Ytterbium-doped fluophosphate laser glass and preparation method thereof

A technology of laser glass and phosphate, applied in the field of laser glass, can solve the problems of not being able to be used as a laser output medium, affecting the stability of glass components, and difficult to control the melting process of fluorine-phosphorus glass components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

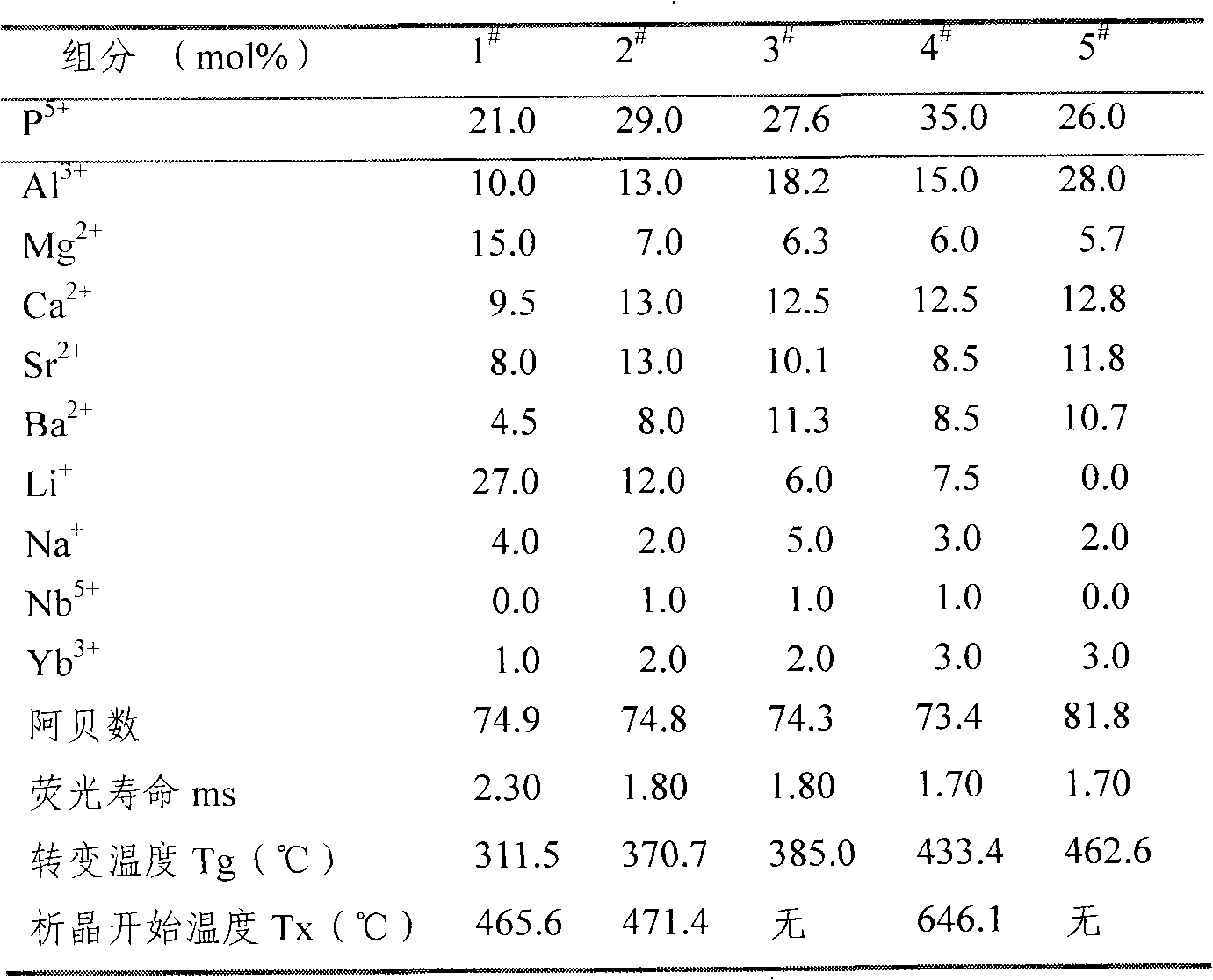

[0024] In the first step, according to Table 1, select 1# glass formula and calculate, weigh 3.5Kg powder and mix well.

