Patents

Literature

79results about How to "High Abbe number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

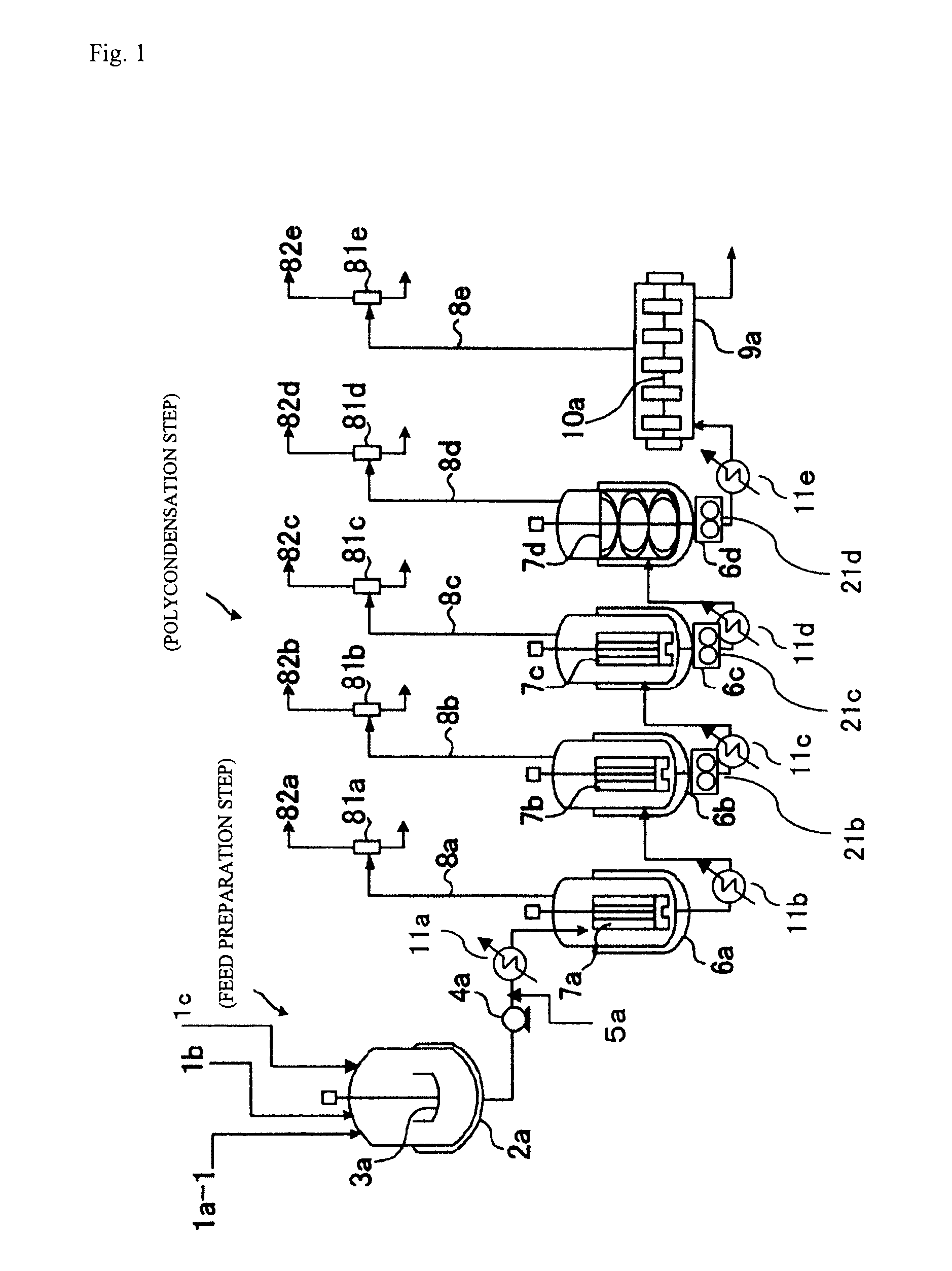

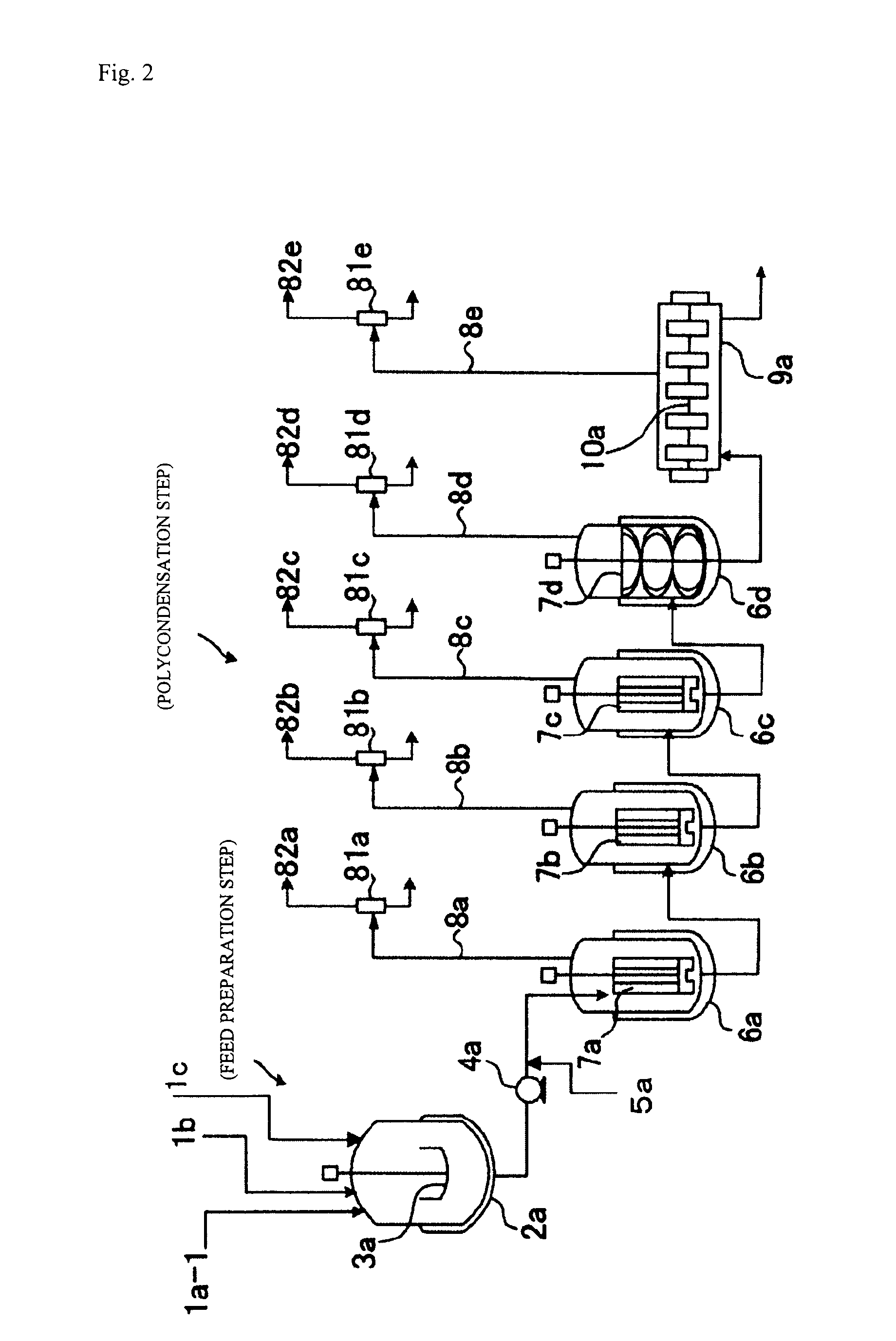

Processes for producing polycarbonate and molded polycarbonate articles

ActiveUS20110003101A1Efficient and stable productionLow refractive indexFlexible coversWrappersHeat resistanceRefractive index

A subject for the invention relates to processes for producing a polycarbonate containing a plant-derived starting material and to molded articles thereof, the polycarbonate having excellent mechanical strength, heat resistance, a low refractive index, a large Abbe number, low birefringence, and excellent transparency. The invention relates to a process for producing a polycarbonate which includes a step in which one or more dihydroxy compounds including a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof are reacted with a carbonic acid diester in the presence of a polymerization catalyst, wherein the dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof has a formic acid content lower than 20 ppm. The invention further relates to a molded article constituted of a polycarbonate or a composition of the polycarbonate, the polycarbonate being a polycarbonate which contains constituent units derived from a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof and has an Abbe number of 50 or larger and a 5% weight loss temperature of 340° C. or higher.

Owner:MITSUBISHI CHEM CORP

Resin lens with high impact resistance

The invention relates to a resin lens with high impact resistance, which is prepared by the steps of mixing the following raw materials by weight percent, then injecting the mixture into an injection mould and carrying out curing molding and quenching, wherein the raw materials comprise 5-15 of solution containing a sulfhydryl (-SH) terminated polythioester / polyurethane prepolymer, 50-60 of solution containing a polyisocyanate compound, 30-40 of poly-sulfhydryl compounds, 0.05-0.15 of ultraviolet absorbent and 0.05-0.15 of catalyst. The resin lens of the invention has the advantage that the impact resistance is improved while the resin lens has high refractive index and Abbe number.

