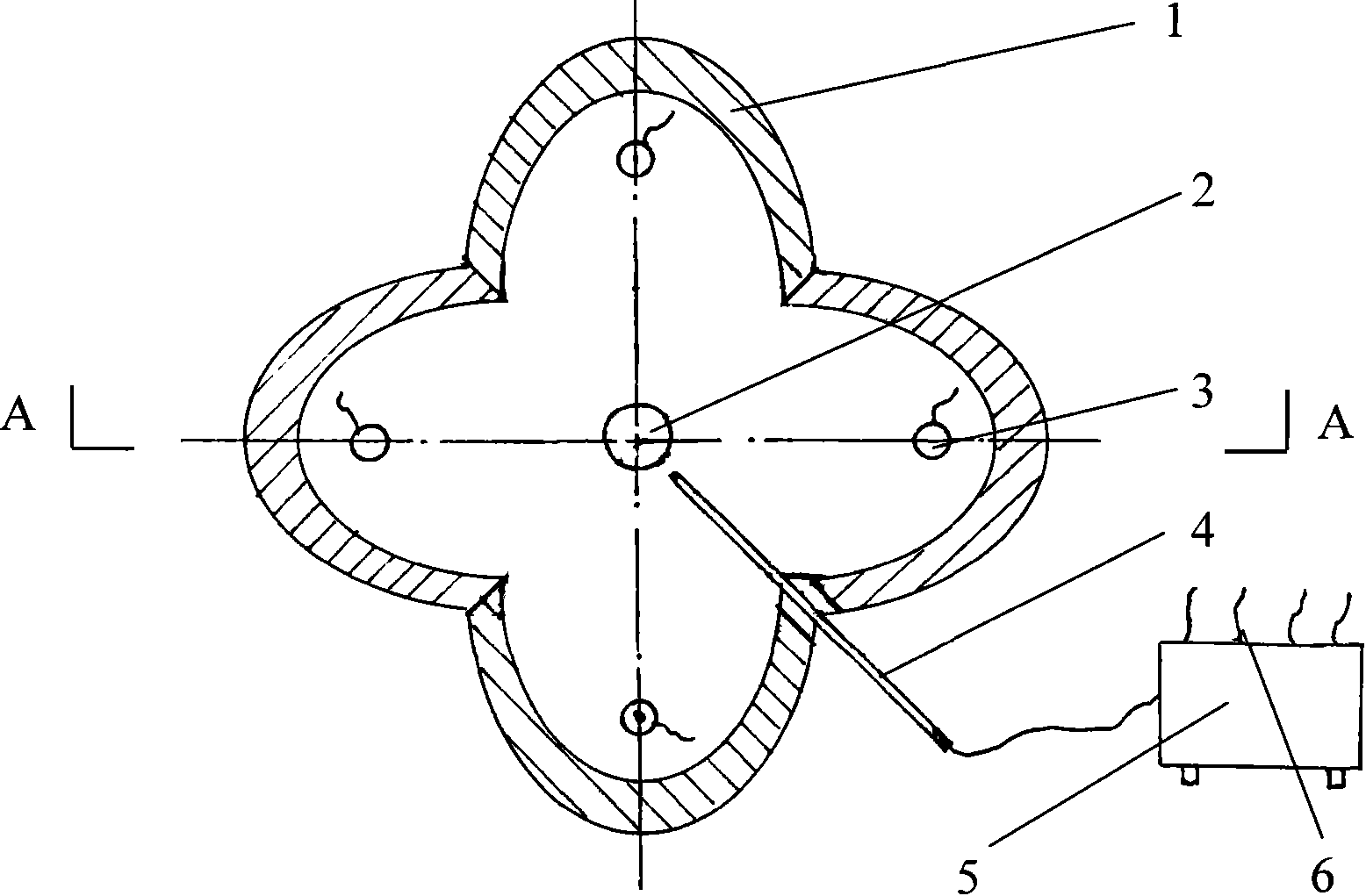

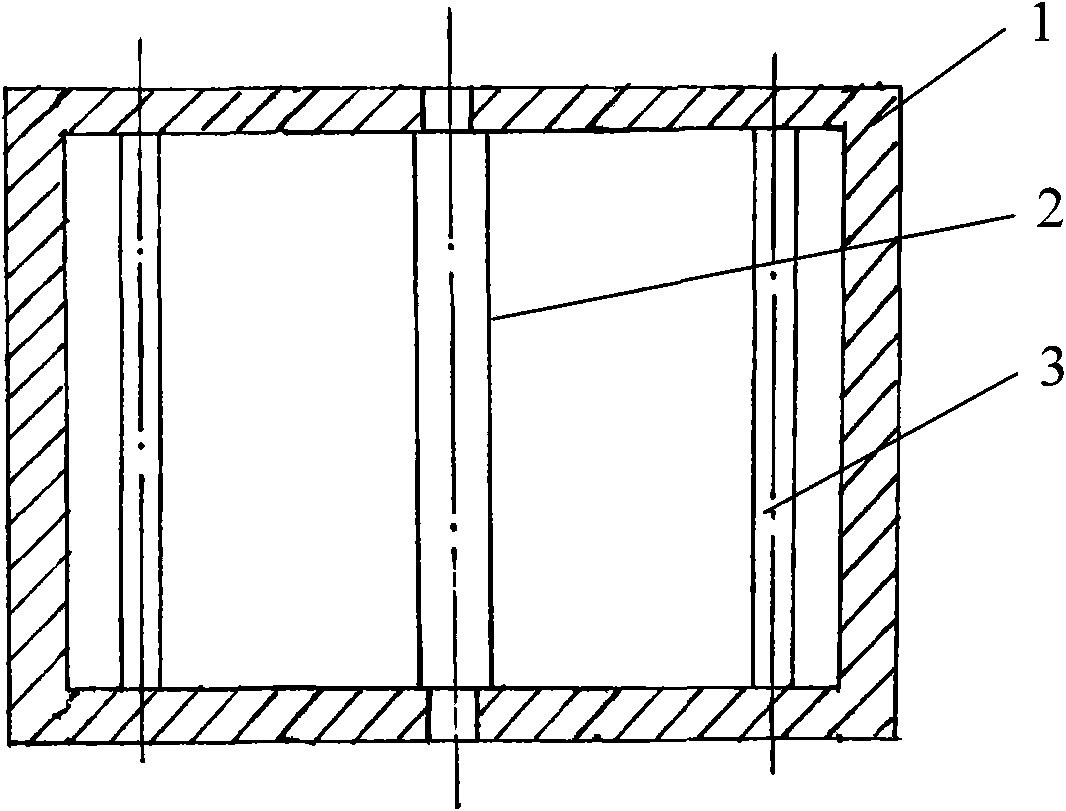

[0016] Such as Figure 1-Figure 2 As shown, the infrared heating furnace device of the present invention has a specific structure comprising:

[0017] (1) A furnace body 1 having elliptical cylindrical surface reflection, the furnace body 1 may be composed of two, three or more elliptical cylindrical surfaces, and the present embodiment is four.

[0018] (2) There is an infrared heating lamp 3 on one focal point of the elliptical cylindrical surface of each furnace body 1, and the infrared heating lamp 3 can be a lamp with a reflective coating on the outer surface or a lamp without a reflective coating on the outer surface; or, infrared The heating lamp 3 can be a thickened lamp in the middle of the filament or a lamp with uniform filament.

[0019] (3) temperature controller 5, the temperature controller 5 is powered by the heating power supply, the input end of the temperature controller 5 is connected to the temperature measuring thermocouple 4, and the temperature measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com