[0025] The specific calculation method of the ingredients is as follows: according to its cationic molar composition P 5+ : 21.0mol%, Al 3+ : 10.0mol%, Mg 2+ : 15.0mol%, Ca 2+ : 9.5mol%, Sr 2+ : 8.0mol%, Ba 2+ : 4.5mol%, Li + : 27.0mol%, Na + : 4.0mol%, Yb 3+ : 1.0mol%, if you choose to introduce 21mol% P 5+ The raw material is: 3Al(PO 3 ) 3 , where 9P 5+ , 3Al 3+ ;2LiPO 3 , where 2P 5+ , 2Li + ; 2Mg(H 2 PO 4 ) 2 , where 4P 5+ , 2Mg 2+ ; 2Sr(H 2 PO 4 ) 2 , where 4P 5+ , 2Sr 2+ ;2NaH 2 PO 4 .2H 2 O, where 2P 5+ , 2Na + , the introduction amount of each cation is: 21mol%P 5+ , 3mol%Al 3+ , 2mol% Li + , 2mol% Mg 2+ , 2mol% Sr 2+, 2mol% Na + , then need to introduce 7mol% AlF 3 , 13mol% MgF 2 , 9.5mol% CaF 2 , 6.0 mol% SrF 2 , 4.5 mol% BaF 2 , 25.0mol% LiF, 2.0mol% NaF, 1.0mol% YbF 3 , then all cations satisfy the compos...

Embodiment 2

[0030] In the first step, according to Table 1, select 3# glass formula and calculate, weigh 3.5Kg powder and mix well. The specific calculation method is as follows: according to its cation molar composition P 5+ : 27.6mol%, Al 3+ : 18.2mol%, Mg 2+ : 6.3mol%, Ca 2+ : 12.5mol%, Sr 2+ : 10.1mol%, Ba 2+ : 11.3mol%, Li + : 6mol%, Na + : 5.0mol%, Nb 5+ : 1.0mol% Yb 3+ : 2.0mol%, if you choose to introduce 27.6mol% P 5+ The raw material is: 5Al(PO 3 ) 3 , where 15P 5+ , 6Al 3+ ; 2Ba(PO 3 ) 2 , where 4P 5+ , 2Ba 2+ ; 2.8Sr(H 2 PO 4 ) 2 , where 5.6P 5+ , 2.8Sr 2+ ; 3NaH 2 PO 4 .2H 2 O, of which 3P 5+ , 3Na + , the introduction amount of each cation is: 27.6mol%P 5+ , 5mol%Al 3+ , 2 mol% Ba 2+ , 2.8 mol% Sr 2+ , 3 mol% Na + , then need to introduce 13.2mol% AlF 3 , 6.3 mol% MgF 2 , 12.5mol% CaF 2 , 7.3 mol% SrF 2 , 9.3 mol% BaF 2 , 6.0mol% LiF, 2.0mol% NaF, 1.0mol% Nb 2 o 5 , 2.0mol% YbF 3 , then all cations satisfy the composition requirements. ...

Embodiment 3

[0034] In the first step, according to Table 1, select 5# glass formula and calculate, weigh 3.5Kg powder and mix well. The specific calculation method is as follows: according to its cation molar composition P 5+ : 26mol%, Al 3+ : 28mol%, Mg 2+ : 5.7mol%, Ca 2+ : 12.8mol%, Sr 2+ : 11.8mol%, Ba 2+ : 10.7mol%, Li + : 6mol%, Na + : 2.0mol%, Yb 3+ : 3.0mol%, if you choose to introduce 26mol% P 5+ The raw material is 6Al(PO 3 ) 3 (18P 5+ , 6Al 3+ ); 2Ba(PO 3 ) 2 (4P 5+ , 2Ba 2+ ); 2Sr(H 2 PO 4 ) 2 (4P 5+ , 2Sr 2+ ); the introduction amount of each cation is respectively: 26mol%P 5+ , 6mol%Al 3+ , 2 mol% Ba 2+ , 2mol% Sr 2+ , then need to introduce 22mol% AlF 3 , 5.7 mol% MgF 2 , 12.8 mol% CaF 2 , 9.8 mol% SrF 2 , 8.7 mol% BaF 2 , 2.0mol% NaF, 3.0mol% YbF 3 , then all cations satisfy the composition requirements.

[0035] The second step is to melt the fluorophosphorus glass: raise the temperature of the 1 liter platinum crucible furnace to 950°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com