Owner:江阴市茂盛光学材料有限公司

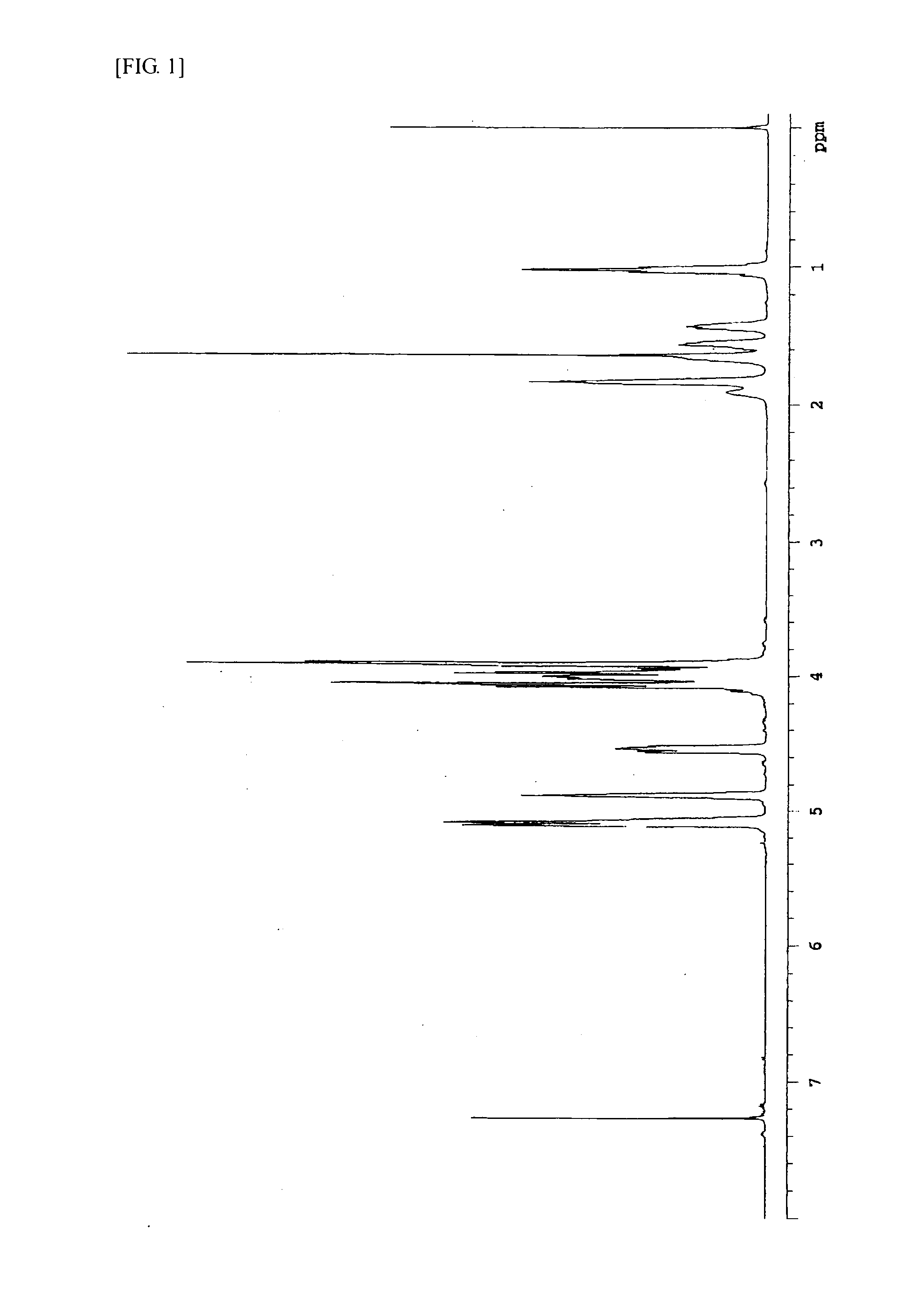

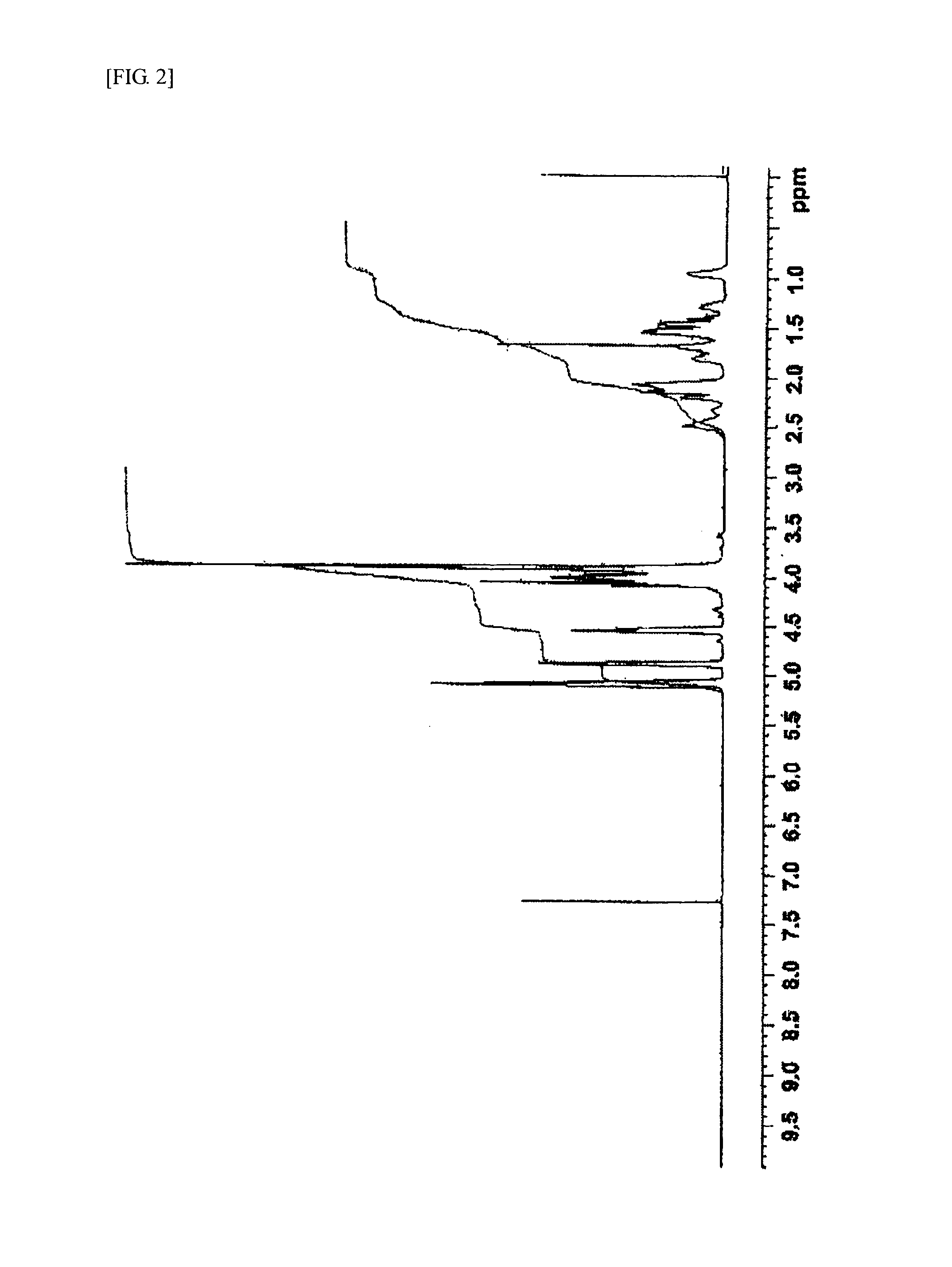

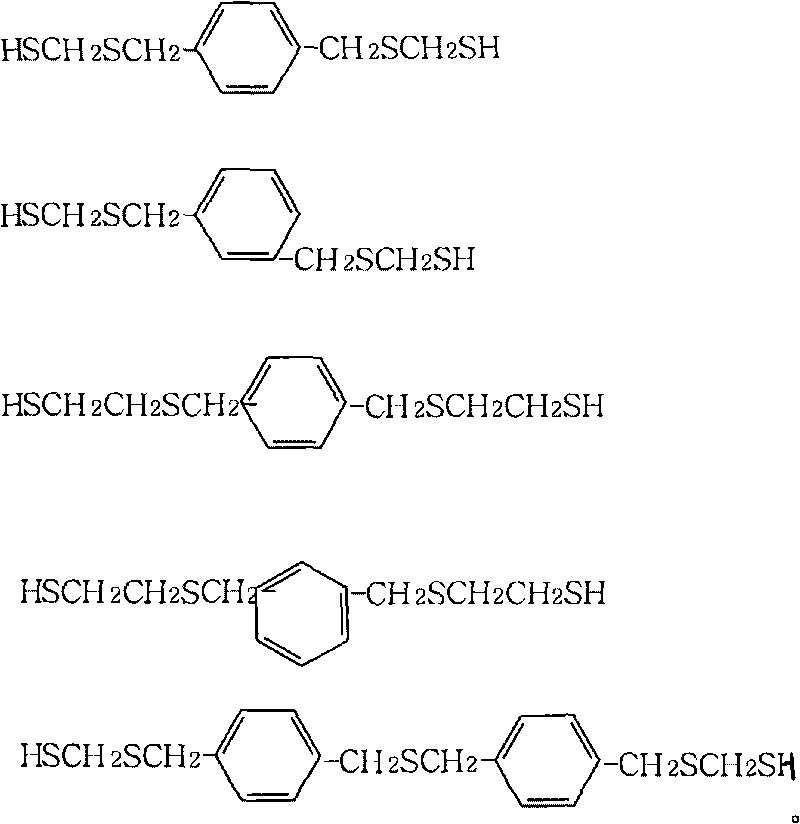

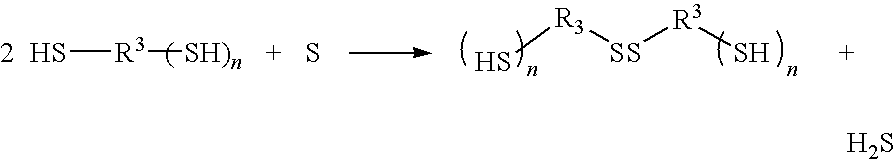

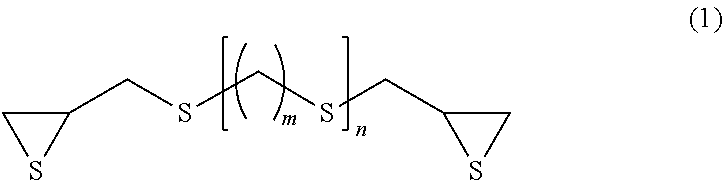

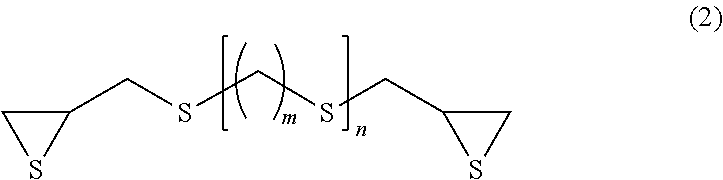

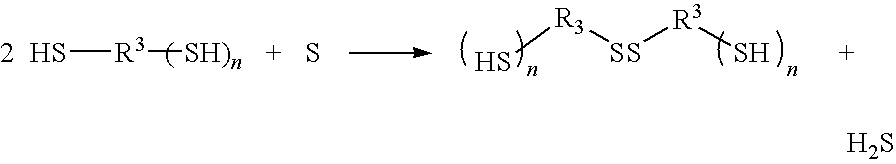

Method for producing polythiourethane resin

A process for producing a polythiourethane resin which comprises (A) a step of synthesizing a polythiol oligomer having disulfide bond by reaction of a polythiol compound having a functionality of two or greater and sulfur and (B) a step of bringing the polythiol oligomer obtained in step (A) and a compound having poly(thio)isocyanate groups into reaction with each other, wherein step (A) is conducted in the absence of solvents using no catalysts or a catalyst substantially inert to the compound having poly(thio)isocyanate groups. A polythiol oligomer exhibiting a greater refractive index than that of the polythiol compound having a functionality of two or greater used as the starting material is produced at a low cost, and a process for producing a practically useful polythiourethane resin exhibiting a stable great refractive index and a great Abbe number is provided.

Owner:HOYA CORP

Processes for producing polycarbonate

ActiveUS8445624B2Improve the heating effectHigh strengthSynthetic resin layered productsChemical recyclingPolymer scienceCarbonate ester

Owner:MITSUBISHI CHEM CORP

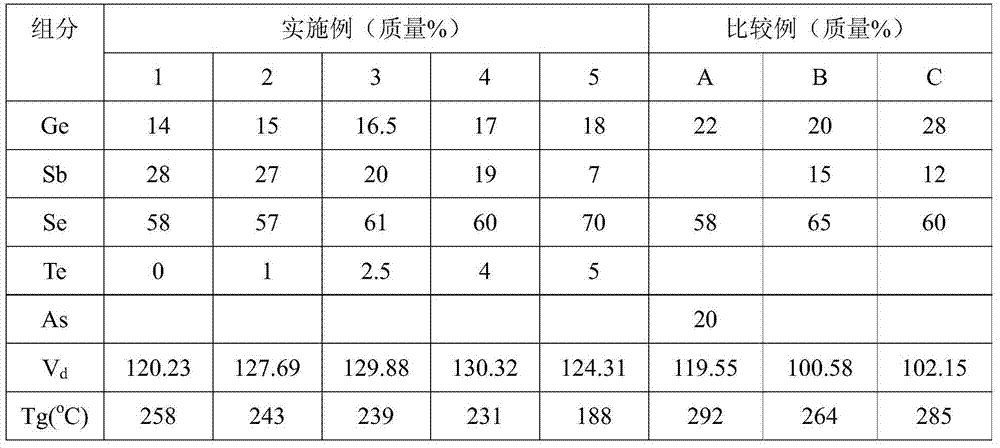

Environmentally friendly low-dispersion chalcogenide glass and preparation method thereof

InactiveCN104843996AGood infrared transmission performanceUniform optical qualityTransmittanceEnvironmentally friendly

The invention discloses an environmentally friendly low-dispersion chalcogenide glass and a preparation method thereof. The chalcogenide glass comprises, by mass, 14-18% of Ge, 7-28% of Sb, 57-70% of Se, and 0-5% of Te. Composition components of the chalcogenide glass do not contain As, the Abbe number of the chalcogenide glass disclosed in the invention is higher than the Abbe number of As-containing chalcogenide glass Ge22As20Se58 of 119.55, the Abbe number of commercial Ge20 (Ge20Sb15Se65) of 100.58 and the Abbe number of commercial Ge28 (Ge28Sb12Se60) of 102.15, and the V8-12 of the chalcogenide glass is the ratio of (n10-1) / (n8-n12) and is 120-130; and the chalcogenide glass has a good infrared transmittance performance, can be stably produced in batches, and can be used in infrared night vision lenses. The preparation method of the environmentally friendly low-dispersion chalcogenide glass is characterized in that a glass raw material tube and a purified glass tube are respectively placed in two hearths with different temperatures, and glass is purified by controlling a temperature difference between the two hearths, so the highly pure chalcogenide glass with uniform optical quality and good infrared light transmittance is obtained.

Owner:宁波鼎创红外精密光学科技有限公司

Optical material and uses thereof

InactiveUS20160017218A1Good lookingHigh Abbe numberLuminescent compositionsSpectral modifiersPhosphorUltraviolet lights

An optical material of the present invention includes: a phosphor which has an excitation wavelength in a range from 220 nm to 500 nm, a fluorescence wavelength in a range from 380 nm to 650 nm, a maximum excitation wavelength in a range from 350 nm to 400 nm, and a maximum fluorescence wavelength in a range from 400 nm to 500 nm; and an ultraviolet light absorber, and the light transmittance thereof measured at a thickness of 2 mm satisfies the following features (1) to (3):(1) The light transmittance at a wavelength of 440 nm is 80% or higher.(2) The light transmittance at a wavelength of 420 nm is 70% or lower.(3) The light transmittance at a wavelength of 410 nm is 5% or lower.

Owner:MITSUI CHEM INC

Ytterbium-doped fluophosphate laser glass and preparation method thereof

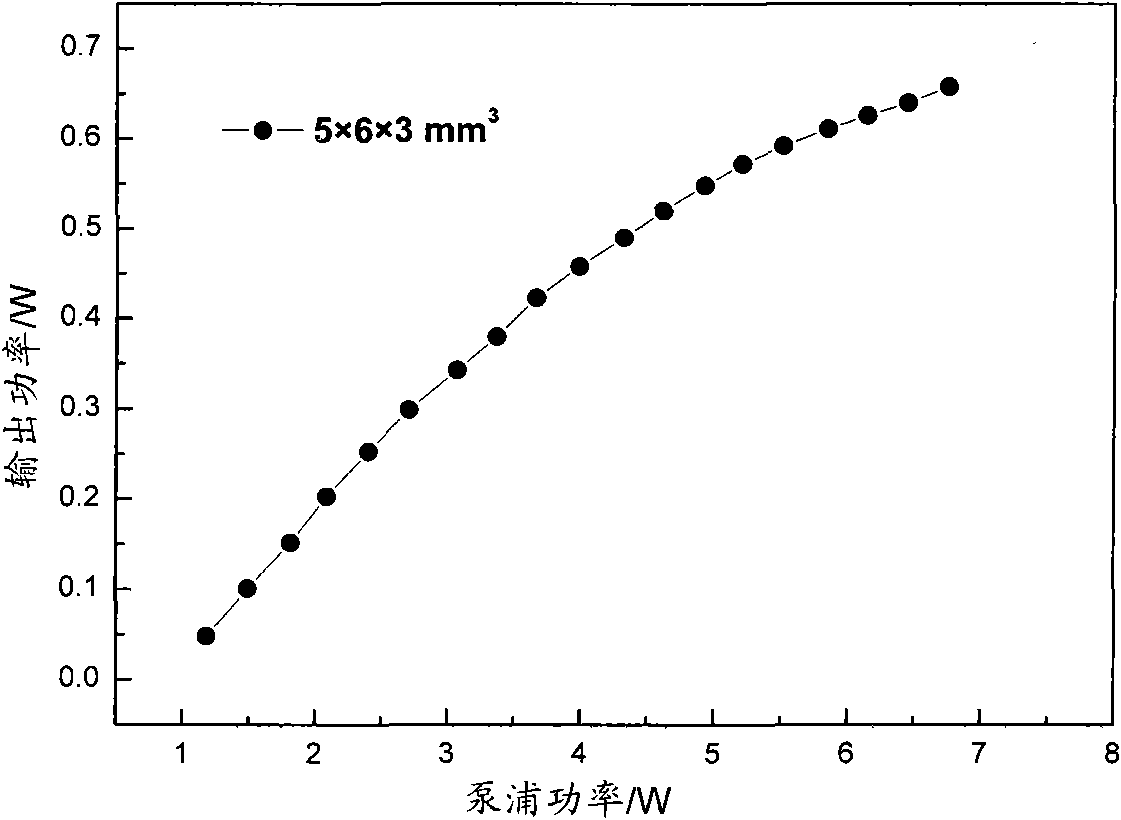

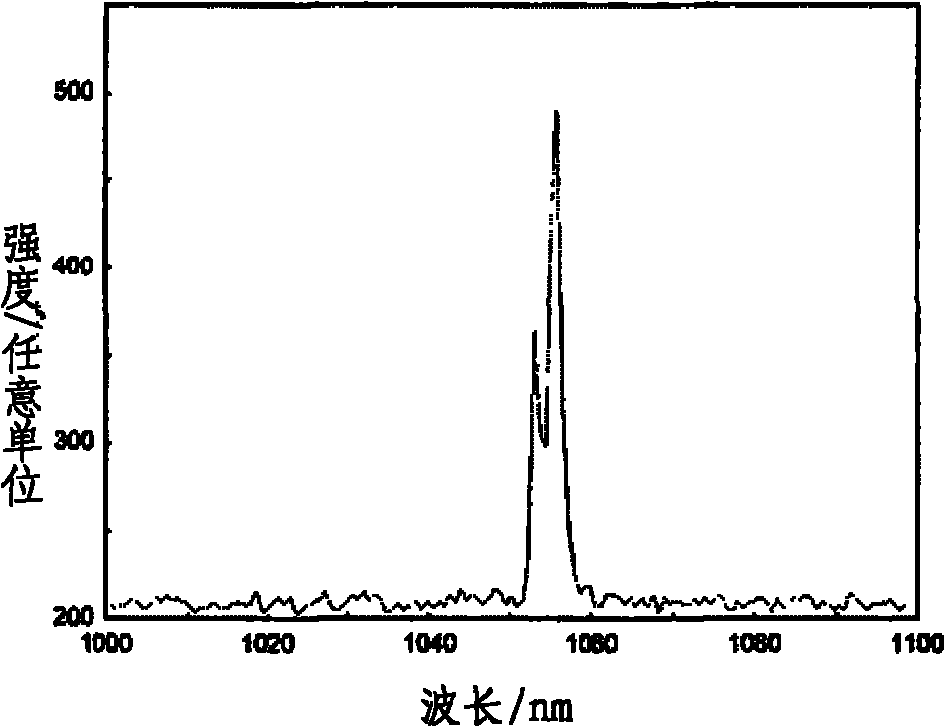

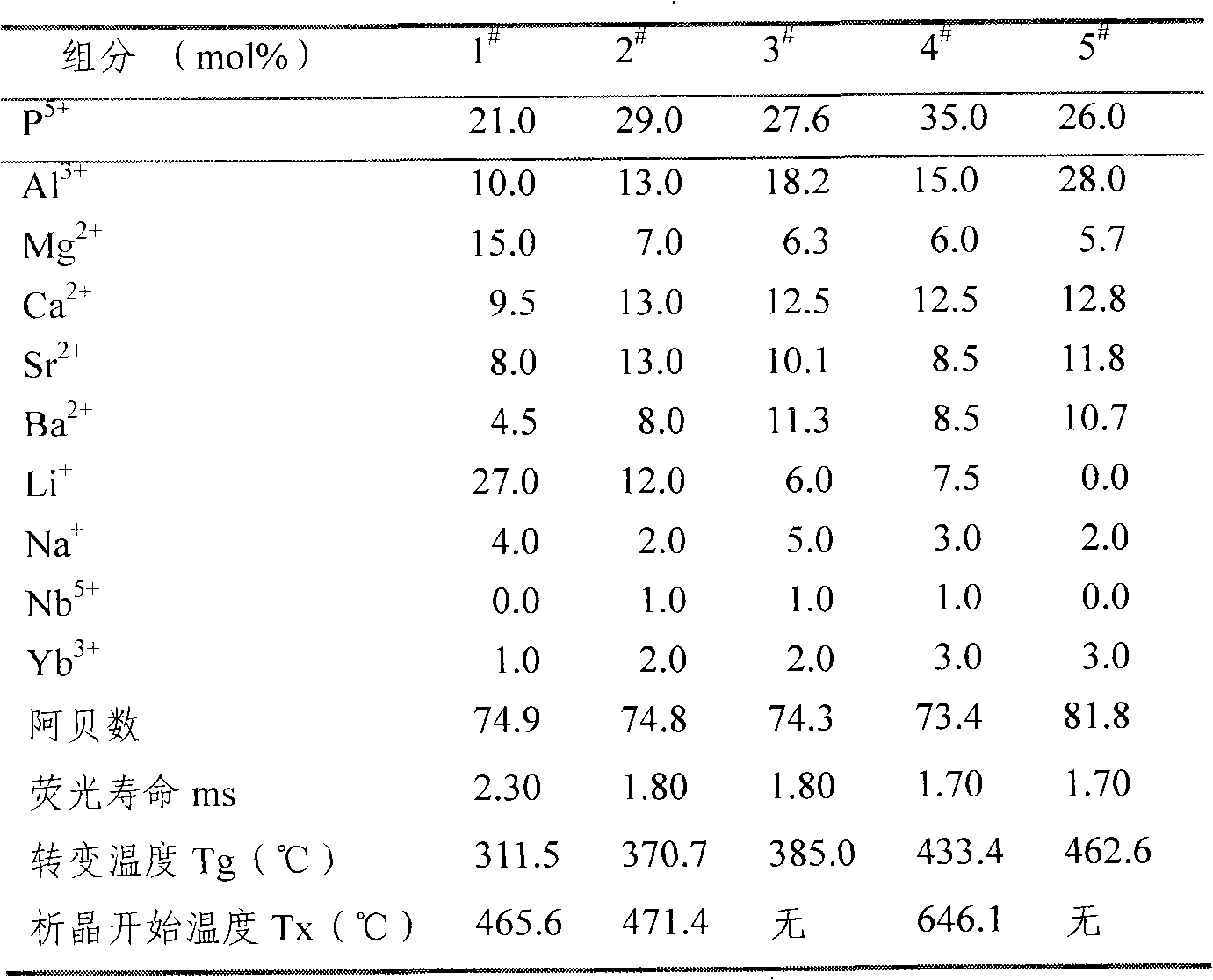

InactiveCN101973706AIncreased fluorescence lifetimeHigh Abbe numberFluorescenceUltrashort pulse laser

