Method for coating surface of black phosphor nano particles with mesoporous silica

A technology of mesoporous silica and nanoparticles, which is applied in the field of biomedicine and nanomaterials, can solve the problems of affecting performance, easy aggregation and instability of black phosphorus, etc., achieve low cost, alleviate easy agglomeration characteristics, and enhance photoacoustic signal intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for coating mesoporous silica on the surface of black phosphorus nanoparticles, comprising the following steps:

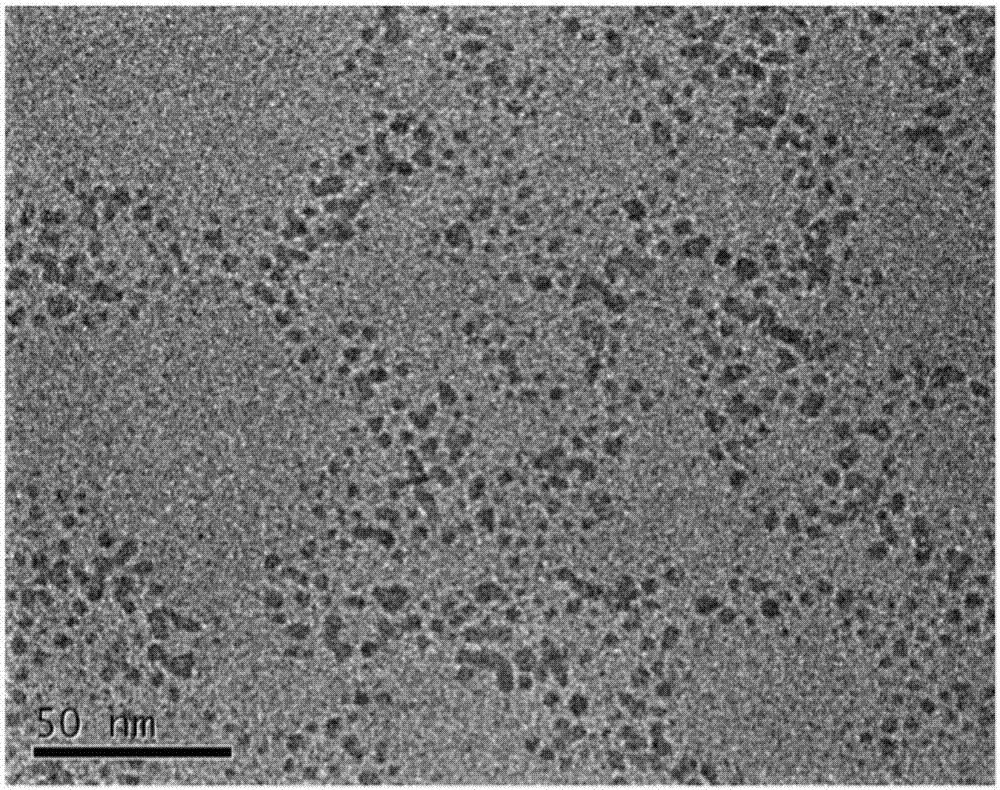

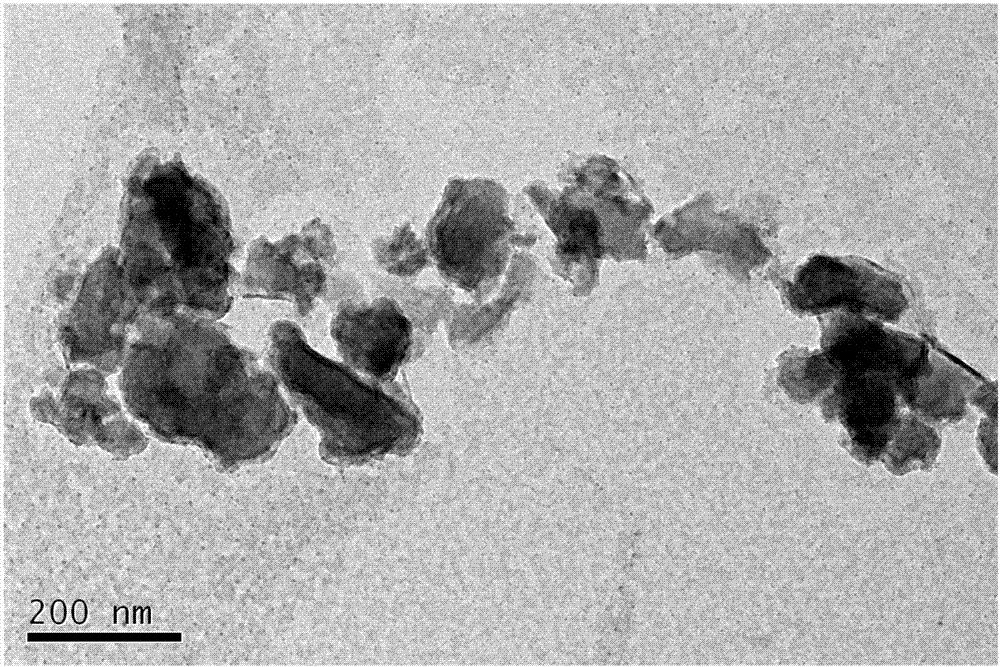

[0032] Weigh 0.2g of black phosphorus powder with a precision electronic scale, suspend it in 25mL of ultrapure water, and shake well. The dispersion was subjected to ice-bath probe ultrasonication for 60 minutes in a probe ultrasonic machine with a power of 300w. In order to prevent excessive heat generation, the mode of the ultrasonic machine was adjusted to ultrasonic for 5 seconds, and then stopped for 2 seconds, and so on for 60 minutes. Change the ice cubes every half hour. After the probe sonication, the dispersion was ultrasonicated in an ice-water bath for 9 hours. The power of the water-bath ultrasonic machine was 300w. In order