Antipollution lens protective microscopes

A technology for protecting mirrors and lenses, which is applied in the field of optical instruments. It can solve the problems of glass slide and cover glass being broken, difficult to hold, economic loss, etc., and achieve the effects of preventing lens pollution, easy loading and unloading, and strong transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] Embodiment of the present invention.

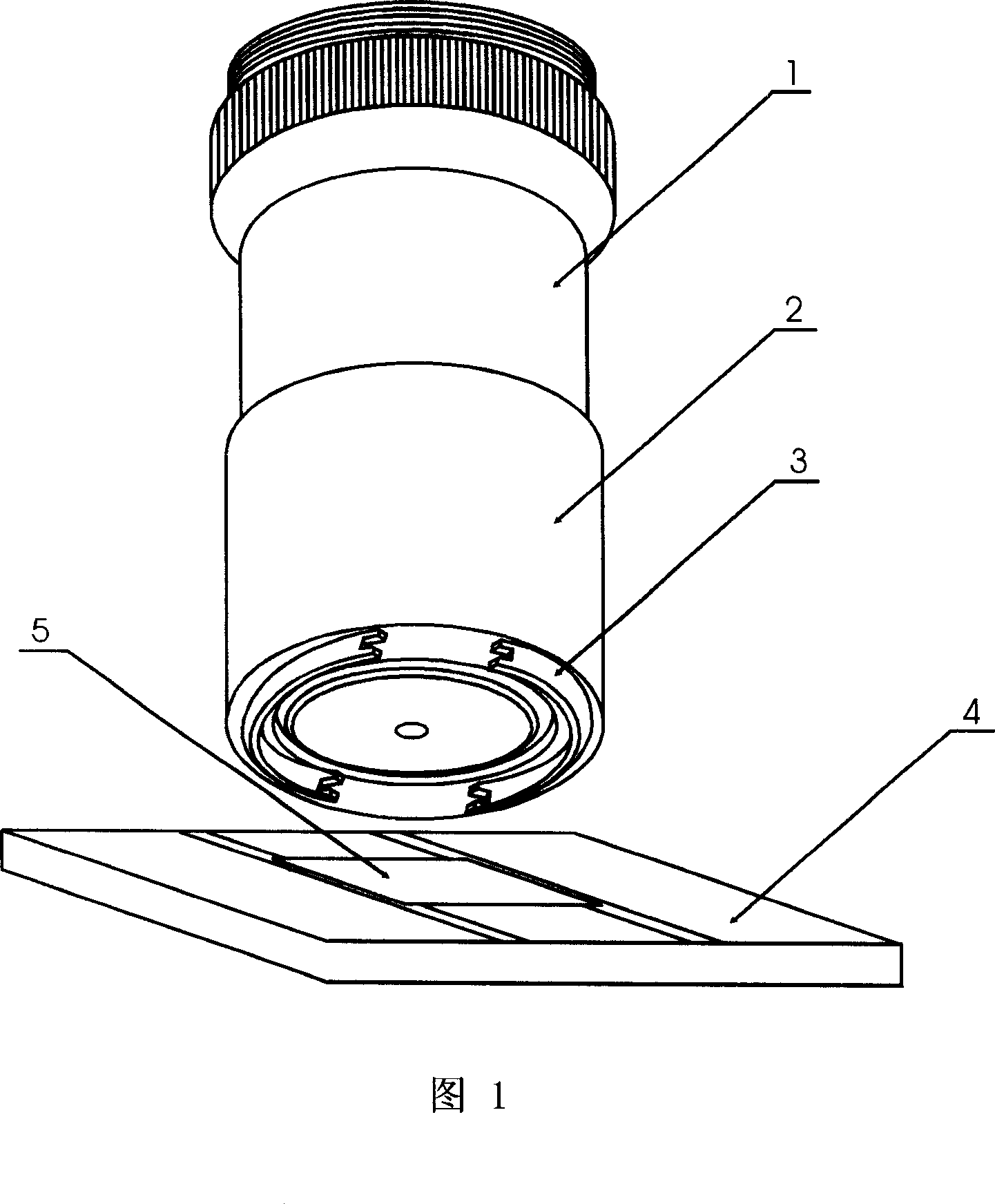

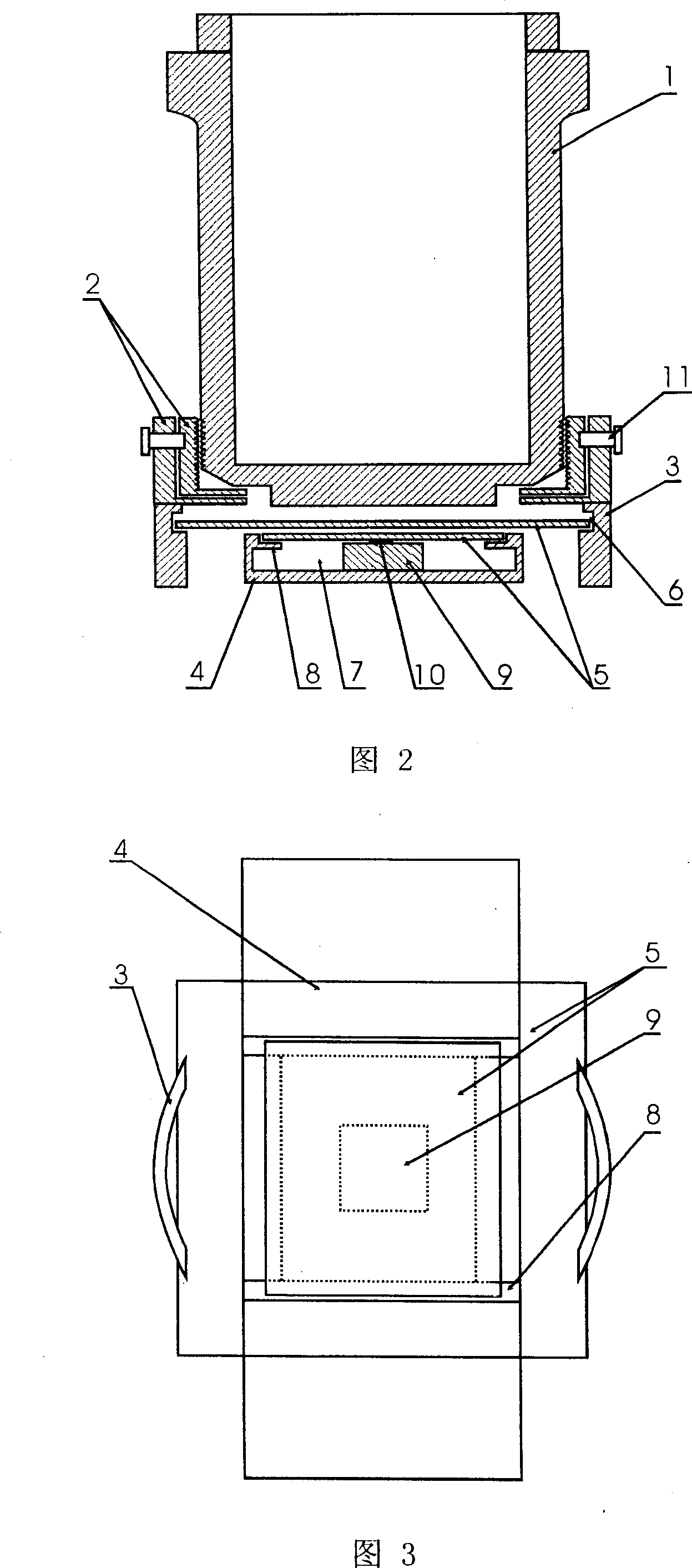

[0023] As shown in Figure 1-3, the lens antifouling protective mirror, the high power lens 1 is provided with a protective frame 2, the lower end of the frame 2 is provided with a rubber layer 3, the frame 2 and the rubber layer 3 are integrated, and its shape can be arc or obtuse angle Opening on one side of the shape or square. Frame material, available plastics, metal, any non-elastic material all can; Socket rubber layer can be used rubber, also available polyurethane, all elastic materials with soft middle band are all all can, the connection of plastic picture frame and rubber socket layer, both can be cold Welding can also be bonded with 502 superglue, and any fixed connection can be used. There is a cover glass socket on the rubber layer 3, and the thickness of the rubber layer below the cover glass socket is equal to the thickness of the slide glass. 6. The mirror frame 2 is connected to the high-magnification lens 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com