The invention relates to ytterbium-doped fluophosphate laser glass and a preparation method thereof. The glass comprises phosphate, fluoride and little oxide, wherein cation contains the following elements in mole percentage: 21.0-35.0 mol percent of P<5+>, 10.0-28.0 mol percent of Al<3+>, 6.0-15.0 mol percent of Mg<2+>, 9.5-13.0 mol percent of Ca<2+>, 8.0-13.0 mol percent of Se<2+>, 4.5-11.3 mol percent of Ba<2+>, 0-27.0 mol percent of Li<+>, 2.0-5.0 mol percent of Na<+>, 0-1.0 mol percent of Nb<5+> and 1.0-3.0 mol percent of Yb<3+>. The glass is prepared by adopting the traditional fusion method. The fluorescence lifetime of Yb<3+> is from 1.70ms to 2.3ms in a 2mm sample, and the Abbe number is between 73.4 and 81.8. Proved by experiments, the ytterbium-doped laser glass is a practical medium material for outputting ultrahigh power and ultrashort pulse laser.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

Polymerizable composition for optical material, optical material, and method of manufacturing optical material

ActiveUS20160280840A1Low refractive indexGood optical performanceOptical articlesOptical elementsCompound (substance)Triple bond

The polymerizable composition for an optical material of the present invention includes: (A) a compound having a carbon-carbon triple bond and at least one group selected from an isocyanate group and an isothiocyanate group in a molecule; and (B) a polythiol compound.

Owner:MITSUI CHEM INC

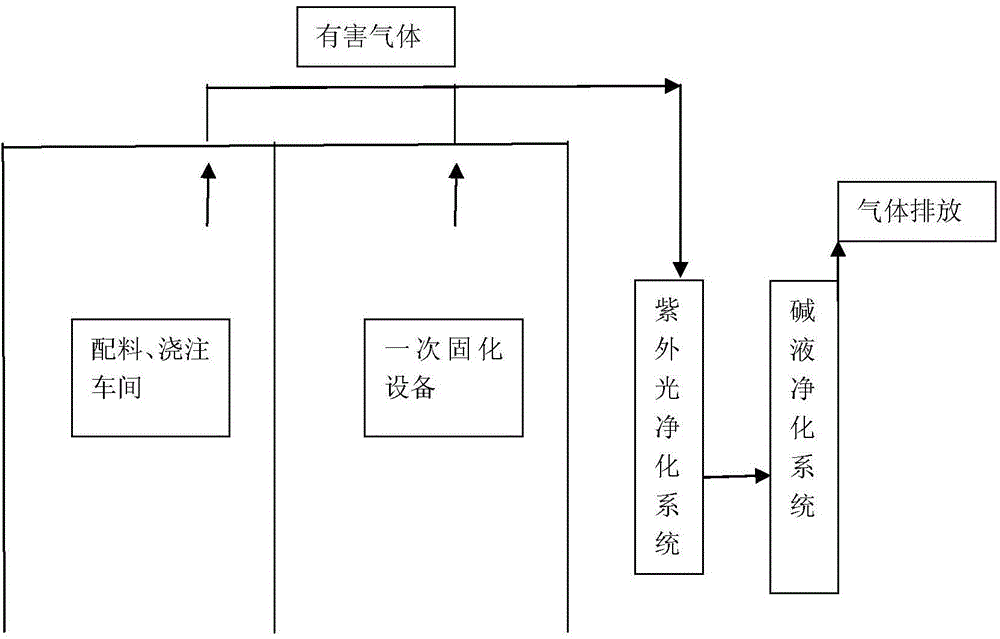

Photochromic resin lens with refractive index of 1.50 and preparation method thereof

The invention discloses a photochromic resin lens with refractive index of 1.50. The photochromic resin lens with refractive index of 1.50 comprises the following materials: a resin monomer, an initiator and color changing liquid based on the ratio of 100:(0.5-3.0):(1.0-4.0); the resin monomer is a mixture of diglycol allyl carbonate and a polymer of diglycol allyl carbonate; the initiator is one or the mixture of peroxide-2-ethylhexyl tert-butyl carbonate, peroxide-2-ethylhexyl tert-amyl carbonate and 1,1-bi(tert-butyl peroxide)-3,3,5-trimethyl-cyclohexane; the color changing liquid is a photochromic organic material dissolved with an organic solvent. The preparation method comprises the following steps: (1) weighting the resin monomer, the initiator and the color changing liquid based on the ratio, and uniformly mixing; (2) casting; (3) thermally curing for the first time; (4) opening a die, turning the edge, and washing; (5) thermally curing for the second time for 2 hours at the temperature of 110 DEG C; (6) checking and warehousing. The prepared photochromic resin lens with refractive index of 1.50 is high in abbe number, clear in imaging, and suitable for a customer wearing; the visible light transmittance after the color changing is equal to or less than 30%.

