Polarized plate structure

A polarizing plate and polarizing layer technology, which is applied in optics, optical elements, polarizing elements, etc., can solve the problems of variation in the optical properties of polarizing plates, and achieve the effects of low yellowing index, simple manufacturing process, and high Abbe number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Here, the present invention will describe some embodiments in detail. It is to be noted, however, that the invention may be practiced in a wide range of other embodiments than those explicitly described, and that the scope of the invention is not limited to the above-described embodiments, as determined by the claims.

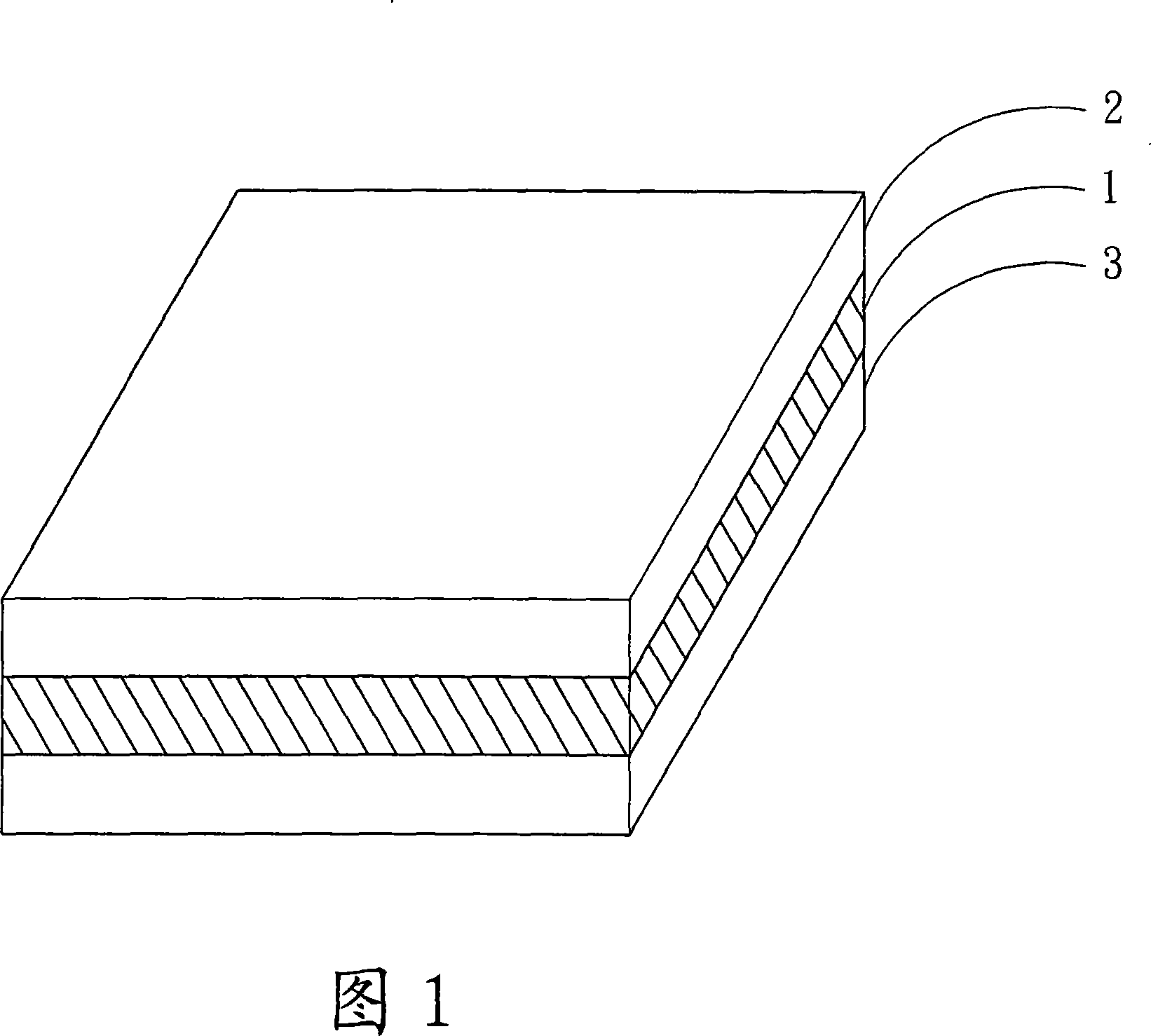

