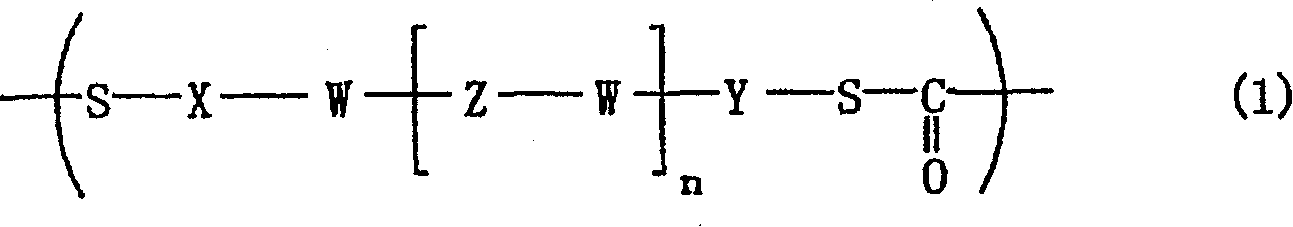

Sulfur-containing compound, method for producing same, sulfur-containing polymer, and optical material

A compound, dithiophenol technology, applied in the field of sulfur-containing compounds, can solve the problems of insufficient Abbe number and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

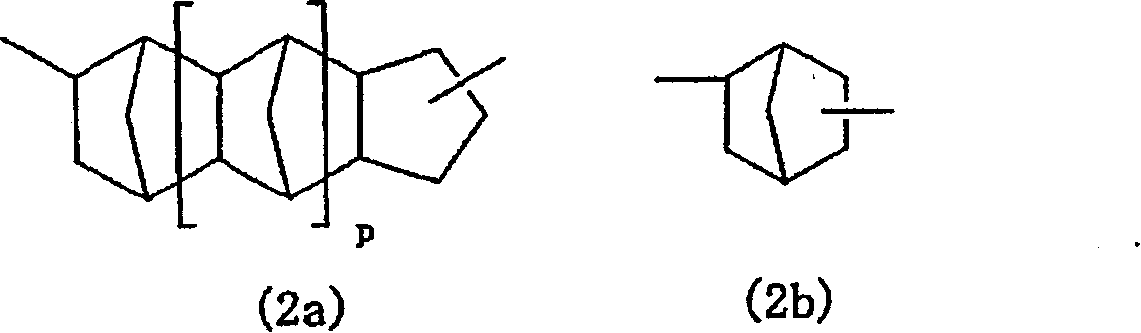

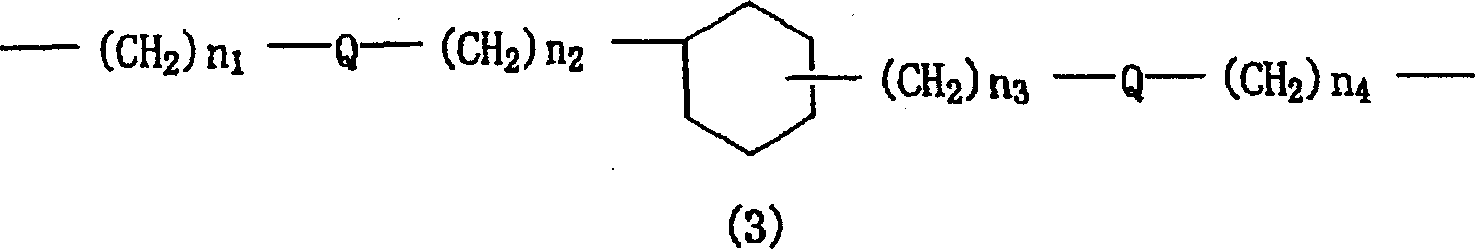

Method used

Image

Examples

Embodiment

[0359] The following examples illustrate the present invention in more detail, but the present invention is not limited by these examples.

[0360] In addition, evaluation of physical properties in each Example and Comparative Example is as follows.

[0361] (1) Refractive index (n D ) and Abbe number (ν D )

[0362] It measured at 20 degreeC using the Abbe refractometer manufactured by Atago Corporation.

[0363] Moreover, when the sample is a resin, the test piece of length x width x thickness = 20 mm x 8 mm x 3 mm was produced, and it measured using sulfur-diiodomethane as an intermediate liquid. When the sample is a solid powder at normal temperature, the refractive index is obtained by an extrapolation method, and the Abbe number is obtained from the refractive index.

[0364] (2) Relative viscosity (ηsp / C)

[0365] Using the automatic viscosity measuring device VMR-042 manufactured by Clutch Co., Ltd., the automatic viscosity is used with the ウツベベロ-デ modified viscom...

Synthetic example 1

[0387] Synthesis method of 2,2-bis(4-hydroxyphenyl)propane polythiocarbonate resin with chloroformate group at molecular end

[0388] A solution in which 74 parts by mass of 2,2-bis(4-hydroxyphenyl)propane (bisphenol A; double A) was dissolved in 585 parts by mass of 6% by weight aqueous sodium hydroxide solution was mixed with 334 parts by mass of dichloromethane While stirring and mixing, phosgene was blown into the solution at a rate of 4.2 parts by mass / minute for 15 minutes under cooling.

[0389] Then leave the reaction solution to stand and separate the organic layer to obtain a degree of polymerization of 2 to 4 and 2,2-bis(4-hydroxyphenyl)propane polythiocarbonate resin (4-hydroxyphenyl)propane polythiocarbonate resin ( Hereinafter, it is described as a dichloromethane solution of bis-A oligomer).

Synthetic example 2

[0391] Synthesis method of 1,1-bis(4-hydroxyphenyl)cyclohexane polythiocarbonate resin with chloroformate group at molecular terminal

[0392]87 parts by mass of 1,1-bis(4-hydroxyphenyl)cyclohexane (bisphenol Z; double Z) dissolved in 607 parts by mass of 9.4% by weight concentration of potassium hydroxide aqueous solution and 334 parts by mass of dichloromethane Stirring and mixing were carried out, and phosgene was blown into the solution at a rate of 4.2 parts by mass / minute for 15 minutes under cooling.

[0393] Then the reaction solution was left to stand and the organic layer was separated to obtain 1,1-bis(4-hydroxyphenyl)cyclohexane polythiocarbonate with a polymerization degree of 2 to 4 molecules and a chloroformate group at the end. Dichloromethane solution of resin (hereinafter referred to as double Z oligomer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com