Owner:JIANGSU CONANT OPTICS +1

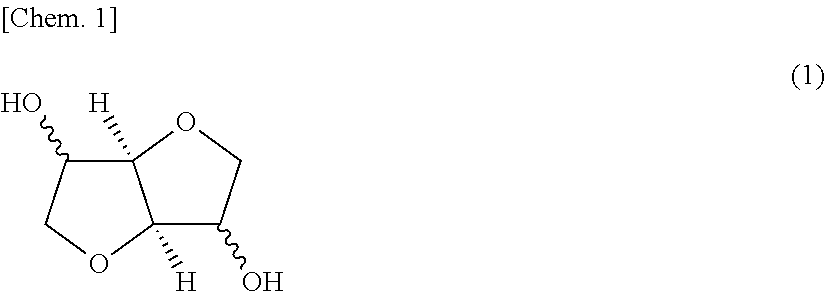

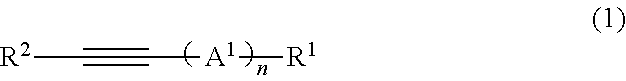

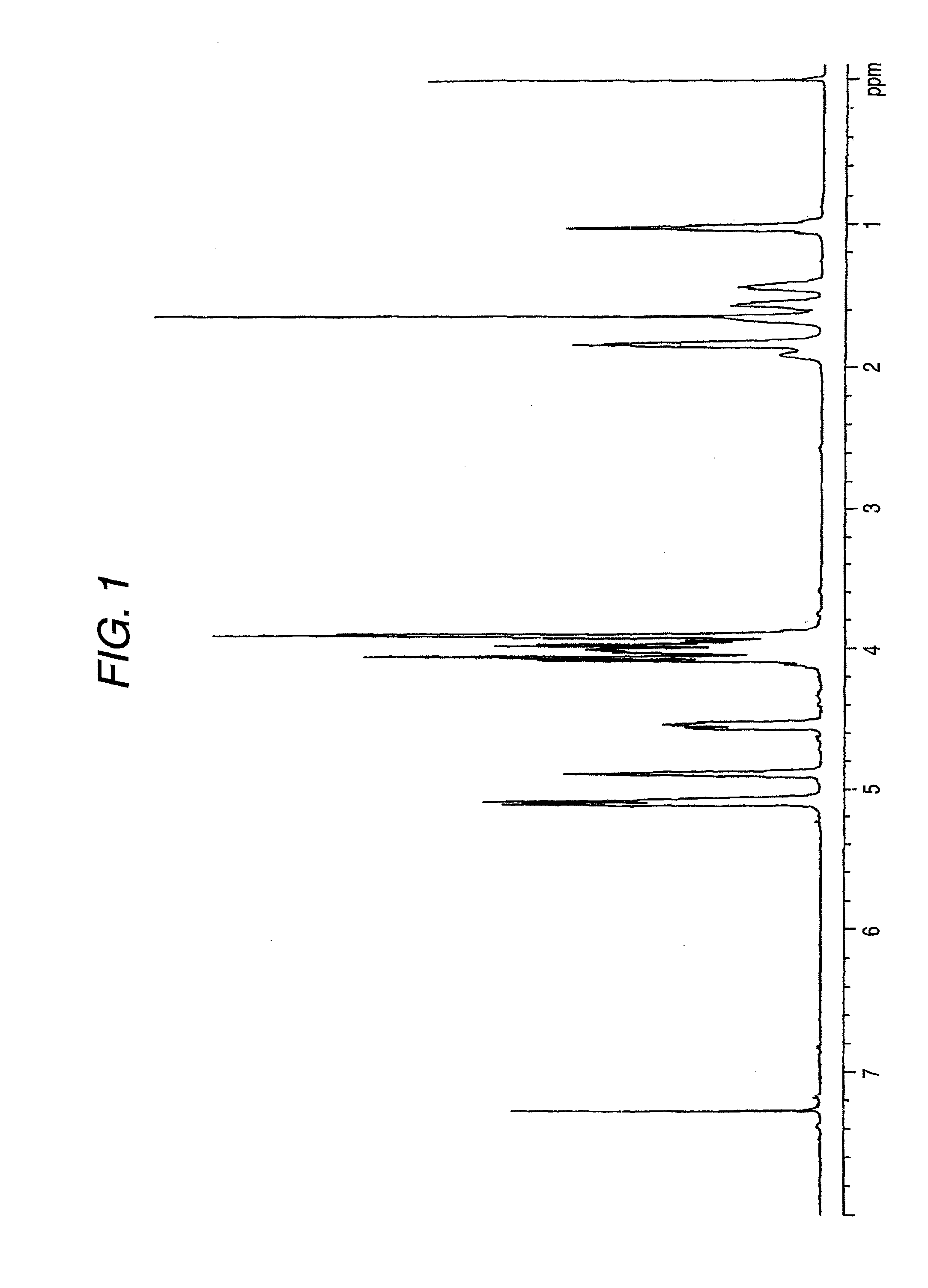

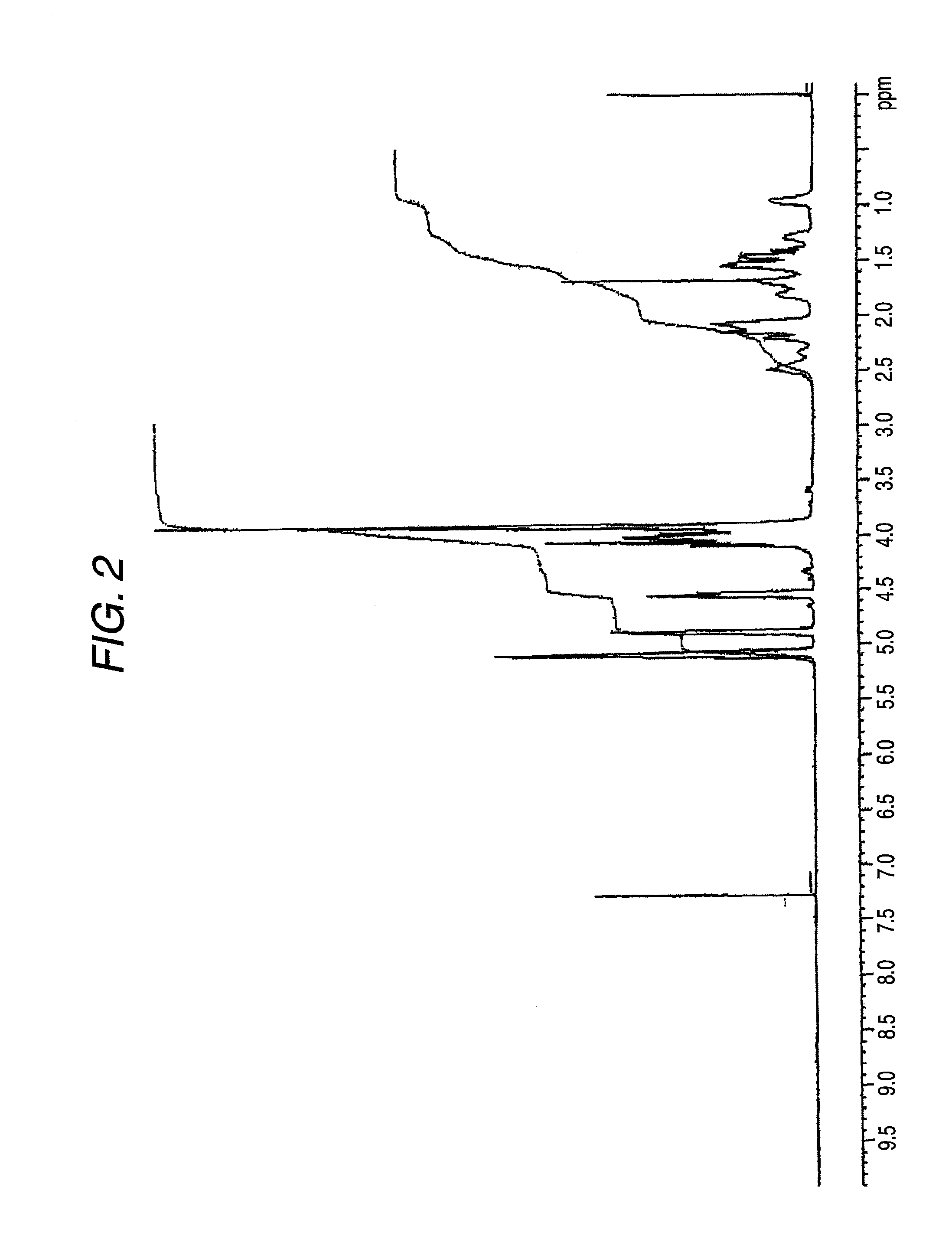

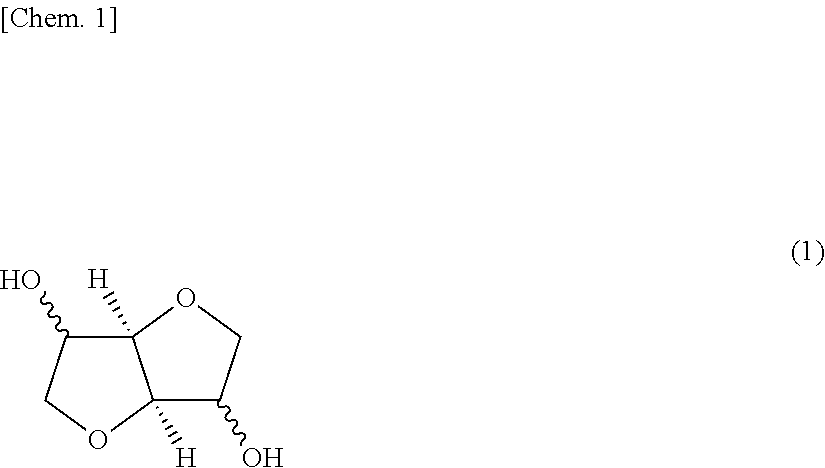

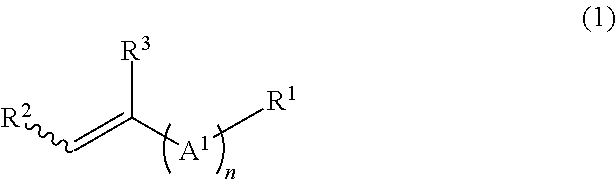

Polycarbonate copolymer and method of producing the same

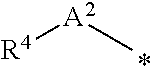

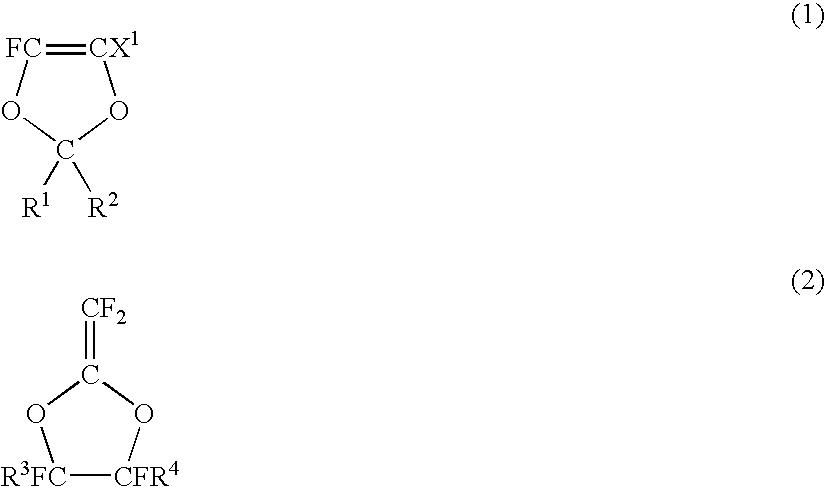

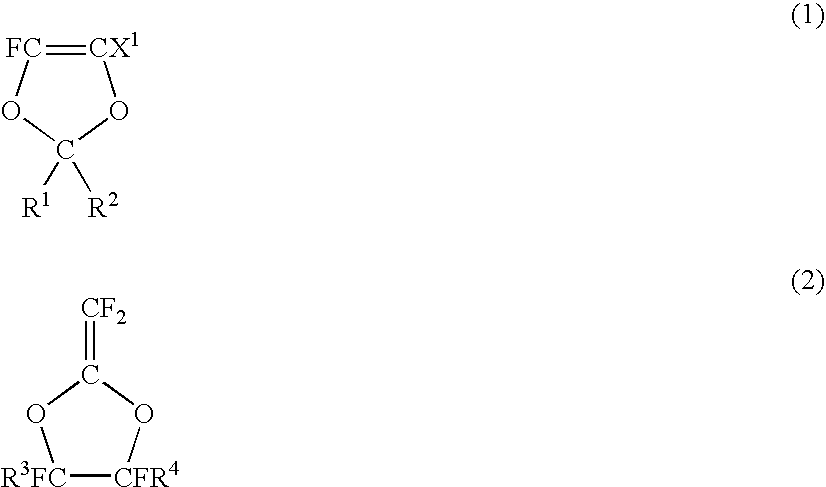

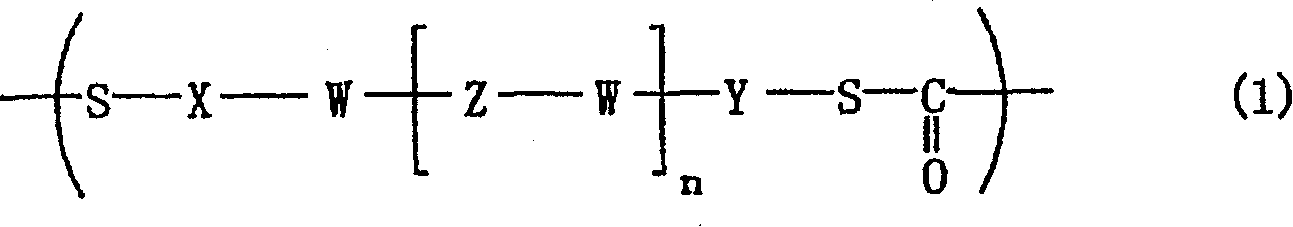

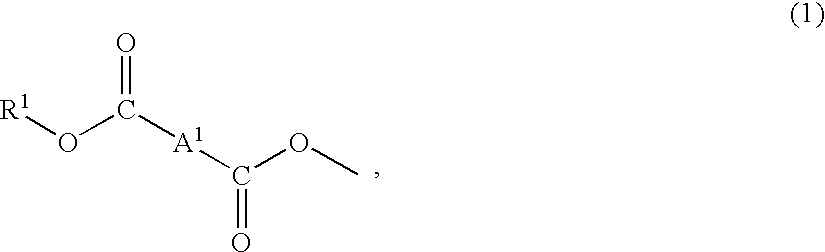

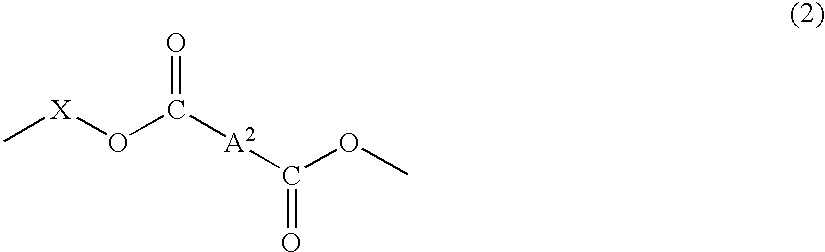

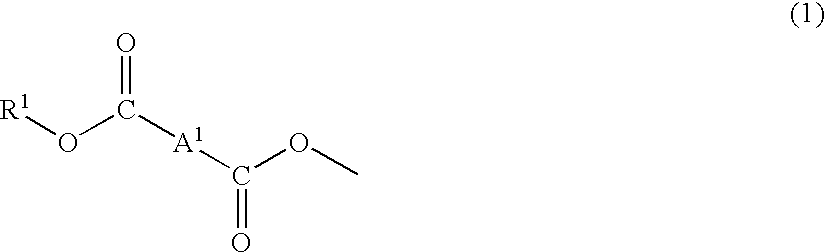

The problem to be solved by the present invention is to provide a polycarbonate copolymer containing a plant-derived raw material, which is excellent in the mechanical strength and heat-resistant and assured of small refractive index, large Abbe number, small birefringence and excellent transparency. The present invention provides a polycarbonate copolymer containing a constitutional unit derived from a dihydroxy compound represented by the following formula (1) and a constitutional unit derived from an alicyclic dihydroxy compound, wherein the Abbe number is 50 or more and the 5% thermal reduction temperature is 340° C. or more; and a method of producing this polycarbonate copolymer by reacting a dihydroxy compound represented by the following formula (1) and an alicyclic hydroxy compound with a carbonic acid diester in the presence of a polymerization catalyst.