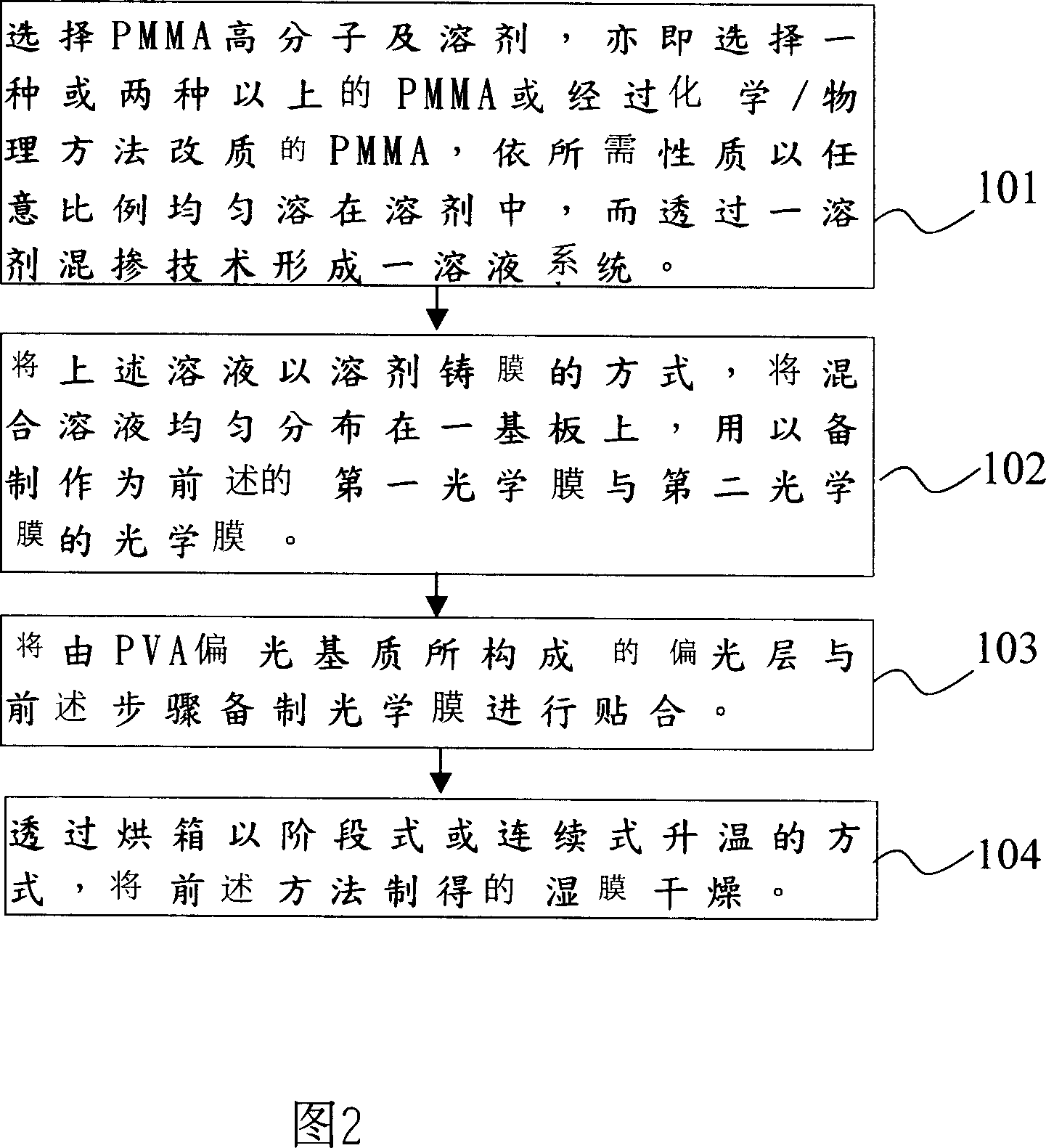

[0023] FIG. 1 is a perspective view of a specific embodiment of a polarizer structure of the present invention. Shown with reference to Fig. 1, the polarizer structure of the present invention is that the upper surface and the lower surface of polarizing layer 1 have first optical film 2 and second optical film 3 respectively, and described first optical film 2 and second optical film 3 Among them, at least one optical film is a polymethyl methacrylate (Polymethyl Methacrylate, PMMA) optical film.

[0024] In addition, in the above-mentioned first optical film 2 and second optical film 3, one optical film is a polymethyl methacrylate optical film, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com