to prevent excessive heat generation, the ice was changed every 0.5 hours. After the ultrasonication in the water bath, centrifuge with a centrifuge for 2 hours at a speed of 7000 rpm, and set the temp...

Embodiment 2

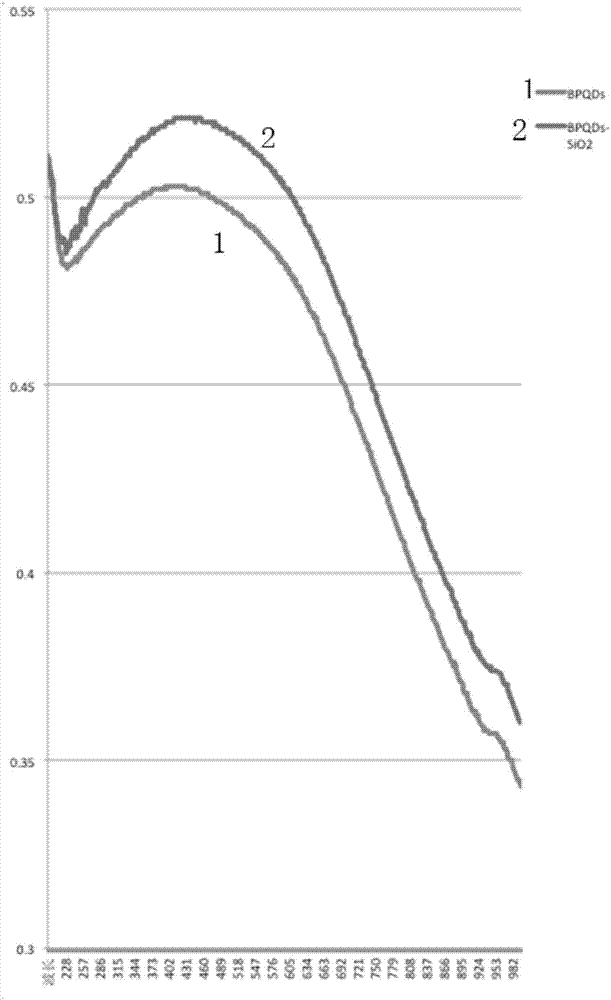

[0036]The product obtained in Example 1 was subjected to fluorescence lifetime imaging, and the instrument model used was FV1200 / PicoquantFLIM / FCS. A 637nm laser source was used to excite the black phosphorus nanoparticles centrifuged under the condition of centrifuge parameters of 5000rpm*40min, and the measured average fluorescence lifetime was 0.788ns. Using a 637nm laser source to excite black phosphorus nanoparticles coated with mesoporous silica and centrifuge them at 5000rpm*40min, the measured average fluorescence lifetime is 0.289ns, that is to say, they are wrapped with mesoporous silica. The average fluorescence lifetime of silicon oxide black phosphorus nanoparticles is 3.67 times longer than that of uncoated black phosphorus nanoparticles. The black phosphorus nanoparticles used in the fluorescence lifetime imaging in Example 2 and the black phosphorus nanoparticles wrapped with mesoporous silica were all prepared and left for one month before imaging. It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com