Owner:MITSUBISHI CHEM CORP

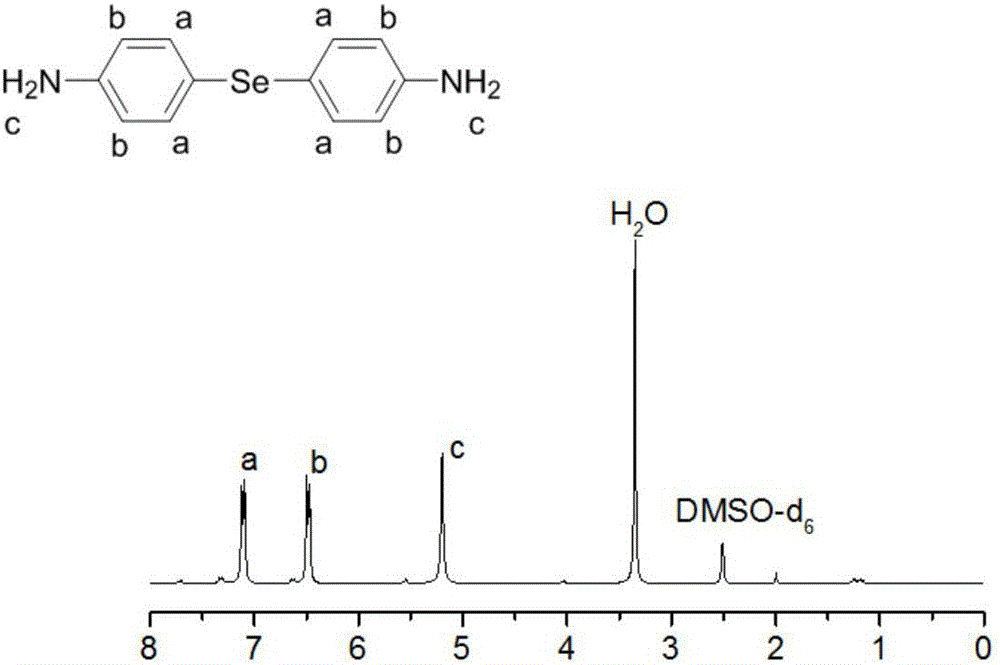

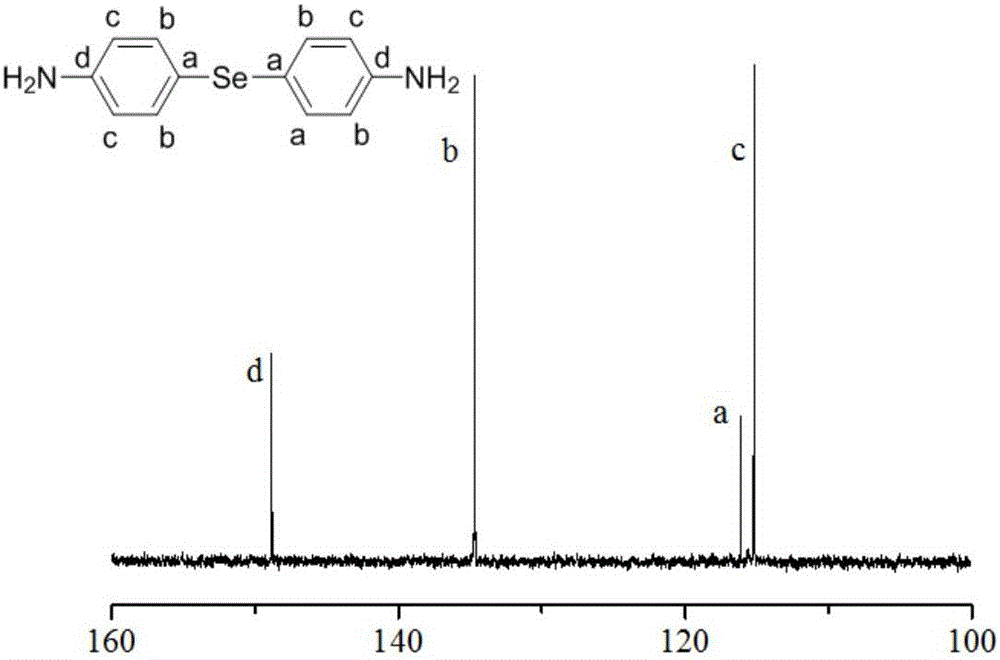

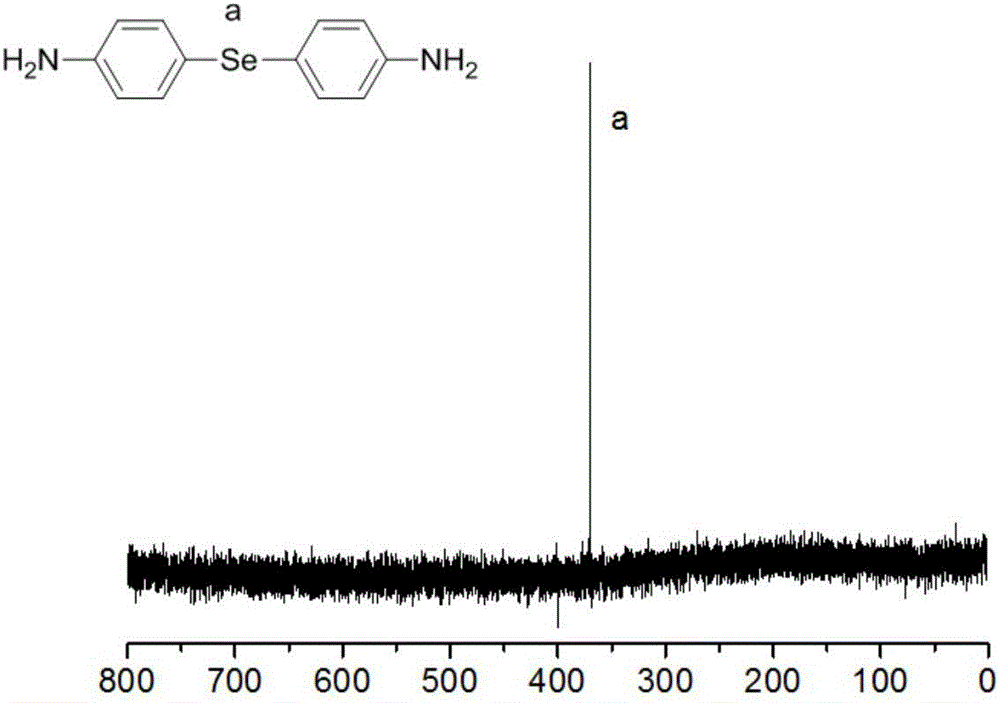

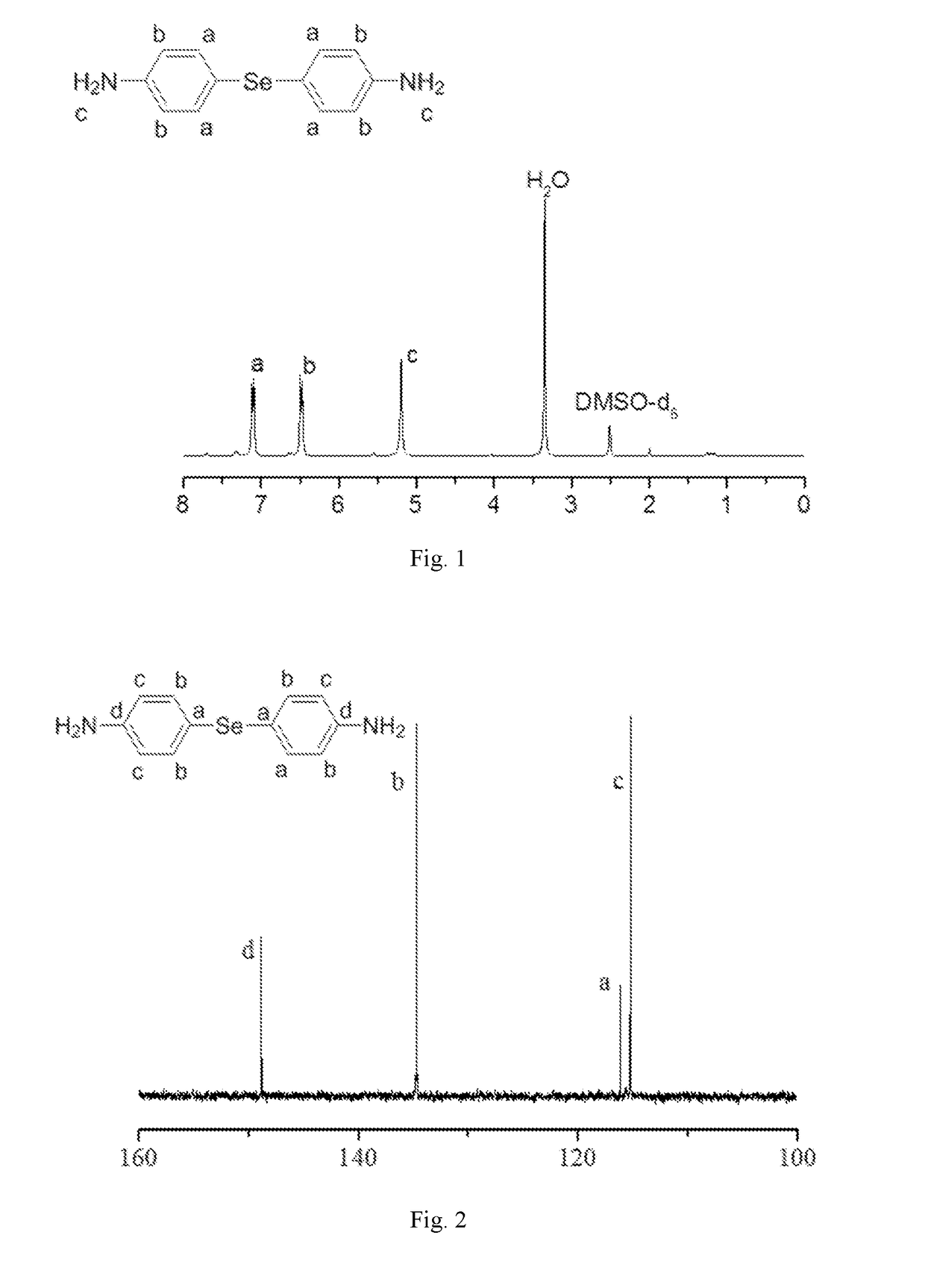

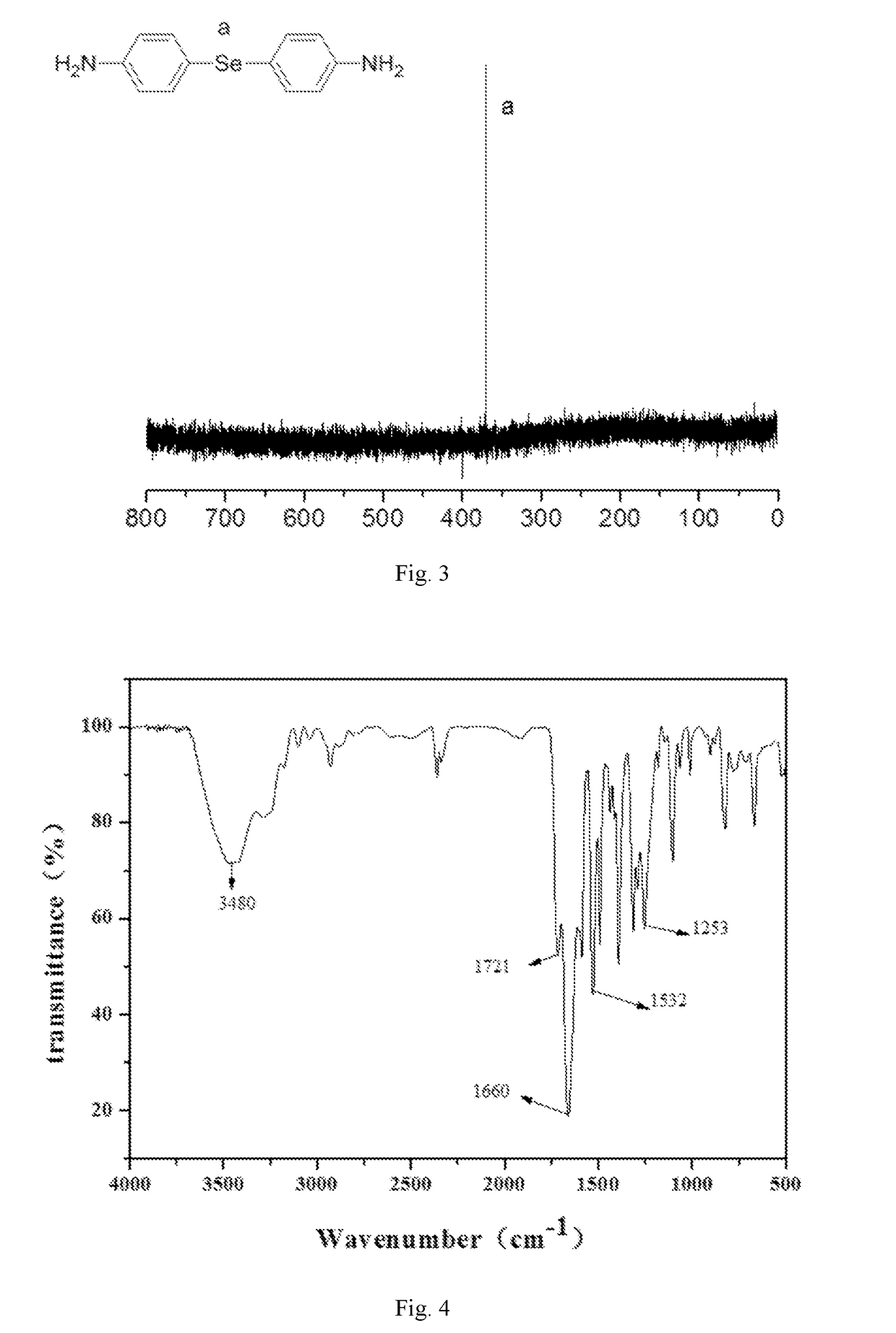

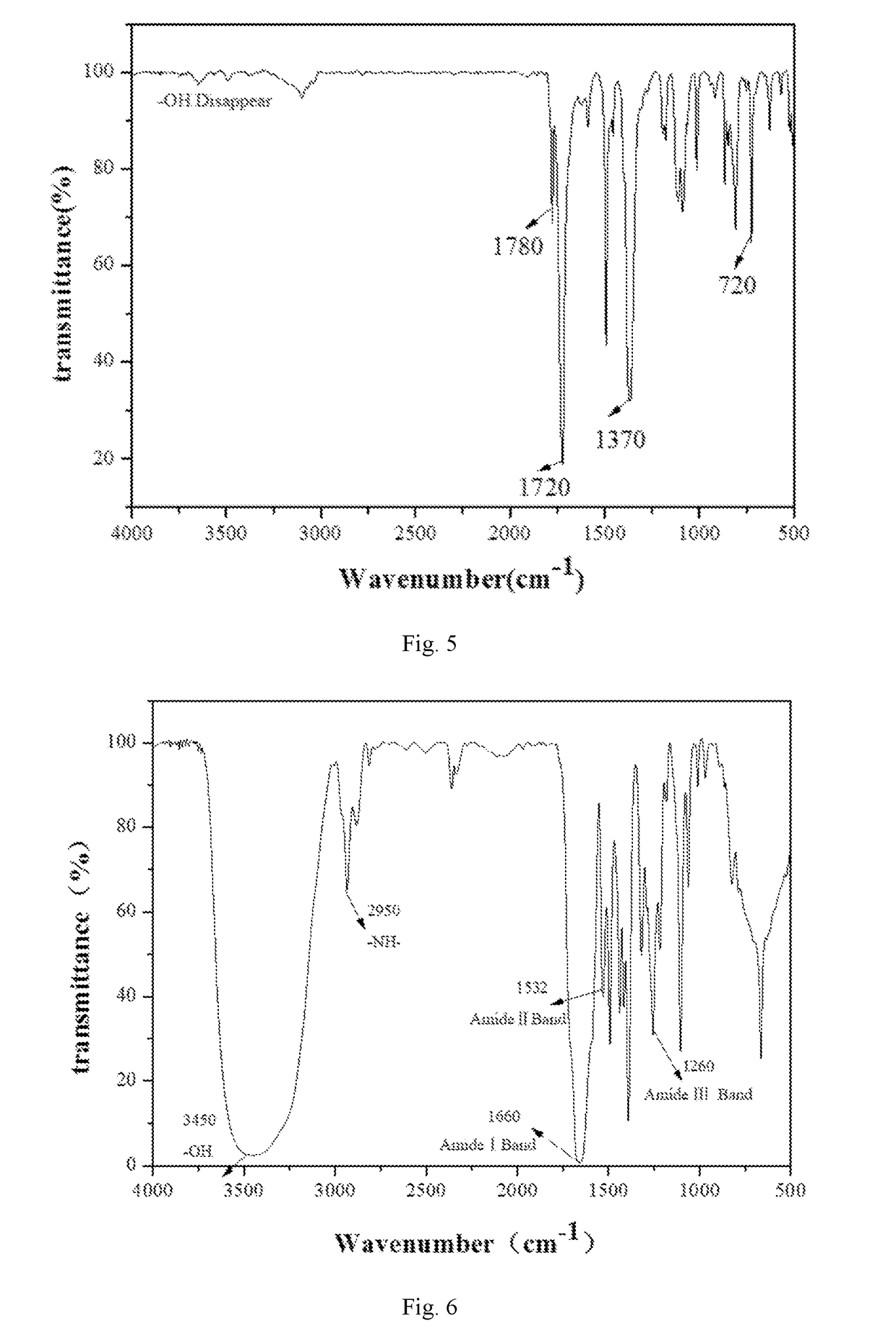

Polyimide polymer containing selenium and preparation method and application thereof

ActiveCN106565955AHigh refractive indexPromote absorptionOptical elementsPolymer scienceRefractive index

The invention provides a high-refractive-index polyimide polymer containing selenium and a preparation method and application of the high-refractive-index polyimide polymer containing the selenium. The preparation method and application of the high-refractive-index polyimide polymer containing the selenium comprises the steps that (1) selenide diamine monomer and dianhydride monomer are polymerized, so that polyamide acid containing the selenium is obtained; and (2) thermal imidization is conducted on the polyamide acid containing selenium, obtained in the step (1), so that the polyimide polymer containing the selenium is obtained. According to the high-refractive-index polyimide polymer containing the selenium and the preparation method and application of the high-refractive-index polyimide polymer containing the selenium, the refractive index can be improved because the selenium element is introduced to the polyimide, the refractive index is 1.7-1.82, the defect that an existing polyimide polymer material is not high in refractive index is greatly relieved, and therefore the application of the polyimide polymer to the optical field is extended.

Owner:SUZHOU UNIV

Optoceramics, optical elements manufactured thereof and their use as well as imaging optics

InactiveUS7710656B2Novel imaging propertyReduce weightRare earth metal compoundsMountingsRare earthSingle crystal

The transparent polycrystalline optoceramic has single crystallites and at least 95 percent by weight of the single crystallites have a cubic pyrochlore or fluorite structure. The optoceramic is composed of an oxide of stoichiometry:A2+xByDzE7 wherein 0<x<1, 0<y<2, 0<z<1.6 and 3x+4y+5z=8; wherein A is at least one trivalent rare earth cation; B is at least one tetravalent cation; D is at least one pentavalent cation; and E comprises at least one divalent anion. Refractive, diffractive or transmissive optical elements are made with these optoceramics.

Owner:SCHOTT AG

Cladding glass for solid-state lasers

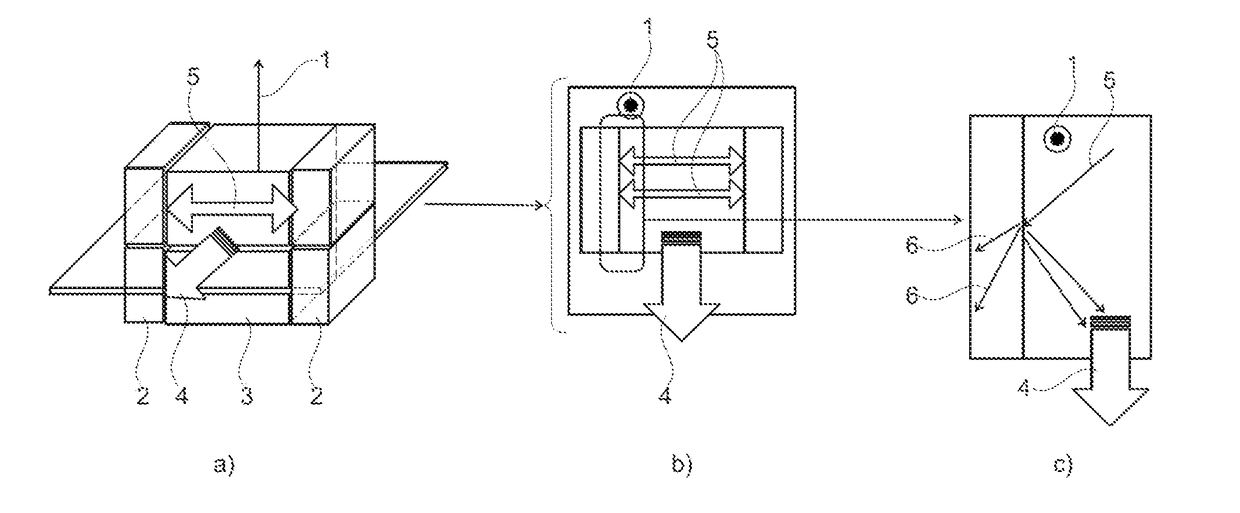

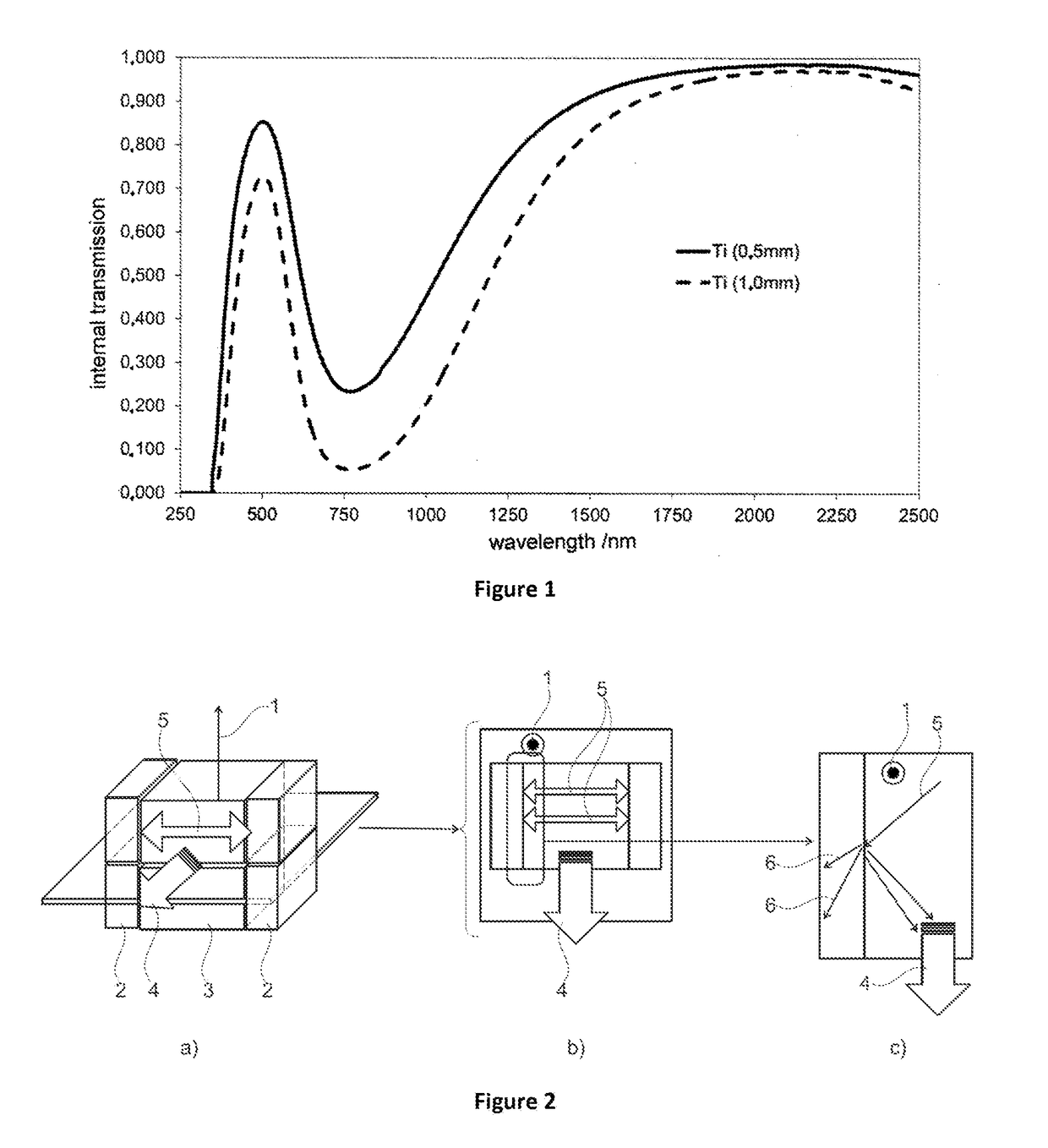

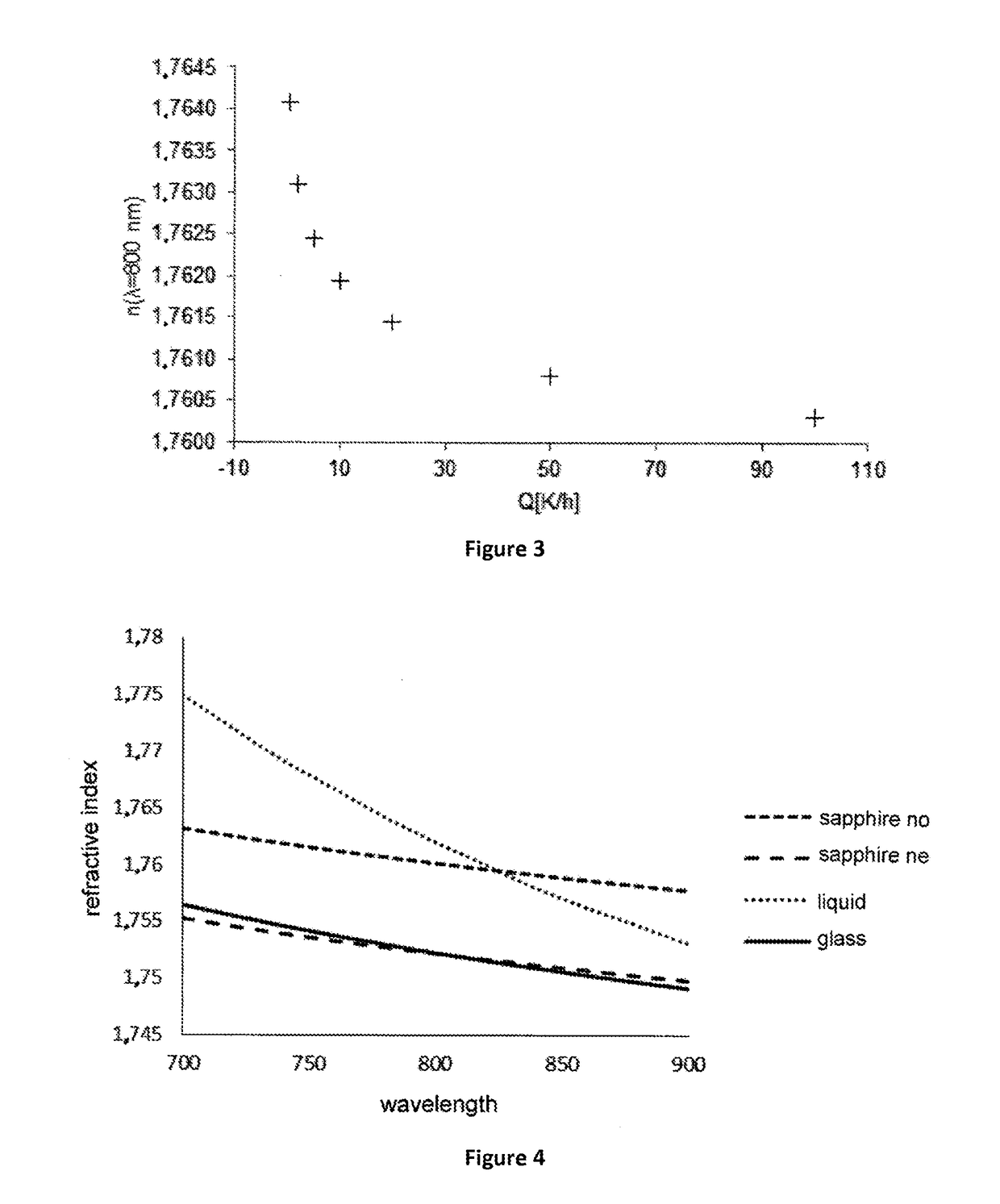

ActiveUS20180090904A1High Abbe numberEasy to adjustActive medium materialActive medium shape and constructionRefractive indexSolid-state laser

The present invention relates to a glass having a refractive index of at least 1.7 as well as the use of the glass as a cladding glass of a solid-state laser. The invention also relates to a laser component comprising a core of doped sapphire and a cladding glass being placed on said core. The cladding glass is arranged on said core such that light exiting from the core due to parasitic laser activity can enter the cladding glass and can be absorbed there. The present invention also relates to a method for producing the laser component.

Owner:SCHOTT AG

Material of gradient refrative index lens and its preparation method

InactiveCN1410376AImprove mobilityHigh refractive indexPot furnacesGlass shaping apparatusRefractive indexPotassium

A material for the lens with gradient refractivity is prepared from thallium oxide 30-45 wt%, sodium (or potassium) oxide 5-12%, zinc oxide 6-12%, SiO2 34-50%, calcium oxide 0-5%, Al2O3 1-6%, zirconium oxide 0-2%, La2O5 0-5% and B2O3 0-10% through compounding, smelting, drawing into filament, ion exchange, surface treating and examining. Its advantages are less color difference, less volatilization in smelting, high Abbe number and high consistence.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

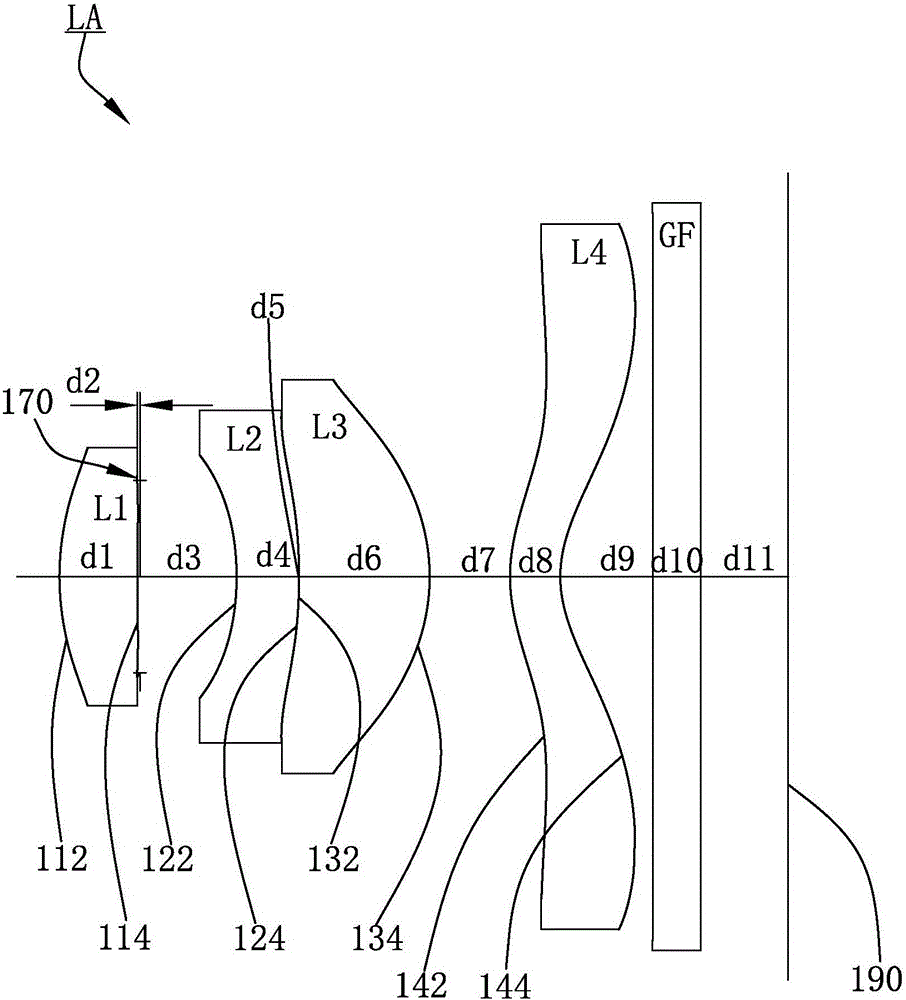

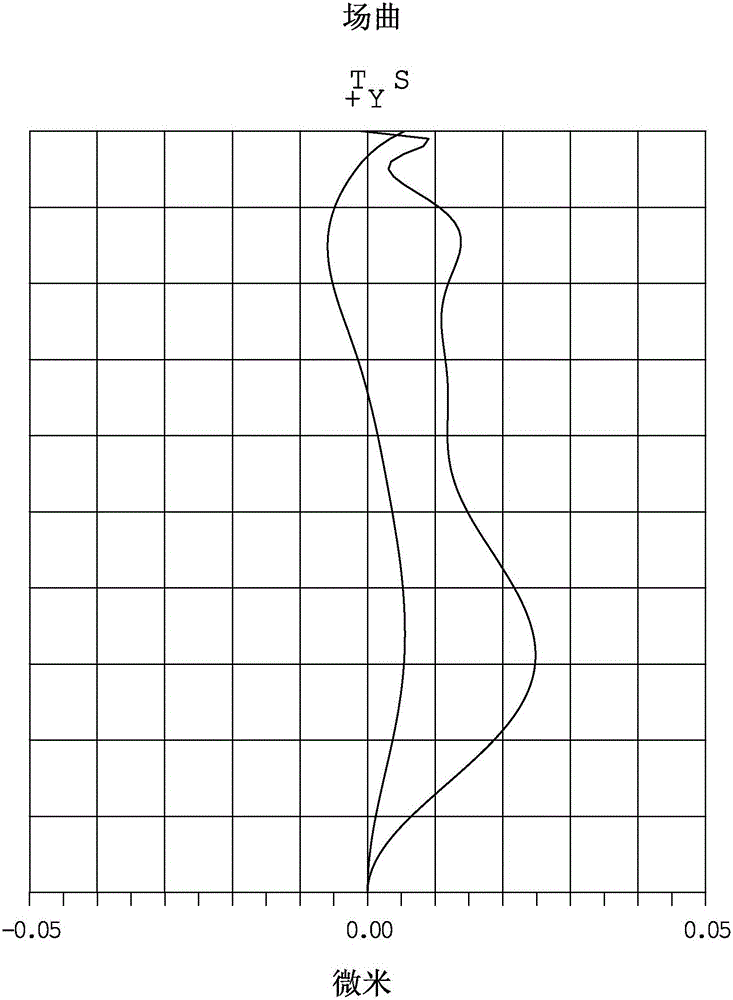

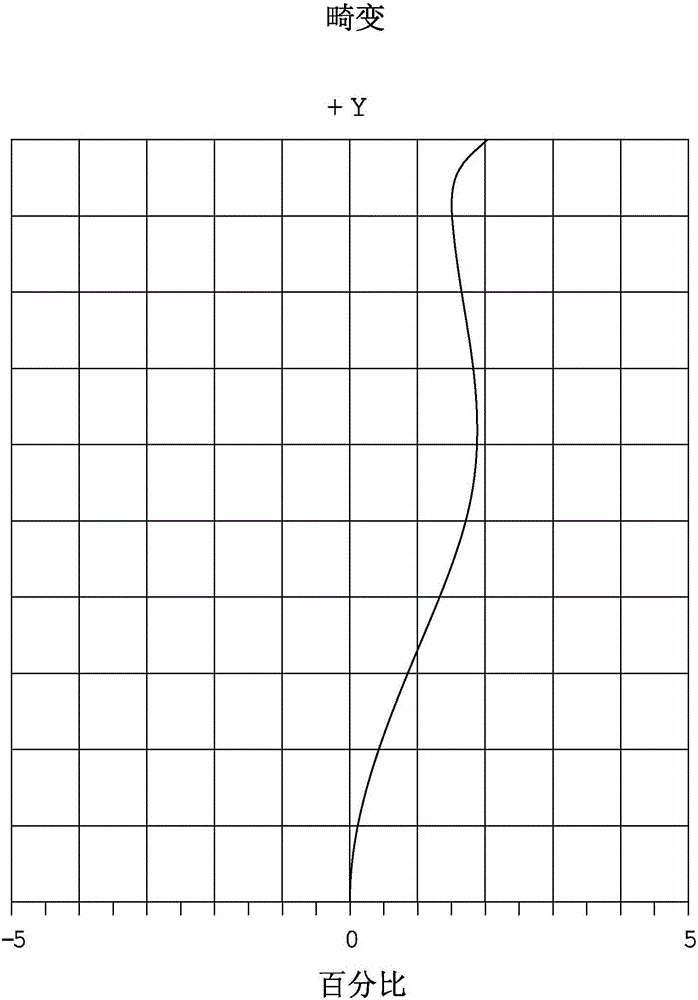

Camera lens

ActiveCN106094167ASmall color differenceImprove imaging effectOptical elementsCamera lensConditional expression

The invention provides a camera lens, which is equipped with a first lens (with a focal length to be f1), a second lens (with a focal length to be f2), a third lens (with a focal length to be f3), and a fourth lens (with a focal length to be f4) sequentially from an object side to an image side. The following conditional expressions are met: 0.5<f1 / f<1.1, -2<f2 / f<-0.5, 0.65<f3 / f<1.1, -2.5<f4 / f<-1.8, and f is the focal length of the whole camera lens. Through reasonably optimizing the contour, distributing the focal power and selecting the optical material, a small camera lens is designed, and the camera lens has the advantages that the sensitivity is high, the sensibility is low, the color difference can be well corrected, and the optical performance is good.

Owner:AAC OPTICS SOLUTIONS PTE LTD

Polymerizable composition for optical materials, optical material, and method of manufacturing optical material

InactiveUS20170029553A1High Abbe numberImprove balanceOptical articlesOptical partsPolymer scienceDouble bond

The polymerizable composition for optical materials of the present invention includes: (A) a compound having a carbon-carbon double bond and at least one group selected from an isocyanate group and an isothiocyanate group in a molecule; and (B) a polythiol compound.

Owner:MITSUI CHEM INC

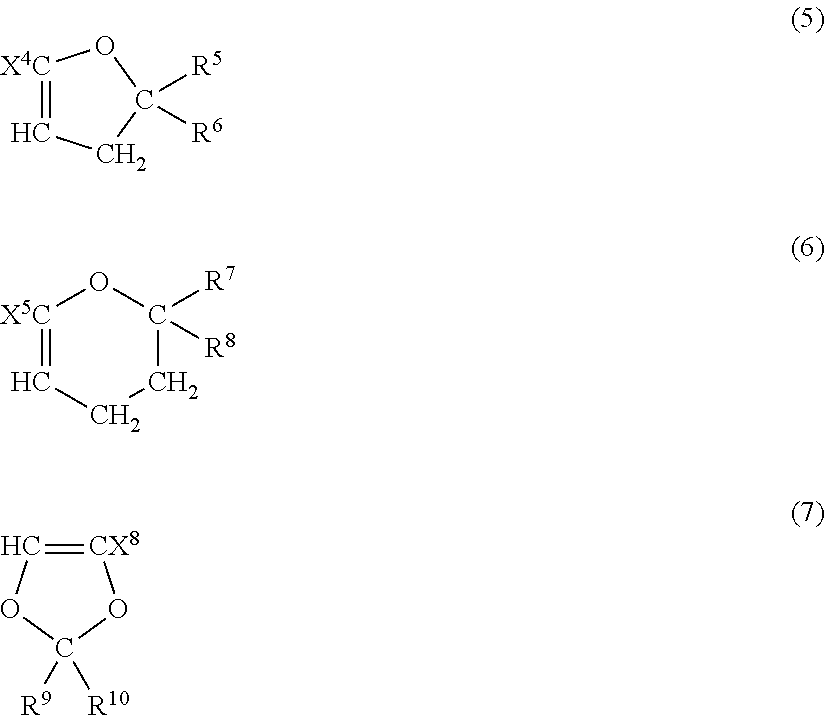

Fluoropolymer for chromatic aberration-free lens and chromatic aberration-free lens

Owner:ASAHI GLASS CO LTD

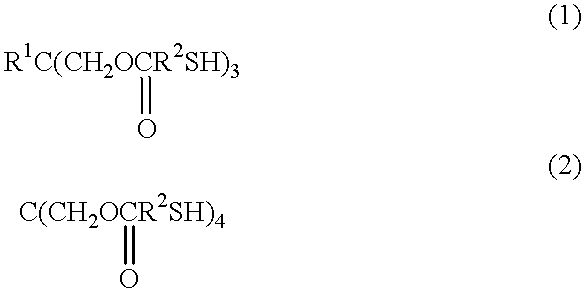

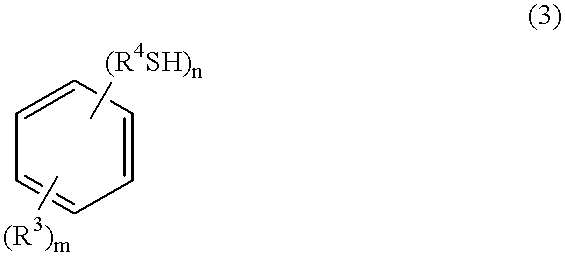

Curable resin composition

InactiveUS6573348B2Improve heat resistanceHigh transparencyOptical articlesSpecial tyresMeth-Acid derivative

A curable resin composition containing (A) an aromatic diallyl compound, (B) an acid derivative or an aliphatic group-containing compound having at least 4 (meth)acryl groups in one molecule, (C) divinylbenzene, and (D) a polythiol compound having at least two mercapto groups in one molecule provides an optical material having a desirable refractive index, Abbe number and transparency, and excellent heat resistance.

Owner:DAISO CO LTD

Passive optoceramics with cubic crystal structure, process for manufacturing the same and their uses

InactiveUS20100248938A1High refractive effectivenessHigh Abbe numberMaterial nanotechnologyCeramic shaping apparatusCrystal structureSingle crystal

The optoceramics are transparent to visible light and / or infrared radiation. The optoceramics each consist of a crystal matrix, i.e. of polycrystalline material, wherein at least 95% by weight, preferably at least 98% by weight, of the single crystallites have a cubic pyrochlore or a fluorite structure. Refractive, transmissive or diffractive optical elements made with the optoceramics, their uses and an optical imaging system comprising at least one of the optical elements are also disclosed. Methods of manufacturing the optoceramics are described.

Owner:SCHOTT AG

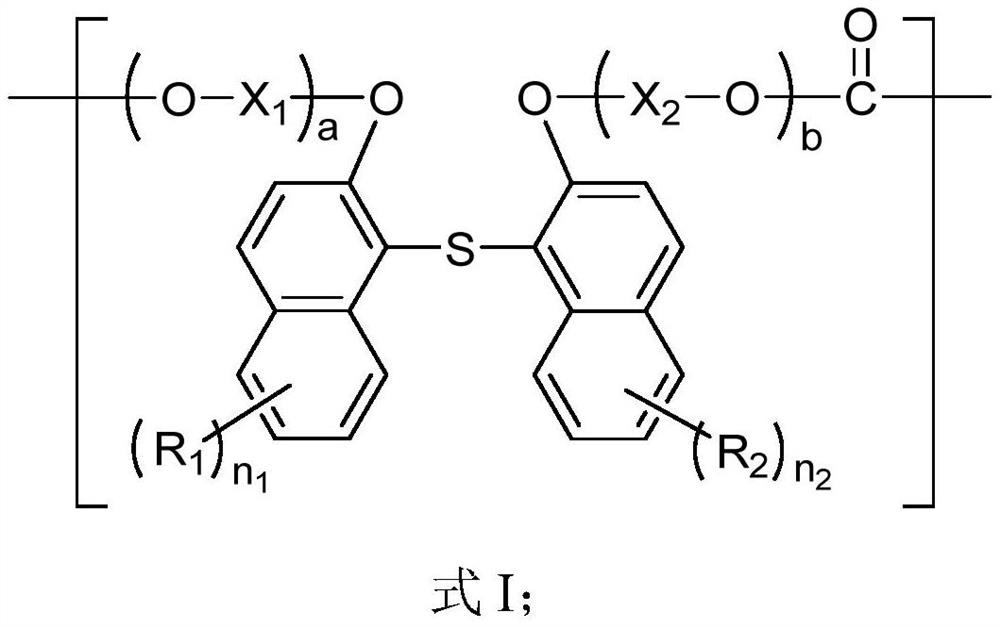

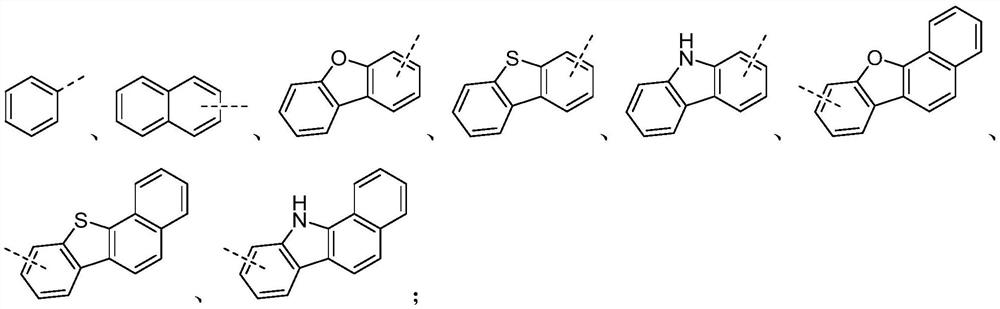

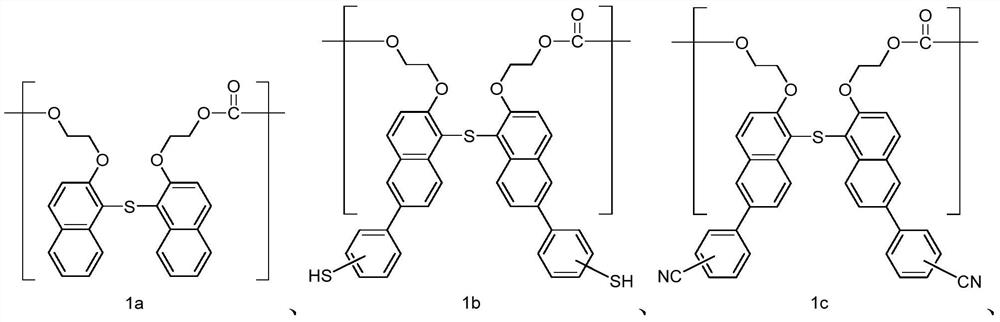

Polycarbonate and preparation method and application thereof

PendingCN112175178AHigh refractive indexHigh Abbe numberOptical elementsPhotovoltaic energy generationPolycarbonateChemistry

The invention provides polycarbonate and a preparation method and application thereof, the polycarbonate comprises a repeating unit with a structure as shown in a formula I, and the repeating unit comprises a specific dithionaphthalene group, so that the polycarbonate has high refractive index, high Abbe number and excellent hydrothermal stability, and the performance requirements of polycarbonateserving as optical resin in optical parts can be fully met. The refractive index of the polycarbonate reaches up to 1.66-1.75, the Abbe number is 20-40, and the polycarbonate has high transparency, high refractive index, high Abbe number and excellent hydrothermal stability, and can fully meet the application requirements of polycarbonate materials in high-performance optical components. The optical lens comprising the polycarbonate has the characteristics of lightness, thinness, low chromatic aberration and low chromatic dispersion, and provides more selectivity for the combination of optical systems.

Owner:WANHUA CHEM GRP

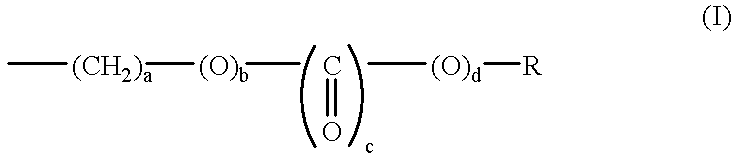

Sulfur-containing compound, method for producing same, sulfur-containing polymer, and optical material

InactiveCN1946769AStrong transparencyHigh refractive indexShaft and bearingsElectrographic process apparatusPolymer scienceChemical compound

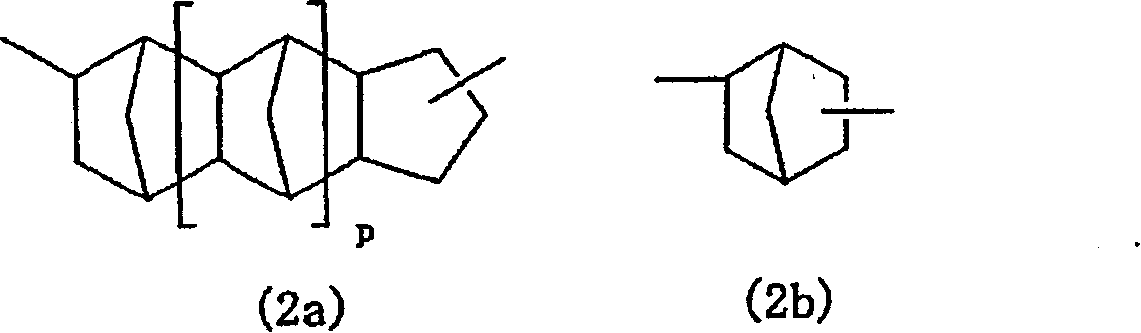

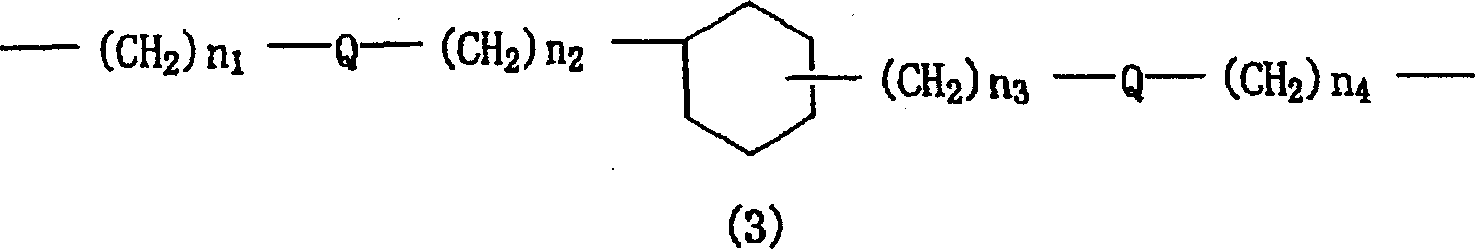

Disclosed is a polythiocarbonate resin containing a repeating unit represented by the general formula (I) below, which is high in transparency, refractive index and Abbe number while being excellent in heat resistance and impact resistance. Also disclosed is an optical material using such a polythiocarbonate resin. Further disclosed is a sulfur-containing compound having an Abbe number of not less than 40 which has a high refractive index, high Abbe number, excellent transparency and excellent heat resistance, and is obtained by reacting a dithiol compound represented by the general formula (II) below with a diene compound represented by the general formula (III) below, so that it contains a repeating unit composed of a structural unit derived from the residue of the dithiol compound and a structural unit derived from the residue of the diene compound. Still further disclosed are a method for producing such a sulfur-containing compound, a sulfur-containing polymer including such a sulfur-containing compound as a constitutional unit, and an optical material containing such a polymer.

Owner:IDEMITSU KOSAN CO LTD

Manufacturing technology for resin lens with high refraction index and high abbe number

ActiveCN104802430AHigh refractive indexImproved UV protectionOptical articlesManufacturing technologyUltraviolet lights

The invention relates to a manufacturing technology for a resin lens with high refraction index and high abbe number. The manufacturing technology is implemented through the following steps: cleaning a mould, and then assembling the mould; adding a component B, a component C and an ultraviolet light absorbent into a mixing barrel, and uniformly mixing; adding a catalyst, a release agent, a blue organic pigment and a red organic pigment, uniformly mixing, adding a component A, and uniformly mixing; filtering, then, injecting raw materials into the assembled mould, and sealing the mould; performing primary solidification on the filled mould, prying the solidified mould, and separating out the mould and molded lenses; trimming the lenses; performing multi-grooved ultrasonic cleaning and secondary solidification on the trimmed lenses; inspecting the lenses subjected to the secondary solidification, and selecting a qualified lens; coating the qualified lens with a film, then, performing hardening solidification on the lens coated with the film; evaporating an antireflection film on the hardened lens. The refraction index of the lens manufactured by adopting the manufacturing technology is 1.693-1.701, and the abbe number of the lens is 34-37.

Owner:JIANGSU MINGYUE PHOTOELECTRICS TECH

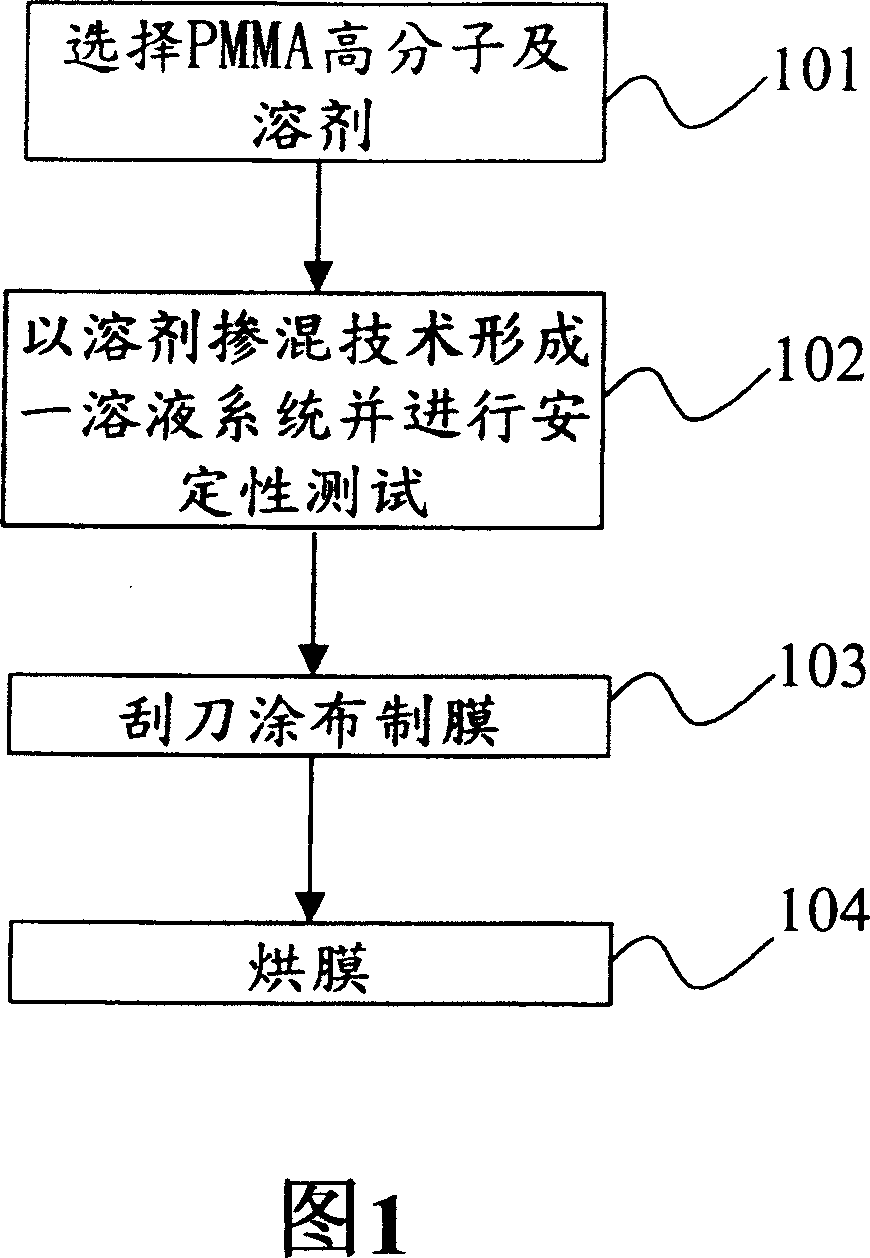

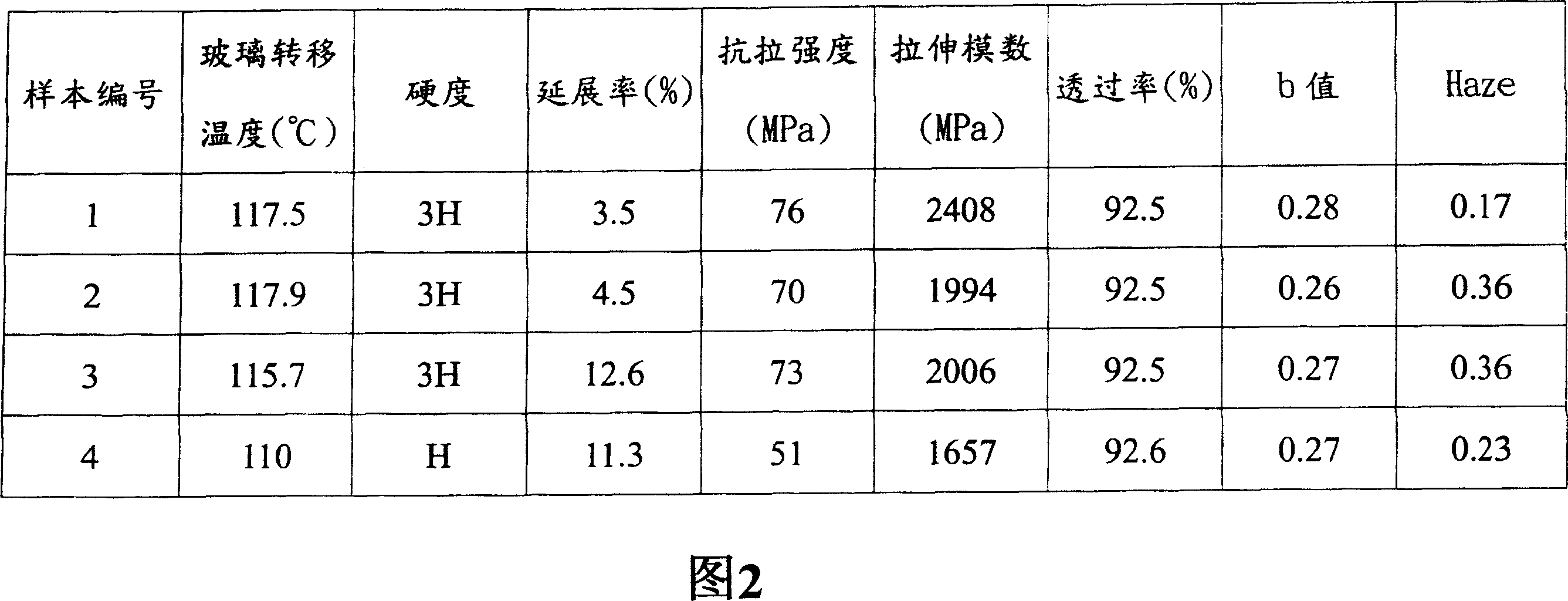

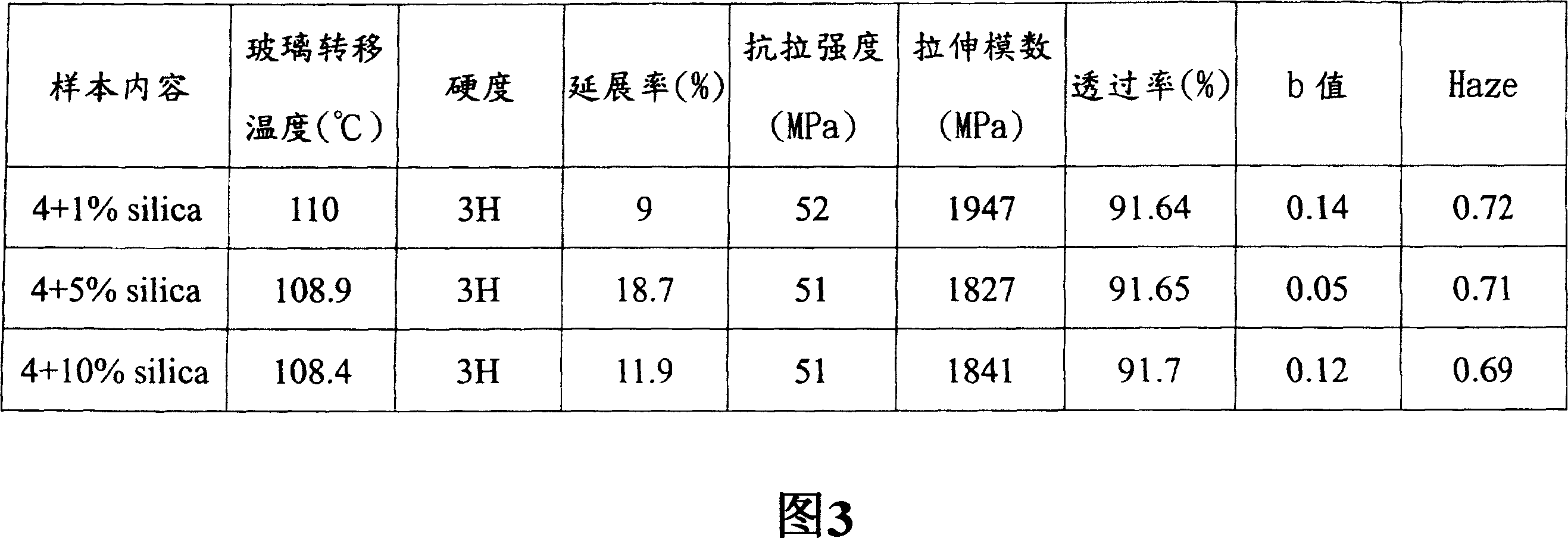

Optical film, and preparation method

InactiveCN1959440AAvoid harmSolve the problem of optical property variationOptical elementsSolventHeat treated

A method for preparing optical film includes mixing PMMA mixture with solvent uniformly to form a wet film, heating said wet film to form an optical dried film, enabling to mix PMMA mixture in any ratio as per required property with solvent to form a mixed solution then carrying out heat treatment on mixed solution to obtain optical film.

Owner:OPTIMAX TECHNOLOGY CORPORATION

Selenium-containing polyimide polymer, preparing method and use thereof

ActiveUS20190010290A1High refractive indexHigh Abbe numberOptical elementsPolymer scienceRefractive index

The invention provides a selenium-containing polyimide polymer, preparation method and use thereof. The method comprises: (1) polymerizing a selenide diamine monomer with a dianhydride monomer to give a selenium-containing polyamic acid; and (2) performing thermal imidization on the selenium-containing polyamic acid obtained in the step (1) to give a selenium-containing polyimide polymer. In the invention, selenium is introduced into polyimides for increasing refractive index to 1.7-1.82, this greatly improves the defects of low refractive index of the existing polyimide materials, thereby expanding its applications in the optics field.

Owner:SUZHOU UNIV

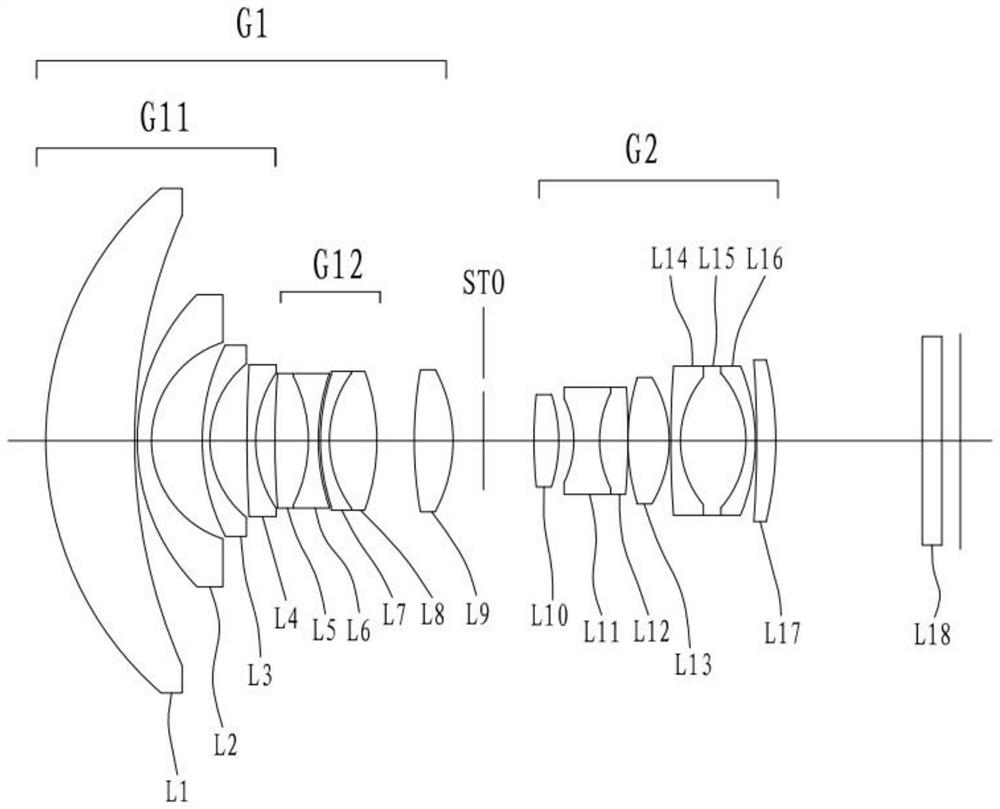

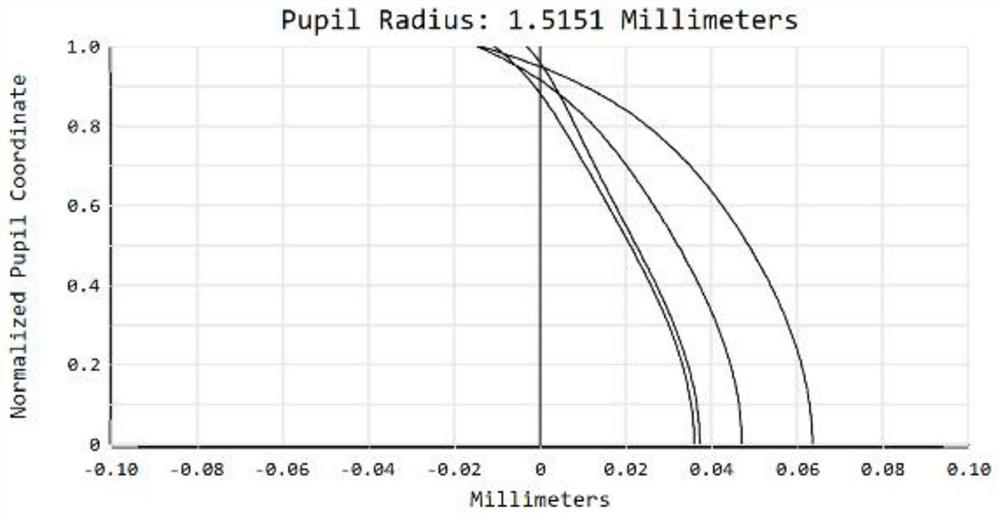

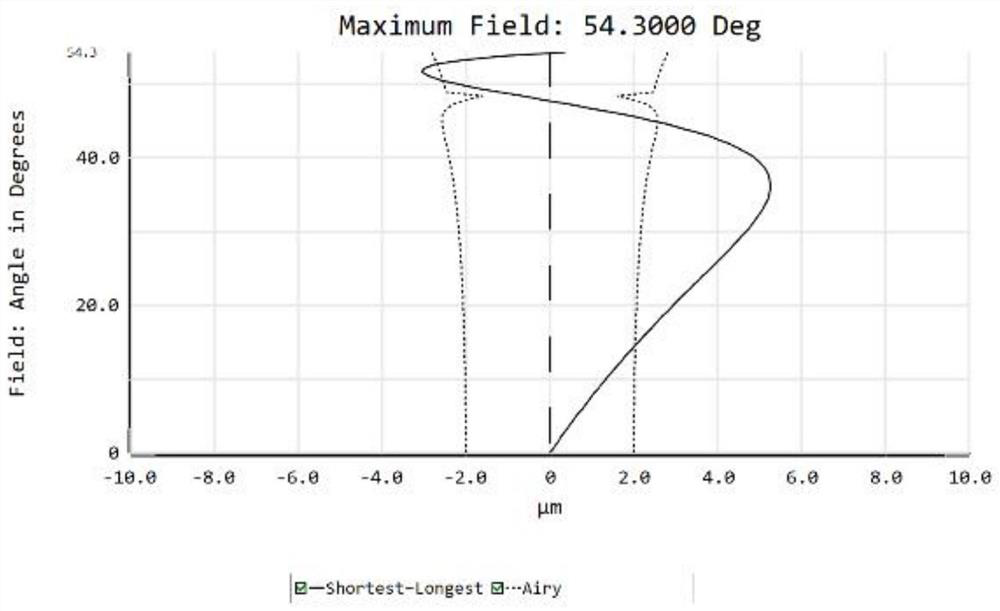

Large-wide-angle video lens with focal length of 8mm

The invention discloses a large wide-angle video lens with a focal length of 8mm, and the lens sequentially comprises a first lens group, a second lens group, a third lens group, a fourth lens group and a fifth lens group from an object side to an image side, the first lens group has positive focal power and is fixed in position, the second lens group has positive focal power and can move along the direction of the optical axis; the first lens group comprises a first negative lens group and a second negative lens group. The first negative lens group comprises at least three negative lenses; the second negative lens group comprises a positive-negative cemented lens with negative focal power and a negative-positive cemented lens with positive focal power, the first lens group is provided with three negative lenses, so that the lens has a large wide angle, the light transmission amount and the resolution of the edge part of the lens can be increased, and the chromatic aberration and the distortion can be corrected due to the arrangement of the two cemented lenses which are matched with each other.

Owner:北创光电科技(邵阳)有限公司

Optical elements made from ceramics comprising one or more oxides of Y, Sc, in and/or lanthanide elements and mapping optics including the optical elements

InactiveUS7751123B2High refractive indexLight scatteringMaterial nanotechnologyMountingsCrystal structureLanthanide

The refractive, transmissive or diffractive optical elements are made from a ceramic containing one or more oxides of the type X2O3, which is transmissive for visible light and / or for infrared radiation and which has a cubic crystal structure analogous to that of Y2O3. In preferred embodiments X is Y, Sc, In, or a lanthanide element, namely La to Lu, and in particular is Lu, Yb, Gd, or La. Also mixtures of oxides of the type X2O3 with oxides having different stoichiometries, such as HfO2 and / or ZrO2, may be present, as long as the cubic structure of the ceramic is maintained.

Owner:SCHOTT AG

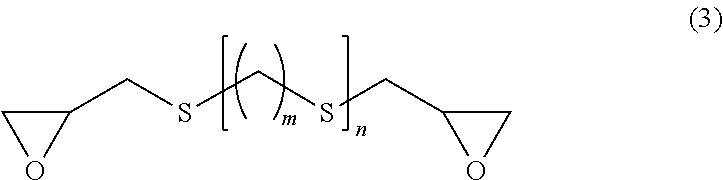

Composition for optical material, and method for producing same

ActiveUS20150166720A1Improve reduction in yieldHigh refractive indexOther chemical processesOptical elementsPolymerization catalystsGlycylxylidide

A composition for an optical material includes (a) a compound having two β-epithiopropyl groups and having a specific structure, (b) a compound having one β-epithiopropyl group and one glycidyl group and having a specific structure, (c) polyisocyanate and (d) polythiol, enables the prevention of the occurrence of such a defect that peeling traces linger on a lens. In the composition for an optical material, an embodiment in which (e) sulfur is additionally contained is preferred. Another embodiment of the present invention is a method for producing an optical material, characterized by adding an onium salt as a polymerization catalyst to the composition for an optical material in an amount of 0.0001 to 10% by mass relative to the total amount of the compound (a), the compound (b), polyisocyanate (c) and polythiol (d) and then polymerizing and curing the resultant mixture.

Owner:MITSUBISHI GAS CHEM CO INC

Method for producing polythiourethane resin

Owner:HOYA CORP

Plastic lens composition, plastic lens, and process for producing the plastic lens

A plastic lens composition having a low viscosity, a plastic lens by curing the composition, and a method for producing the plastic lens are disclosed. The plastic lens composition contains a bromine-containing (meth)allyl ester-based compound and exhibits low viscosity and the cured composition has a high refractive index of 1.58 or more and a low specific gravity of 1.40 or less.

Owner:SHOWA DENKO KK

Aromatic thermoplastic copolyesters comprising 1,4:3,6-dianhydrohexitol and various cyclic diols

InactiveUS20180362707A1High glass transition temperatureEasy to transformSynthetic resin layered productsOptical articlesCyclohexanedimethanolCopolyester

A thermoplastic polyester including: at least one 1,4:3,6-dianhydrohexitol unit (A); at least one cyclic diol unit (B) other than cyclohexanedimethanol units and 1,4:3,6-dianhydrohexitol units (A); and at least one aromatic carboxylic diacid unit (C), the polyester being free from ethylene glycol units. It also relates to the production method and use of same.

Owner:ROQUETTE FRERES SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com